Acrylic Resins Market Report

Published Date: 02 February 2026 | Report Code: acrylic-resins

Acrylic Resins Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Acrylic Resins market, detailing market size, growth forecasts, segment analysis, regional insights, industry challenges, and emerging trends from 2023 to 2033.

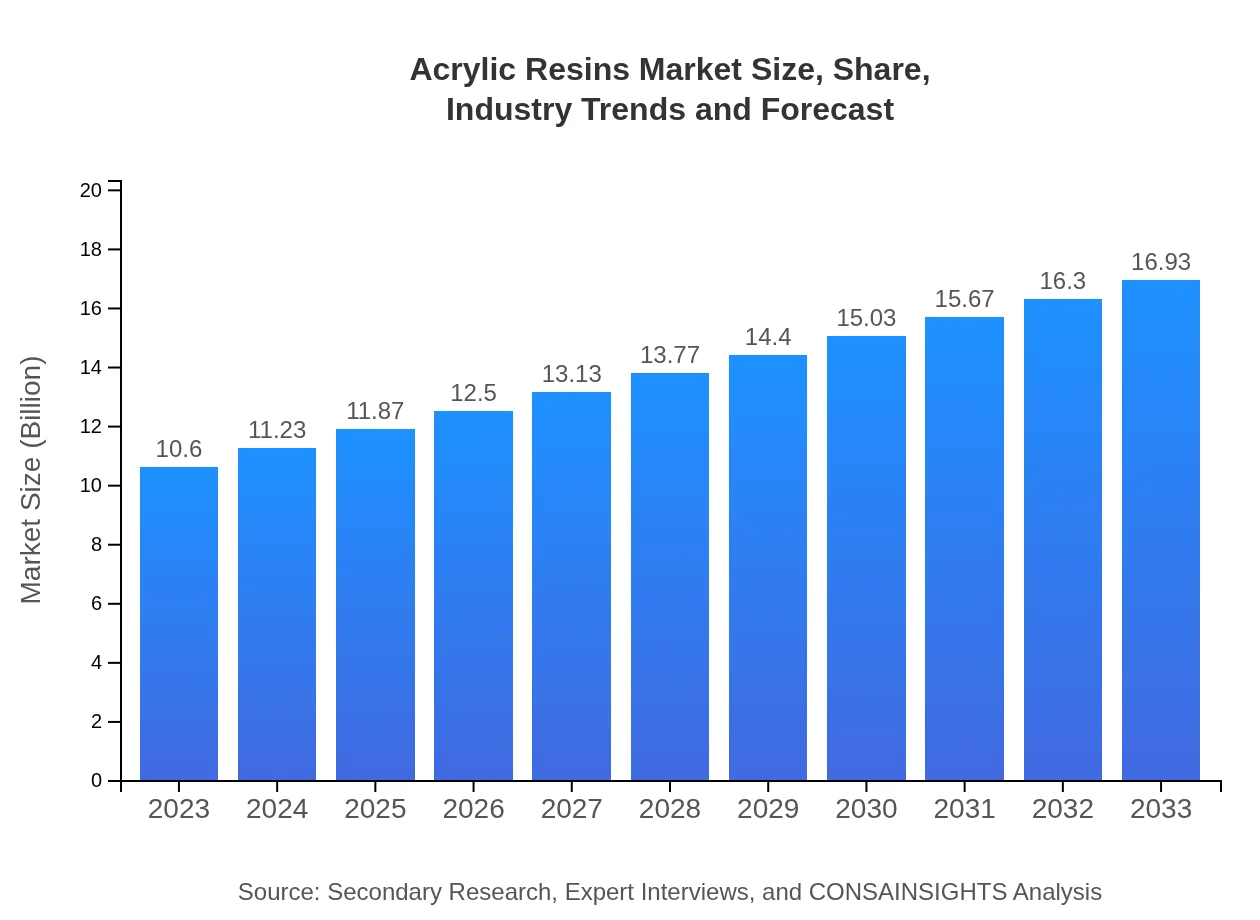

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.60 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $16.93 Billion |

| Top Companies | BASF SE, Dow Chemical Company, Evonik Industries AG, Arkema S.A., Mitsubishi Chemical Corporation |

| Last Modified Date | 02 February 2026 |

Acrylic Resins Market Overview

Customize Acrylic Resins Market Report market research report

- ✔ Get in-depth analysis of Acrylic Resins market size, growth, and forecasts.

