3d Concrete Printing Market Report

Published Date: 22 January 2026 | Report Code: 3d-concrete-printing

3d Concrete Printing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the 3D Concrete Printing market, covering market size forecasts from 2023 to 2033, industry trends, regional insights, and key market segments. Key players, technologies, and future growth predictions are also discussed, making it a valuable resource for industry stakeholders.

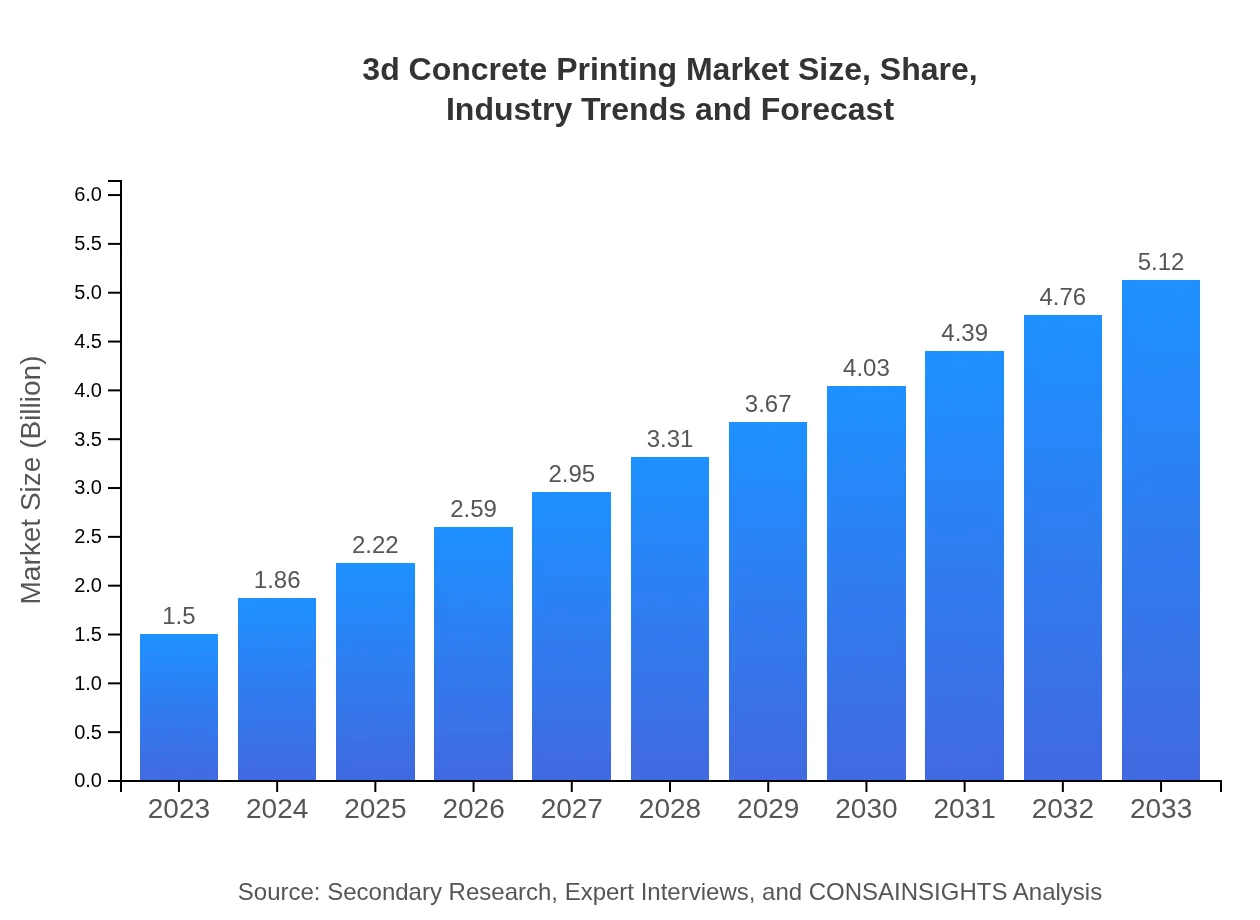

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 12.5% |

| 2033 Market Size | $5.12 Billion |

| Top Companies | ICON, CyBe Construction, Vertico, Apis Cor |

| Last Modified Date | 22 January 2026 |

3d Concrete Printing Market Overview

Customize 3d Concrete Printing Market Report market research report

- ✔ Get in-depth analysis of 3d Concrete Printing market size, growth, and forecasts.

