Acrylate Monomers Market Report

Published Date: 02 February 2026 | Report Code: acrylate-monomers

Acrylate Monomers Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Acrylate Monomers market, detailing market size, segmentation, regional dynamics, trends, and forecasts for the period 2023 to 2033.

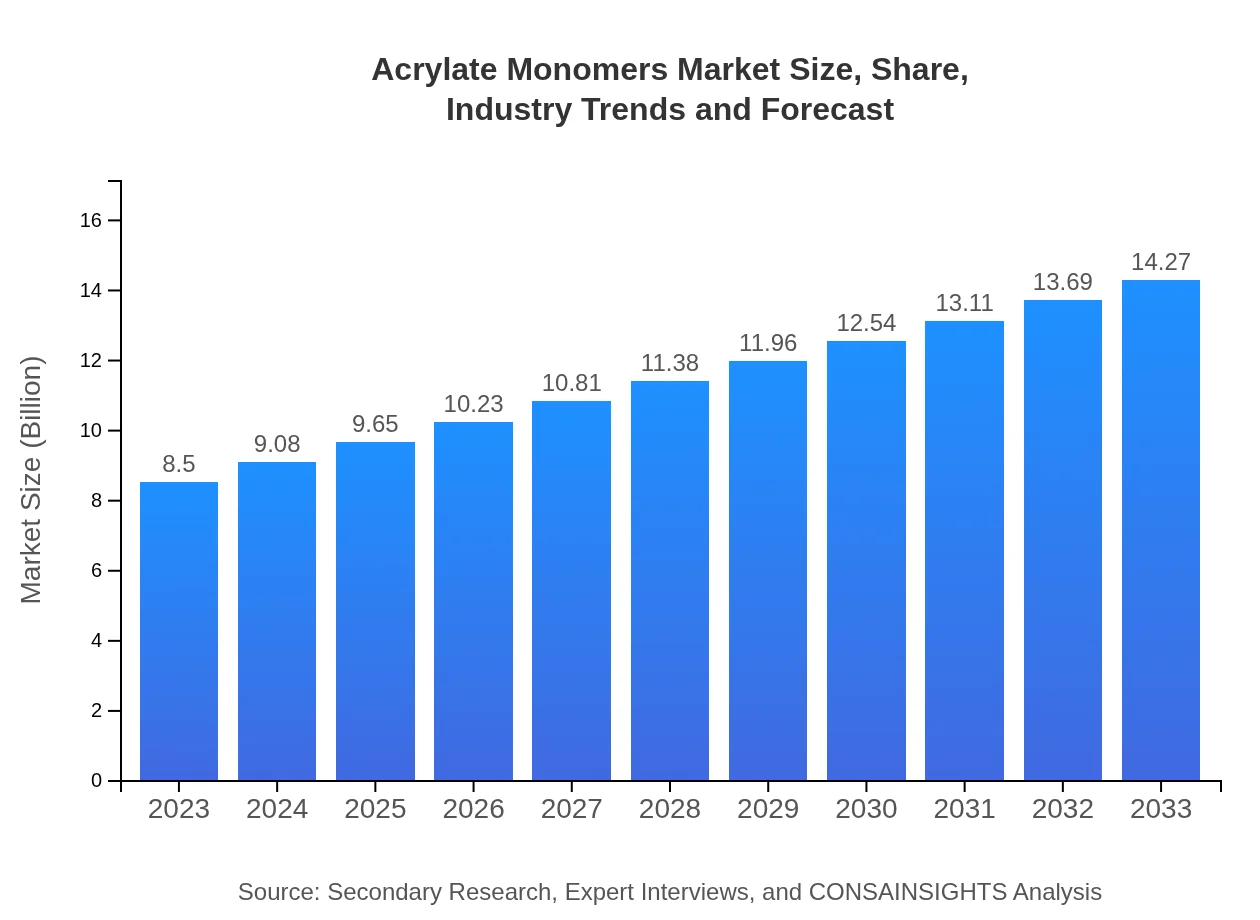

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $8.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $14.27 Billion |

| Top Companies | BASF SE, Mitsubishi Chemical Corporation, Dow Chemical Company, SABIC, Hexion Inc. |

| Last Modified Date | 02 February 2026 |

Acrylate Monomers Market Overview

Customize Acrylate Monomers Market Report market research report

- ✔ Get in-depth analysis of Acrylate Monomers market size, growth, and forecasts.

