Acrylic Adhesives Market Report

Published Date: 02 February 2026 | Report Code: acrylic-adhesives

Acrylic Adhesives Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the acrylic adhesives market, exploring its growth potential, key trends, and competitive landscape. It includes market forecasts from 2023 to 2033, highlighting insights into market size, regional dynamics, and technological advancements.

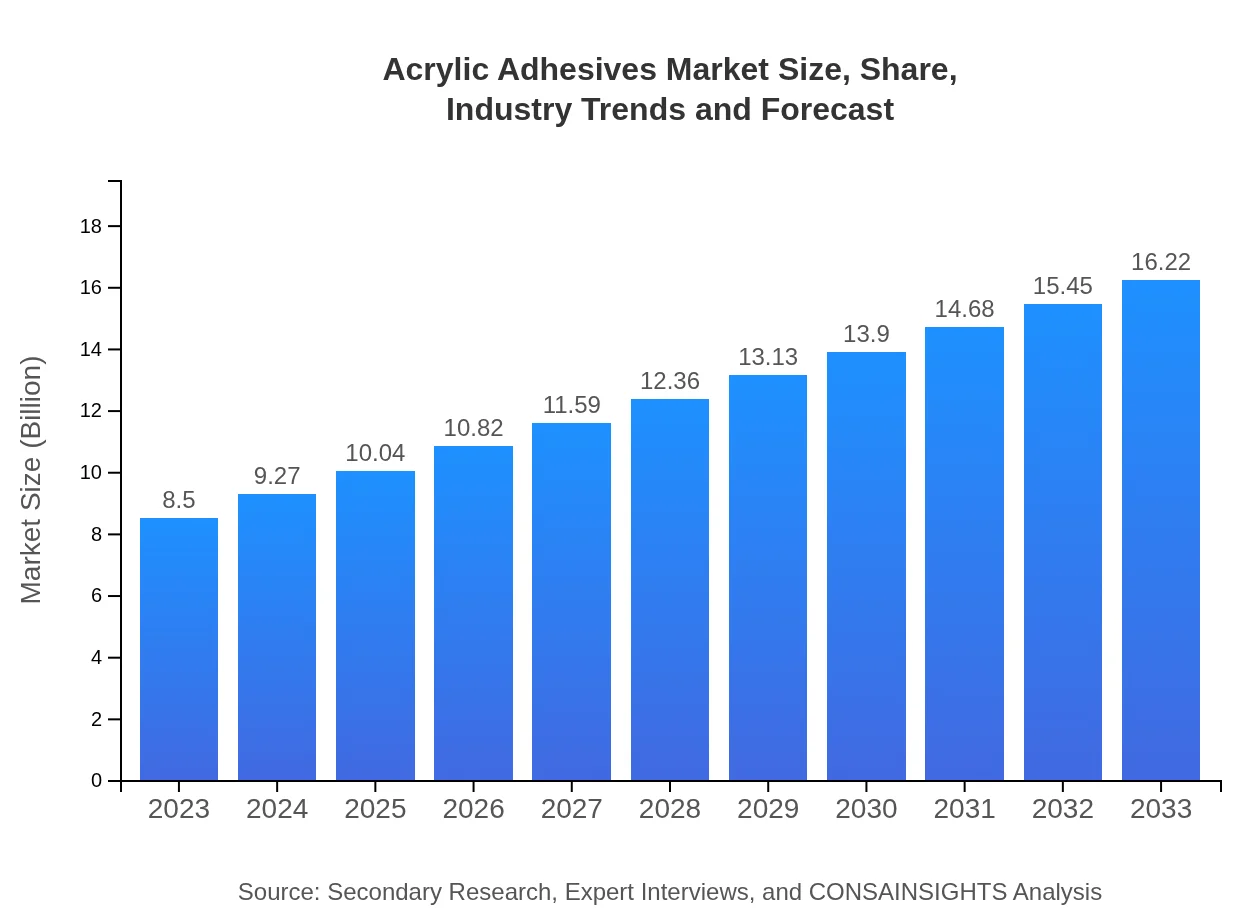

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $8.50 Billion |

| CAGR (2023-2033) | 6.5% |

| 2033 Market Size | $16.22 Billion |

| Top Companies | Henkel AG & Co. KGaA, 3M Company, BASF SE, Sika AG |

| Last Modified Date | 02 February 2026 |

Acrylic Adhesives Market Overview

Customize Acrylic Adhesives Market Report market research report

- ✔ Get in-depth analysis of Acrylic Adhesives market size, growth, and forecasts.

