3d Printing Powder Market Report

Published Date: 22 January 2026 | Report Code: 3d-printing-powder

3d Printing Powder Market Size, Share, Industry Trends and Forecast to 2033

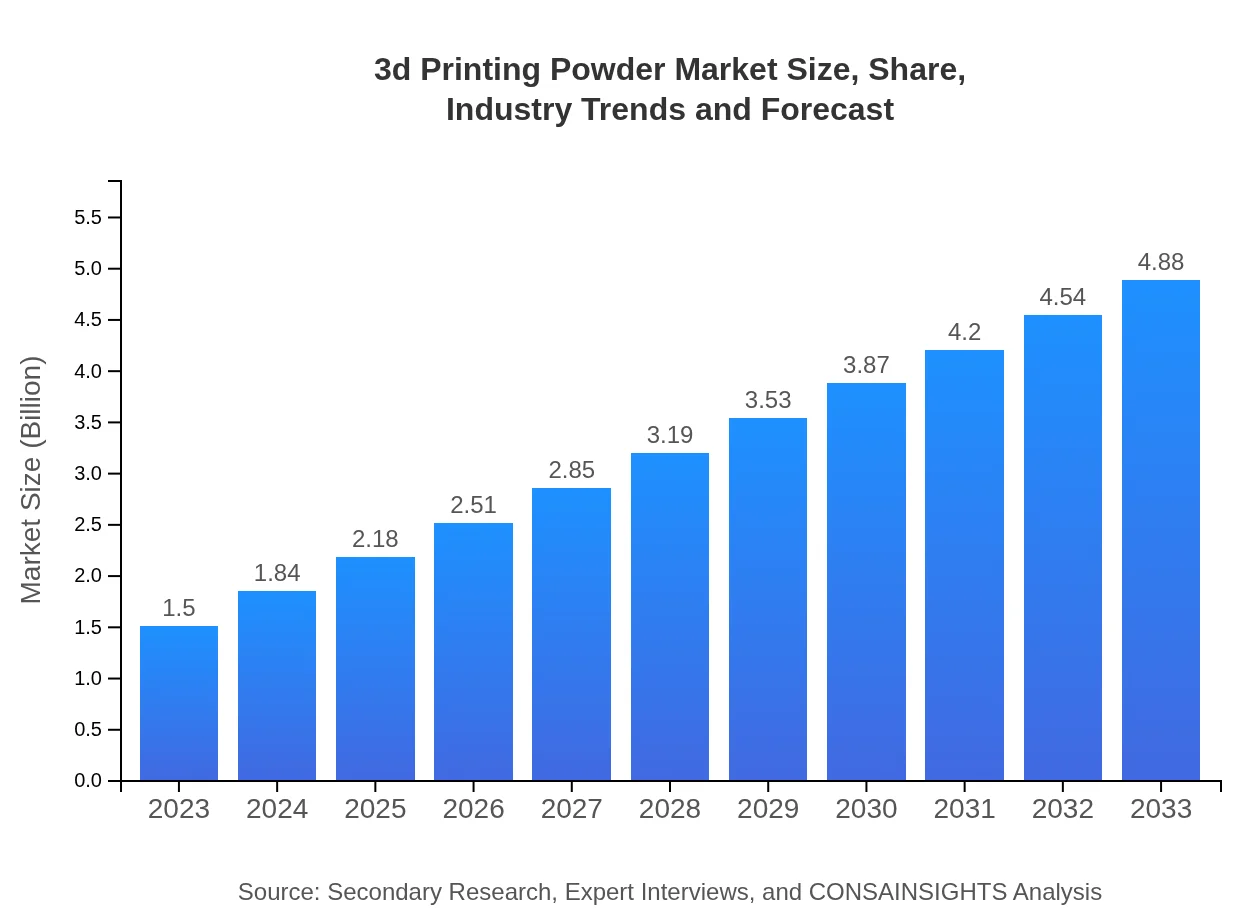

This report analyzes the 3D Printing Powder market from 2023 to 2033, providing insights into market size, growth forecasts, and key trends that are shaping the industry landscape. It covers regional analyses and competitive dynamics to offer a comprehensive perspective.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 12% |

| 2033 Market Size | $4.88 Billion |

| Top Companies | 3D Systems Corporation, Stratasys Ltd., EOS GmbH, Materialise NV, SLM Solutions Group AG |

| Last Modified Date | 22 January 2026 |

3d Printing Powder Market Overview

Customize 3d Printing Powder Market Report market research report

- ✔ Get in-depth analysis of 3d Printing Powder market size, growth, and forecasts.

