4d Printing Market Report

Published Date: 02 February 2026 | Report Code: 4d-printing

4d Printing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the 4D printing market, covering market size, CAGR forecasts from 2023 to 2033, segmentation, regional insights, leading companies, and future market trends.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

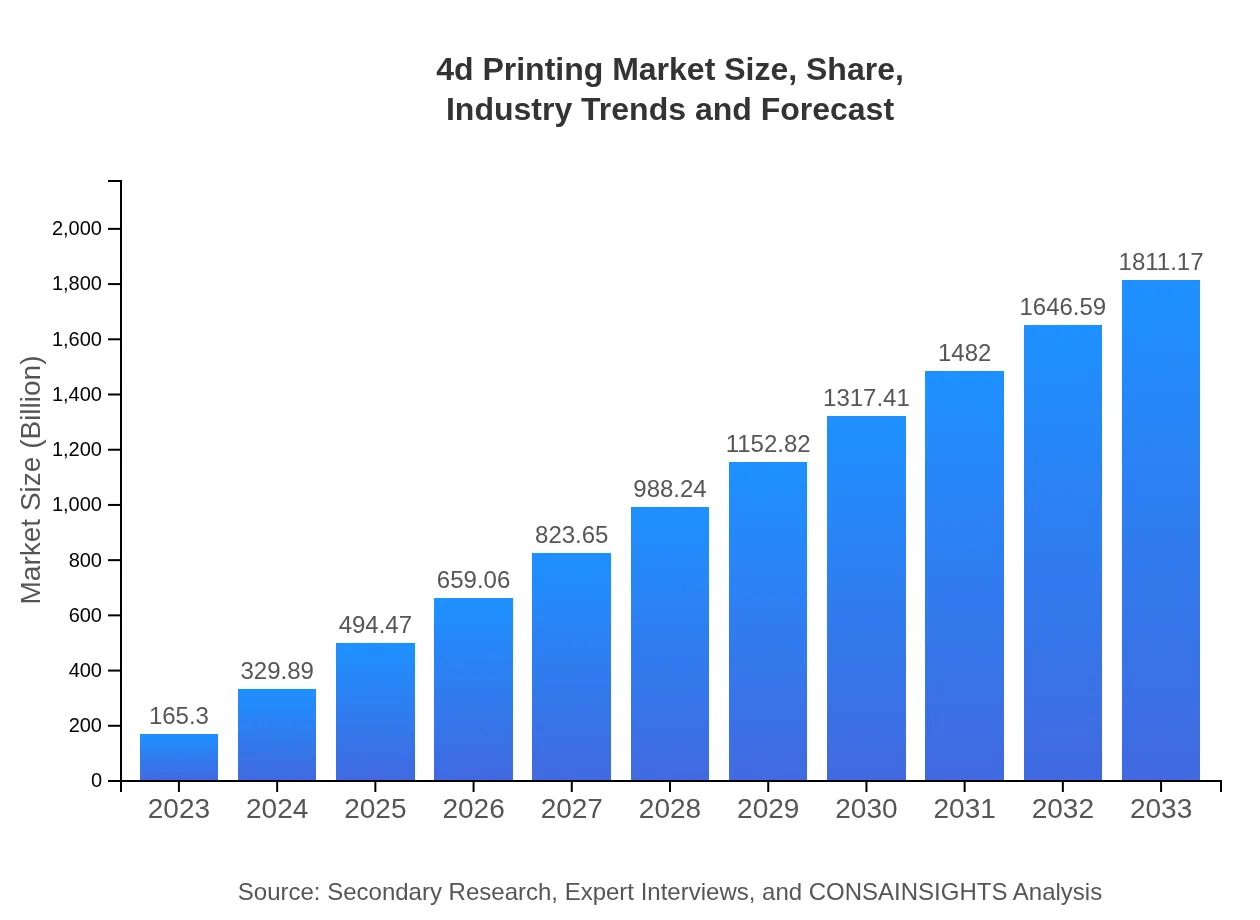

| 2023 Market Size | $165.30 Million |

| CAGR (2023-2033) | 25.3% |

| 2033 Market Size | $1811.17 Million |

| Top Companies | Stratasys Ltd., 3D Systems Corporation, MIT's Self-Assembly Lab, HP Inc. |

| Last Modified Date | 02 February 2026 |

4d Printing Market Overview

Customize 4d Printing Market Report market research report

- ✔ Get in-depth analysis of 4d Printing market size, growth, and forecasts.