- ✔ Understand Acrylic Adhesives's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylic Adhesives

What is the Market Size & CAGR of Acrylic Adhesives market in 2023?

Acrylic Adhesives Industry Analysis

Acrylic Adhesives Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylic Adhesives Market Analysis Report by Region

Europe Acrylic Adhesives Market Report:

In Europe, the acrylic adhesives market size in 2023 is $2.79 billion, anticipated to grow to $5.33 billion by 2033. The region's strict regulations concerning the use of solvents are boosting the demand for environmental-friendly options, thereby driving innovations in adhesive formulations.Asia Pacific Acrylic Adhesives Market Report:

The Asia Pacific region holds a significant share of the acrylic adhesives market, with a market size of $1.48 billion in 2023, expected to grow to $2.83 billion by 2033. The growth is attributed to rapid industrialization and booming construction projects across countries like China and India, alongside a growing automotive industry.North America Acrylic Adhesives Market Report:

North America accounts for a substantial market share, with an estimated size of $3.00 billion in 2023, projected to reach $5.73 billion by 2033. The growth is driven by robust construction activities, particularly in the US and Canada, and significant advancements in automotive manufacturing technologies.South America Acrylic Adhesives Market Report:

South America is poised for gradual growth, starting with a market size of $0.30 billion in 2023 and expected to reach $0.58 billion by 2033. Increased infrastructure development and rising disposable incomes are contributing to the demand for acrylic adhesives in various applications.Middle East & Africa Acrylic Adhesives Market Report:

The Middle East and Africa market reflects growth potential, starting from $0.92 billion in 2023 and expected to reach $1.75 billion by 2033. The increases are primarily associated with infrastructural developments and the growing manufacturing sector.Tell us your focus area and get a customized research report.

