3d Printing Ceramics Market Report

Published Date: 22 January 2026 | Report Code: 3d-printing-ceramics

3d Printing Ceramics Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the 3D Printing Ceramics market from 2023 to 2033, exploring market size, trends, segmentation, regional insights, and leading companies influencing the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

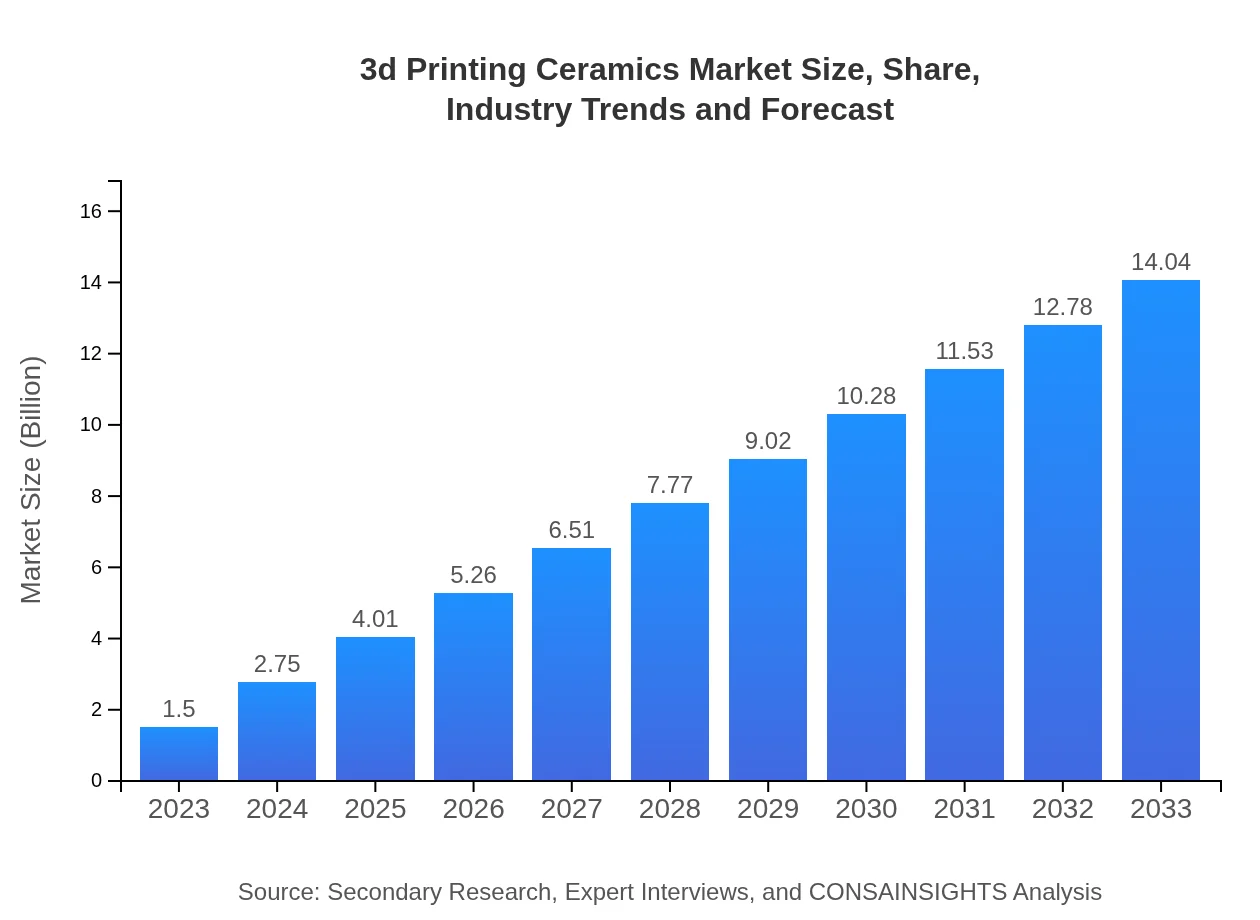

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 23.5% |

| 2033 Market Size | $14.04 Billion |

| Top Companies | 3D Systems Corporation, Materialise NV, Formlabs Inc., ExOne Company |

| Last Modified Date | 22 January 2026 |

3d Printing Ceramics Market Overview

Customize 3d Printing Ceramics Market Report market research report

- ✔ Get in-depth analysis of 3d Printing Ceramics market size, growth, and forecasts.