- ✔ Understand 3d Concrete Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in 3d Concrete Printing

What is the Market Size & CAGR of 3d Concrete Printing market in 2023?

3d Concrete Printing Industry Analysis

3d Concrete Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

3d Concrete Printing Market Analysis Report by Region

Europe 3d Concrete Printing Market Report:

In Europe, the 3D Concrete Printing market is expected to rise from $0.40 billion in 2023 to $1.38 billion in 2033. The region’s focus on sustainable construction practices and the integration of 3D printing in urban development projects are vital growth drivers.Asia Pacific 3d Concrete Printing Market Report:

In the Asia Pacific region, the 3D Concrete Printing market is expected to grow from $0.29 billion in 2023 to $0.99 billion by 2033. Countries like China and India are driving factors due to rapid urbanization and infrastructural development demands.North America 3d Concrete Printing Market Report:

North America is projected to witness substantial growth, with the market size expanding from $0.52 billion in 2023 to $1.79 billion by 2033. The advancement of 3D printing technology and supportive governmental regulations will significantly contribute to this increase.South America 3d Concrete Printing Market Report:

The South American market is expected to increase from $0.12 billion in 2023 to approximately $0.40 billion in 2033, facilitated by a focus on affordable housing solutions and innovative construction methods to meet growing population demands.Middle East & Africa 3d Concrete Printing Market Report:

The Middle East and Africa market is projected to grow from $0.17 billion in 2023 to $0.57 billion in 2033, as countries invest in modernizing infrastructure and adopt innovative construction technologies.Tell us your focus area and get a customized research report.