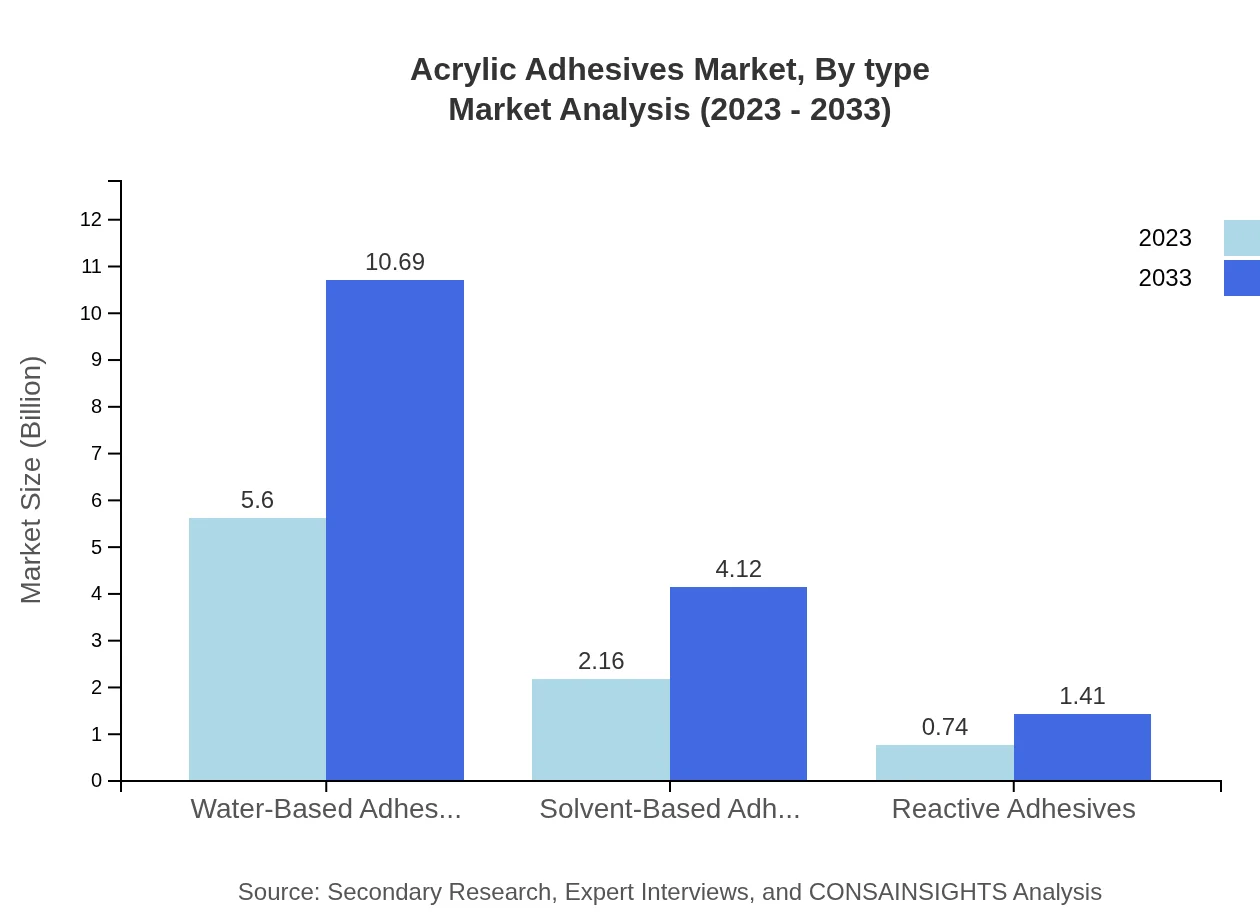

Acrylic Adhesives Market Analysis By Type

The major types of acrylic adhesives include Water-Based, Solvent-Based, and Reactive Adhesives. Water-Based Adhesives dominate the market with a size of $5.60 billion in 2023, expected to grow to $10.69 billion by 2033, maintaining a market share of 65.91%. Solvent-Based Adhesives follow with a 2023 market size of $2.16 billion, expected to double to $4.12 billion by 2033, holding a 25.4% share. Reactive Adhesives contribute a smaller share with $0.74 billion in 2023, anticipating a rise to $1.41 billion by 2033, maintaining an 8.69% market share.