- ✔ Understand Acrylic Resins's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylic Resins

What is the Market Size & CAGR of Acrylic Resins market in 2023?

Acrylic Resins Industry Analysis

Acrylic Resins Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylic Resins Market Analysis Report by Region

Europe Acrylic Resins Market Report:

The European region's market is projected to grow from $2.81 billion in 2023 to $4.48 billion by 2033, supported by stringent regulations on the use of volatile organic compounds (VOCs) in coatings and growing emphasis on sustainability in various applications.Asia Pacific Acrylic Resins Market Report:

The Asia Pacific region holds a significant share of the Acrylic Resins market, valued at approximately $2.32 billion in 2023 and projected to reach $3.71 billion by 2033. The region's growth is driven by booming industrial activities, particularly in China and India, where demand for paints and coatings is surging due to rapid urbanization and industrialization.North America Acrylic Resins Market Report:

North America's Acrylic Resins market is estimated at $3.88 billion in 2023, expected to rise to $6.20 billion by 2033. The U.S. and Canada are spearheading this growth due to advancements in manufacturing technologies and increasing government regulations favoring environmentally friendly products.South America Acrylic Resins Market Report:

In South America, the market is projected to grow from $0.76 billion in 2023 to $1.22 billion by 2033. This growth is manifestations of increasing consumer demand for durable and sustainable materials, primarily in Brazil and Argentina, driven by both construction and automotive industries.Middle East & Africa Acrylic Resins Market Report:

In the Middle East and Africa, the market is expected to progress from $0.83 billion in 2023 to $1.33 billion by 2033, with significant contributions from the construction sectors of the UAE and South Africa leveraging acrylic resins' beneficial properties.Tell us your focus area and get a customized research report.

