Acetylene Market Report

Published Date: 02 February 2026 | Report Code: acetylene

Acetylene Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the Acetylene market, covering key statistics, trends, and forecasts for the period of 2023 to 2033. Insights on market size, dynamics, and regional performance are included to assist stakeholders in making informed decisions.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

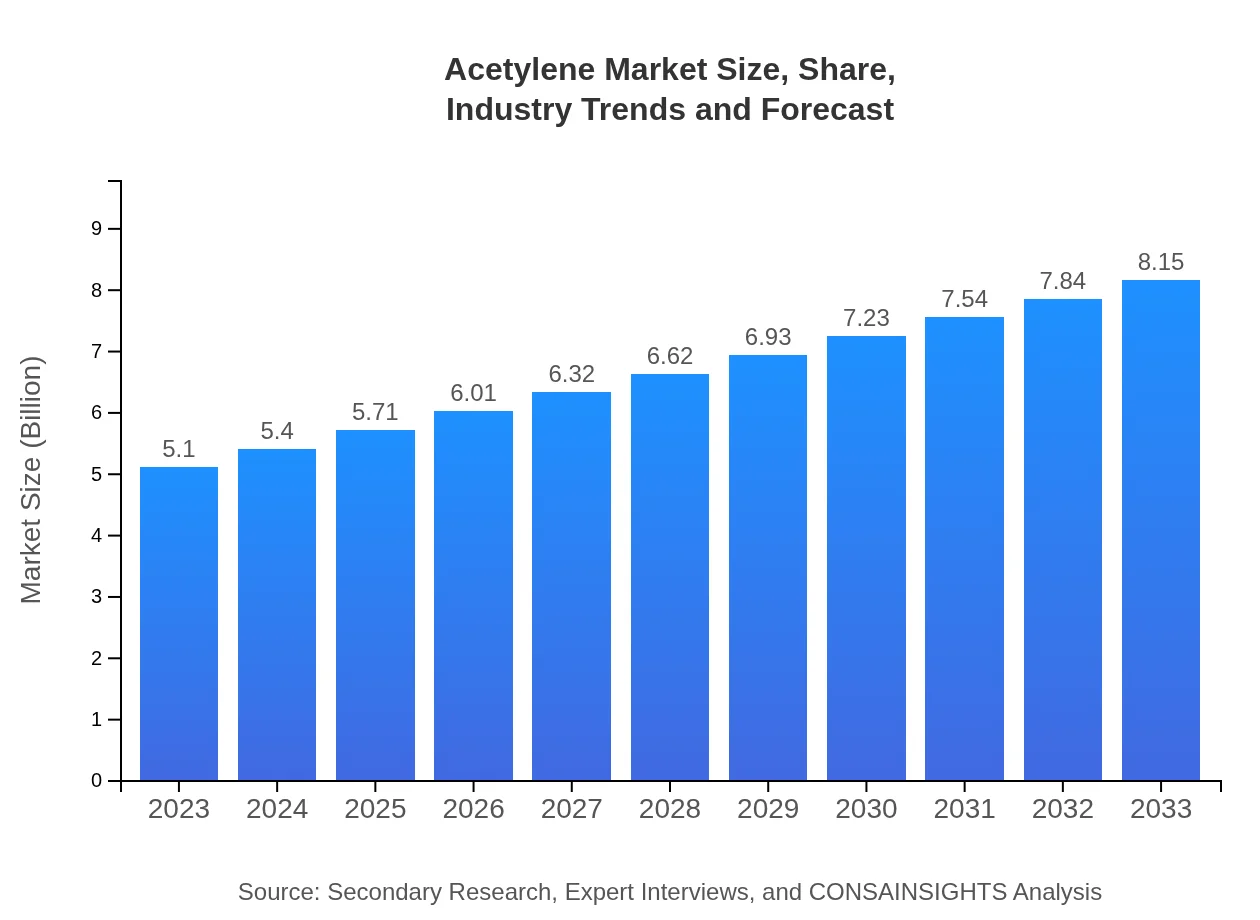

| 2023 Market Size | $5.10 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $8.15 Billion |

| Top Companies | Praxair Technology, Inc., Air Products and Chemicals, Inc., Linde plc., BASF SE |

| Last Modified Date | 02 February 2026 |

Acetylene Market Overview

Customize Acetylene Market Report market research report

- ✔ Get in-depth analysis of Acetylene market size, growth, and forecasts.

