3d Printing Filament Market Report

Published Date: 22 January 2026 | Report Code: 3d-printing-filament

3d Printing Filament Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the 3D printing filament market, exploring market trends, segment performances, and regional insights from 2023 to 2033. It encompasses a comprehensive overview of the market landscape, growth forecasts, and technological advancements shaping the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 15% |

| 2033 Market Size | $10.80 Billion |

| Top Companies | 3D Systems Corporation, Stratasys Ltd., ColorFabb, Hatchbox |

| Last Modified Date | 22 January 2026 |

3D Printing Filament Market Overview

Customize 3d Printing Filament Market Report market research report

- ✔ Get in-depth analysis of 3d Printing Filament market size, growth, and forecasts.

- ✔ Understand 3d Printing Filament's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in 3d Printing Filament

What is the Market Size & CAGR of 3D Printing Filament market in 2023?

3D Printing Filament Industry Analysis

3D Printing Filament Market Segmentation and Scope

Tell us your focus area and get a customized research report.

3D Printing Filament Market Analysis Report by Region

Europe 3d Printing Filament Market Report:

Europe’s 3D printing filament market is forecasted to grow from $0.65 billion in 2023 to $2.80 billion in 2033. The push for sustainability and eco-friendly materials is driving demand for bioplastics like PLA. Innovation in material sciences is prevalent in this region, making Europe a hotbed for advanced manufacturing technologies.Asia Pacific 3d Printing Filament Market Report:

In the Asia Pacific region, the 3D printing filament market is expected to grow from $0.50 billion in 2023 to approximately $2.16 billion by 2033. The rapid industrialization, coupled with increased adoption of advanced manufacturing technologies, positions Asia Pacific as a significant market player. Countries like China and Japan are leading this growth, focusing on R&D and technological advancements in 3D printing.North America 3d Printing Filament Market Report:

North America, valued at $0.88 billion in 2023, is anticipated to reach $3.81 billion by 2033. The region is a leader in technological innovation and application variety. The presence of major players and extensive use in sectors like aerospace and healthcare are key factors driving this rapid growth. Moreover, increasing investments in Research and Development (R&D) are expected to support market expansion.South America 3d Printing Filament Market Report:

The South American market for 3D printing filament shows promising growth, from $0.21 billion in 2023 to an estimated $0.92 billion in 2033. Increased investments in education and awareness around additive manufacturing are driving this growth. Although the market is relatively nascent compared to others, it is set to expand with the rise of local manufacturers and improved distribution networks.Middle East & Africa 3d Printing Filament Market Report:

The Middle East and Africa region presents a relatively small market, projected to expand from $0.26 billion in 2023 to $1.12 billion by 2033. The growth is driven by increasing awareness and adoption of 3D printing within industries such as construction and automotive, with government initiatives focusing on innovation and technology development.Tell us your focus area and get a customized research report.