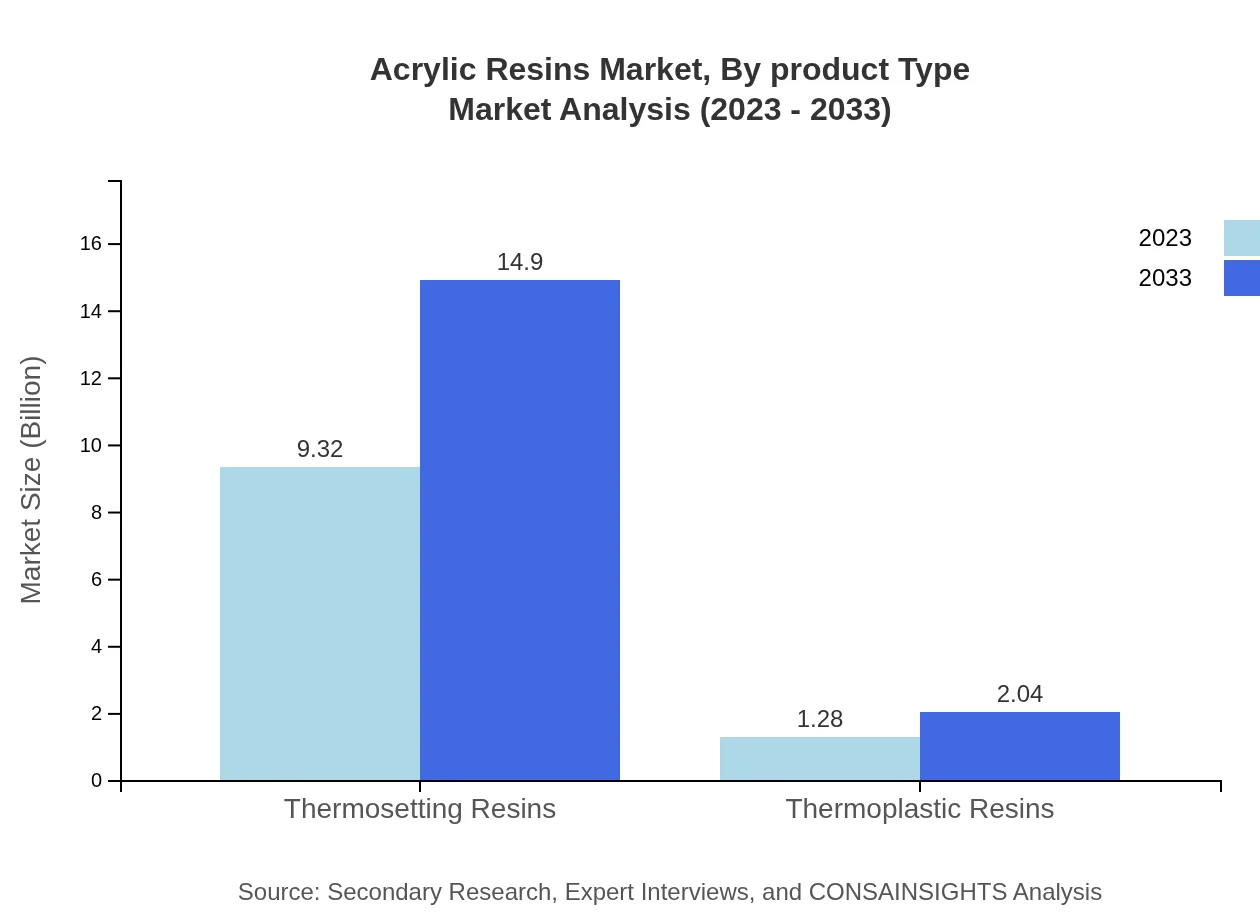

Acrylic Resins Market Analysis By Product Type

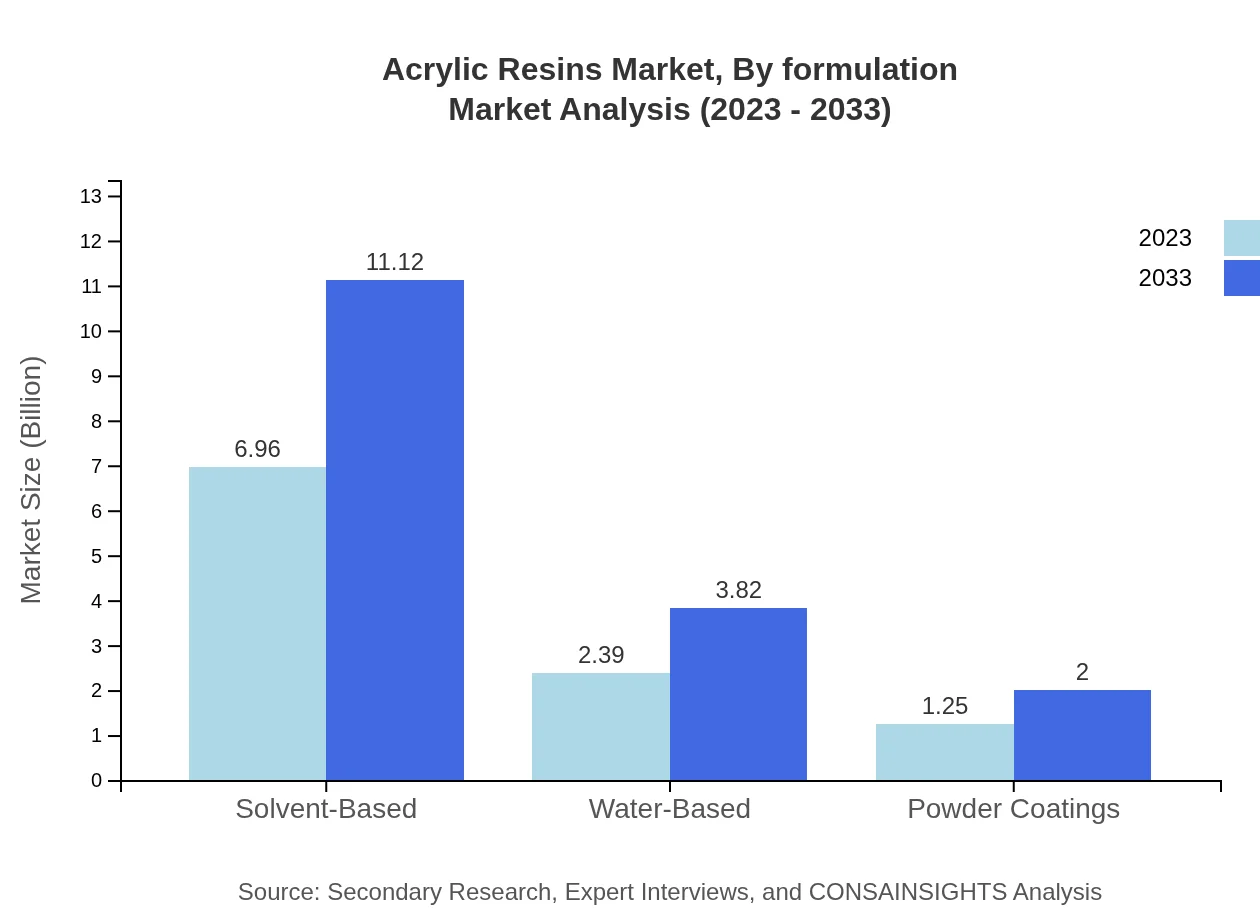

The Acrylic Resins market by product type reveals that solvent-based products dominate the market with an estimated size of $6.96 billion in 2023, anticipated to reach $11.12 billion by 2033. Water-based products follow, growing from $2.39 billion to $3.82 billion, while powder coatings are projected to rise from $1.25 billion to $2.00 billion within the same timeframe.