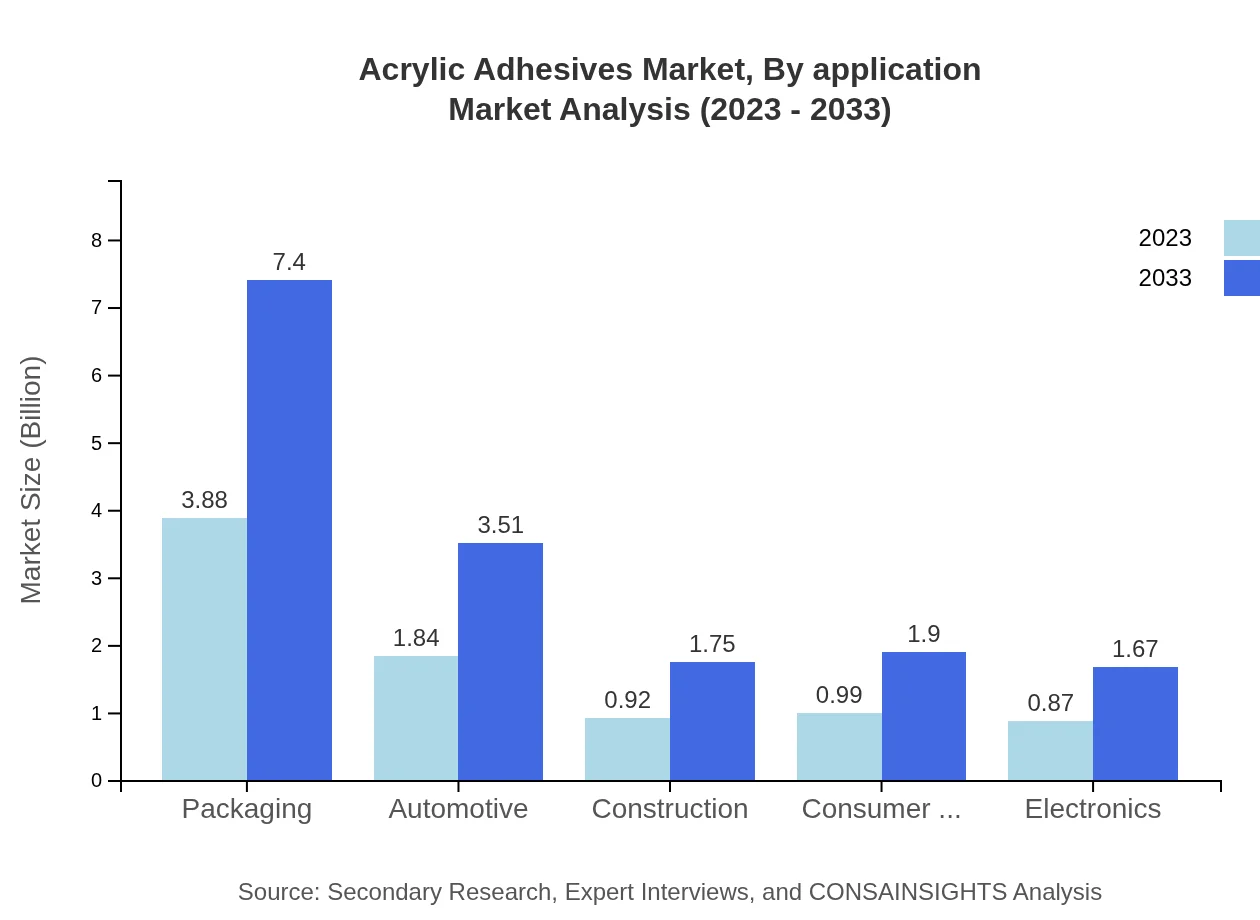

Acrylic Adhesives Market Analysis By Application

Key applications of acrylic adhesives span Packaging, Automotive, Construction, Electronics, and Healthcare. Packaging accounts for $3.88 billion in 2023, projected to reach $7.40 billion by 2033, with a substantial market share of 45.64%. The Automotive sector has a current size of $1.84 billion, expected to increase to $3.51 billion by 2033, accounting for 21.61% of the market.