- ✔ Understand Acetylene's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acetylene

What is the Market Size & CAGR of Acetylene market in 2023?

Acetylene Industry Analysis

Acetylene Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acetylene Market Analysis Report by Region

Europe Acetylene Market Report:

Europe's Acetylene market is anticipated to grow from $1.31 billion in 2023 to $2.09 billion by 2033. A stringent regulatory environment promoting sustainable processes, along with an evolving chemical sector in the region, supports robust market growth.Asia Pacific Acetylene Market Report:

The Asia Pacific Acetylene market is projected to reach $1.76 billion by 2033, up from $1.10 billion in 2023. Rapid industrialization and the growing automotive sector in countries like China and India are significant growth drivers. The region's large population and subsequent demand for in-demand products further bolster market expansion.North America Acetylene Market Report:

The North American market will see growth from $1.81 billion in 2023 to $2.89 billion in 2033. The industrial sectors in the US and Canada, particularly in manufacturing and automotive, play a pivotal role in driving demand for Acetylene.South America Acetylene Market Report:

In South America, the Acetylene market is expected to grow from $0.24 billion in 2023 to $0.39 billion by 2033. This growth is largely influenced by increasing industrial activities and a rising emphasis on infrastructure development, reflecting the region's expanding economic landscape.Middle East & Africa Acetylene Market Report:

The Middle East and Africa market for Acetylene is forecasted to increase from $0.64 billion in 2023 to $1.02 billion by 2033. This growth is largely driven by expanding industrial operations and investment in petrochemical sectors, making it a vital region for future development.Tell us your focus area and get a customized research report.