- ✔ Understand Acrylate Monomers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylate Monomers

What is the Market Size & CAGR of Acrylate Monomers market in 2023?

Acrylate Monomers Industry Analysis

Acrylate Monomers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylate Monomers Market Analysis Report by Region

Europe Acrylate Monomers Market Report:

Europe, with a market size of $2.40 billion in 2023, is anticipated to grow to $4.03 billion by 2033, reflecting a vigorous CAGR of 5.53% as well. The ongoing shift towards green and sustainable products amidst extensive regulations enhances the adoption of acrylate-based applications in various industries.Asia Pacific Acrylate Monomers Market Report:

The Asia Pacific region holds the largest market share in the Acrylate Monomers market, valued at approximately $1.60 billion in 2023. This region is anticipated to grow to $2.69 billion by 2033, representing a healthy CAGR of 5.51%. The increasing demand from developing economies, coupled with a robust manufacturing sector, contributes significantly to this growth.North America Acrylate Monomers Market Report:

North America exhibits a significant market valuation of $3.24 billion in 2023, with expectations to expand to $5.44 billion by 2033, marking a CAGR of 5.53%. The region's advanced technological landscape and stringent regulations on product quality and sustainability continue to drive the acrylate monomers demand.South America Acrylate Monomers Market Report:

In South America, the Acrylate Monomers market is valued at $0.47 billion in 2023 and is projected to reach $0.79 billion by 2033, with a CAGR of about 5.26%. This growth is driven by the rising automotive and construction industries in countries like Brazil and Argentina, fostering demand for adhesive and coating applications.Middle East & Africa Acrylate Monomers Market Report:

This region is projected to grow from a market size of $0.78 billion in 2023 to $1.32 billion in 2033, with a CAGR of 5.37%. The growth is fueled by increasing infrastructural investments and urbanization in key markets like the UAE and South Africa.Tell us your focus area and get a customized research report.