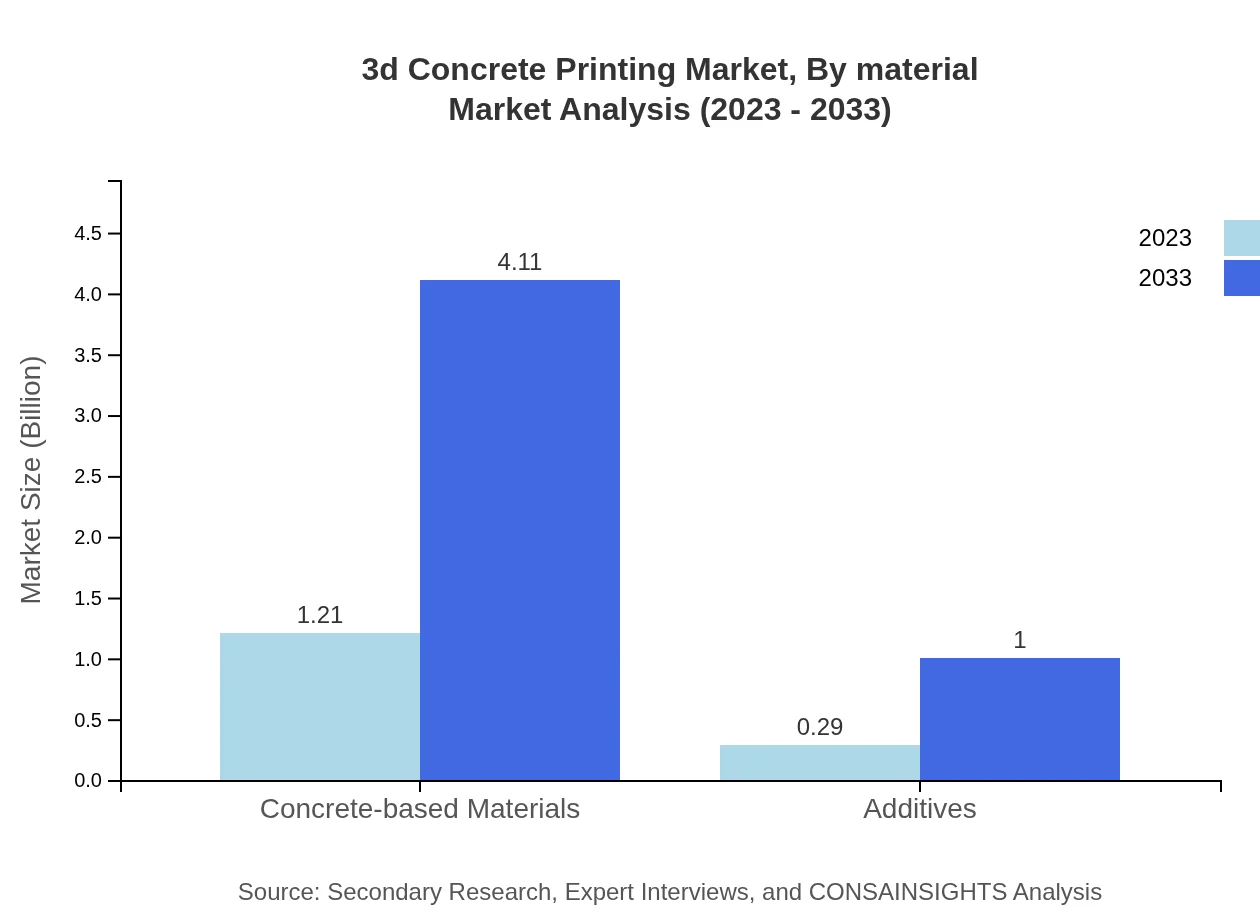

3d Concrete Printing Market Analysis By Material

The material segment of the 3D Concrete Printing market is dominated by concrete-based materials, which accounted for approximately 80.4% market share in 2023, projected to remain steady through 2033. Additives are gaining traction for their ability to enhance properties of the printed structures, making up 19.6% of the market share.