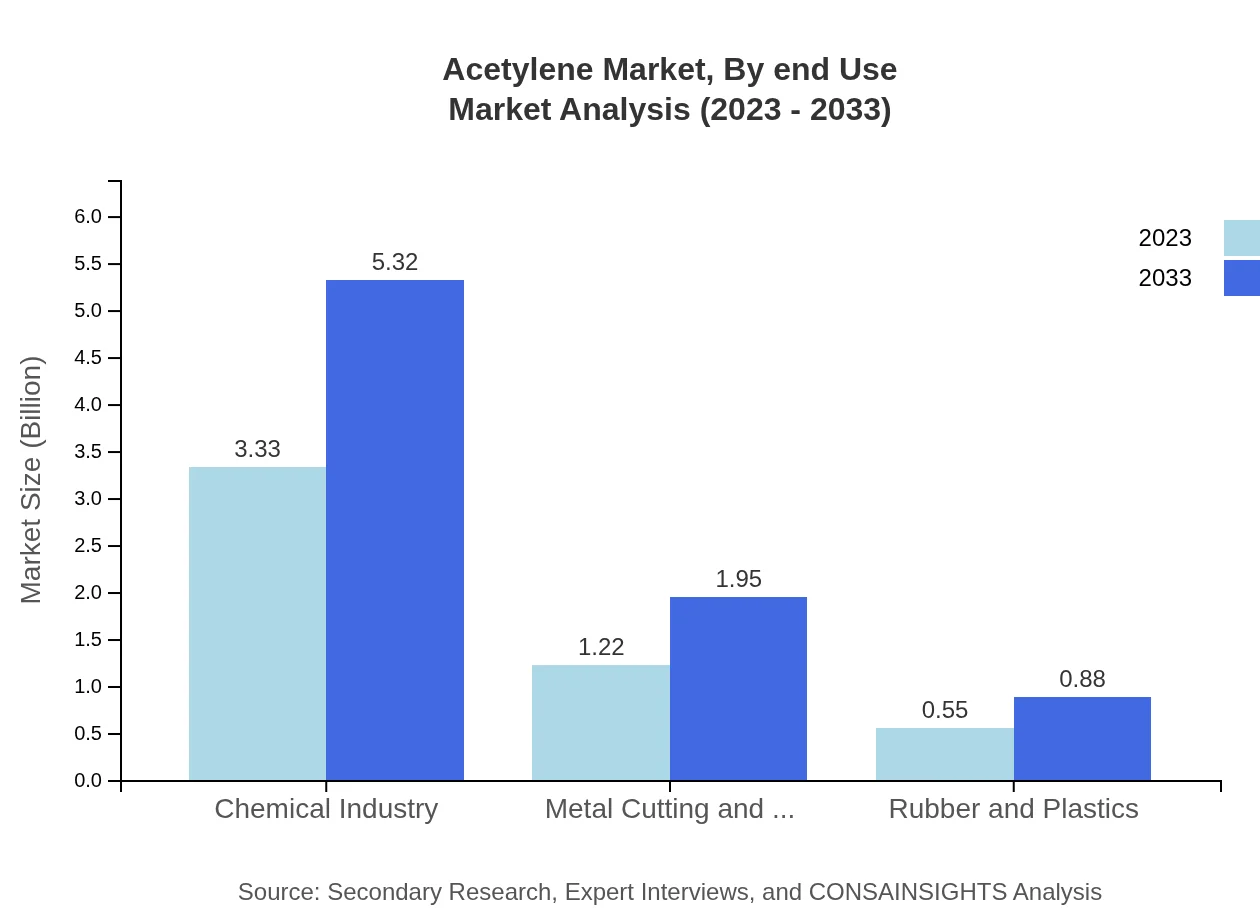

Acetylene Market Analysis By End Use

The major end-use segments within the Acetylene market encompass chemical industries, welding, and lighting. As of 2023, the chemical industry holds a market size of approximately $3.33 billion, representing 65.24% of total market share. The metal cutting and welding segment follows with a size of $1.22 billion and a share of 23.9%. Projected figures suggest a continued dominance of these segments, with significant growth anticipated up to 2033.