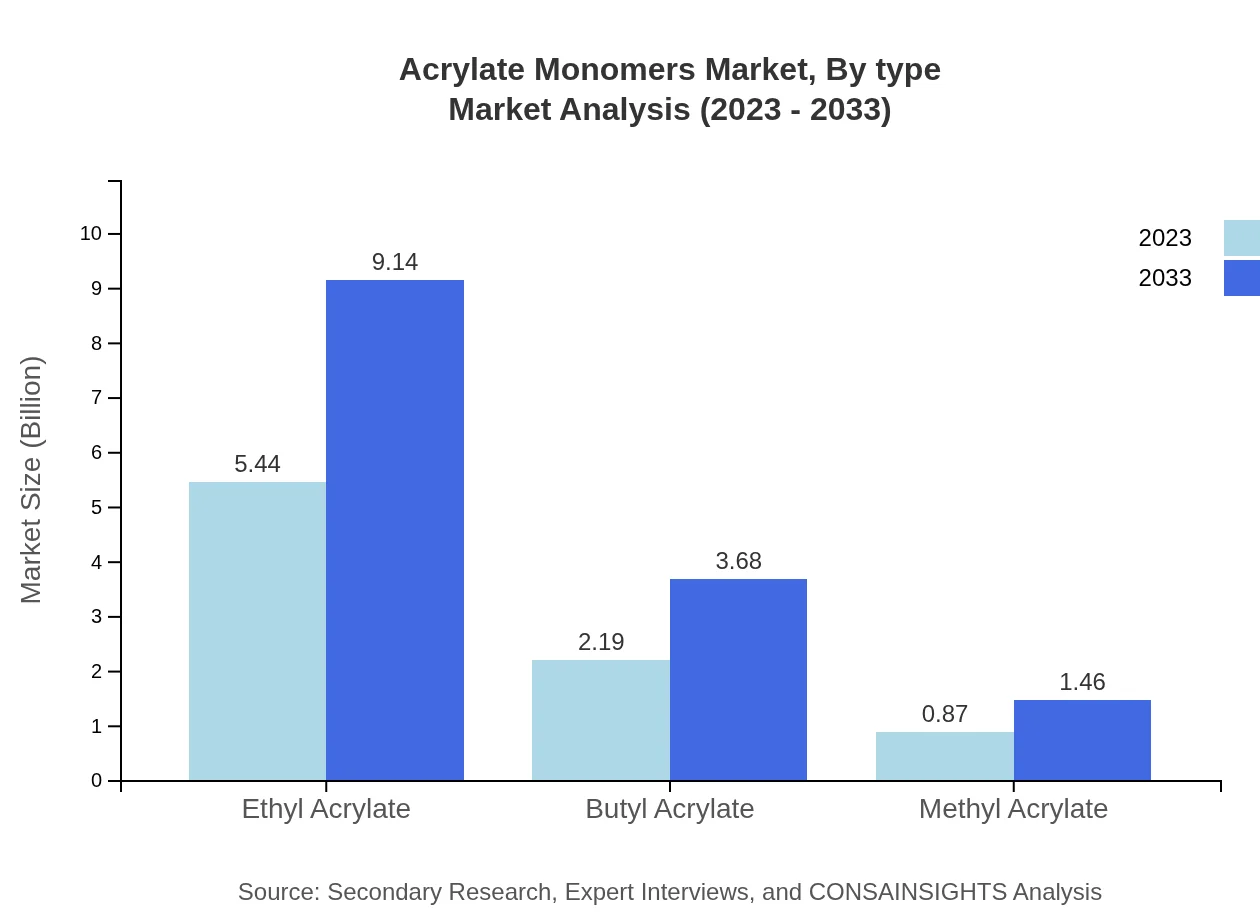

Acrylate Monomers Market Analysis By Type

Ethyl acrylate dominates the market, with a size of $5.44 billion in 2023, projected to rise to $9.14 billion by 2033, maintaining a significant market share of 64.03%. Butyl acrylate follows with a market size of $2.19 billion, expected to reach $3.68 billion by 2033, constituting 25.77% of the market. Methyl acrylate, while smaller, contributes with $0.87 billion in 2023 and is likely to grow to $1.46 billion, representing 10.20% of the share.

