Acrylic Surface Coating Market Report

Published Date: 02 February 2026 | Report Code: acrylic-surface-coating

Acrylic Surface Coating Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Acrylic Surface Coating market, including current trends, size, CAGR, and forecasts through 2033. It covers regional insights, technological innovations, and competitive landscape, offering valuable information for stakeholders.

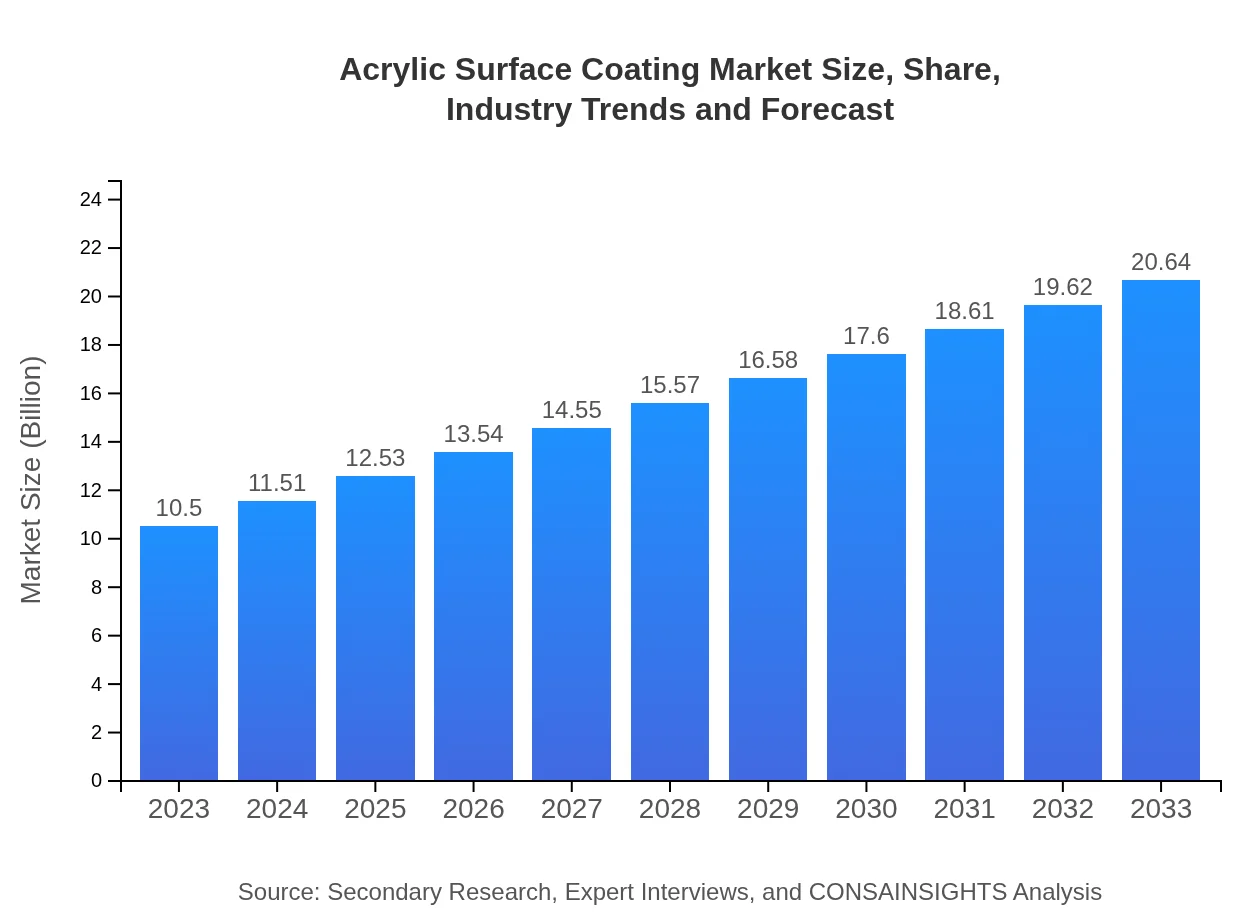

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $20.64 Billion |

| Top Companies | Axalta Coating Systems, BASF SE, PPG Industries, Sherwin-Williams |

| Last Modified Date | 02 February 2026 |

Acrylic Surface Coating Market Overview

Customize Acrylic Surface Coating Market Report market research report

- ✔ Get in-depth analysis of Acrylic Surface Coating market size, growth, and forecasts.