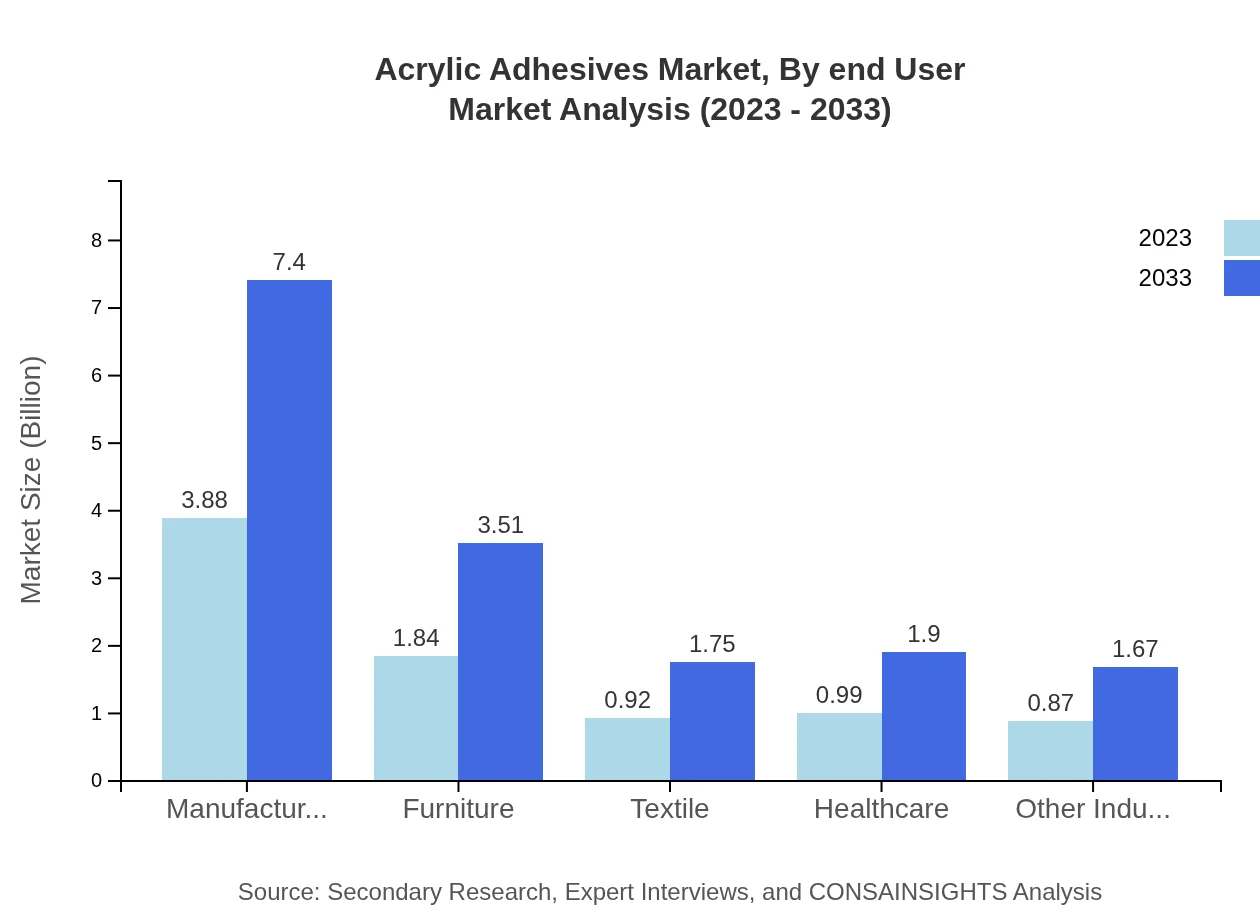

Acrylic Adhesives Market Analysis By End User

The end-user industries include Manufacturing, Furniture, Textile, and Consumer Goods. Manufacturing leads with $3.88 billion in 2023, projected at $7.40 billion by 2033 (45.64% share). Furniture follows with $1.84 billion in 2023 and is expected to reach $3.51 billion by 2033, holding a significant share of 21.61%.