- ✔ Understand 3d Printing Powder's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in 3d Printing Powder

What is the Market Size & CAGR of 3d Printing Powder market in 2023?

3d Printing Powder Industry Analysis

3d Printing Powder Market Segmentation and Scope

Tell us your focus area and get a customized research report.

3d Printing Powder Market Analysis Report by Region

Europe 3d Printing Powder Market Report:

Europe’s market is set to increase from $0.37 billion in 2023 to $1.20 billion by 2033. Germany and the UK are leading the way, utilizing 3D printing for advanced manufacturing capabilities, particularly in aerospace and automotive applications.Asia Pacific 3d Printing Powder Market Report:

In the Asia Pacific region, the 3D Printing Powder market is expected to grow from $0.32 billion in 2023 to $1.03 billion by 2033. The region's strong manufacturing base and increasing investments in 3D printing technologies contribute significantly to this growth. Countries like China and Japan are at the forefront of implementing advanced 3D printing techniques.North America 3d Printing Powder Market Report:

North America is anticipated to expand from $0.58 billion in 2023 to $1.88 billion by 2033. The region is a pioneer in 3D printing adoption, especially within industries like aerospace, defense, and healthcare, driving substantial demand for high-performance powders.South America 3d Printing Powder Market Report:

The South American market is projected to grow from $0.10 billion in 2023 to $0.33 billion by 2033. Brazil and Argentina are leading in the adoption of 3D printing technology, mainly within the automotive and consumer goods sectors, thus boosting demand for 3D Printing Powders.Middle East & Africa 3d Printing Powder Market Report:

In the Middle East and Africa, the market is expected to grow from $0.13 billion in 2023 to $0.43 billion by 2033. The emerging industrial base and investment in tech infrastructure are promising trends that bolster the 3D printing market in this region.Tell us your focus area and get a customized research report.