- ✔ Understand Acrylic Surface Coating's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylic Surface Coating

What is the Market Size & CAGR of Acrylic Surface Coating market in 2023?

Acrylic Surface Coating Industry Analysis

Acrylic Surface Coating Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylic Surface Coating Market Analysis Report by Region

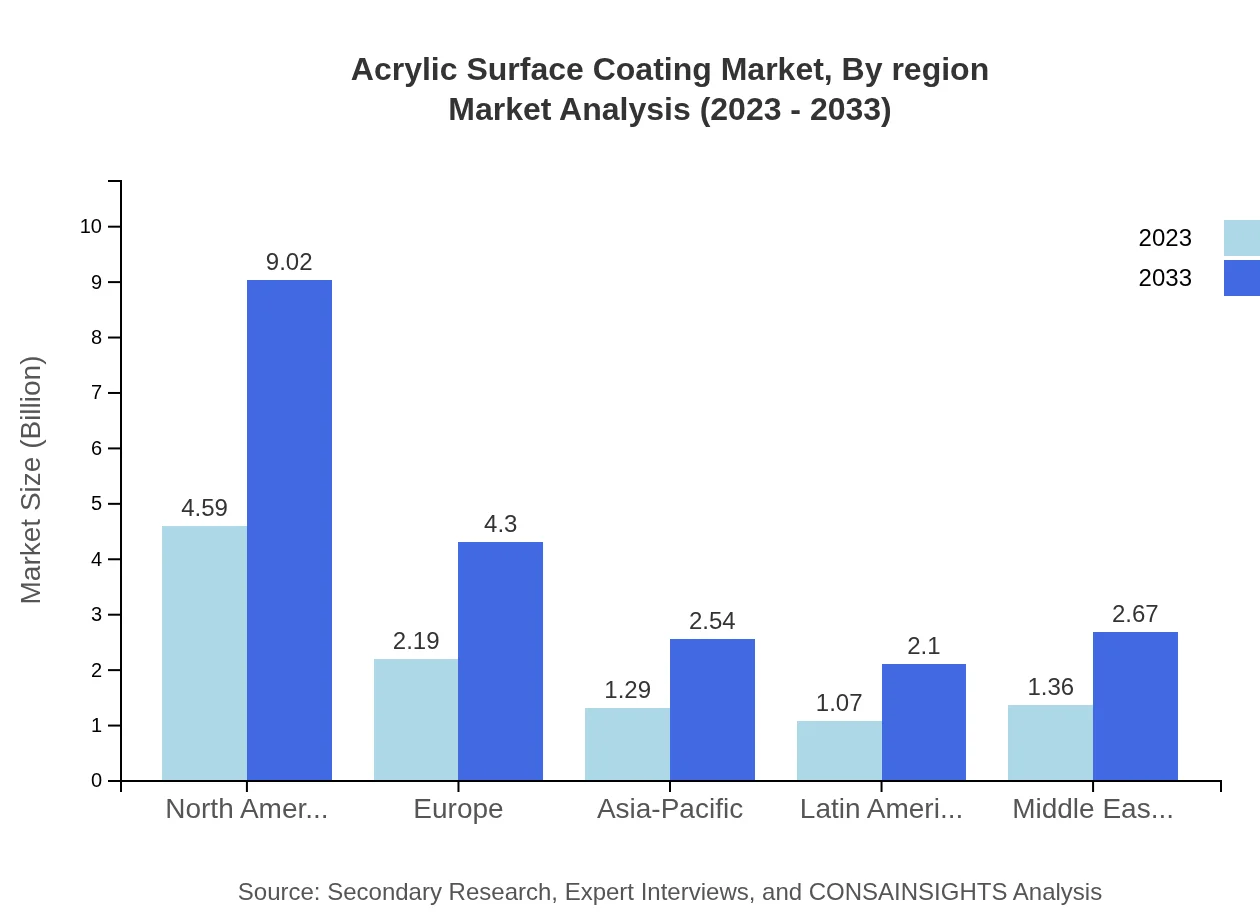

Europe Acrylic Surface Coating Market Report:

The European market for acrylic surface coatings is valued at $2.84 billion in 2023 and is anticipated to grow to $5.57 billion by 2033. The region's stringent regulations regarding VOC emissions are leading to a shift towards eco-friendly coatings, creating opportunities for market players to develop innovative products.Asia Pacific Acrylic Surface Coating Market Report:

In 2023, the Asia-Pacific market is valued at approximately $2.05 billion, expected to reach $4.03 billion by 2033, driven by rapid industrialization and infrastructure development. Countries like China and India are leading the charge with significant growth in automotive and construction sectors, which in turn bolsters the demand for acrylic surface coatings.North America Acrylic Surface Coating Market Report:

North America holds one of the largest shares in the acrylic surface coating market, valued at $3.88 billion in 2023 and expected to double to $7.62 billion by 2033. The automotive sector significantly influences this market, with a rising preference for stronger and more durable coatings.South America Acrylic Surface Coating Market Report:

The South American market is currently valued at $0.72 billion and is projected to grow to $1.41 billion by 2033. The increasing focus on sustainable construction practices and furniture manufacturing is fostering market expansion, though economic fluctuations in the region may pose challenges.Middle East & Africa Acrylic Surface Coating Market Report:

Valued at $1.02 billion in 2023, the Middle East and Africa market is expected to expand to $2.00 billion by 2033. Growth is driven by increasing construction activity and economic development in the region, alongside rising awareness of the benefits of high-quality surface coatings.Tell us your focus area and get a customized research report.

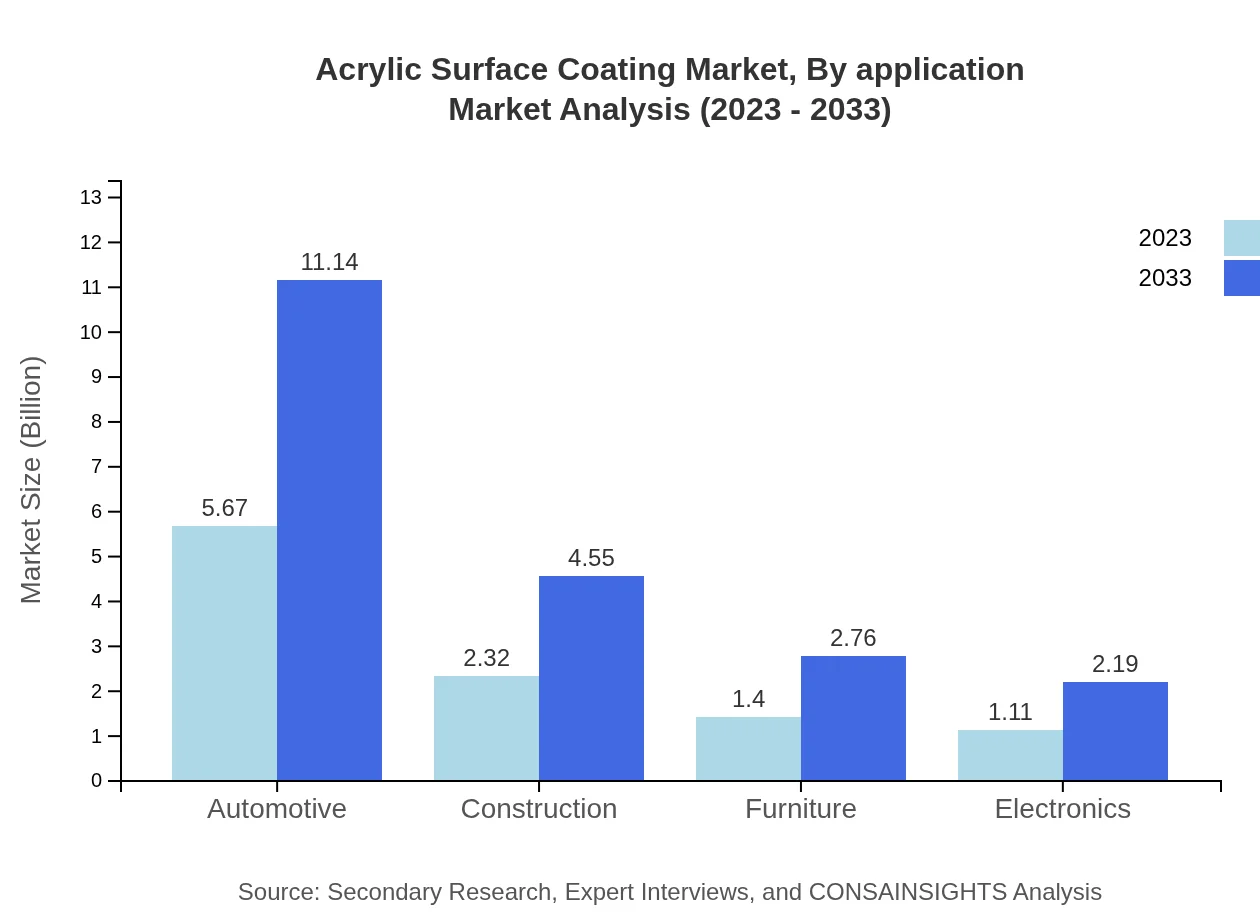

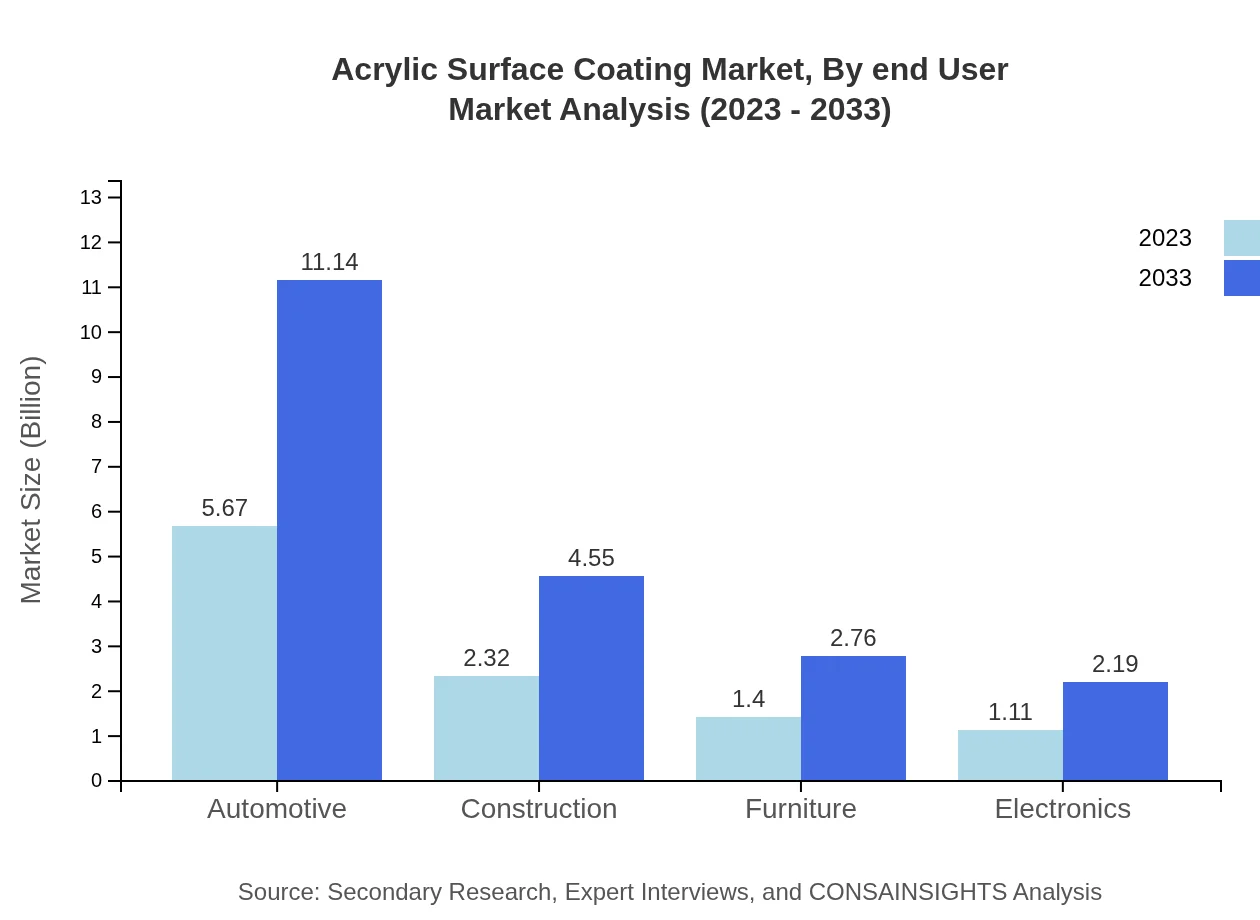

Acrylic Surface Coating Market Analysis By Application

In 2023, the automotive application segment leads the acrylic surface coating market, valued at $5.67 billion, with projections of reaching $11.14 billion by 2033. Other significant segments include construction, furniture, and electronics, contributing to diverse market dynamics.