- ✔ Understand 4d Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in 4d Printing

What is the Market Size & CAGR of 4D Printing market in 2023?

4D Printing Industry Analysis

4D Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

4D Printing Market Analysis Report by Region

Europe 4d Printing Market Report:

In Europe, the market is projected to rise from $45.61 million in 2023 to $499.70 million by 2033. Countries like Germany and France are crucial players, leveraging their advanced technology sectors to promote 4D printing capabilities.Asia Pacific 4d Printing Market Report:

The Asia Pacific region is anticipated to witness a significant increase in the 4D printing market, growing from $31.77 million in 2023 to $348.11 million by 2033. Factors driving this growth include heightened industrial activity and significant investments in technology advancements across countries like China and Japan.North America 4d Printing Market Report:

North America holds a leading position in the 4D printing market, expanding from $63.08 million in 2023 to $691.14 million in 2033. The United States remains a hub of innovation, with many companies and research institutes driving advancements in smart materials.South America 4d Printing Market Report:

In South America, the market grows modestly from $6.78 million in 2023 to $74.26 million in 2033. Brazil and Argentina are key players, with increasing governmental support for additive manufacturing technologies enhancing market potential.Middle East & Africa 4d Printing Market Report:

The Middle East and Africa market is expected to grow from $18.07 million in 2023 to $197.96 million in 2033, driven by demands for modernization and efficiency in manufacturing processes, along with emerging technological infrastructure.Tell us your focus area and get a customized research report.