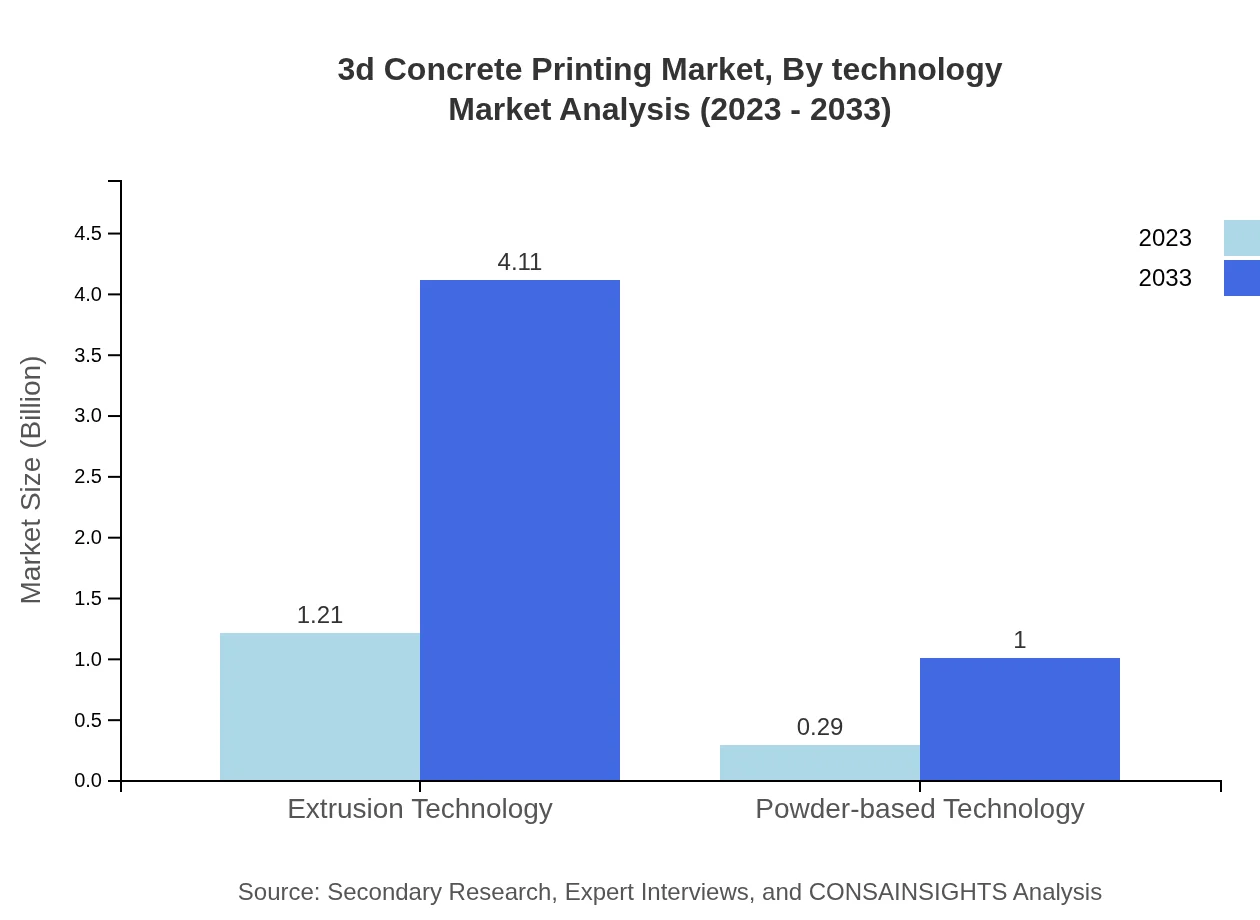

3d Concrete Printing Market Analysis By Technology

Extrusion technology leads the 3D Concrete Printing market, holding 80.4% market share in 2023 and showing strong growth forecasts. Powder-based technology also plays a critical role, capturing 19.6% as it diversifies the applications and capabilities of 3D printing.

