Acrylic Elastomers Market Report

Published Date: 02 February 2026 | Report Code: acrylic-elastomers

Acrylic Elastomers Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Acrylic Elastomers market, including current trends, forecasts for 2023-2033, market segmentation, and insights across regions. Detailed assessments of technologies and product performances are also covered.

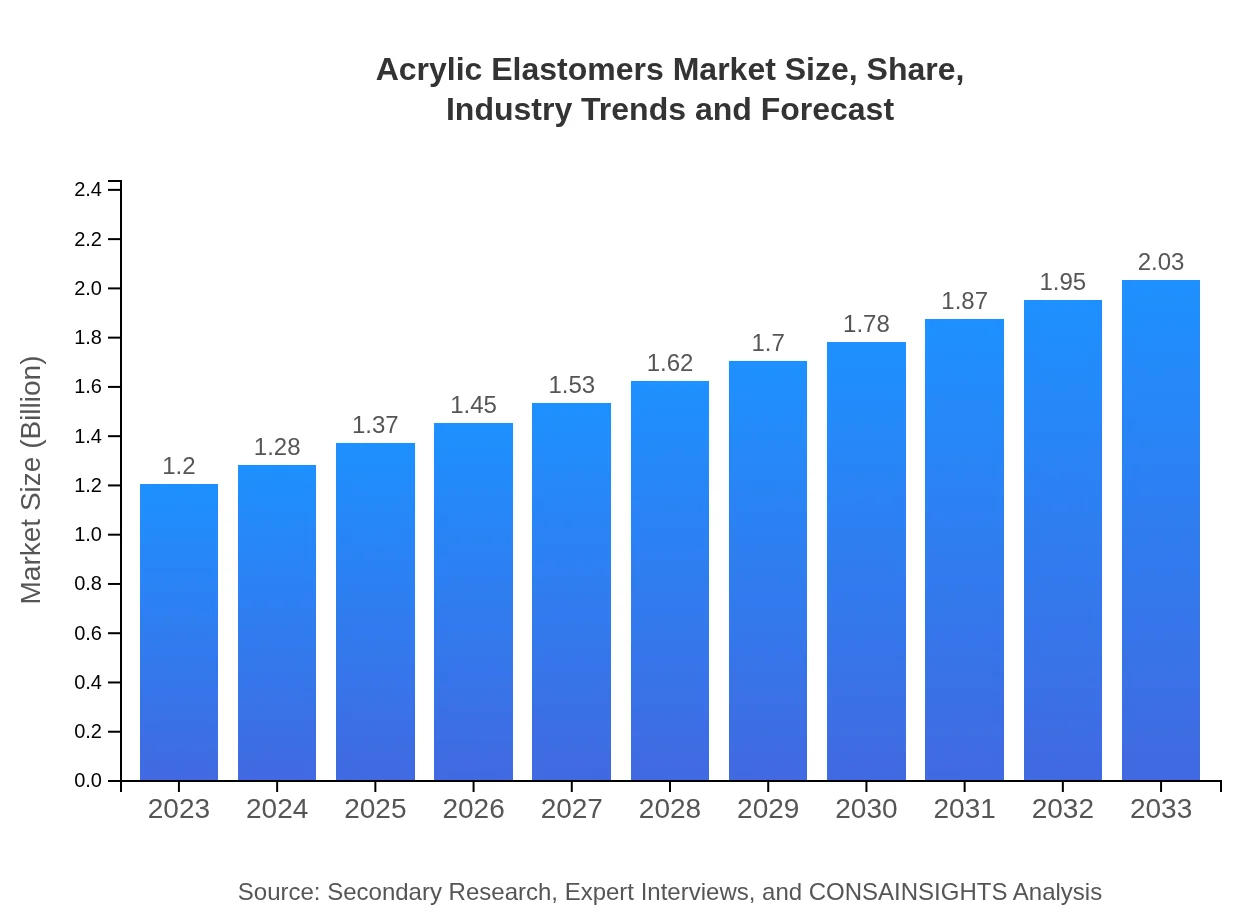

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 5.3% |

| 2033 Market Size | $2.03 Billion |

| Top Companies | BASF SE, DOW Chemical Company, Kraton Corporation, Mitsui Chemicals, Inc. |

| Last Modified Date | 02 February 2026 |

Acrylic Elastomers Market Overview

Customize Acrylic Elastomers Market Report market research report

- ✔ Get in-depth analysis of Acrylic Elastomers market size, growth, and forecasts.