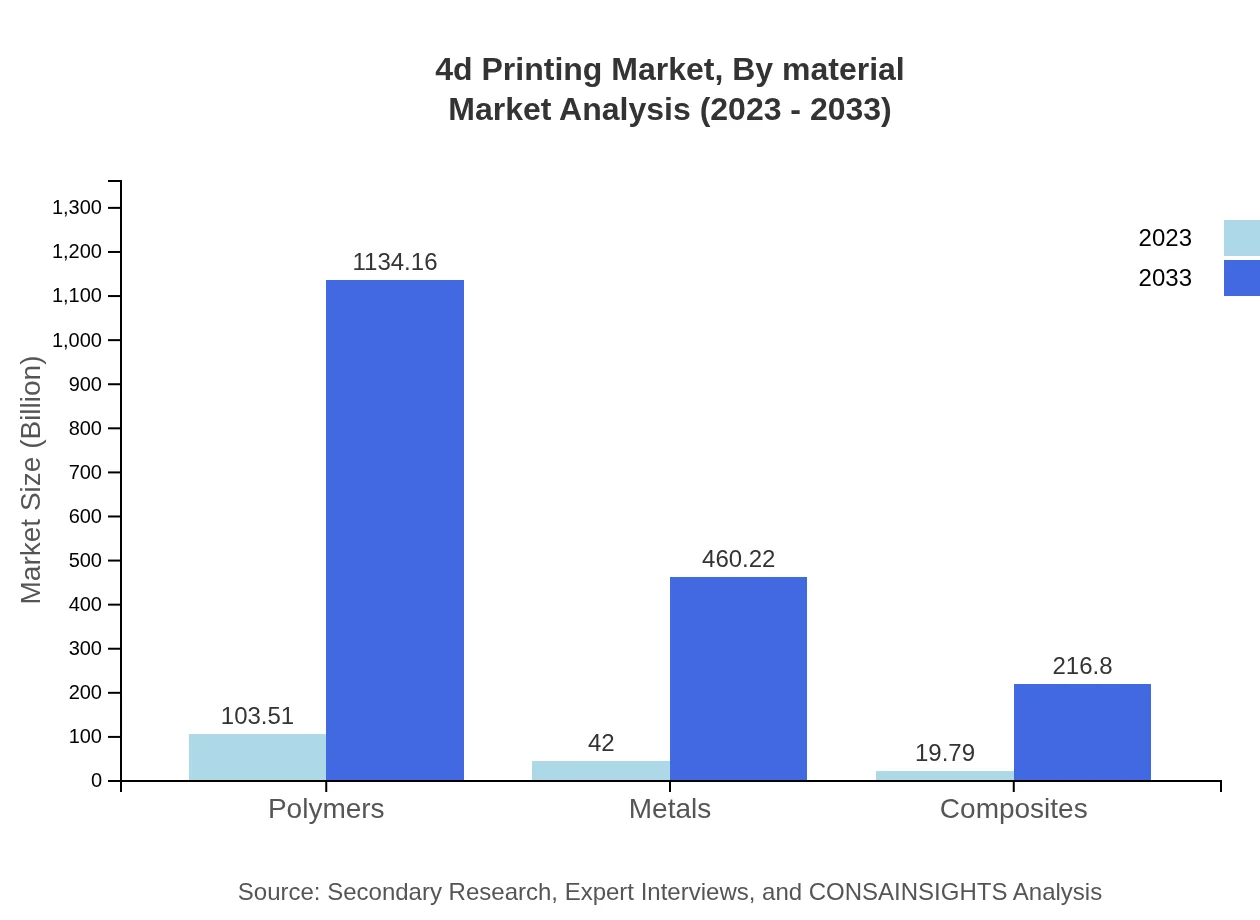

4d Printing Market Analysis By Material

The 4D printing market, by material, includes polymers, metals, composites, and other materials. Polymers dominate with a market size of $103.51 million in 2023, projected to grow to $1.134 billion by 2033, representing a significant share within the industry. Metals follow closely with a projected market increase from $42 million in 2023 to $460.22 million by 2033, showcasing their crucial role in durable applications.