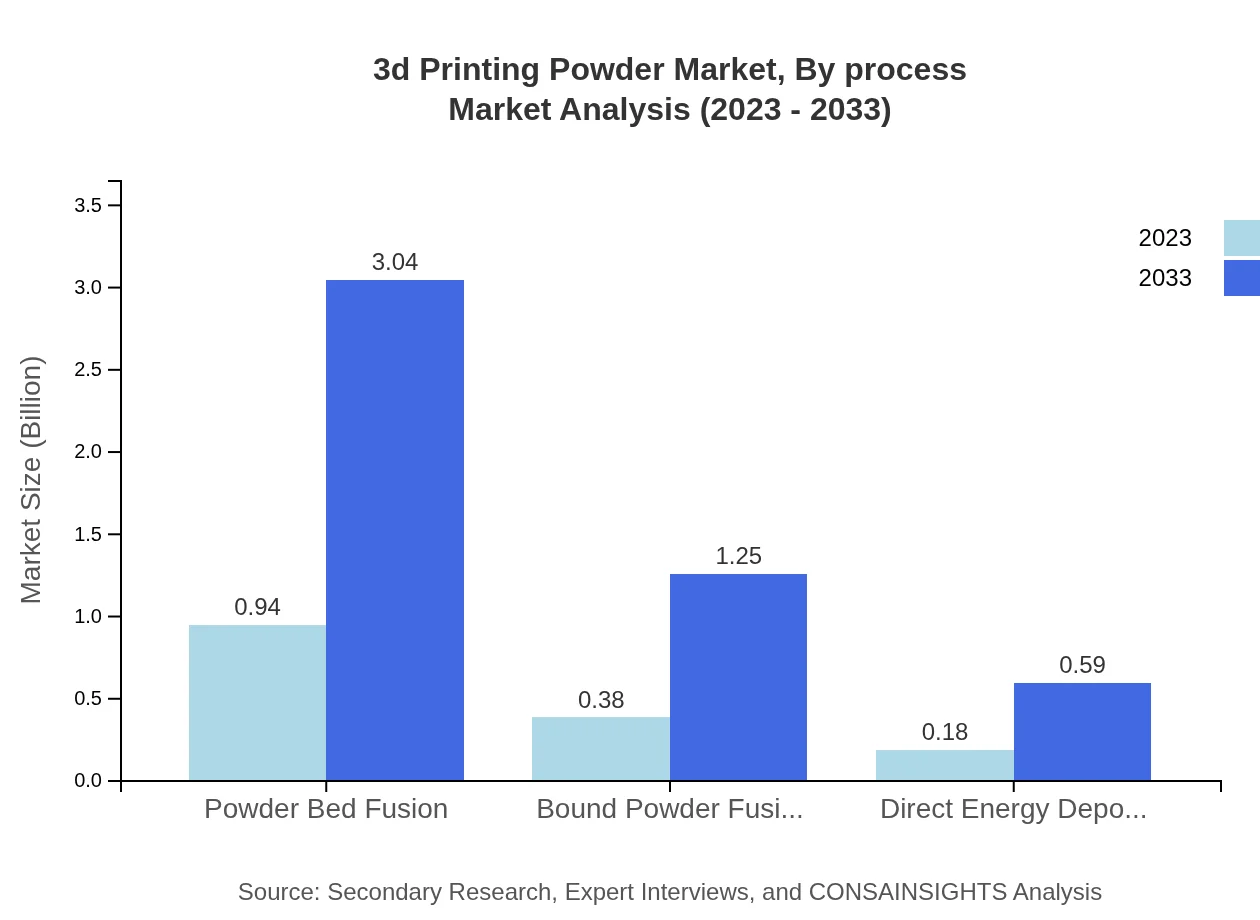

3d Printing Powder Market Analysis By Process

In 2023, the Powder Bed Fusion segment leads the market with a size of $0.94 billion, accounting for 62.34% of the market share. This segment is projected to grow to $3.04 billion by 2033. Bound Powder Fusion follows with a market size of $0.38 billion (25.59% share) in 2023, expected to reach $1.25 billion by 2033. Direct Energy Deposition, while smaller at $0.18 billion (12.07% share), is projected to expand to $0.59 billion over the same period.