- ✔ Understand Acrylic Elastomers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylic Elastomers

What is the Market Size & CAGR of Acrylic Elastomers market in 2023?

Acrylic Elastomers Industry Analysis

Acrylic Elastomers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylic Elastomers Market Analysis Report by Region

Europe Acrylic Elastomers Market Report:

Europe's acrylic elastomers market is set to increase from $0.32 billion in 2023 to $0.54 billion in 2033, with stringent regulations on material performance spurring growth. The automotive sector in Germany, coupled with green construction practices across the EU, drives demand for acrylic elastomers.Asia Pacific Acrylic Elastomers Market Report:

The Asia-Pacific region is a major player in the acrylic elastomers market, expected to grow from $0.23 billion in 2023 to $0.40 billion by 2033. Rapid industrialization, particularly in countries like China and India, and increasing investments in infrastructure development drive substantial demand for high-performance materials.North America Acrylic Elastomers Market Report:

North America is anticipated to grow significantly, from $0.40 billion in 2023 to $0.67 billion by 2033. The United States leads this growth due to the robust automotive industry and increased consumer demand for innovative materials.South America Acrylic Elastomers Market Report:

In South America, the acrylic elastomers market is projected to expand from $0.10 billion in 2023 to $0.17 billion in 2033. Factors such as urbanization and a growing construction sector contribute to this growth, albeit at a slower pace compared to leading regions.Middle East & Africa Acrylic Elastomers Market Report:

The Middle East and Africa region will grow from $0.15 billion in 2023 to $0.26 billion by 2033, influenced by increasing construction and automotive activities. Countries engaging in large infrastructure projects showcase heightened demand for durable elastomer materials.Tell us your focus area and get a customized research report.