- ✔ Understand 3d Printing Ceramics's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in 3d Printing Ceramics

What is the Market Size & CAGR of 3d Printing Ceramics market in 2023?

3d Printing Ceramics Industry Analysis

3d Printing Ceramics Market Segmentation and Scope

Tell us your focus area and get a customized research report.

3d Printing Ceramics Market Analysis Report by Region

Europe 3d Printing Ceramics Market Report:

Europe's market, currently at $0.47 billion in 2023, is anticipated to surge to $4.44 billion by 2033. The region benefits from stringent regulations supporting innovation and sustainability in manufacturing.Asia Pacific 3d Printing Ceramics Market Report:

In 2023, the Asia Pacific region holds a market size of $0.31 billion, projected to grow to $2.90 billion by 2033. This expansion is driven by increased manufacturing capabilities, technological adoption, and a strong emphasis on research and development activities.North America 3d Printing Ceramics Market Report:

North America, with a market size of $0.48 billion in 2023, is projected to reach approximately $4.51 billion by 2033, led by advancements in aerospace and automotive sectors and a significant presence of key players.South America 3d Printing Ceramics Market Report:

The South America market is valued at $0.12 billion in 2023, expected to rise to $1.14 billion by 2033. Growth factors include increasing industrialization and emerging applications in healthcare and consumer products.Middle East & Africa 3d Printing Ceramics Market Report:

In the Middle East and Africa, the market is slated to increase from $0.11 billion in 2023 to $1.05 billion by 2033, with an emphasis on new construction technologies and healthcare applications boosting demand.Tell us your focus area and get a customized research report.