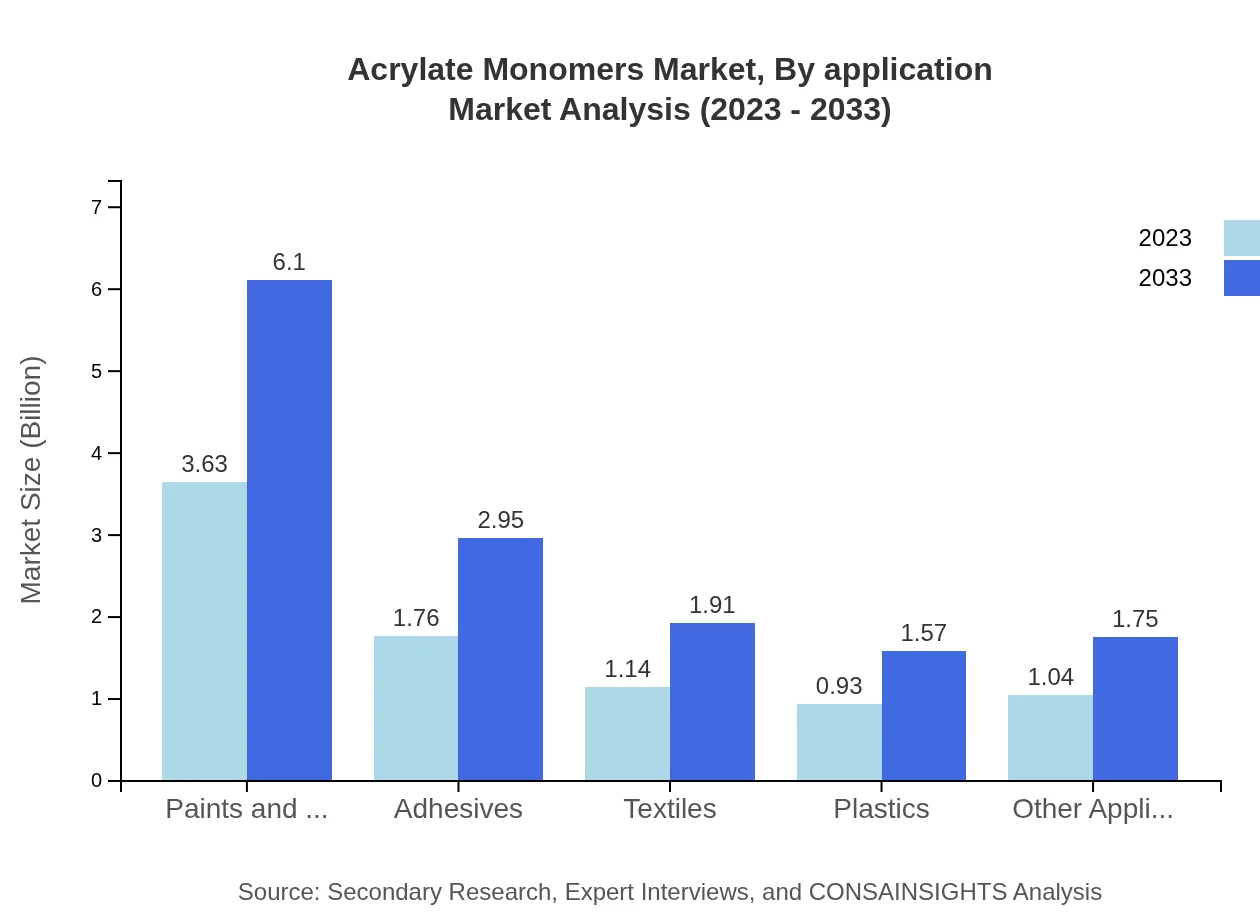

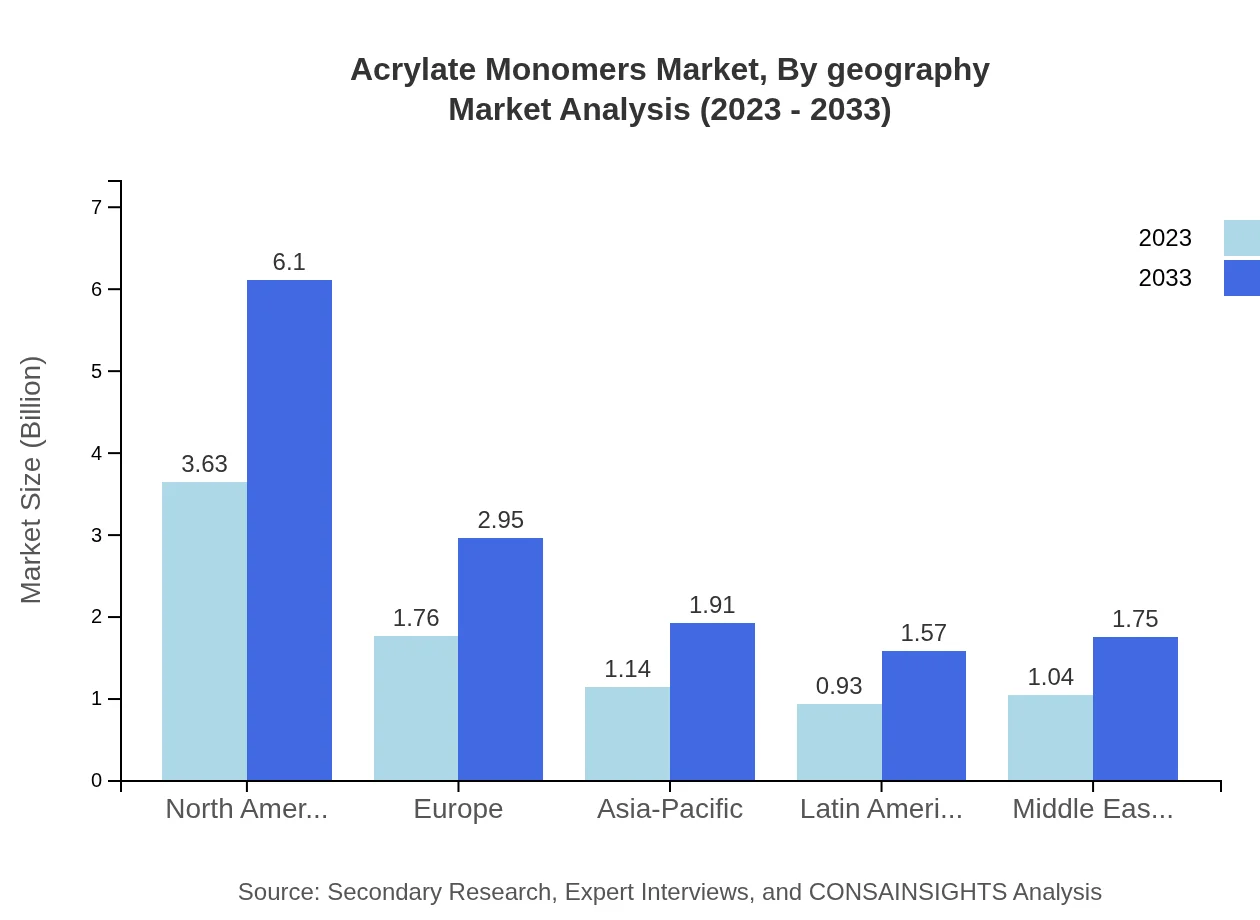

Acrylate Monomers Market Analysis By Application

The paints and coatings application leads the market with a size of $3.63 billion in 2023, anticipated to reach $6.10 billion by 2033 (42.73% market share). Adhesives, valued at $1.76 billion, will grow to $2.95 billion, capturing a 20.7% market share. The textiles application currently represents a share of 13.37% with an increase from $1.14 billion to $1.91 billion in the same timeframe.