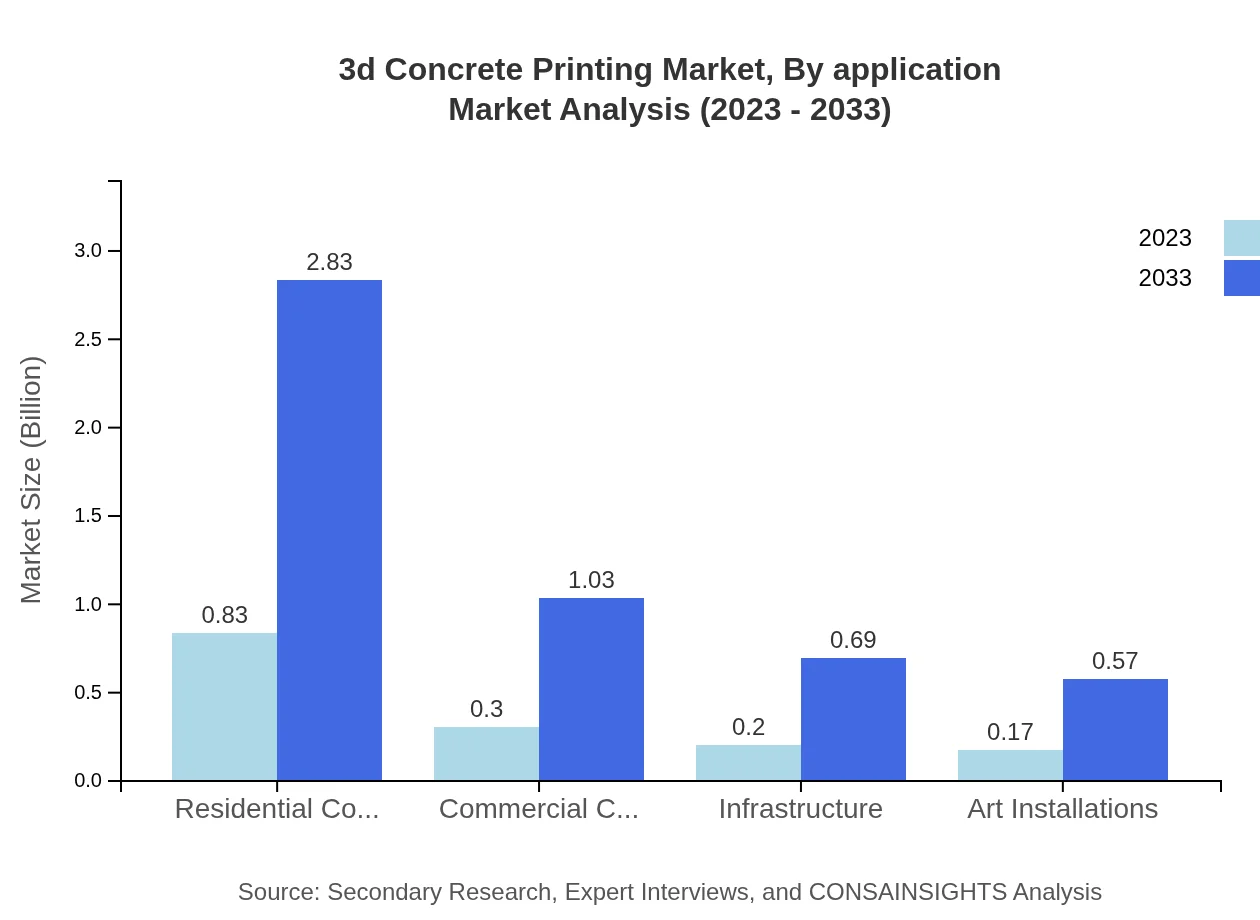

3d Concrete Printing Market Analysis By Application

Residential construction is the leading application of 3D concrete printing, representing 55.37% of the market in 2023 and projected to see steady growth. Commercial construction and art installations follow, encompassing 20.07% and 11.04% market shares respectively.