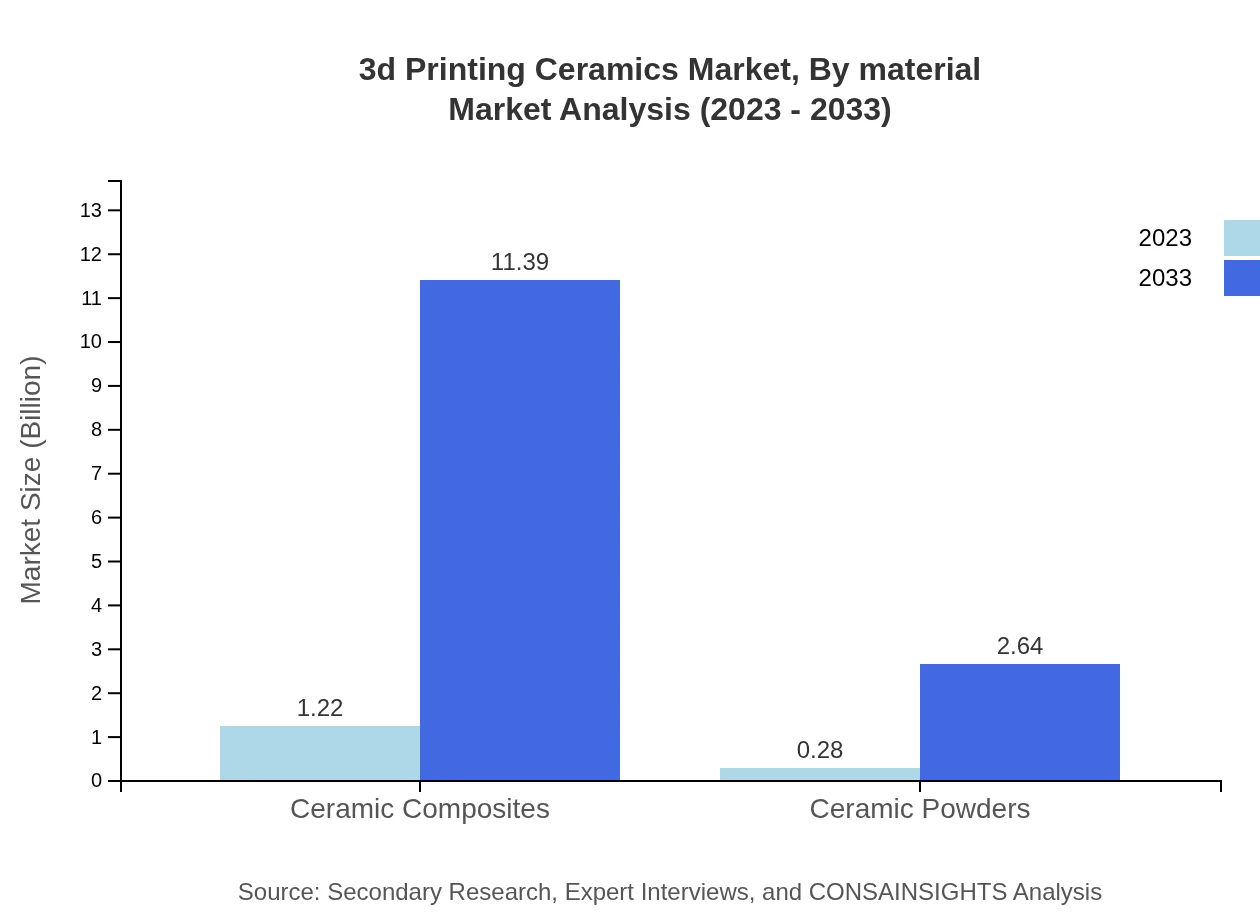

3d Printing Ceramics Market Analysis By Material

The materials segment, particularly Ceramic Composites and Ceramic Powders, dominates the market, accounting for an 81.17% and 18.83% share of the overall market in 2023, respectively. By 2033, their significance is expected to persist as manufacturers seek efficient, high-performance materials to meet emerging market demands.