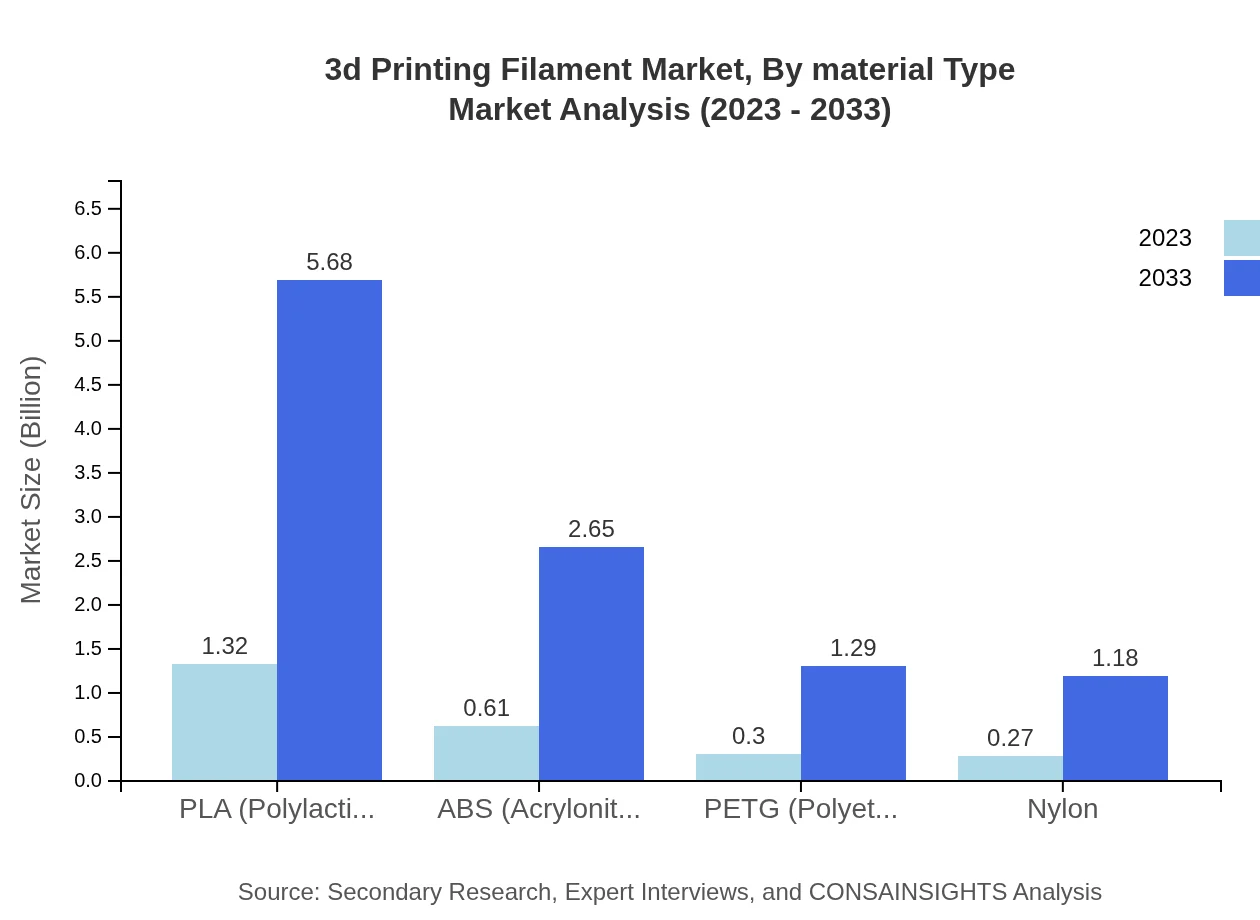

3d Printing Filament Market Analysis By Material Type

Different material types in the 3D printing filament market exhibit varied performance and application potential. PLA leads the market with its significant market share of 52.63% in 2023, expected to grow from $1.32 billion in 2023 to $5.68 billion by 2033. ABS follows with a market size expected to increase from $0.61 billion to $2.65 billion, with a steady share of 24.53% throughout the forecast period. PETG and Nylon also present promising growth opportunities, showcasing their importance in diverse applications.