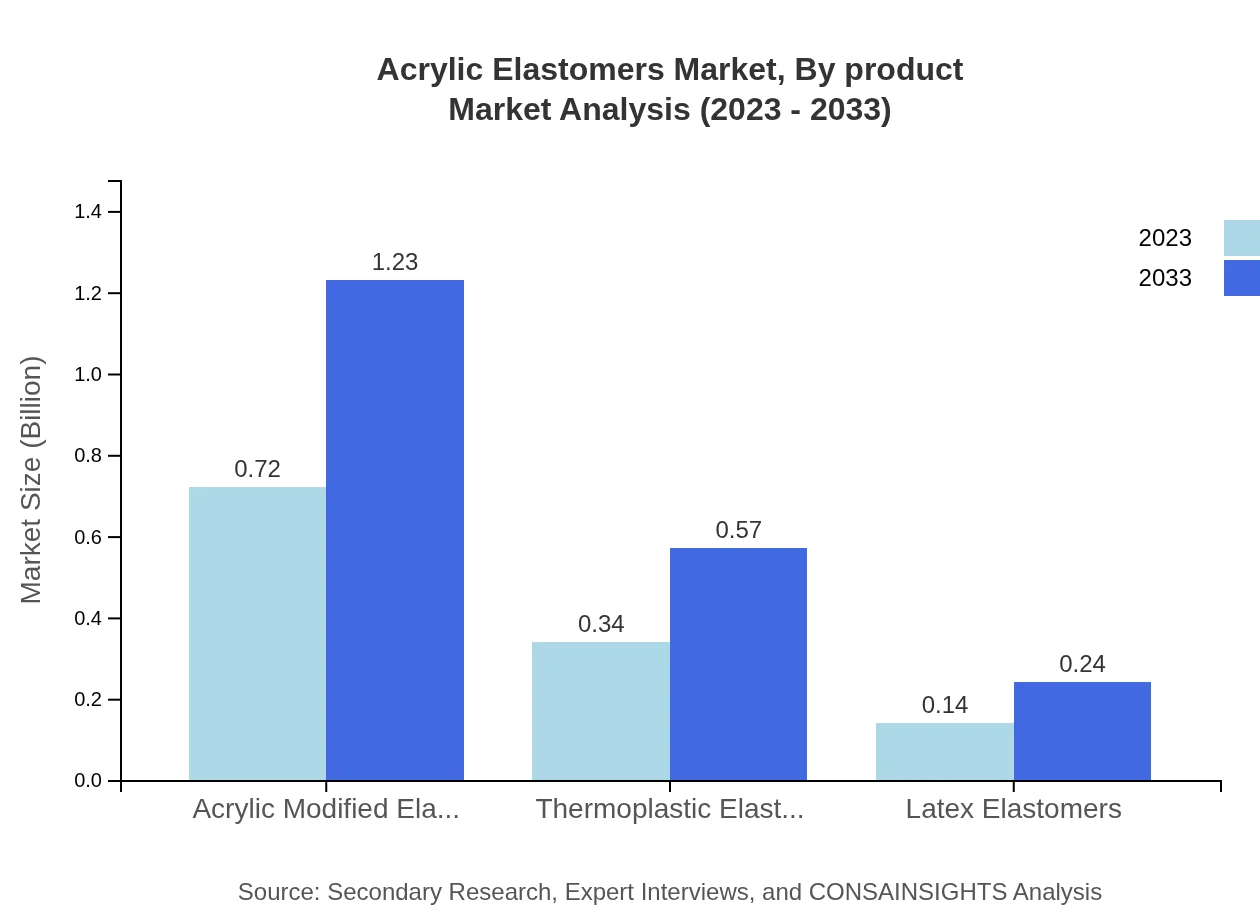

Acrylic Elastomers Market Analysis By Product

Acrylic Modified Elastomers lead the market, valued at $0.72 billion in 2023 and projected to reach $1.23 billion by 2033, showcasing their dominance with a market share of 60.24%. Thermoplastic and Latex Elastomers follow with shares of 28.17% and 11.59%, respectively.