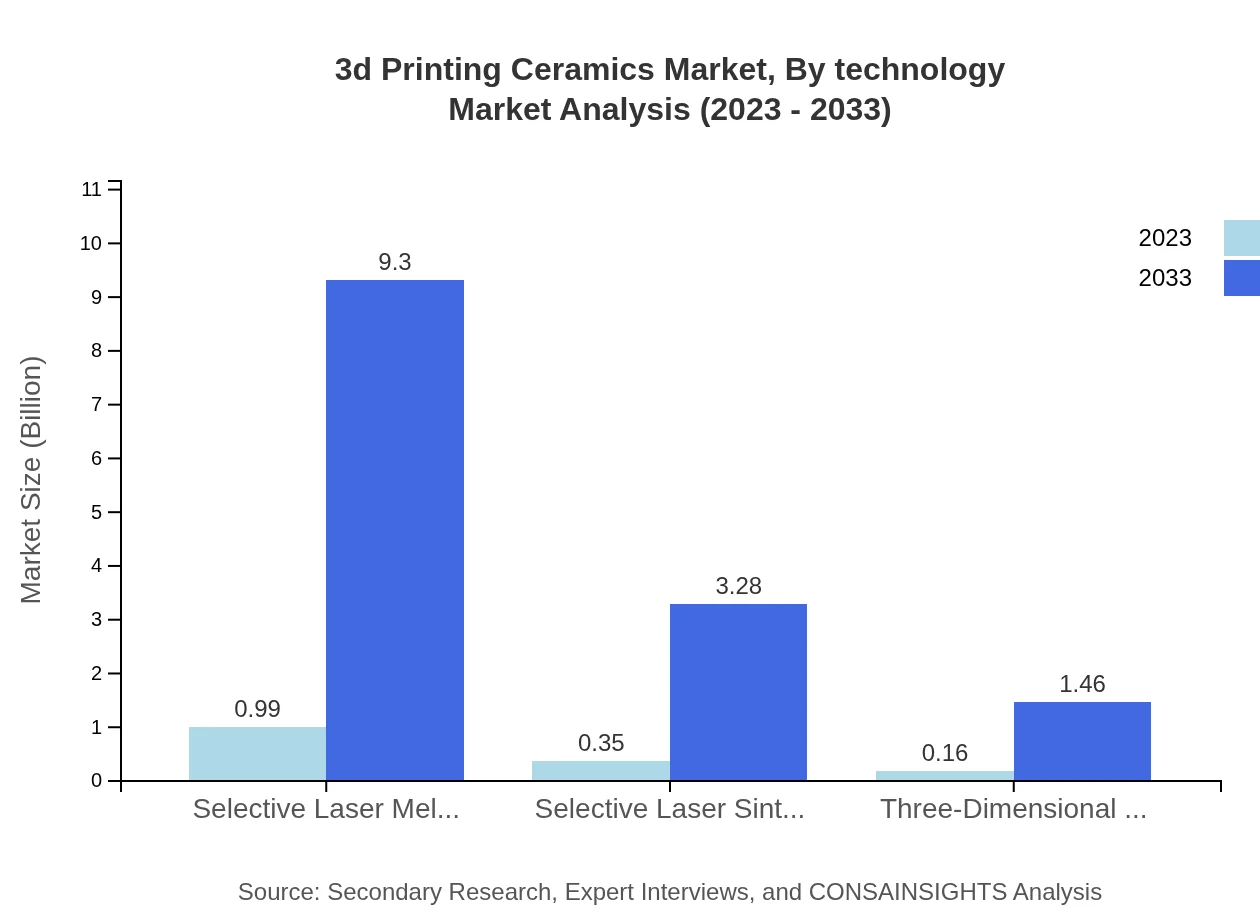

3d Printing Ceramics Market Analysis By Technology

Among the technologies, Selective Laser Melting (SLM) is expected to hold the largest market share of 66.24% in 2023 and maintain a strong position moving towards 2033. Selective Laser Sintering (SLS) and Three-Dimensional Printing (3DP) follow, illustrating the varied technological preferences within the industry.