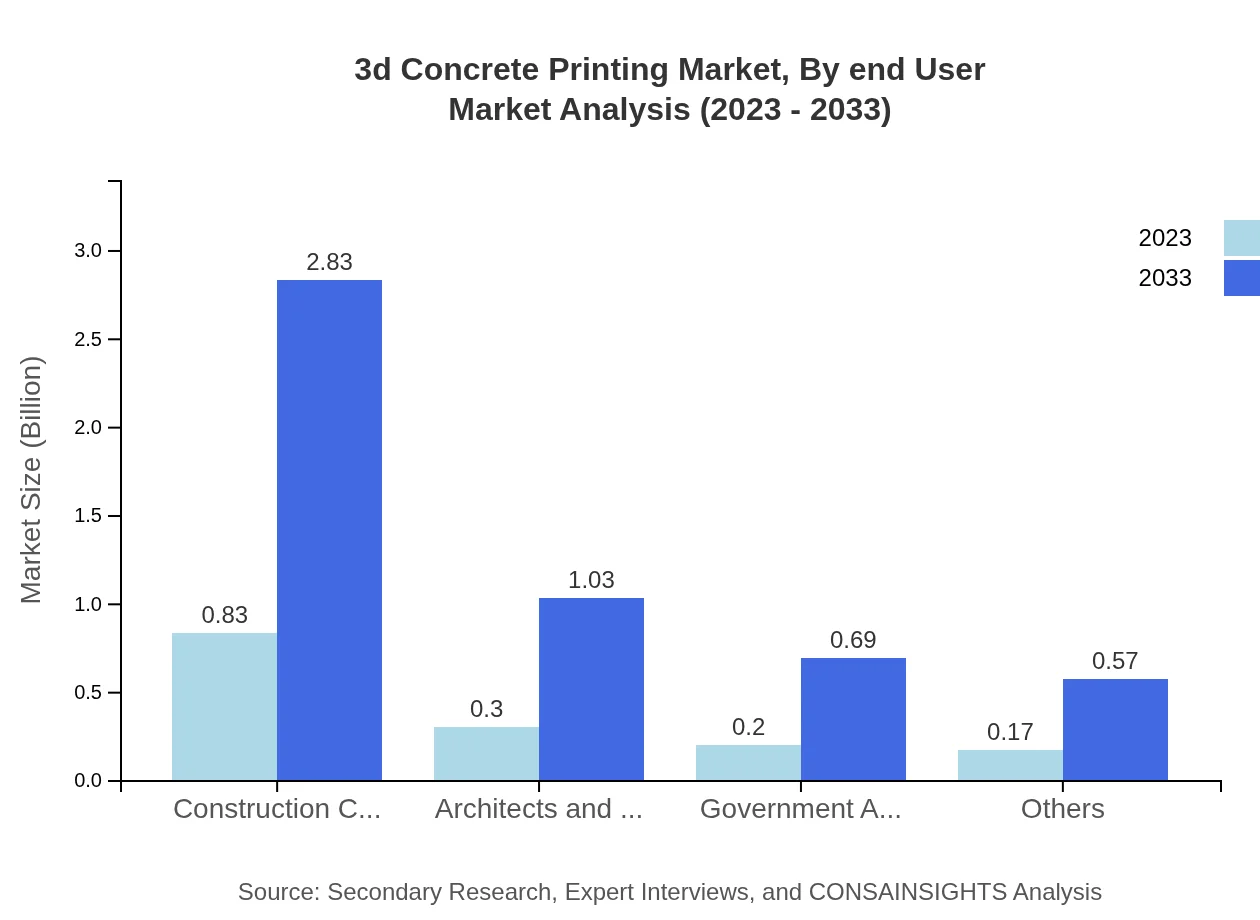

3d Concrete Printing Market Analysis By End User

Construction companies are the primary end-users in the 3D Concrete Printing market, holding 55.37% of the market share, followed by architects and designers at 20.07%. Government agencies contribute significantly, emphasizing the growing governmental interest in adopting innovative construction technologies.