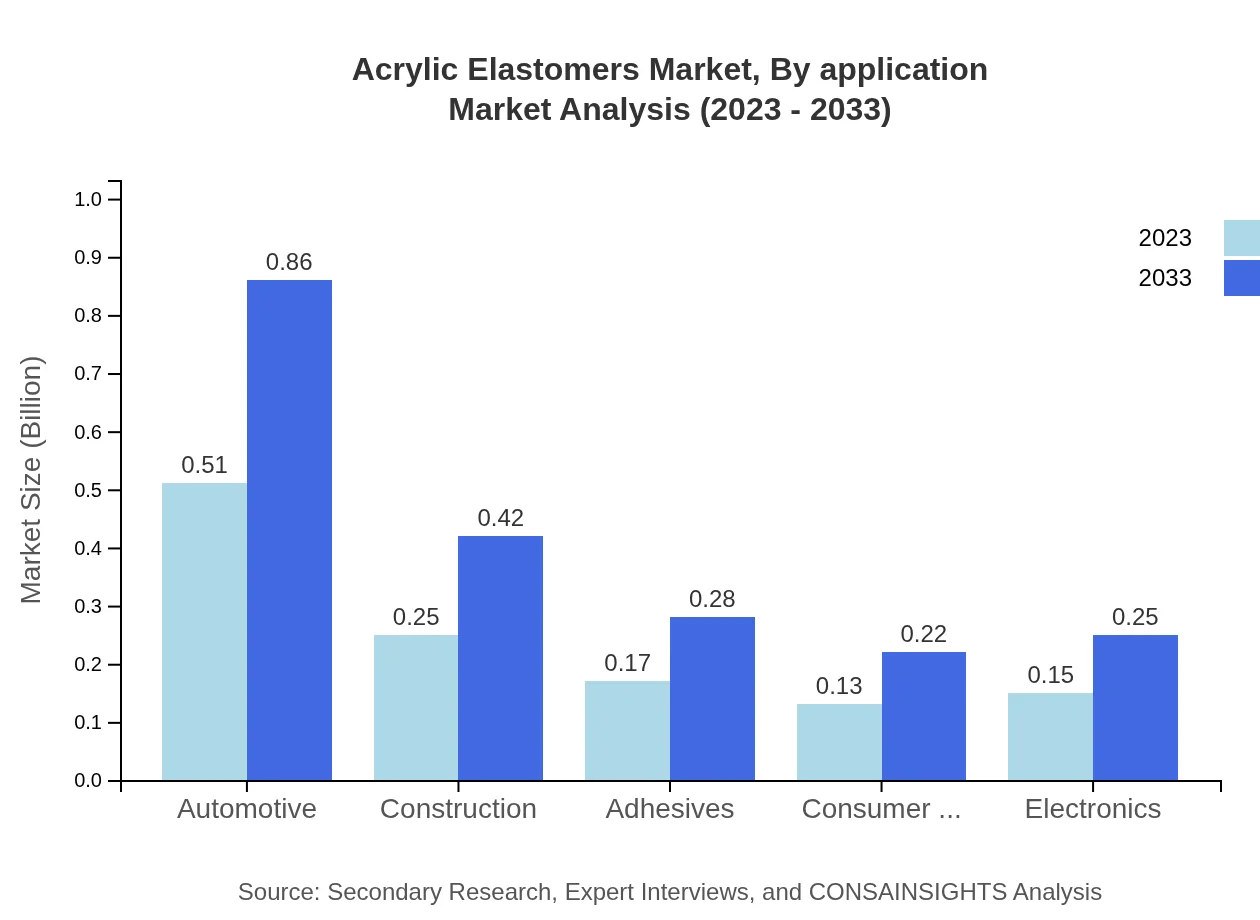

Acrylic Elastomers Market Analysis By Application

The automotive industry dominates acrylic elastomers applications, with a market size of $0.61 billion in 2023 projected to grow to $1.03 billion by 2033. Construction applications also show strong growth potential, influenced by increasing residential and commercial projects.