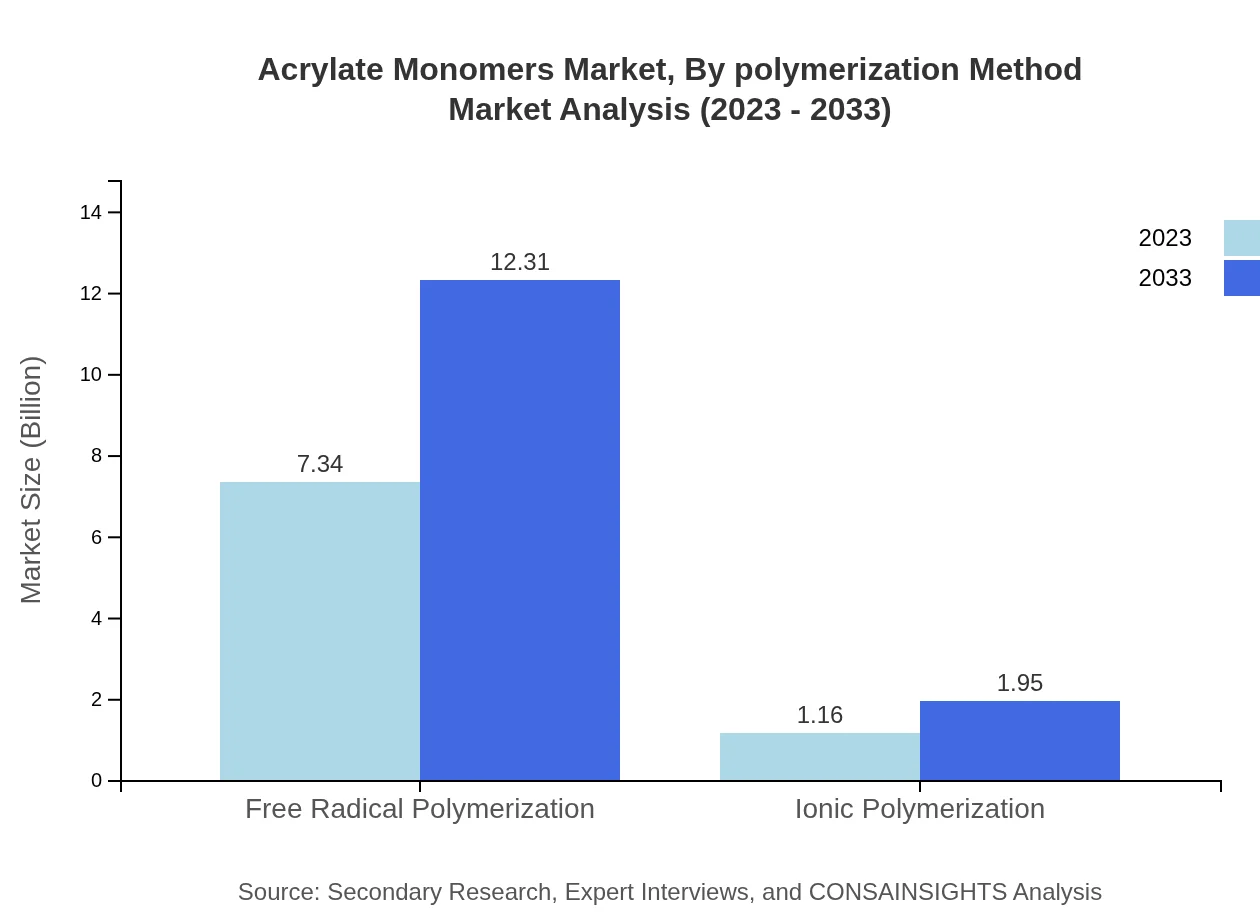

Acrylate Monomers Market Analysis By Polymerization Method

Free radical polymerization dominates the acrylate monomers market with a size of $7.34 billion in 2023, expected to expand to $12.31 billion by 2033, retaining an 86.30% share. Ionic polymerization, while smaller at $1.16 billion initially, is projected to grow to $1.95 billion, capturing a 13.70% market share.