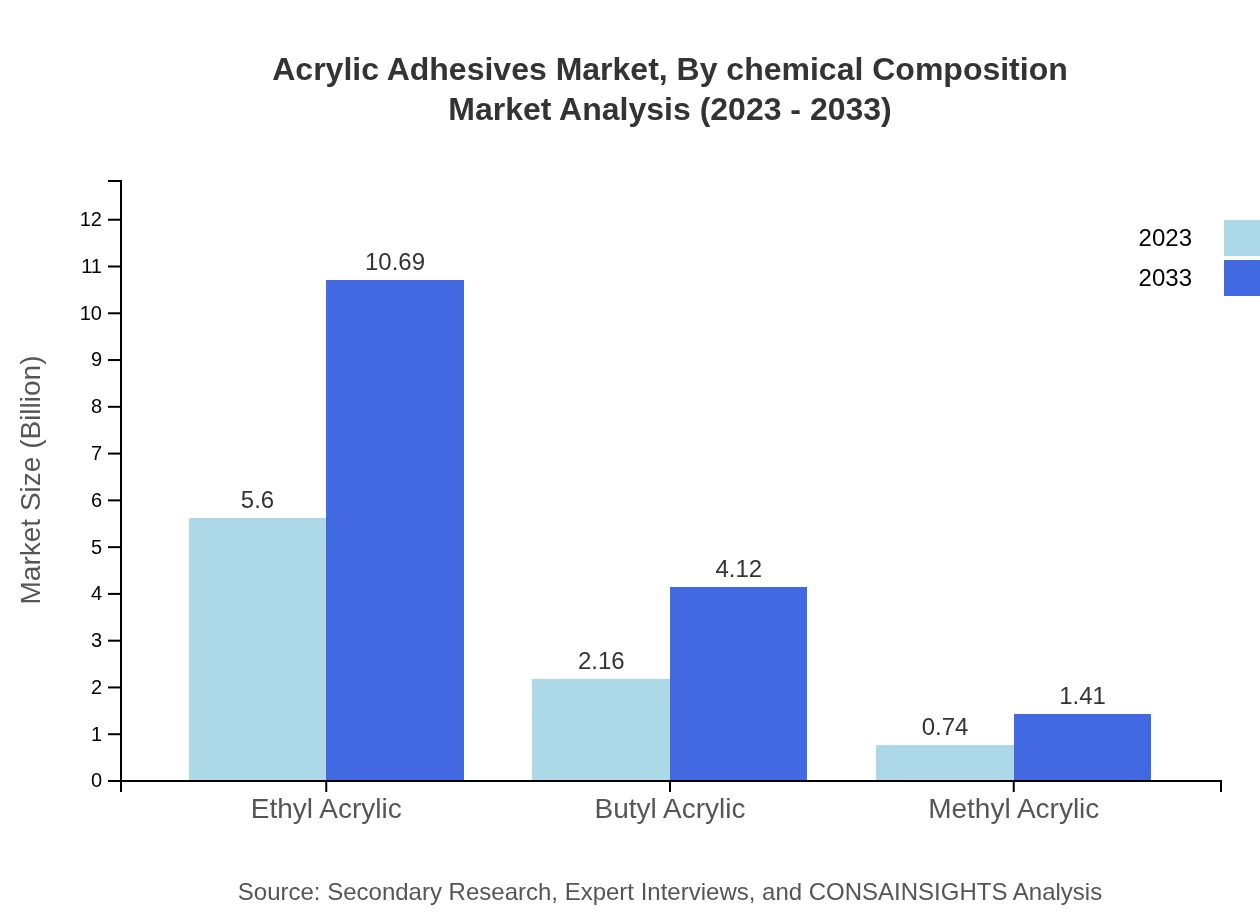

Acrylic Adhesives Market Analysis By Chemical Composition

The market is characterized by different chemical compositions such as Ethyl Acrylic, Butyl Acrylic, and Methyl Acrylic. Ethyl Acrylic dominates with $5.60 billion in 2023 and expected to grow to $10.69 billion by 2033. Butyl Acrylic presents a market size of $2.16 billion in 2023, forecasted at $4.12 billion by 2033, while Methyl Acrylic generates $0.74 billion and is expected to reach $1.41 billion by 2033.