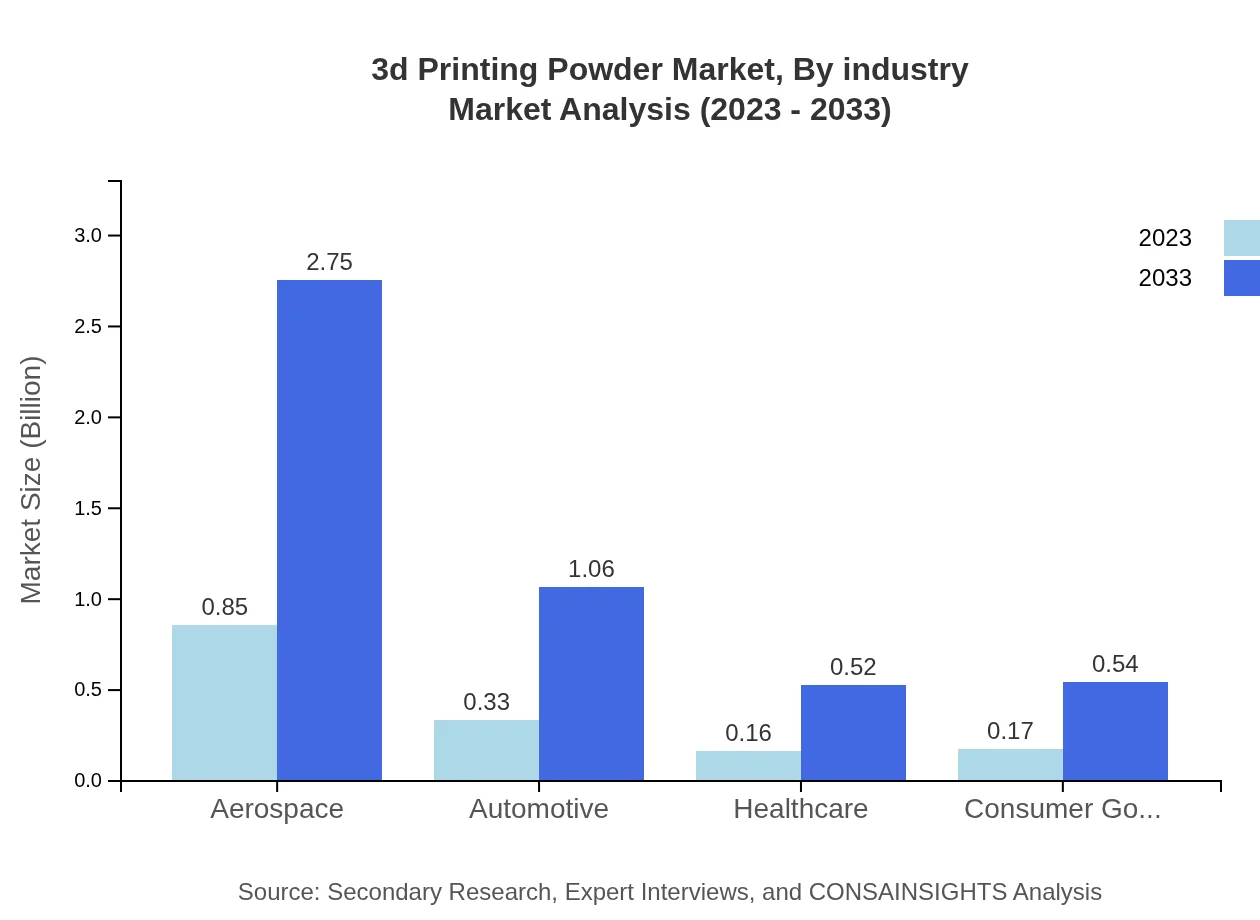

3d Printing Powder Market Analysis By Industry

The Aerospace industry is the largest consumer of 3D printing powders, with a size of $0.85 billion in 2023, expected to grow to $2.75 billion by 2033 (56.38% share). The Automotive industry follows closely with a current size of $0.33 billion (21.78% share), expected to reach $1.06 billion. The Healthcare sector is growing steadily, currently at $0.16 billion (10.7% share), projected to reach $0.52 billion by 2033.