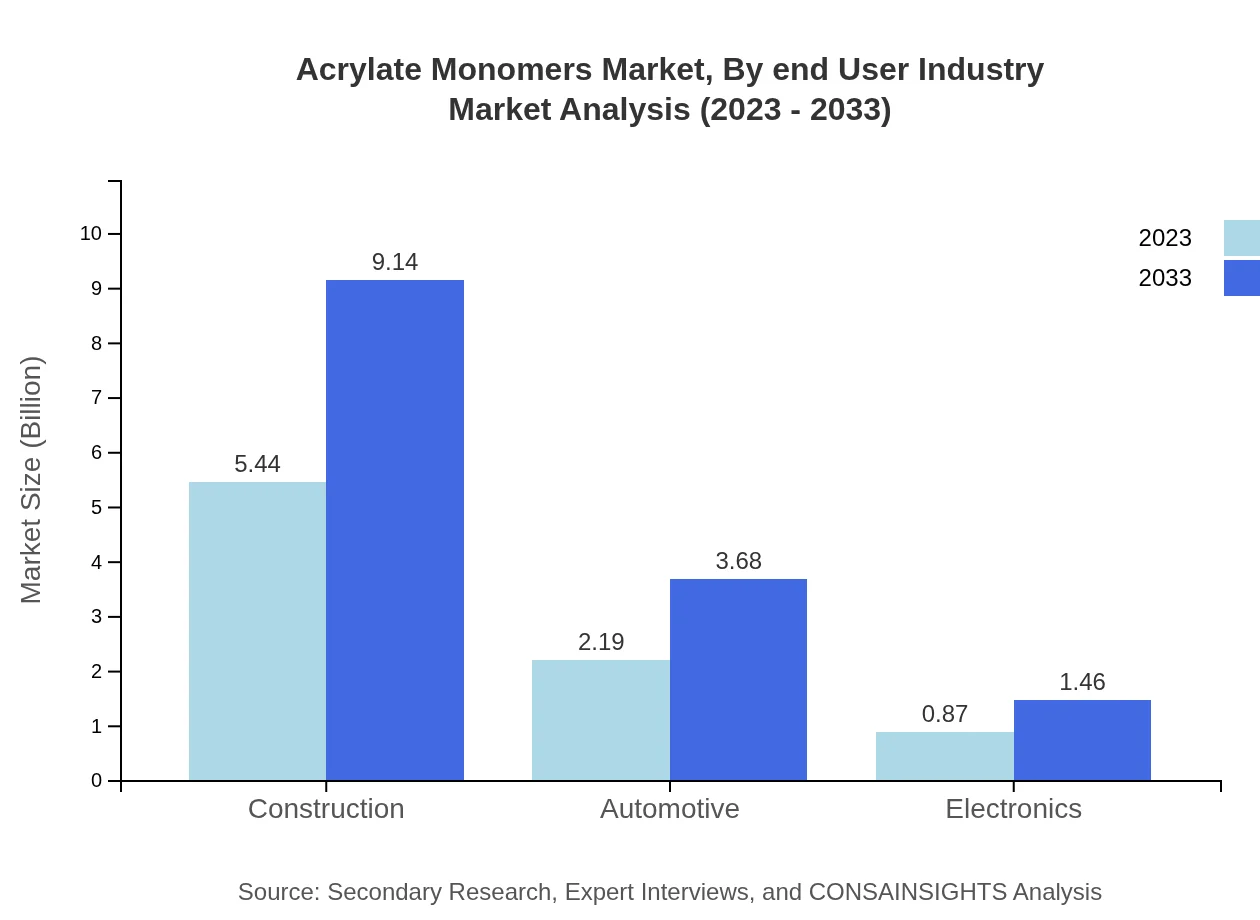

Acrylate Monomers Market Analysis By End User Industry

The construction industry is the largest consumer of acrylate monomers, consuming $5.44 billion in 2023 and expected to grow to $9.14 billion by 2033, maintaining a 64.03% market share. Following this, the automotive sector, with an estimated size of $2.19 billion, is projected to reach $3.68 billion, signifying 25.77% share by 2033.

Acrylate Monomers Market Analysis By Geography

Geographically, North America and Europe represent considerable portions of the market, collectively accounting for significant shares due to advanced technological infrastructure and strong regulations on product standards. In Asia Pacific, rapid industrialization coupled with burgeoning demand in key sectors indicates a strong growth trajectory in the coming years.

Acrylate Monomers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylate Monomers Industry

BASF SE:

A top chemical company that operates in the acrylates segment, renowned for its research and development capabilities, producing a wide range of high-performance acrylate products.Mitsubishi Chemical Corporation:

This key player offers various grades of acrylate monomers and is focused on innovation and sustainability in producing acrylic products and solutions.Dow Chemical Company:

Known for its extensive portfolio of acrylate products, Dow Chemical emphasizes eco-friendly processes and cutting-edge technology in its manufacturing operations.SABIC:

This global leader in diversified chemicals leverages its extensive knowledge to develop high-performance acrylate solutions, catering to various industries.Hexion Inc.:

Specializes in resins and specialized chemicals, Hexion's acrylate monomers are integral in producing high-quality coatings and adhesives.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylate Monomers?

The acrylate monomers market is valued at approximately $8.5 billion in 2023, with a projected CAGR of 5.2%, reaching about $14 billion by 2033. This growth reflects the increasing demand across various industries.

What are the key market players or companies in this acrylate Monomers industry?

Key market players include companies like BASF SE, Evonik Industries AG, and Dow Chemical Company. These firms dominate due to their extensive product portfolios, strong distribution networks, and a focus on innovation in acrylate applications.

What are the primary factors driving the growth in the acrylate Monomers industry?

The growth in the acrylate monomers industry is driven by the rising demand in paints and coatings, adhesives, and construction sectors. Additionally, advancements in polymer technology and increasing use in automotive applications also contribute to market expansion.

Which region is the fastest Growing in the acrylate Monomers?

North America is currently the fastest-growing region for acrylate monomers, projected to grow from $3.24 billion in 2023 to $5.44 billion by 2033, due to high industrial activity and innovation in product formulations.

Does ConsInsights provide customized market report data for the acrylate Monomers industry?

Yes, ConsInsights offers customized market report data tailored to specific needs, providing in-depth insights into regional trends, competitive analysis, and market forecasts for the acrylate-monomers industry.

What deliverables can I expect from this acrylate Monomers market research project?

Deliverables include comprehensive market analysis reports, competitive landscape overviews, forecasts by region and segment, and actionable insights into market trends, which aid strategic decision-making.

What are the market trends of acrylate Monomers?

Current trends include an increasing shift towards eco-friendly and sustainable acrylate formulations, innovation in polymerization techniques, and expanding applications in high-growth sectors like electronics and automotive.