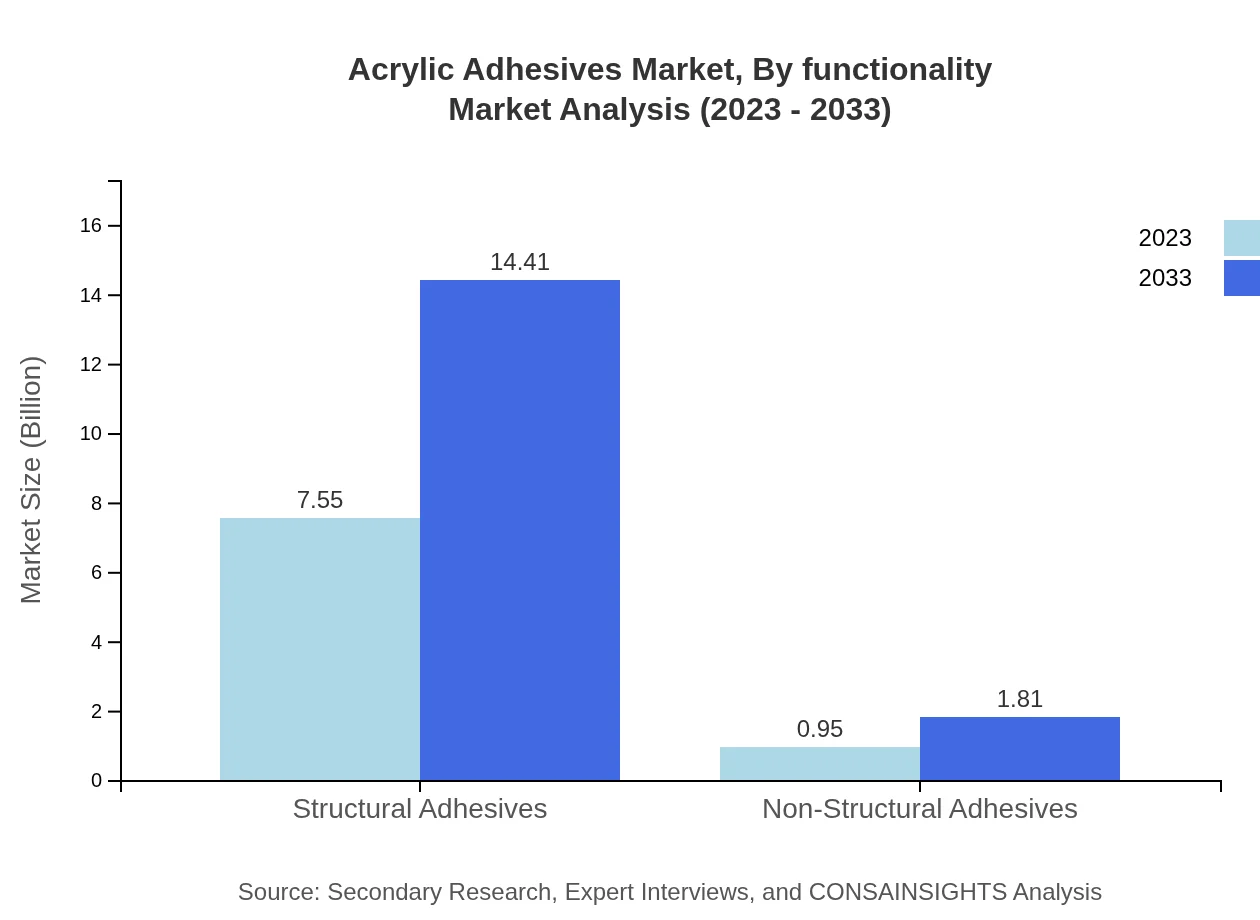

Acrylic Adhesives Market Analysis By Functionality

The functionality classification includes Structural and Non-Structural Adhesives. Structural Adhesives constitute the largest segment, with a market size of $7.55 billion in 2023, increasing to $14.41 billion by 2033. Non-Structural Adhesives yield a smaller market size of $0.95 billion in 2023, expected at $1.81 billion in 2033.

Acrylic Adhesives Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylic Adhesives Industry

Henkel AG & Co. KGaA:

A global leader in adhesive technologies, Henkel produces a wide range of acrylic adhesives for various applications, known for their quality and sustainability.3M Company:

Renowned for innovation, 3M offers an extensive portfolio of acrylic adhesive products, catering to industries like automotive, construction, and healthcare.BASF SE:

BASF is one of the largest chemical producers globally, providing cutting-edge acrylic adhesive solutions with a strong commitment to sustainability and environmental compliance.Sika AG:

Sika specializes in construction and building materials, offering high-performance acrylic adhesives suitable for demanding applications in construction and industry.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylic Adhesives?

The global acrylic adhesives market is expected to reach USD 8.5 billion by 2033, fueled by a compound annual growth rate (CAGR) of 6.5% from 2023 to 2033. Market advancements are driven by increasing applications in multiple industries.

What are the key market players or companies in the acrylic Adhesives industry?

Key players in the acrylic adhesives market include Henkel AG, 3M Company, Dow Inc., BASF SE, and Sika AG. These companies are pivotal in innovation and production, helping to drive market growth within the sector.

What are the primary factors driving the growth in the acrylic Adhesives industry?

The growth of the acrylic adhesives market is driven by rising demand in automotive and construction industries, technological advancements, increasing applications in packaging, and a shift towards eco-friendly adhesives enhancing overall market expansion.

Which region is the fastest Growing in the acrylic Adhesives market?

The fastest-growing region in the acrylic adhesives market is projected to be Europe, with revenues increasing from USD 2.79 billion in 2023 to USD 5.33 billion by 2033, reflecting robust industrial activity and increased demand for adhesive solutions.

Does ConsaInsights provide customized market report data for the acrylic Adhesives industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the acrylic adhesives industry, covering comprehensive market trends, forecasts, and competitive analysis for insightful decision-making.

What deliverables can I expect from this acrylic Adhesives market research project?

Deliverables from the acrylic adhesives market research project will include market size analysis, growth forecasts, competitive landscape reviews, regional segmentation data, and insights into key trends and consumer demand influencing the market.

What are the market trends of acrylic Adhesives?

Current market trends include a growing preference for water-based adhesives, increasing applications in the healthcare sector, a shift towards sustainable options, and advances in technology driving efficiency in production and usage across various industries.