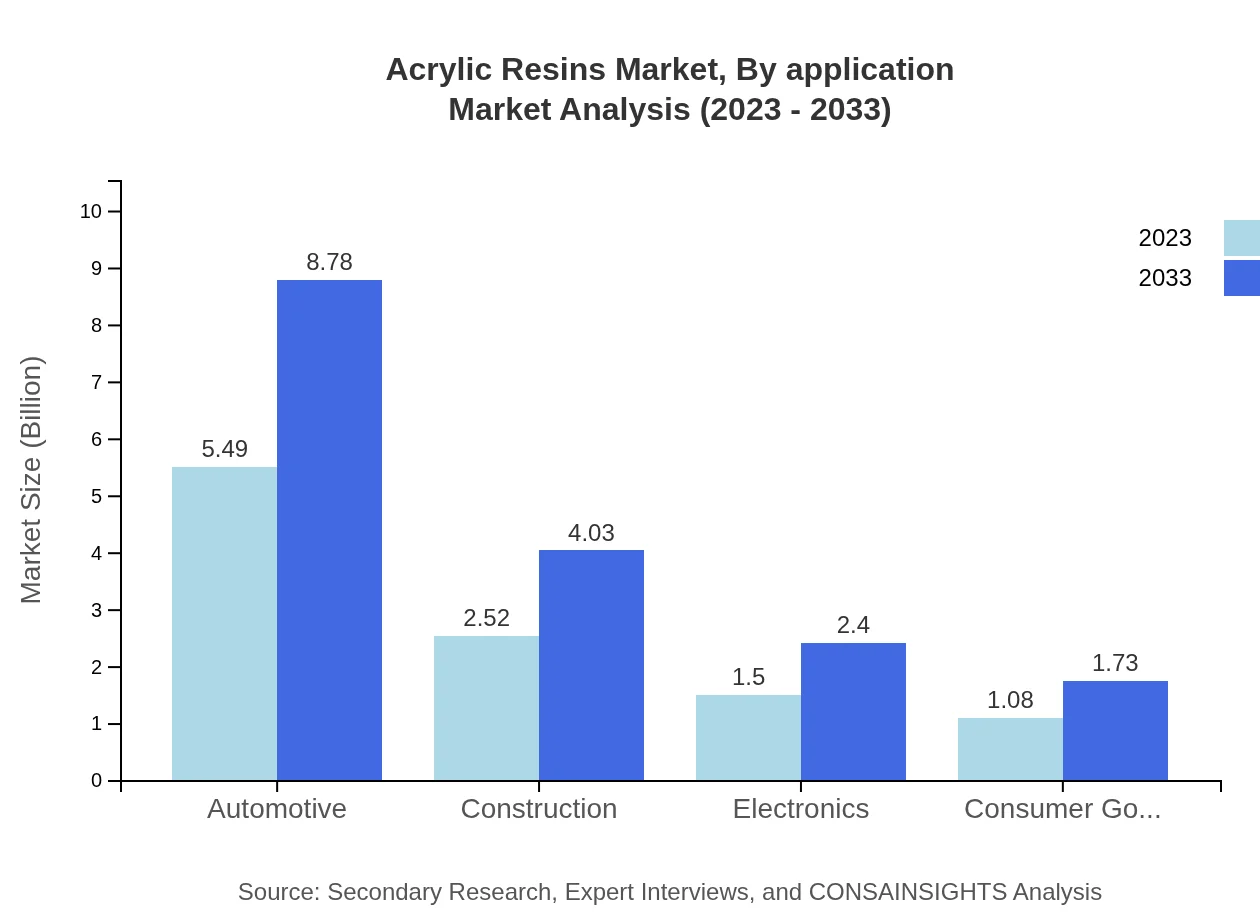

Acrylic Resins Market Analysis By Application

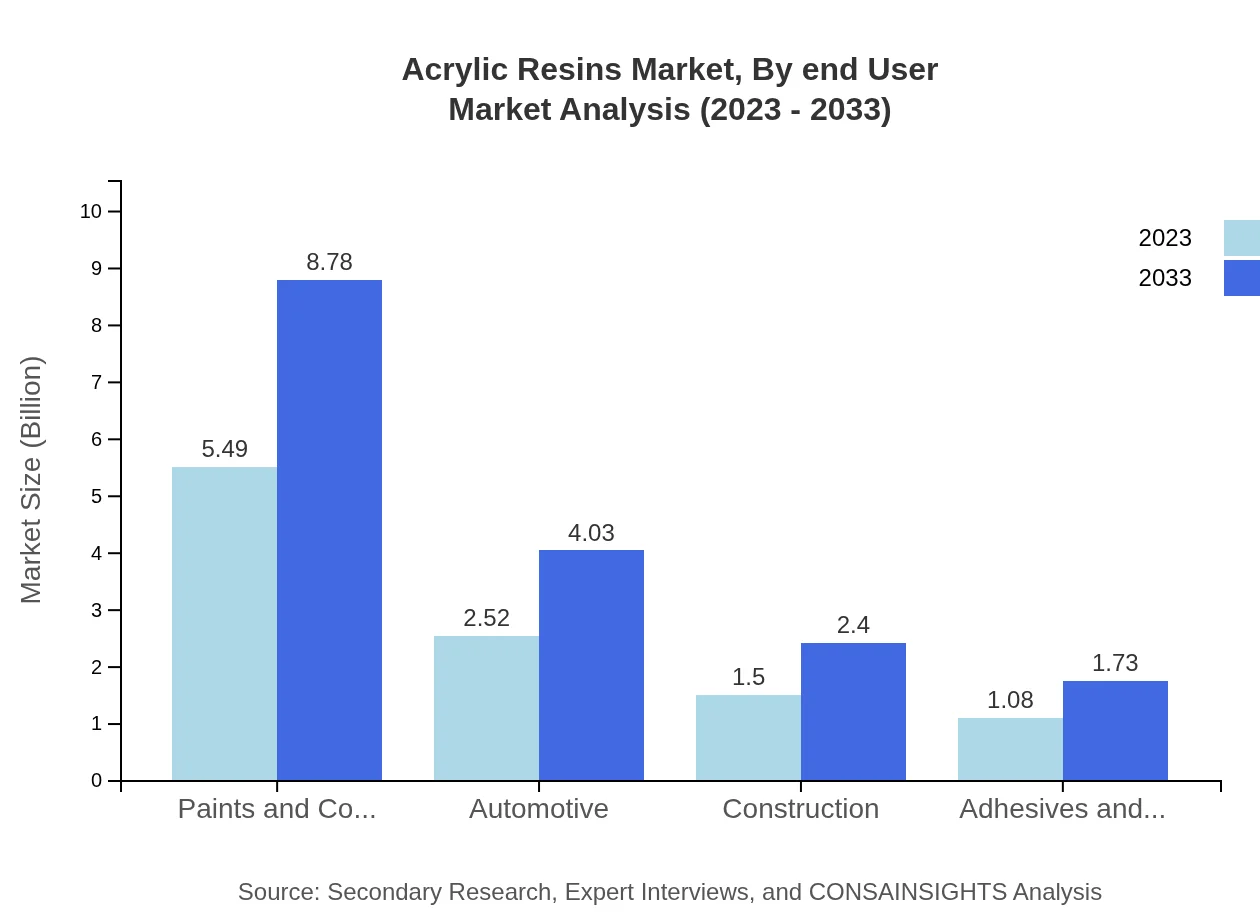

In terms of application, the paints and coatings segment is poised for substantial growth, accounting for $5.49 billion in 2023 and projected to escalate to $8.78 billion by 2033. This segment's significant contribution is tied to rising construction and automotive activities globally. The automotive sector also shows strong growth potential, evolving from $2.52 billion to $4.03 billion.

Acrylic Resins Market Analysis By End User

Acrylic resins serve various end-user industries including automotive, construction, electronics, and consumer goods. The automotive industry is projected to maintain a share of 23.78% by 2033, growing significantly given the boom in electric vehicle production and manufacturing efficiencies. The construction industry follows closely, reflecting growth trends in infrastructure investments.

Acrylic Resins Market Analysis By Formulation

The formulations of Acrylic Resins can be segmented into solvent-based, water-based, and powder coatings. Solvent-based resins take the majority market share with 65.65% in 2023, supported by strong demand in heavy-duty applications. Water-based alternatives are gaining traction as eco-friendly solutions, projected to hold 22.53% by 2033.

Acrylic Resins Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylic Resins Industry

BASF SE:

BASF is a leading global chemical company that produces a variety of polymer-based products, including acrylic resins which serve as key materials in coatings, adhesives, and other applications.Dow Chemical Company:

Dow provides a wide range of acrylic resins, known for their exceptional versatility and efficiency in various applications, especially focusing on sustainability and innovation.Evonik Industries AG:

Evonik is a technology-driven specialty chemicals company producing innovative acrylic resins tailored for high-performance and sustainable applications.Arkema S.A.:

Arkema offers a comprehensive range of acrylic resins and is committed to advancing sustainability through innovative product development.Mitsubishi Chemical Corporation:

Mitsubishi Chemical produces high-quality acrylic resins, with a focus on research and development to enhance performance and sustainable solutions.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylic resins?

The acrylic resins market is projected to reach a size of $10.6 billion by 2033, growing at a CAGR of 4.7% from its 2023 valuation. This reflects a robust demand across various applications underlining the industry's potential growth.

What are the key market players or companies in the acrylic resins industry?

Key players in the acrylic resins market include major corporations like BASF SE, Evonik Industries AG, and Mitsubishi Chemical Corporation, among others. These companies leverage innovation and strategic partnerships to maintain their competitive edge in the industry.

What are the primary factors driving the growth in the acrylic resins industry?

Growth in the acrylic resins market is driven by rising demand across sectors such as automotive, construction, and consumer goods, alongside advancements in product formulations that enhance performance and sustainability.

Which region is the fastest Growing in the acrylic resins market?

The Asia Pacific region is identified as the fastest-growing market for acrylic resins, expected to rise from $2.32 billion in 2023 to $3.71 billion by 2033, showcasing its expansive industrial and consumer base.

Does ConsaInsights provide customized market report data for the acrylic resins industry?

Yes, ConsaInsights offers tailored market report data for the acrylic resins industry. Clients can request specific insights based on their unique business needs, ensuring relevant and actionable information.

What deliverables can I expect from this acrylic resins market research project?

The acrylic resins market research project will deliver comprehensive reports including market size forecasts, competitive analysis, trend observations, and regional breakdowns, providing a holistic view for strategic decision-making.

What are the market trends of acrylic resins?

Current trends in the acrylic resins market include a shift towards eco-friendly formulations, increased demand for specialty resins in high-performance coatings, and innovations in product applications such as in the automotive and electronics sectors.