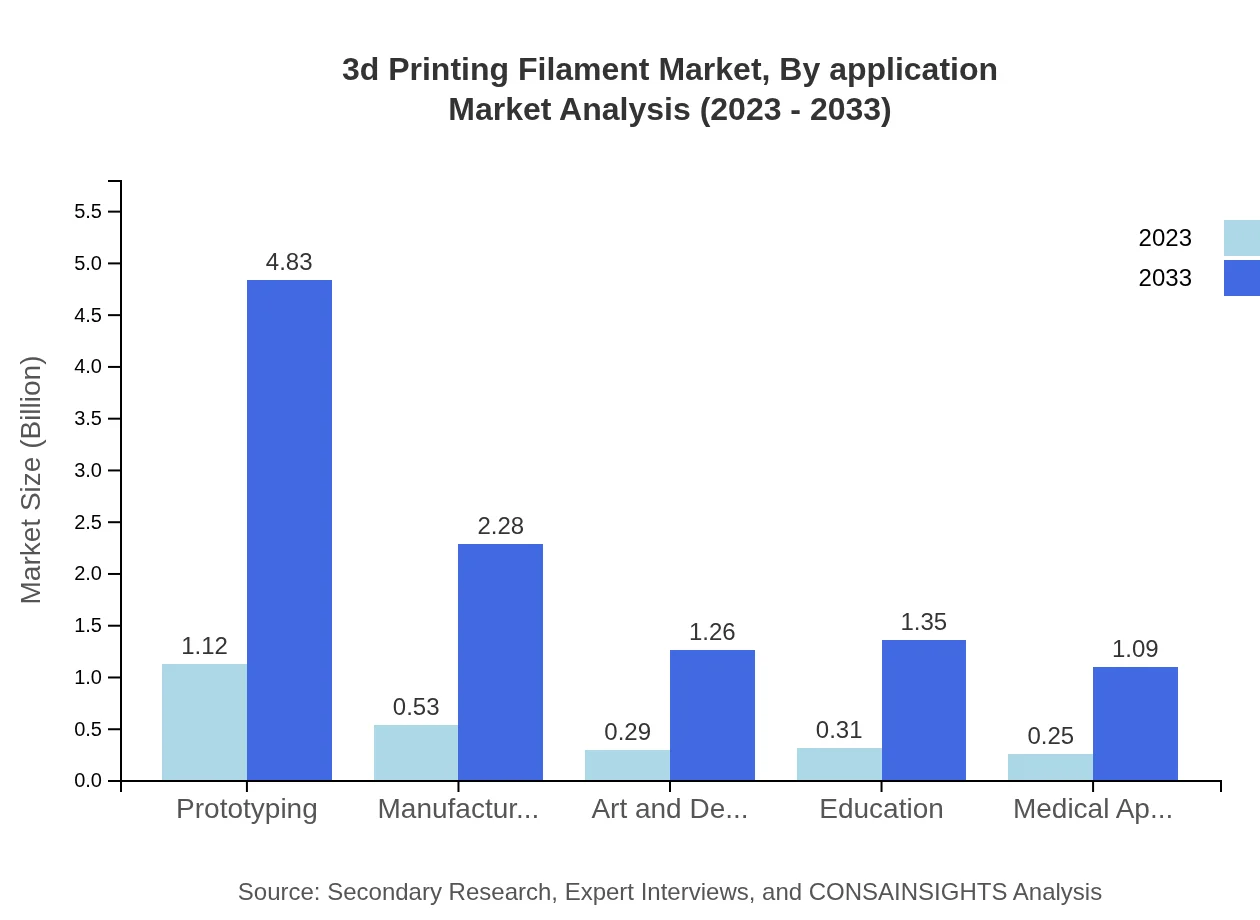

3d Printing Filament Market Analysis By Application

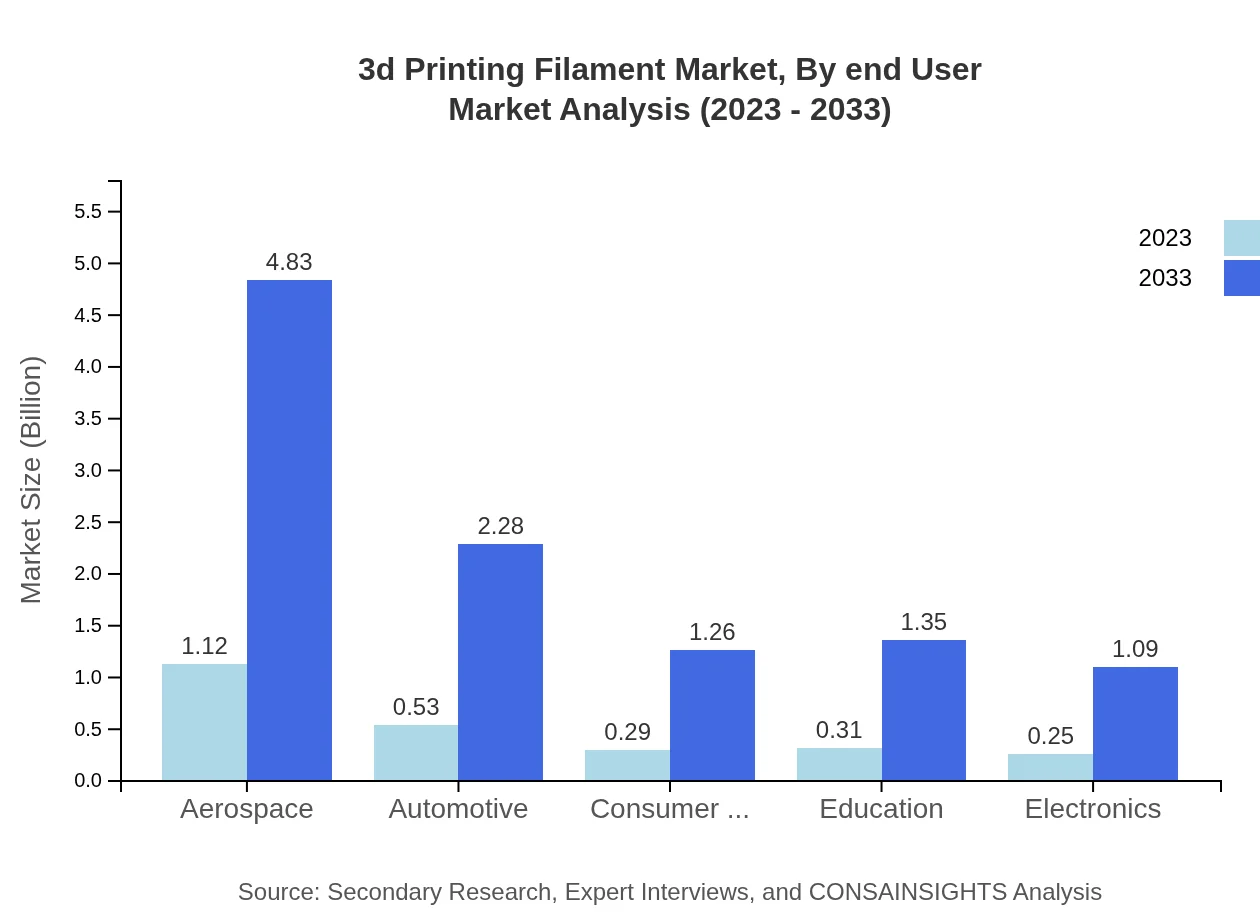

Applications such as aerospace, automotive, and prototyping dominate the 3D printing filament market. Notably, the aerospace segment is expected to grow heavily from $1.12 billion in 2023 to $4.83 billion by 2033, maintaining a significant share of 44.72%. Similarly, the automotive sector will see growth from $0.53 billion to $2.28 billion, representing 21.13% of market share, indicating a robust demand for high-performance materials in both industries.

3d Printing Filament Market Analysis By End User

End-user industries such as healthcare, education, and consumer products highlight the extensive applicability of 3D printing filament. The prototyping segment remains dominant with continued growth, illustrating its critical role in product development. Education is expected to expand notably as institutions increasingly adopt 3D printing technologies for experimental learning, showcasing the diverse applications and rising demand across multiple sectors.