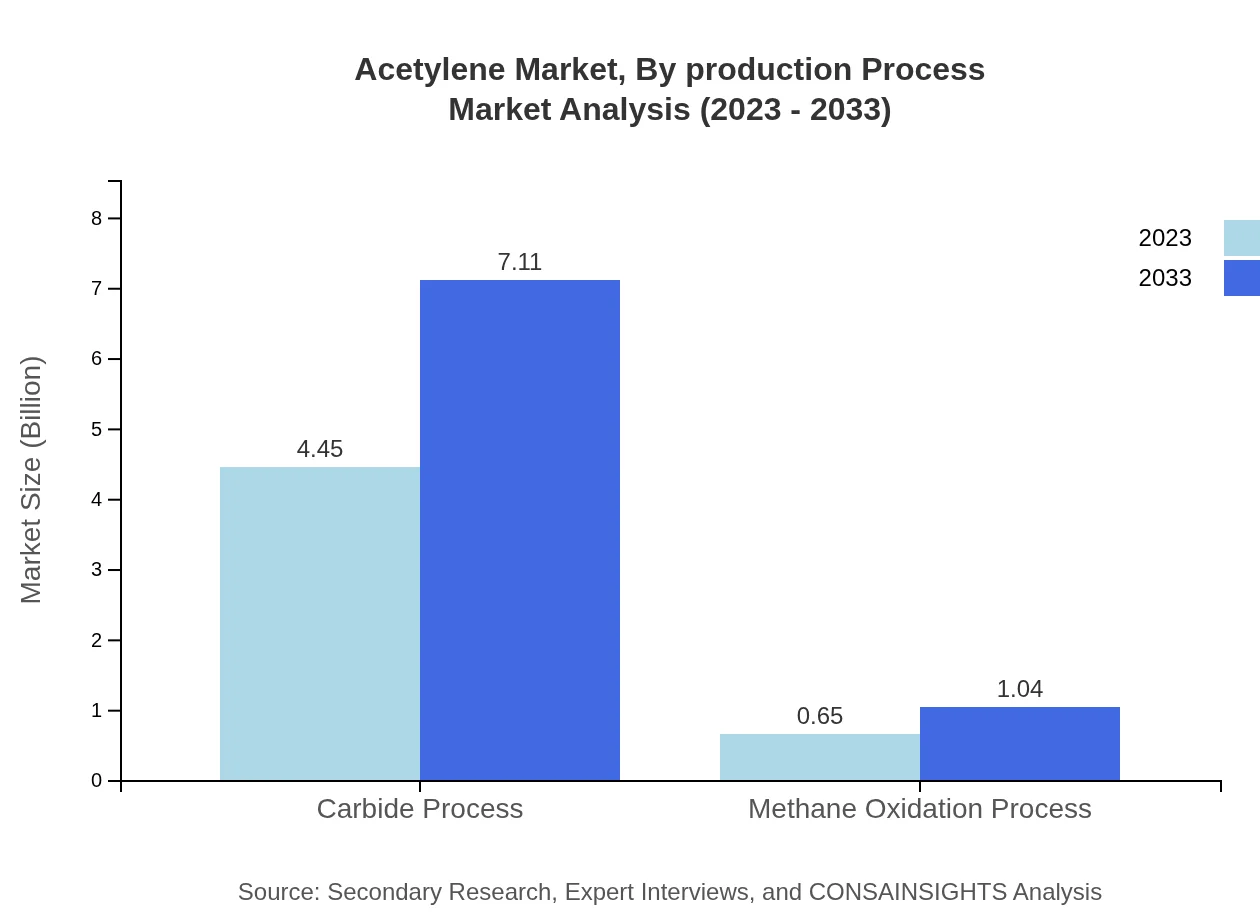

Acetylene Market Analysis By Production Process

The production process segment is primarily divided into carbide process and methane oxidation process, with both processes holding significant shares of the market. The carbide process currently represents 87.24% of production for Acetylene, valued at $4.45 billion in 2023. The replacement of less efficient technologies with innovations will shape further market dynamics in this segment.