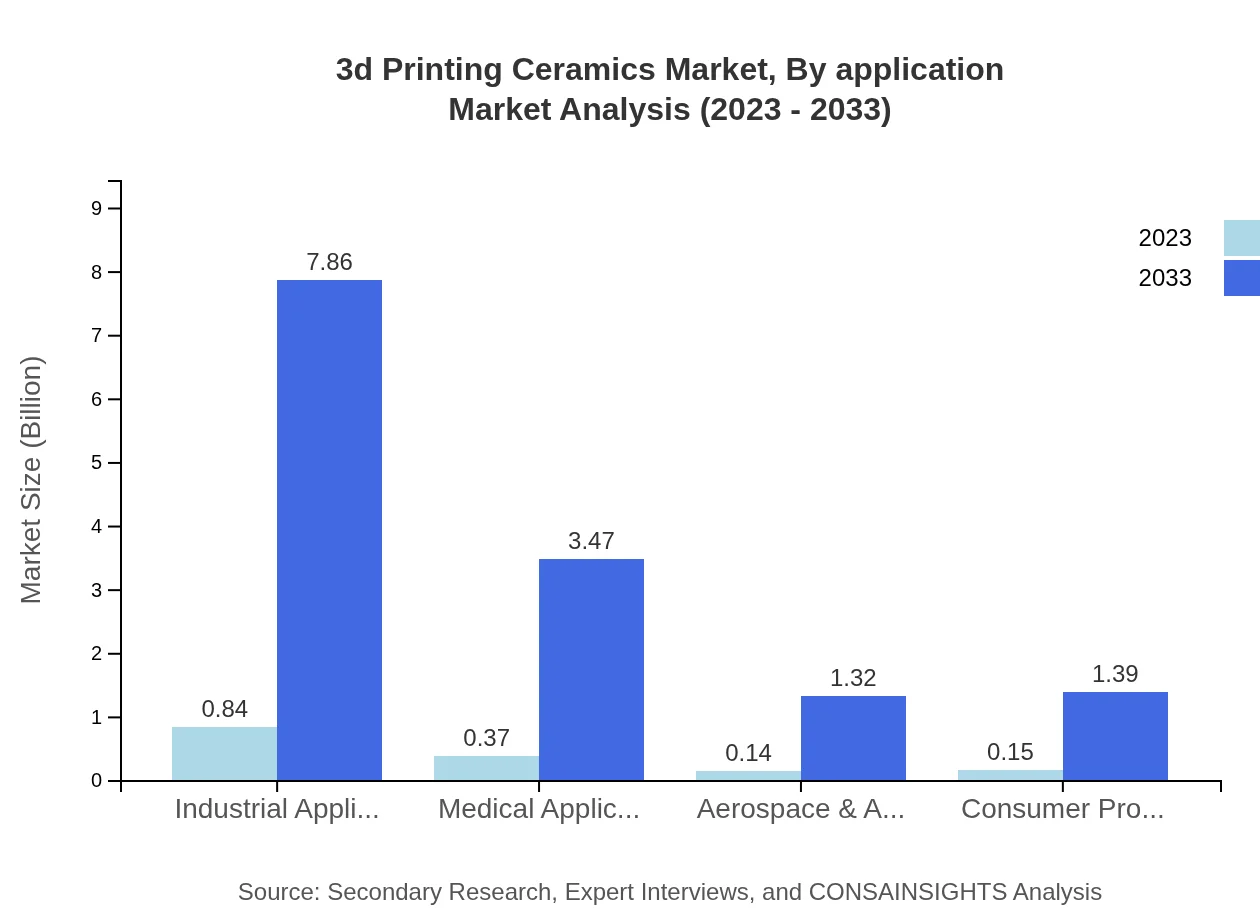

3d Printing Ceramics Market Analysis By Application

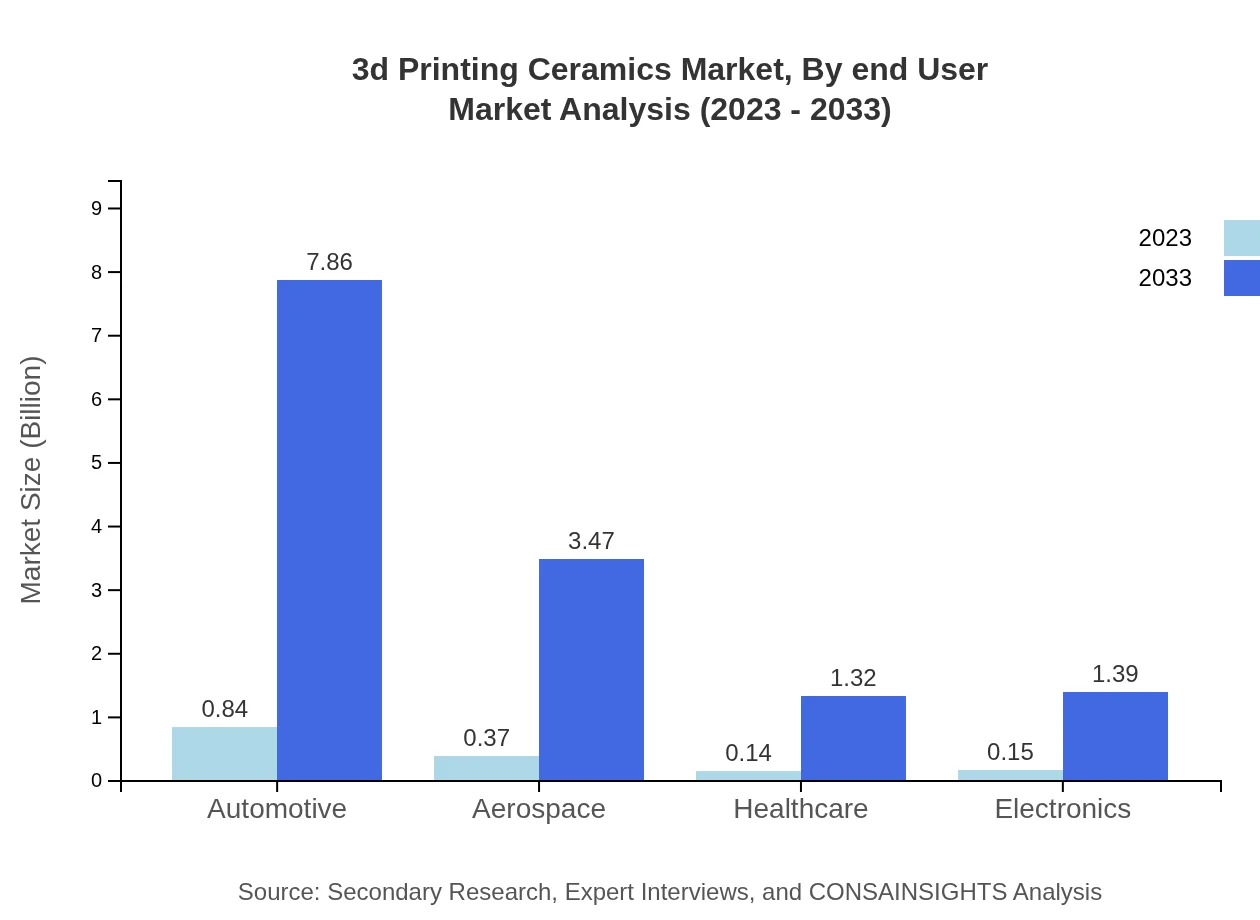

The Automotive segment leads the market, representing 56.01% in 2023, fueled by a strong demand for lightweight and durable components. Aerospace follows with 24.69%, reflective of the increasing use of 3D printing for complex part manufacturing. Healthcare and Consumer Products also feature notable segments indicating rising trends in personal use and specialized medical applications.

3d Printing Ceramics Market Analysis By End User

End-use applications span a wide range of sectors, with industrial applications comprising 56.01% in 2023. Aerospace & Automotive, healthcare, and consumer products segments collectively highlight the versatility of 3D printing ceramics in addressing diverse functional requirements.

3d Printing Ceramics Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in 3d Printing Ceramics Industry

3D Systems Corporation:

A pioneer in 3D printing solutions, 3D Systems offers comprehensive services including 3D printing ceramics technology that caters to various industries, leveraging significant research and development.Materialise NV:

Known for its focus on software and 3D printing technologies, Materialise provides bespoke solutions for the ceramics industry, emphasizing innovative applications and process efficiency.Formlabs Inc.:

Specializing in accessible 3D printing solutions, Formlabs integrates ceramic materials into their portfolio, targeting both professional and consumer markets with versatile applications.ExOne Company:

As a leader in industrial 3D printing technology, ExOne utilizes advanced ceramics in various applications, focusing on sustainability and production efficiency across sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of 3D Printing Ceramics?

The global market size for 3D-printing ceramics is projected to reach $1.5 billion by 2033, growing at a CAGR of 23.5% from 2023 to 2033. This robust growth indicates a burgeoning interest and investment in advanced ceramic technologies.