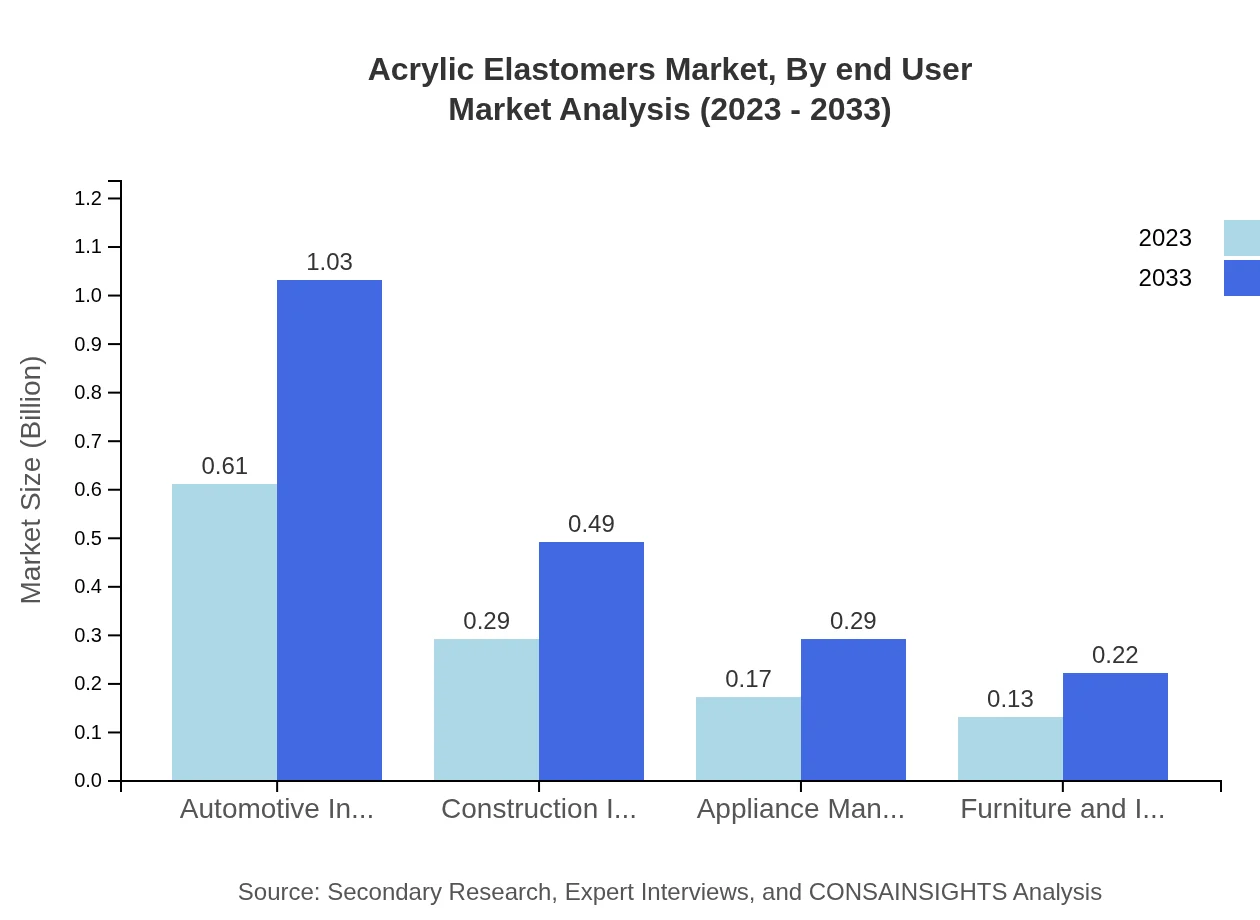

Acrylic Elastomers Market Analysis By End User

The major end-user for acrylic elastomers remains the automotive sector, contributing significantly to revenue growth. Following this, the construction and appliance sectors are expected to reflect remarkable growth in the coming years.