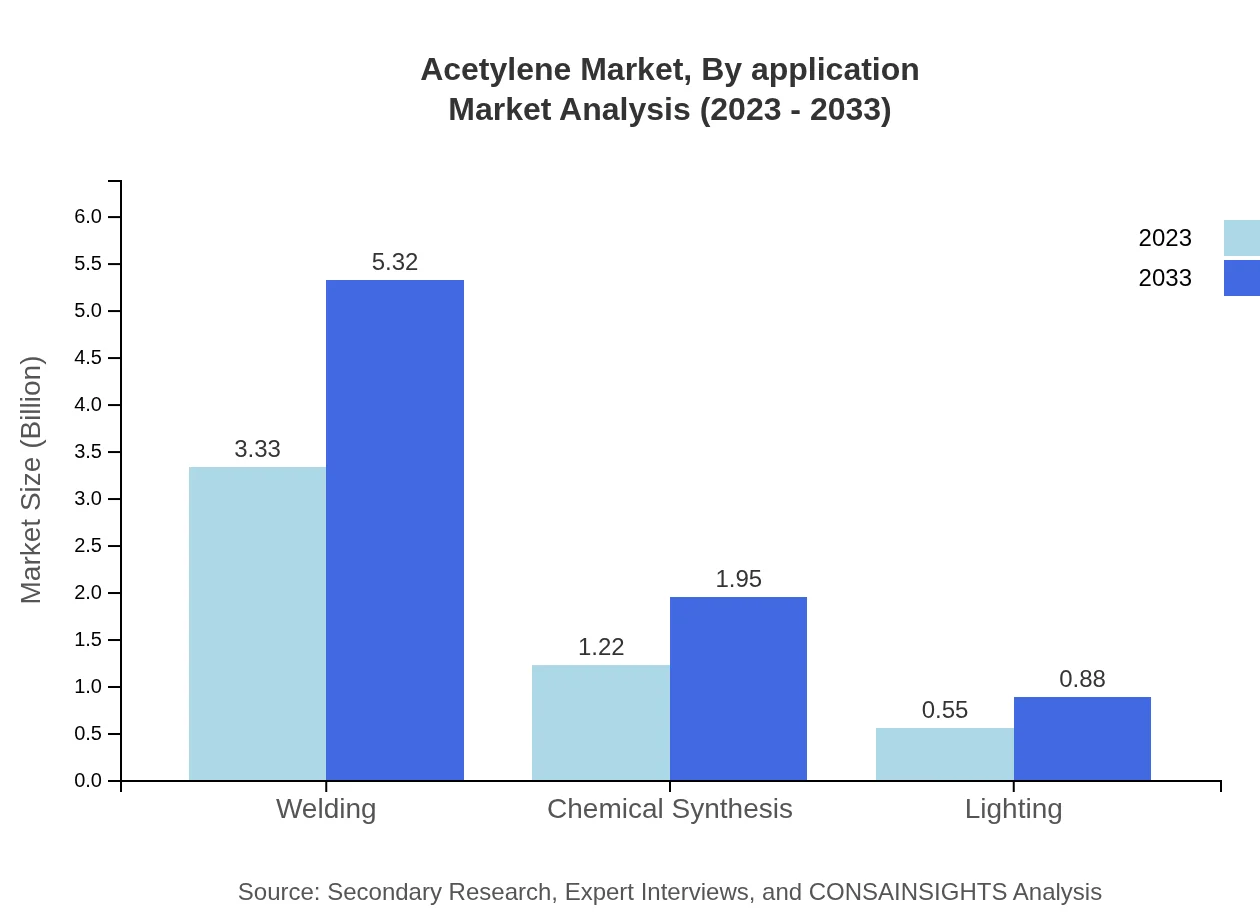

Acetylene Market Analysis By Application

In application terms, the Acetylene market is categorized largely into four domains: chemical synthesis, metal cutting, rubber and plastics, and lighting. Chemical synthesis accounts for a significant market portion, valued at $1.22 billion in 2023. Trends point towards a consistent rise in application-driven demand as industries recognize the versatility of Acetylene.