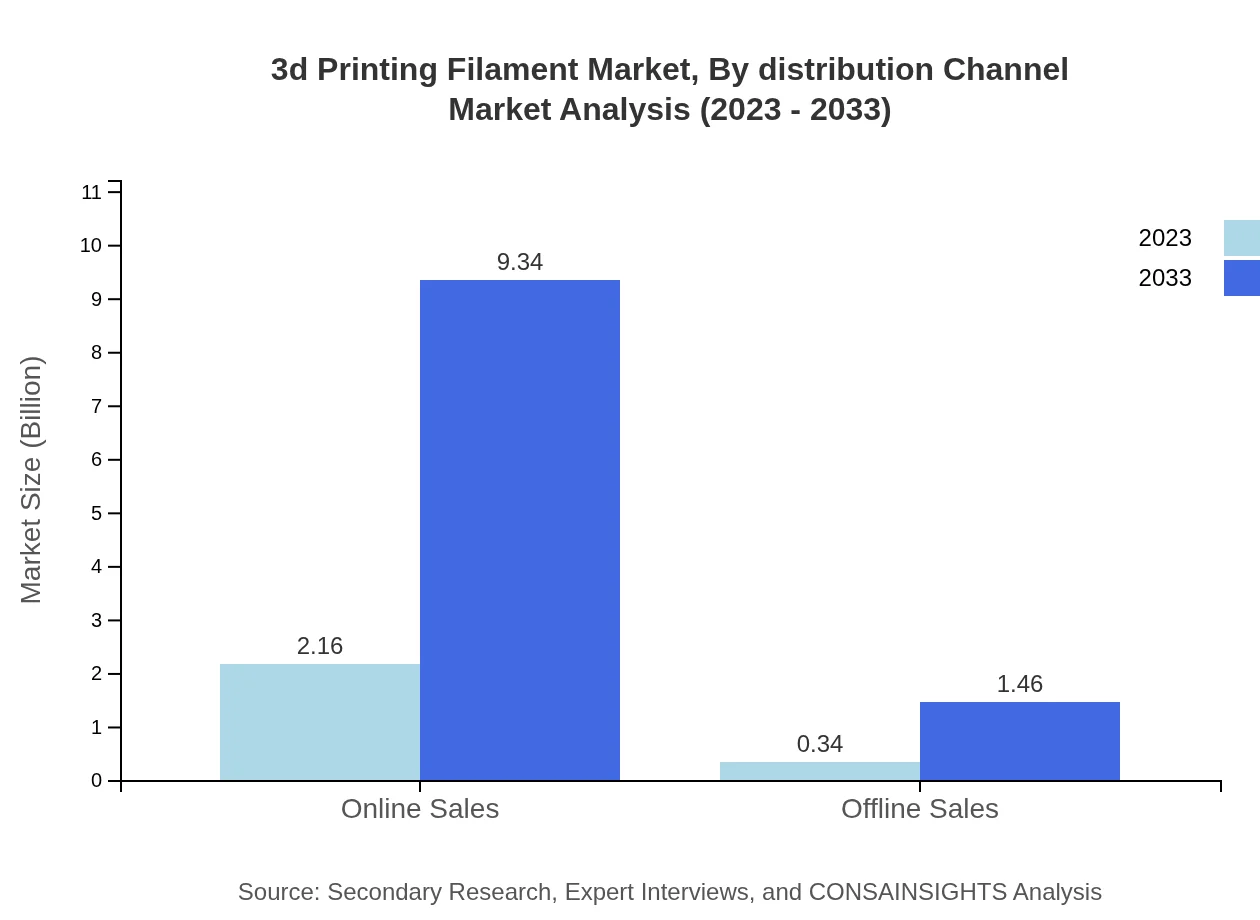

3d Printing Filament Market Analysis By Distribution Channel

The distribution channels for 3D printing filaments are categorized primarily into online and offline sales. Online sales dominate the landscape, accounting for 86.52% of the market share in 2023, growing significantly from $2.16 billion to $9.34 billion by 2033. This growth aligns with the rising trend of digital purchasing. Offline sales, while smaller, are expected to grow from $0.34 billion to $1.46 billion during the same period, indicating a balanced ecosystem for filament distribution.

3D Printing Filament Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in 3D Printing Filament Industry

3D Systems Corporation:

A pioneer in 3D printing solutions, 3D Systems provides a wide range of 3D printers, materials, and software, focusing on manufacturing high-quality 3D printing filaments for various applications.Stratasys Ltd.:

Specializing in polymer 3D printing technologies, Stratasys is renowned for its innovative solutions and materials, catering extensively to the aerospace and automotive industries.ColorFabb:

A leading manufacturer of 3D printing filaments, ColorFabb is known for its quality, sustainability initiatives, and a diverse range of filament products, including specialty materials.Hatchbox:

Hatchbox provides a variety of quality filaments for all types of printing, focusing on affordable products that deliver excellent performance for hobbyists and professionals alike.We're grateful to work with incredible clients.

FAQs

What is the market size of 3D printing filament?

The global 3D printing filament market is currently valued at approximately $2.5 billion, with a robust compound annual growth rate (CAGR) of 15%. This growth trajectory indicates a continued expansion in market demand and production over the coming years.

What are the key market players or companies in the 3D printing filament industry?

Key players in the 3D printing filament market include leading manufacturers such as XYZprinting, Ultimaker, and Formlabs. These companies are recognized for their innovative filament solutions and contributions to expanding 3D printing technologies across various sectors.

What are the primary factors driving the growth in the 3D printing filament industry?

Growth in the 3D printing filament industry is primarily driven by increased adoption of 3D printing technologies in manufacturing, aerospace, and medical applications. Advances in material science and reductions in production costs are also significant contributors.

Which region is the fastest Growing in the 3D printing filament market?

The fastest-growing region for the 3D printing filament market is Europe, projected to increase from $0.65 billion in 2023 to $2.80 billion by 2033. Asia Pacific follows closely, expanding from $0.50 billion to $2.16 billion in the same period.

Does ConsaInsights provide customized market report data for the 3D printing filament industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the 3D printing filament industry. This ensures clients receive relevant insights and detailed analyses for informed decision-making.

What deliverables can I expect from this 3D printing filament market research project?

Clients can expect comprehensive deliverables from the 3D printing filament market research project, including detailed market analysis, segment breakdowns by application and region, growth forecasts, and strategic recommendations tailored to business objectives.

What are the market trends of 3D printing filament?

Current trends in the 3D printing filament market include a surge in biodegradable materials like PLA, increased focus on sustainability, and innovation in composite filaments. These trends indicate a shift towards environmentally friendly solutions and advanced manufacturing techniques.