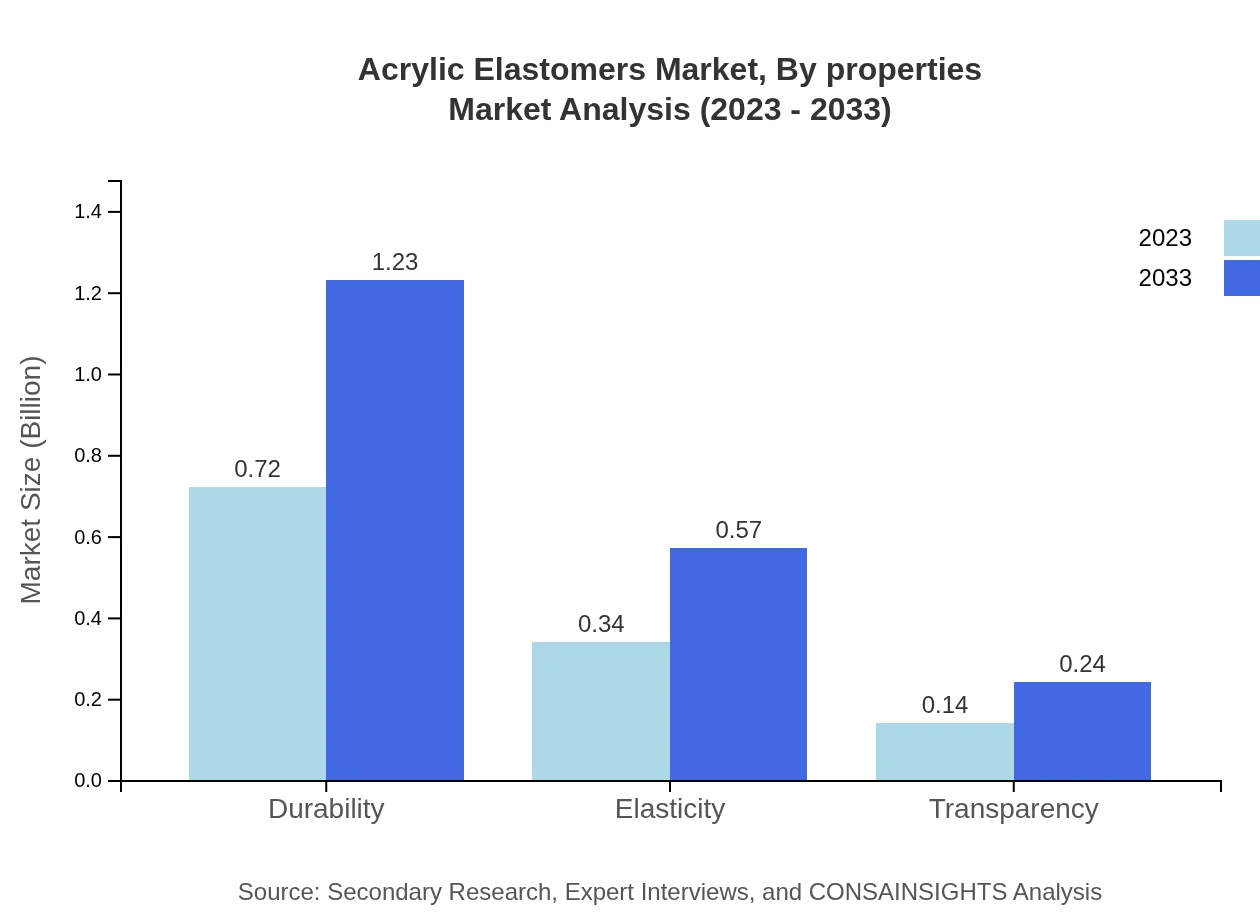

Acrylic Elastomers Market Analysis By Properties

Durability and elasticity are the primary properties driving the demand for acrylic elastomers, accounting for a significant market share. Innovations in transparent and weather-resistant formulations are increasingly attracting consumer interest.