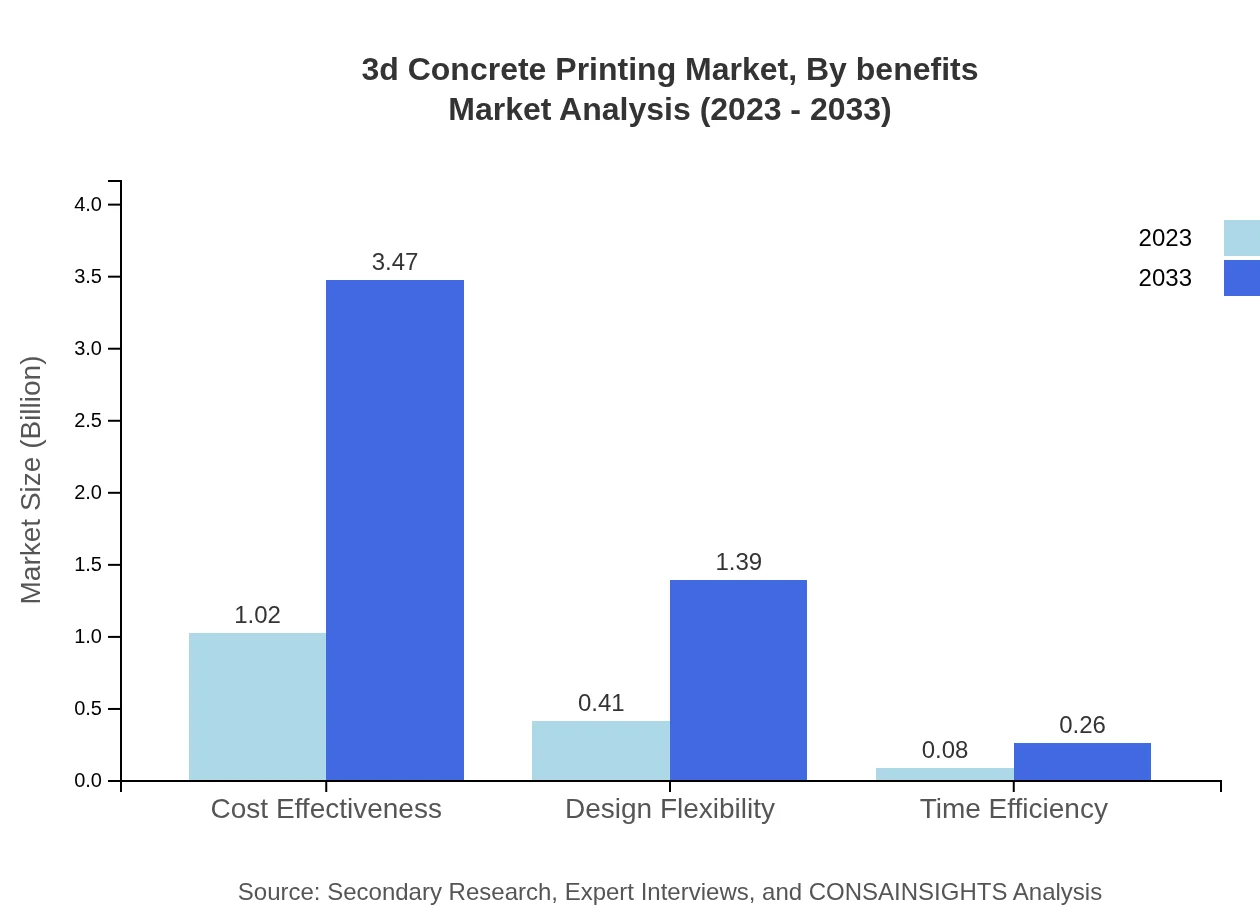

3d Concrete Printing Market Analysis By Benefits

The advantages of 3D Concrete Printing, particularly cost-effectiveness and design flexibility, are driving its adoption. Cost-effectiveness accounts for 67.73% of the market share in 2023 alongside time efficiency, valued at 5.11%, emphasizing the efficiency of 3D printing in modern construction.

3d Concrete Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in 3d Concrete Printing Industry

ICON:

ICON is a pioneer in advancing 3D printing technologies for construction, known for building homes using affordable and sustainable materials.CyBe Construction:

CyBe Construction specializes in 3D printing solutions for urban development and infrastructure projects, focusing on innovative building solutions worldwide.Vertico:

Vertico focuses on architectural 3D concrete printing and customizations, contributing innovative practices to the construction industry.Apis Cor:

Apis Cor is recognized for creating the world's first 3D printed house using mobile technology, significantly reducing construction timelines.We're grateful to work with incredible clients.

FAQs

What is the market size of 3D concrete printing?

The global 3D concrete printing market is projected to reach $1.5 billion by 2033, growing at a CAGR of 12.5%. This growth reflects the increasing demand for innovative construction solutions.

What are the key market players or companies in the 3D concrete printing industry?

Key players in the 3D concrete printing industry include those specializing in construction technologies, material suppliers, and additive manufacturing companies, contributing to advancements in sustainability and efficiency.

What are the primary factors driving the growth in the 3D concrete printing industry?

Growth in the 3D concrete printing industry is driven by the demand for cost-effective solutions, the industry's ability to reduce waste, enhance design capabilities, and meet regulatory requirements in construction.

Which region is the fastest Growing in the 3D concrete printing?

North America is currently the fastest-growing region in the 3D concrete printing market, with market projections rising from $0.52 billion in 2023 to $1.79 billion by 2033, showcasing substantial growth.

Does ConsaInsights provide customized market report data for the 3D concrete printing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the 3D concrete printing industry, allowing for insights and analysis based on targeted market segments.

What deliverables can I expect from this 3D concrete printing market research project?

Deliverables include comprehensive market analysis reports, trend insights, competitive landscape assessments, and tailored recommendations based on market dynamics and consumer behavior.

What are the market trends of 3D concrete printing?

Market trends in 3D concrete printing reflect increasing adoption of technology in various construction segments, with significant focus on sustainability, automation, and integration of digital processes.