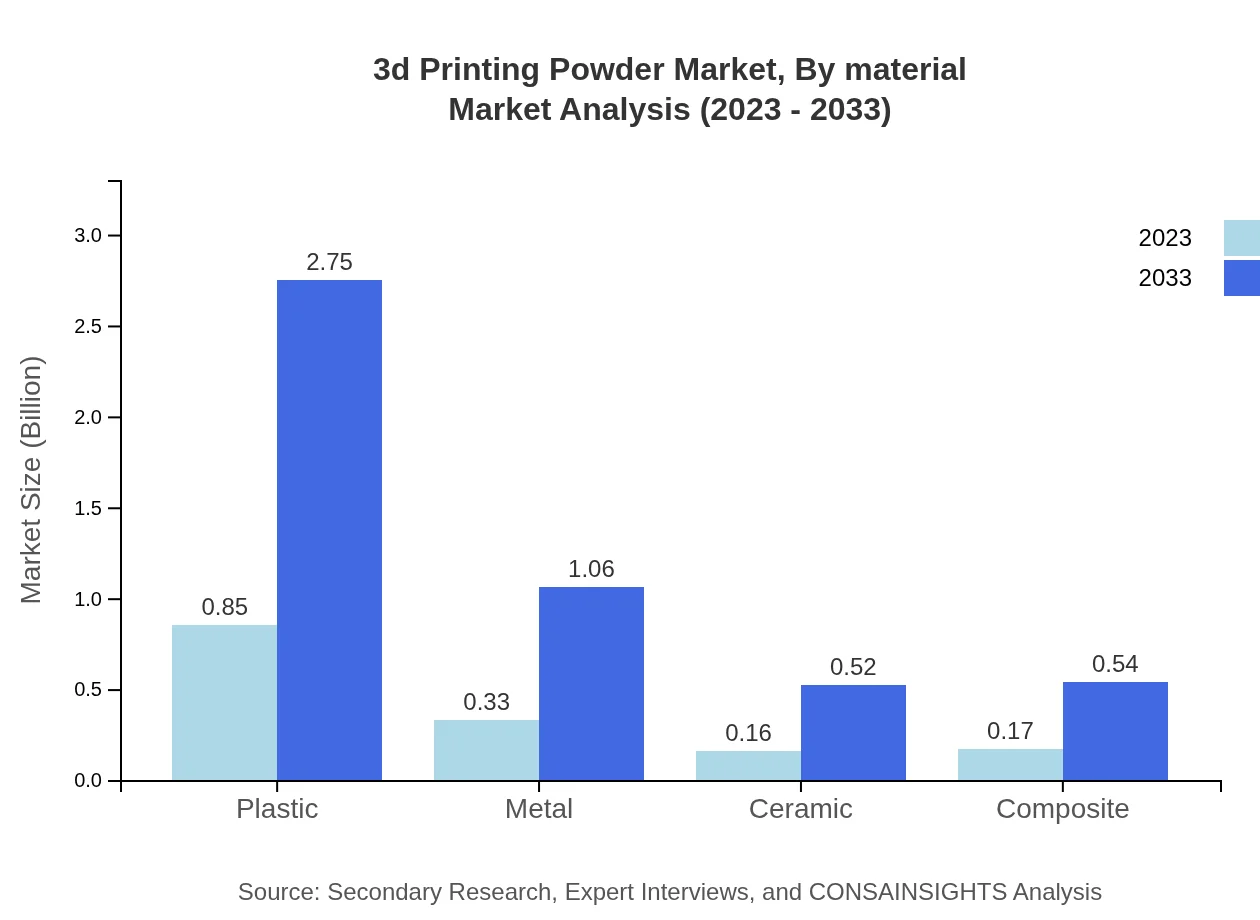

3d Printing Powder Market Analysis By Material

Plastic powders dominate the market, valued at $0.85 billion in 2023, expected to grow to $2.75 billion by 2033, holding a share of 56.38%. Metal powders are also significant, with a current market size of $0.33 billion (21.78% share), expected to reach $1.06 billion. Ceramics and composites are emerging segments, currently valued at $0.16 billion and $0.17 billion respectively.