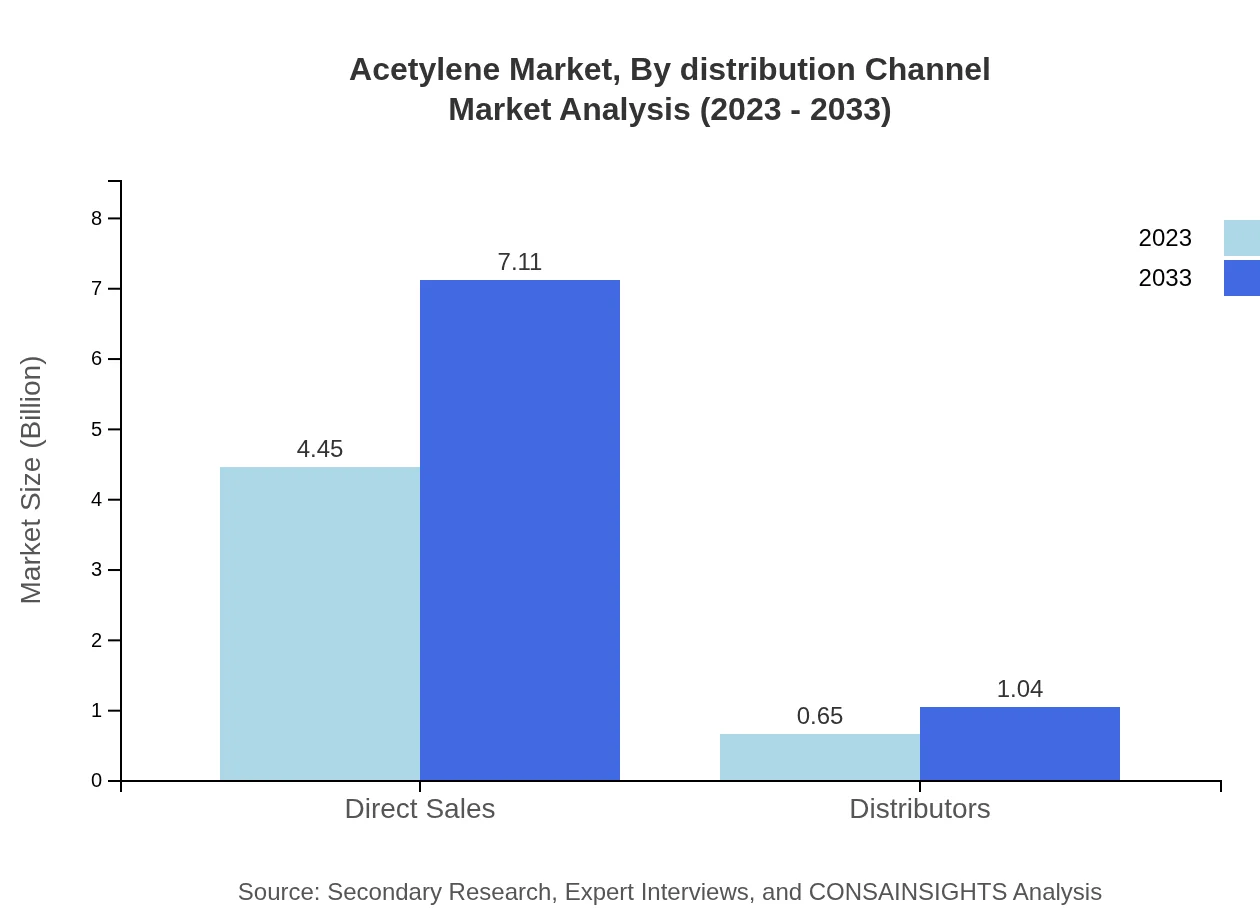

Acetylene Market Analysis By Distribution Channel

Distribution channels include direct sales and distributor networks, with direct sales currently holding approximately 87.24% of the market share in 2023. Effective management of distribution channels will be essential for companies seeking to optimize reach and responsiveness to market demands.