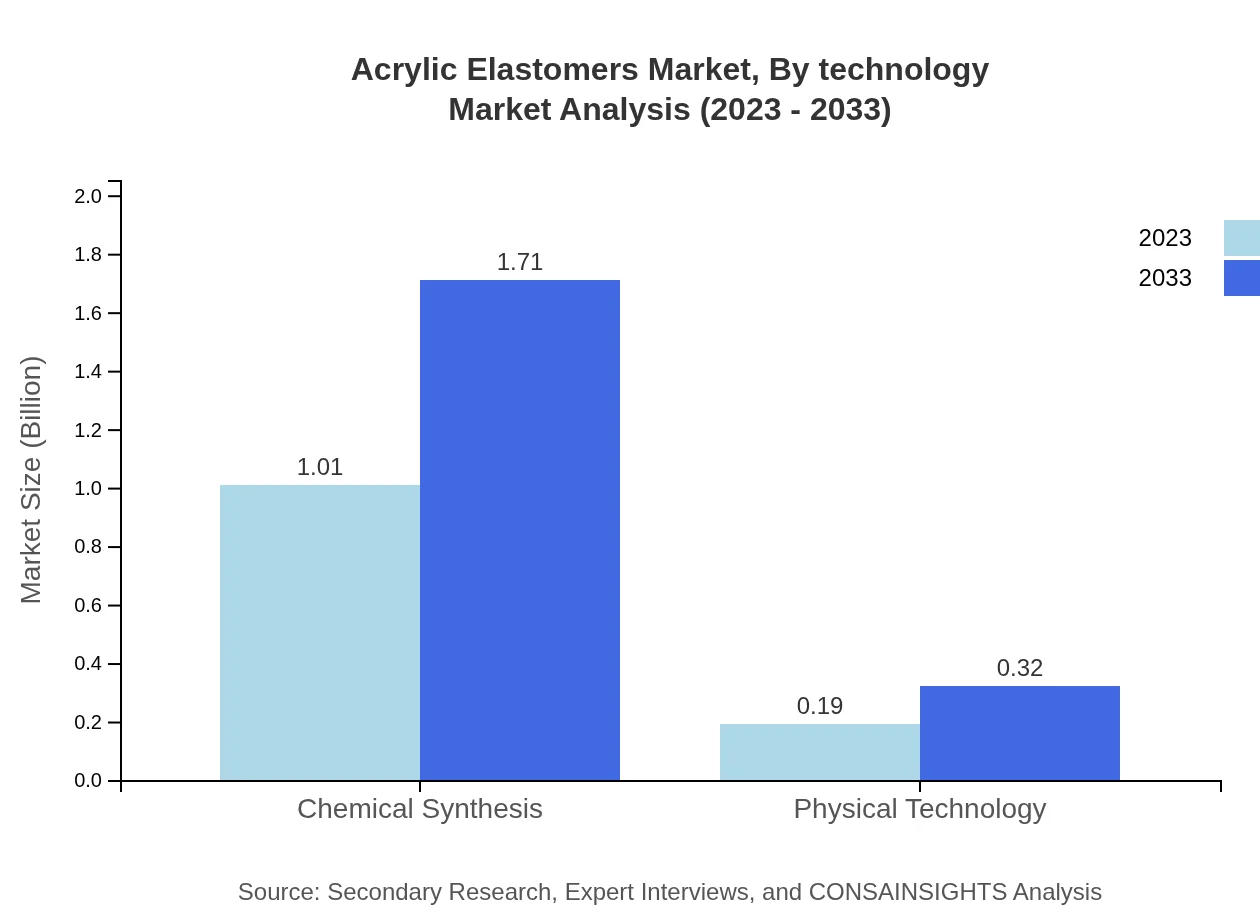

Acrylic Elastomers Market Analysis By Technology

Advanced chemical synthesis technologies are pivotal in determining the market landscape, driving efficiency and reducing production costs. Adoption of eco-friendly methods and continuous improvement in production techniques also define the industry's trajectory.

Acrylic Elastomers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylic Elastomers Industry

BASF SE:

BASF leads the global acrylic elastomers market, offering a wide range of products and innovative solutions, particularly in adhesives and coatings.DOW Chemical Company:

DOW specializes in elastomer technologies and provides high-performance acrylic elastomers critical for automotive and industrial applications.Kraton Corporation:

Kraton focuses on advanced polymer products, particularly in thermoplastic elastomers, contributing significantly to the sustainable materials market.Mitsui Chemicals, Inc.:

Mitsui Chemicals provides high-performance materials and has developed a strong position in the acrylic elastomers sector through innovation.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylic Elastomers?

The global acrylic elastomers market is projected to reach approximately $1.2 billion by 2033, growing at a CAGR of 5.3% from 2023. This growth is driven by increasing demand across various industries, particularly in automotive and construction.

What are the key market players or companies in the acrylic Elastomers industry?

Key players in the acrylic elastomers industry include major manufacturers and suppliers who dominate the market through innovative products and strong distribution networks. These companies continuously focus on R&D to enhance product performance and meet varied industrial requirements.

What are the primary factors driving the growth in the acrylic Elastomers industry?

Drivers of growth in the acrylic elastomers industry include the increasing demand from automotive sectors for durable, elastic materials, rising construction activities necessitating specialized materials, and growing innovation in applications like adhesives and consumer products.

Which region is the fastest Growing in the acrylic Elastomers market?

Asia Pacific is the fastest-growing region in the acrylic elastomers market, with its market size expanding from $0.23 billion in 2023 to $0.40 billion by 2033. This growth is fueled by rapid industrialization and urbanization in the region.

Does ConsaInsights provide customized market report data for the acrylic Elastomers industry?

Yes, ConsaInsights offers customized market report data for the acrylic-elastomers industry. Clients can request tailored insights based on specific segments, geographical focus, or emerging trends to suit their strategic needs.

What deliverables can I expect from this acrylic Elastomers market research project?

Deliverables from the acrylic-elastomers market research project include comprehensive reports featuring market size forecasts, segment analyses, competitive landscape evaluations, and insights into regional trends with detailed data visualizations.

What are the market trends of acrylic Elastomers?

Market trends in acrylic elastomers include a growing emphasis on sustainability, an increase in bio-based elastomers, advancements in manufacturing technologies, and a shift towards high-performance materials in automotive and industrial applications.