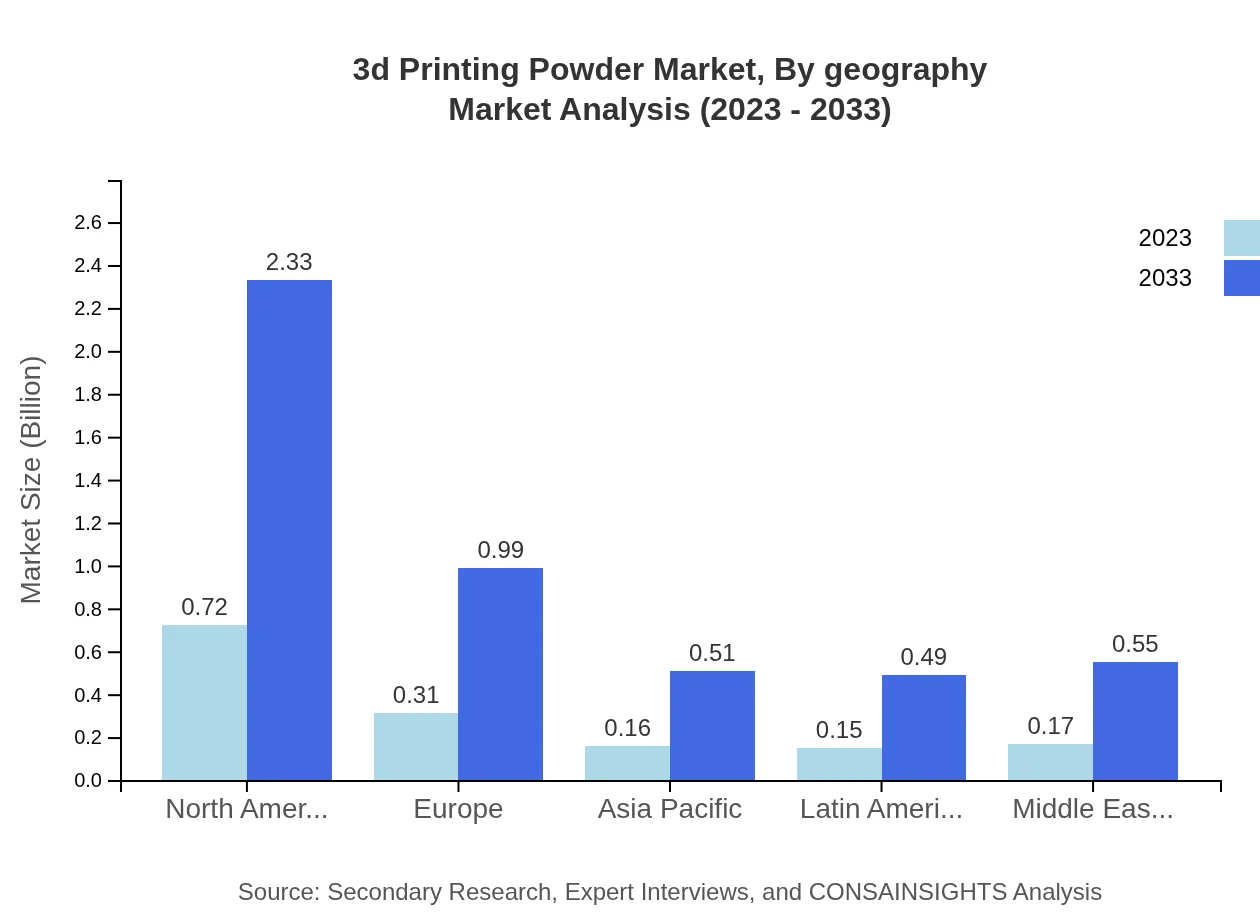

3d Printing Powder Market Analysis By Geography

North America holds a 47.73% market share in 2023, with expectations to grow from $0.72 billion to $2.33 billion. Europe accounts for 20.36% with growth from $0.31 billion to $0.99 billion. The Asia Pacific region, with 10.53% share with a market size growing from $0.16 billion to $0.51 billion, indicates significant growth potentials in manufacturing technologies.

3d Printing Powder Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in 3d Printing Powder Industry

3D Systems Corporation:

A pioneer in 3D printing technology, offering a wide range of 3D printing solutions including powders and printers for various industries.Stratasys Ltd.:

A leading provider of 3D printing solutions, specializing in polymer powders for additive manufacturing, widely used in various applications.EOS GmbH:

Known for their metal 3D printing technologies, EOS provides high-quality metal powders and systems for industrial applications.Materialise NV:

Offers software and manufacturing solutions that integrate with 3D printing technology, supporting various sectors including healthcare and automotive.SLM Solutions Group AG:

Specializes in metal-based solutions, providing advanced 3D printing technologies along with innovative metal powders.We're grateful to work with incredible clients.

FAQs

What is the market size of 3d Printing Powder?

The global 3D printing powder market is currently valued at approximately $1.5 billion in 2023, with an expected CAGR of 12% leading to significant growth by 2033.

What are the key market players or companies in the 3d Printing Powder industry?

Key players in the 3D printing powder industry include prominent companies such as 3D Systems, Stratasys, and EOS, among others, which are at the forefront of innovation and market growth.

What are the primary factors driving the growth in the 3D Printing Powder industry?

Factors such as increased demand for rapid prototyping, advancements in 3D printing technologies, and expansions into various sectors like automotive and healthcare are key drivers of growth in the industry.

Which region is the fastest Growing in the 3D Printing Powder industry?

North America is currently the fastest-growing region in the 3D printing powder market, projected to grow from $0.58 billion in 2023 to $1.88 billion by 2033, reflecting robust demand and technological advancements.

Does ConsaInsights provide customized market report data for the 3D Printing Powder industry?

Yes, ConsaInsights offers customized market report data for the 3D printing powder industry, tailored to meet specific client needs and preferences for accurate market analysis.

What deliverables can I expect from this 3D Printing Powder market research project?

From this market research project, you can expect detailed reports, analyses of market size, growth forecasts, competitive landscapes, and insights into customer preferences and regional performance.

What are the market trends of 3d Printing Powder?

Market trends for 3D printing powder include a shift towards sustainable materials, enhanced focus on technology integration, and rising adoption in industries like aerospace, automotive, and healthcare.