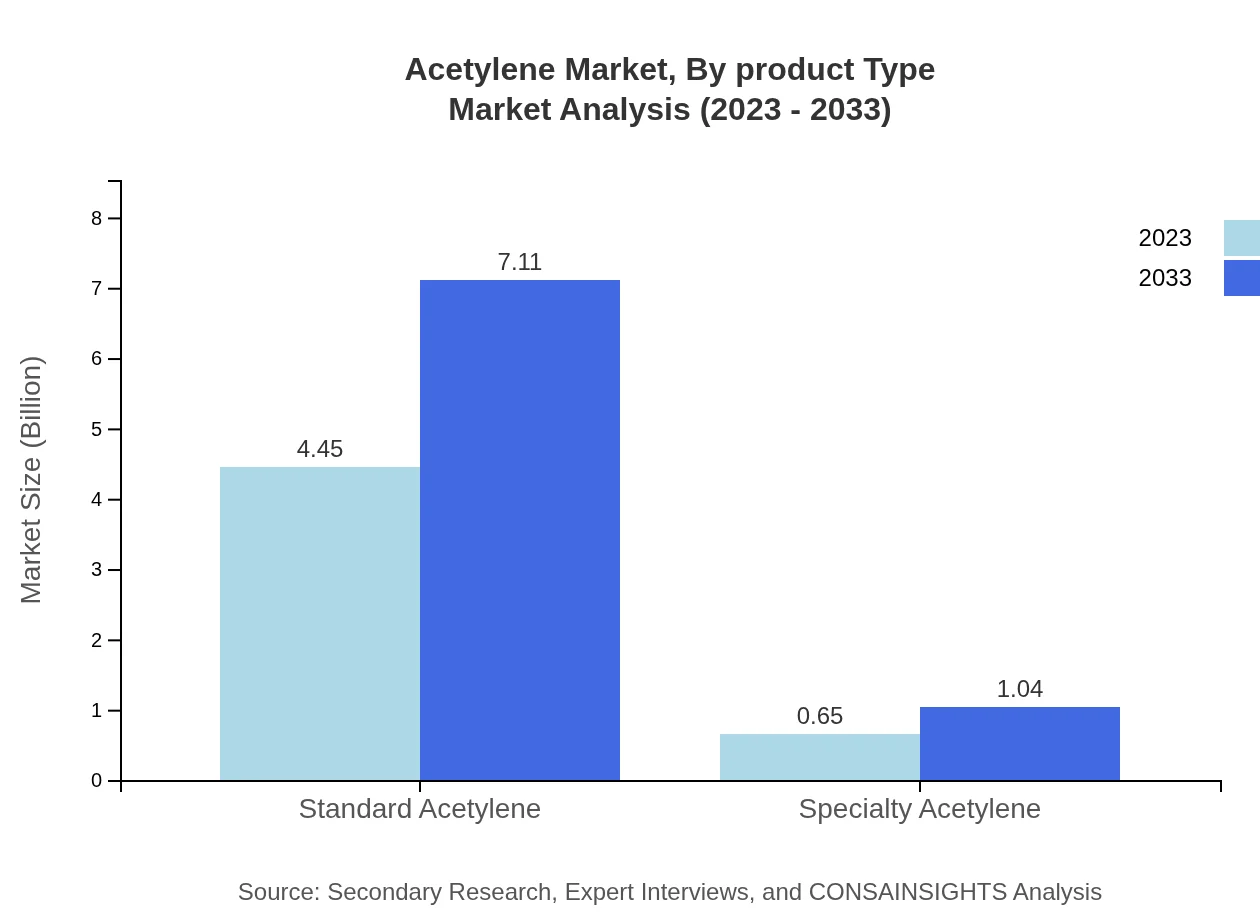

Acetylene Market Analysis By Product Type

The Acetylene product market is divided into standard and specialty acetylene. Standard acetylene dominates with a market size of $4.45 billion in 2023, while specialty acetylene, comprising value-added products with specific applications, is anticipated to grow steadily, reaching $1.04 billion by 2033.

Acetylene Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acetylene Industry

Praxair Technology, Inc.:

One of the leading global suppliers of industrial gases, Praxair plays a significant role in the supply of Acetylene, offering extensive services across various industries.Air Products and Chemicals, Inc.:

A major player in the global gas market, Air Products excels in providing high-quality Acetylene and related products for diverse applications.Linde plc.:

Linde is recognized for its strong presence in the industrial gases sector with innovative and sustainable production methods of Acetylene.BASF SE:

A leading chemical company that utilizes Acetylene in numerous applications, especially in the production of specialty chemicals.We're grateful to work with incredible clients.

FAQs

What is the market size of acetylene?

The acetylene market is valued at approximately $5.1 billion in 2023, with a projected CAGR of 4.7%. By 2033, the market size is expected to grow significantly as demand increases across various applications.

What are the key market players or companies in the acetylene industry?

Key players within the acetylene market include prominent chemical companies and industrial gas suppliers, which are vital for production and distribution. Leading firms typically engage in mergers, acquisitions, and strategic partnerships to enhance market presence.

What are the primary factors driving the growth in the acetylene industry?

The acetylene industry is primarily driven by increasing demand in the chemical sector, expanding applications in welding, and growth in the manufacturing sector. These factors contribute significantly to rising consumption and advancements in production technologies.

Which region is the fastest Growing in the acetylene market?

Regionally, North America is poised as the fastest-growing market for acetylene, expected to increase from $1.81 billion in 2023 to $2.89 billion by 2033, reflecting strong industrial demand and technological advancements.

Does Consainsights provide customized market report data for the acetylene industry?

Yes, Consainsights offers customized market research reports tailored to specific needs in the acetylene industry, providing in-depth insights, analysis, and forecasts that cater to individual business requirements and market conditions.

What deliverables can I expect from this acetylene market research project?

The research project will deliver comprehensive reports including market size, growth forecasts, competitive landscape analysis, segment insights, and regional trends, empowering stakeholders to make informed strategic decisions.

What are the market trends of acetylene?

Current trends in the acetylene market indicate a shift towards sustainable production methods, increased adoption in diverse sectors, and research into innovative applications, particularly in green technologies and advanced manufacturing processes.