What are the key market players or companies in the 3D Printing Ceramics industry?

Key players in the 3D-printing ceramics market include industry leaders such as Lithoz GmbH, 3D Systems Corporation, and ExOne Company. These companies are recognized for their innovative technologies and extensive portfolios targeting various applications across industries.

What are the primary factors driving the growth in the 3D Printing Ceramics industry?

Factors driving the growth of 3D-printing ceramics include technological advancements, increased demand for customized products, and the material's benefits in sectors such as healthcare and aerospace. Ecological considerations are also pushing for sustainable production methods.

Which region is the fastest Growing in the 3D Printing Ceramics?

The fastest-growing region in the 3D-printing ceramics market is Europe, expected to grow from $0.47 billion in 2023 to $4.44 billion in 2033. This region leads in innovation and application development in industrial and healthcare sectors.

Does ConsaInsights provide customized market report data for the 3D Printing Ceramics industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the 3D-printing ceramics industry. Clients can request insights based on particular market segments or geographic focuses, ensuring relevance and applicability.

What deliverables can I expect from this 3D Printing Ceramics market research project?

Deliverables from a 3D-printing ceramics market research project include comprehensive reports, market segmentation analysis, competitive landscape assessment, and growth forecasts. These insights help stakeholders make informed strategic decisions.

What are the market trends of 3D Printing Ceramics?

Current trends in the 3D-printing ceramics market include the rise of bio-based materials, integration of AI in design processes, and growth in applications across automotive, aerospace, and healthcare sectors. Sustainability practices are also becoming paramount.