4d Printing Market Analysis By Application

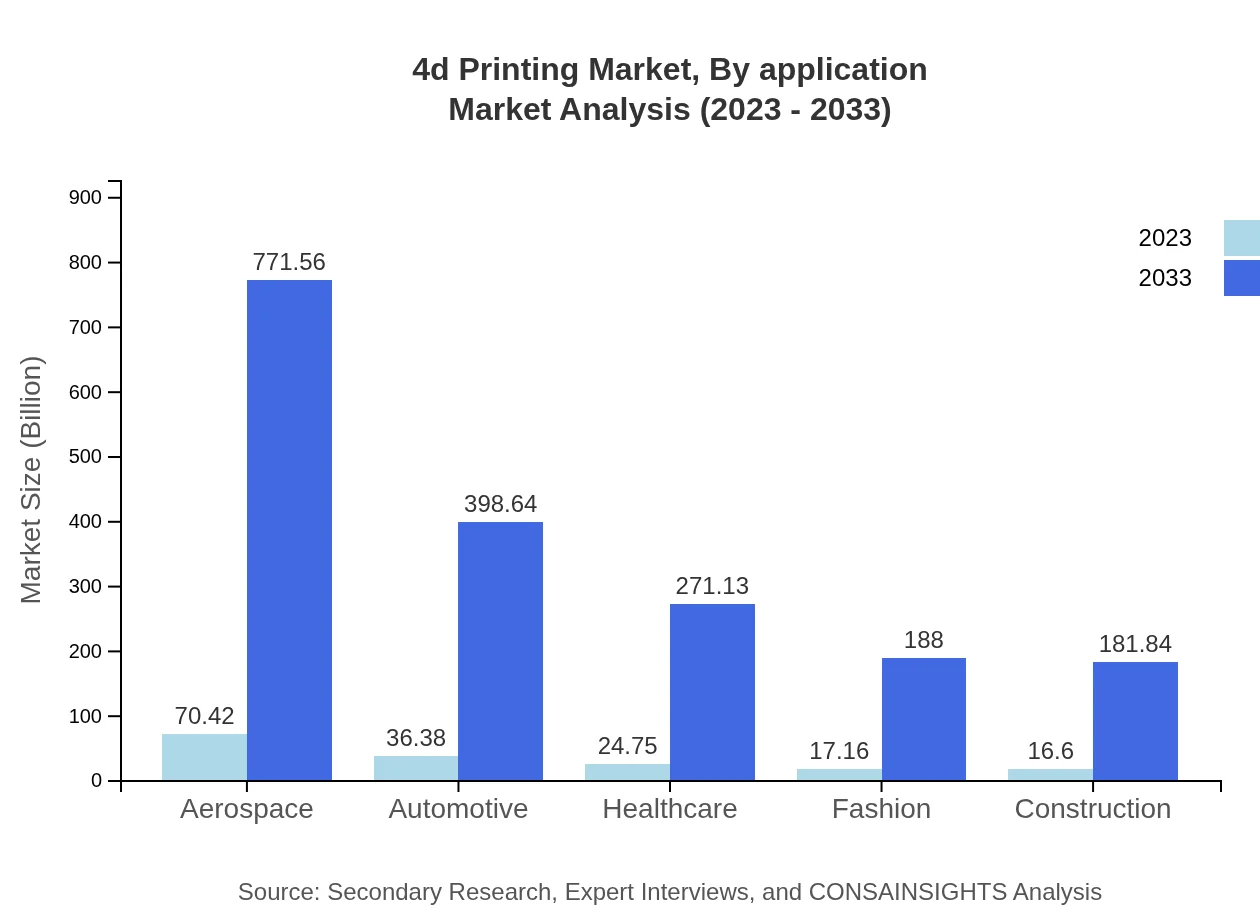

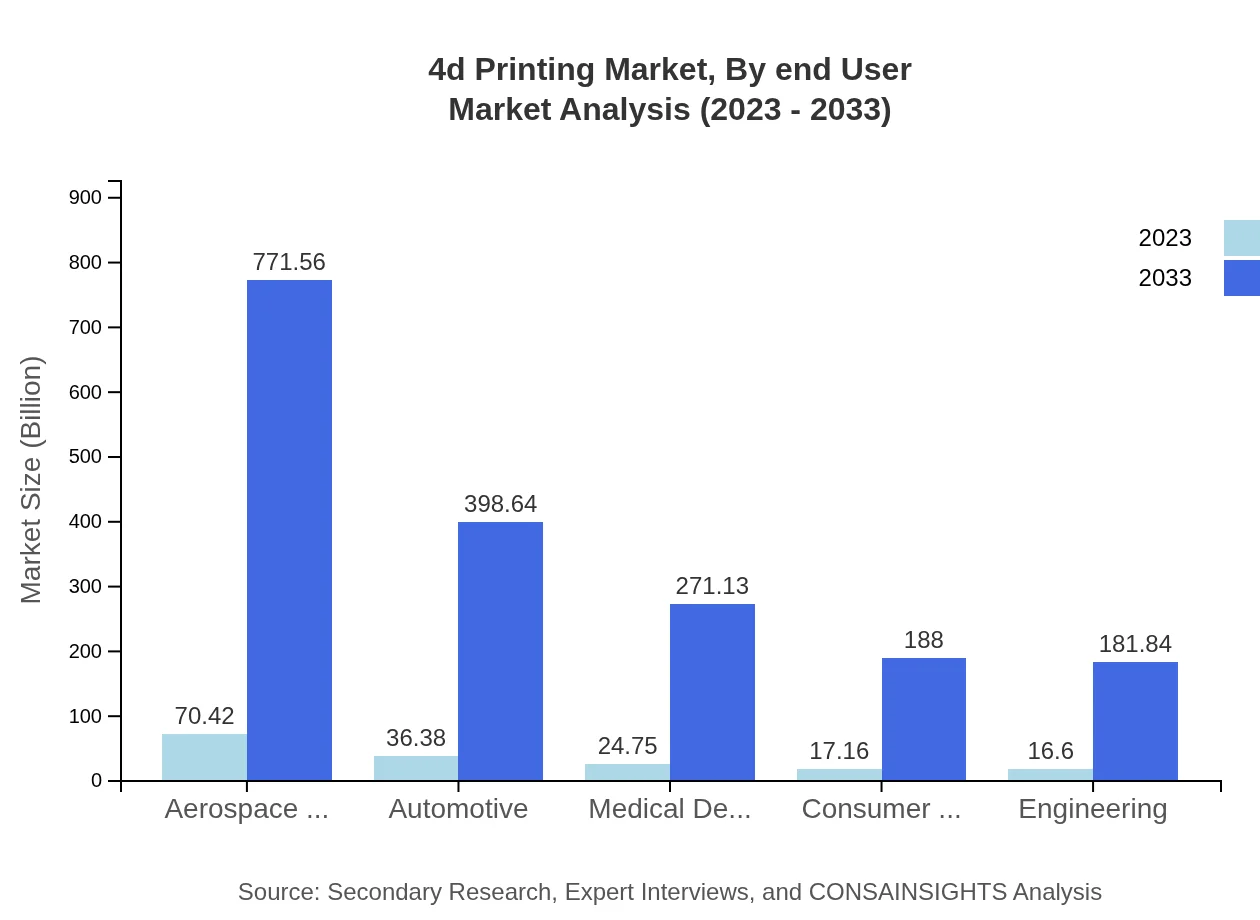

By application, the aerospace and defense segment leads with sizes of $70.42 million in 2023 and $771.56 million by 2033, reflecting the industry's need for adaptive, lightweight materials. The automotive segment is also significant, expected to increase from $36.38 million in 2023 to $398.64 million over the same period, driven by innovations aimed at enhancing vehicle efficiency.

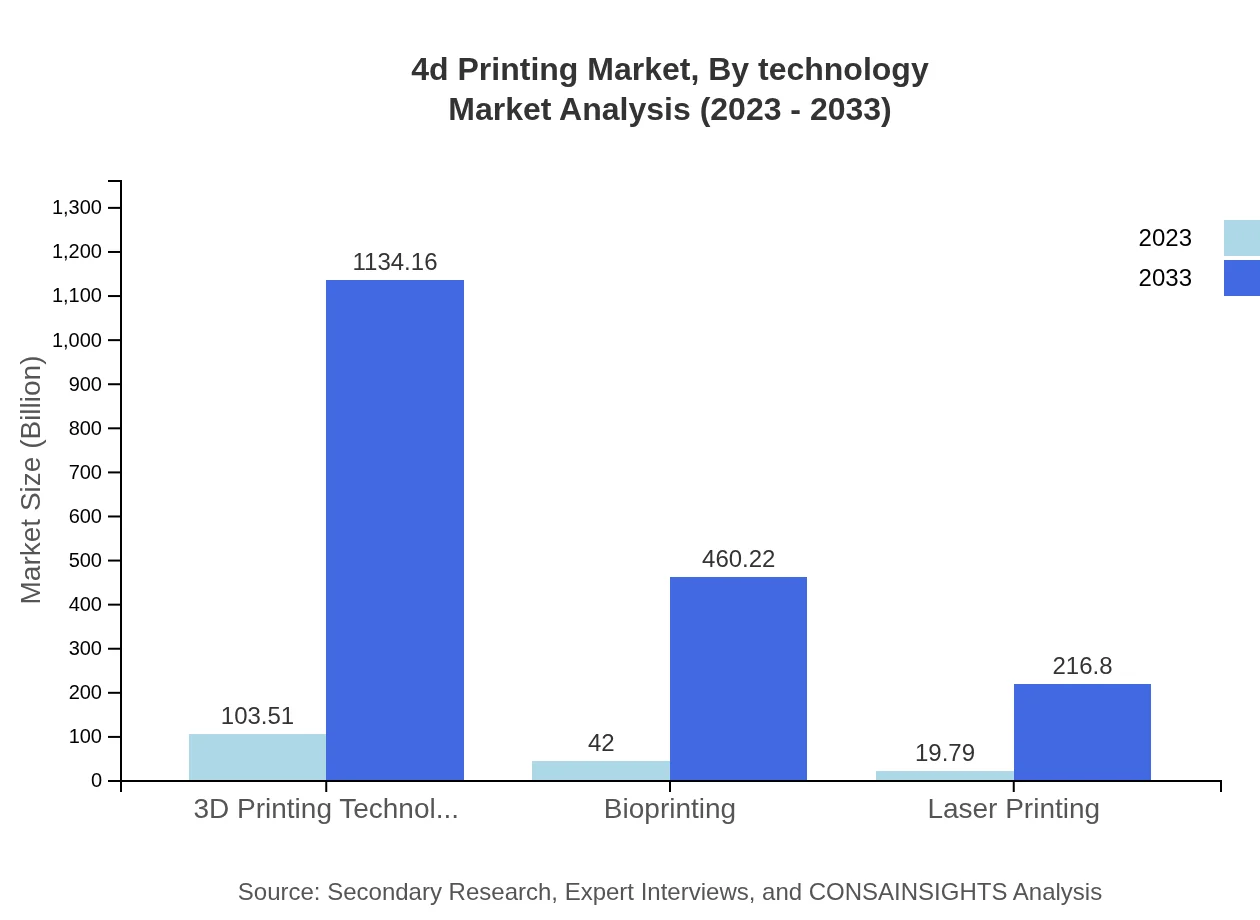

4d Printing Market Analysis By Technology

4D printing technologies include methods such as bioprinting, laser printing, and advanced 3D printing. Bioprinting is set to grow from $42 million to $460.22 million by 2033, reflecting its potential in healthcare applications. Laser printing is expected to expand from $19.79 million to $216.80 million, as adoption increases in various industrial sectors.

4d Printing Market Analysis By End User

Key end-user industries include healthcare, automotive, aerospace, and consumer goods. The healthcare sector is transforming with a market growth from $24.75 million in 2023 to $271.13 million by 2033, indicating strong demand for customized medical solutions. The consumer goods sector is also anticipated to expand from $17.16 million to $188 million, driven by consumer preferences for personalized products.

4D Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in 4D Printing Industry

Stratasys Ltd.:

A leading player in additive manufacturing technologies known for its advanced 3D and 4D printing solutions that enhance production capabilities across multiple sectors.3D Systems Corporation:

Pioneering company in 3D printing with innovative solutions in 4D technologies, focusing on healthcare and aerospace applications to drive market growth.MIT's Self-Assembly Lab:

A research institution recognized for groundbreaking developments in programmable materials and structures, significantly driving advancements in 4D printing technology.HP Inc.:

Known for its 3D printing technologies, HP is a key player focusing on smart materials and expanding its portfolio in the 4D printing sector.We're grateful to work with incredible clients.

FAQs

What is the market size of 4D printing?

The 4D printing market is valued at approximately $165.3 million in 2023, with a robust growth projection of 25.3% CAGR, suggesting significant expansion and increasing adoption of transformative printing technologies.

What are the key market players or companies in the 4D printing industry?

Key players in the 4D printing industry include Stratasys, 3D Systems, and Autodesk, among others, which are at the forefront of driving innovation and expanding market reach with cutting-edge technology and applications.

What are the primary factors driving the growth in the 4D printing industry?

Primary growth drivers for the 4D printing industry include advancements in materials science, increasing demand for customized solutions, and growing investments in R&D for innovative applications across various sectors like aerospace and healthcare.

Which region is the fastest Growing in the 4D printing?

The Asia Pacific region is expected to witness the fastest growth in the 4D printing market, projected to grow from $31.77 million in 2023 to $348.11 million by 2033, driven by technological adoption and increasing manufacturing capabilities.

Does ConsaInsights provide customized market report data for the 4D printing industry?

Yes, Consainsights offers customized market report data tailored to specific requirements in the 4D printing industry, allowing clients to gain insights suited to their unique business needs and strategic objectives.

What deliverables can I expect from this 4D printing market research project?

From the 4D printing market research project, clients can expect detailed reports including market size analysis, competitive landscape, growth drivers, regional analysis, and segmented insights providing a comprehensive overview.

What are the market trends of 4D printing?

Current trends in the 4D printing market include increasing integration with smart technologies, sustainable material development, and a growing emphasis on applications in healthcare and aerospace for dynamic and adaptive solutions.