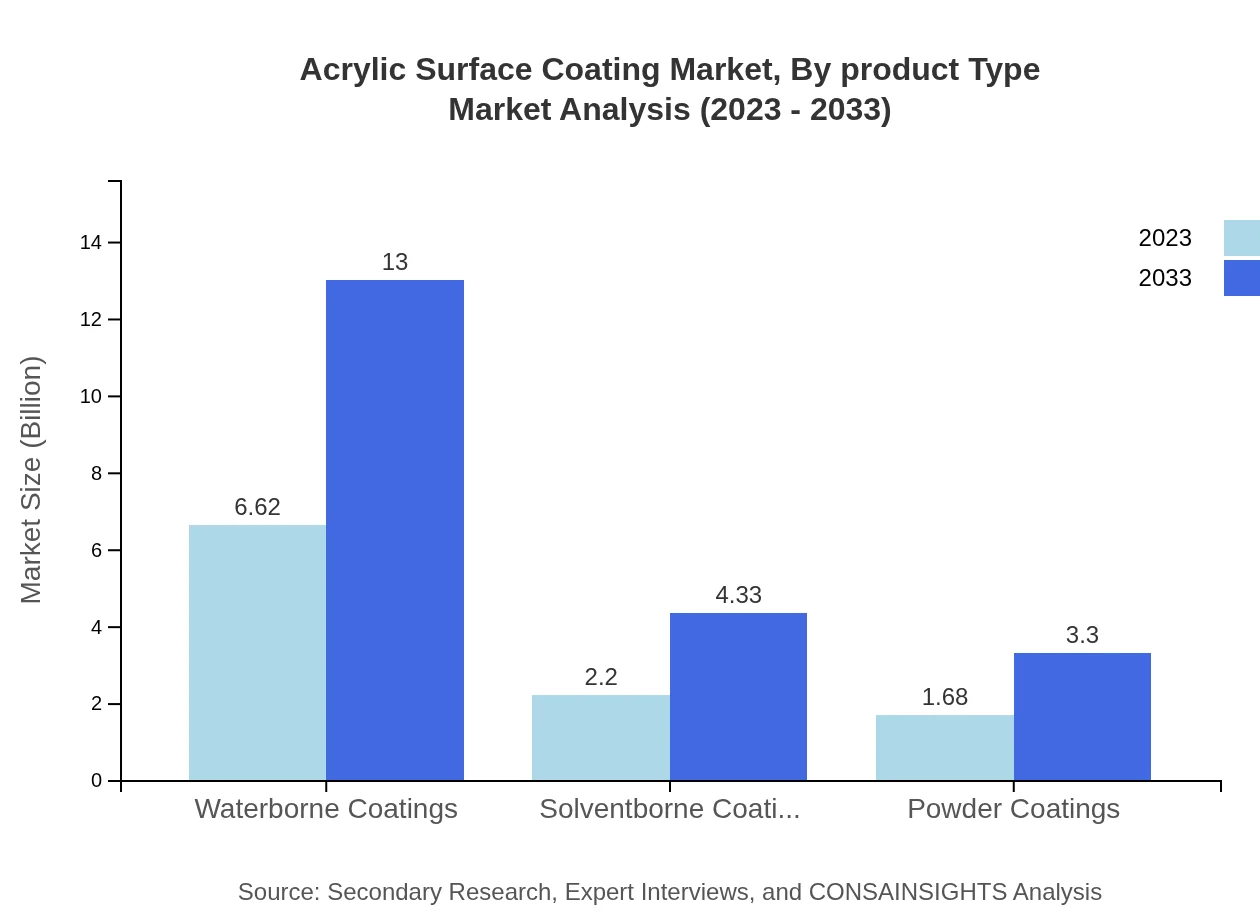

Acrylic Surface Coating Market Analysis By Product Type

Waterborne acrylic coatings dominate the market, valued at $6.62 billion in 2023, followed by solventborne coatings at $2.20 billion. By 2033, the demand for waterborne coatings is expected to continue growing due to environmental regulations and consumer preference for low-VOC products.

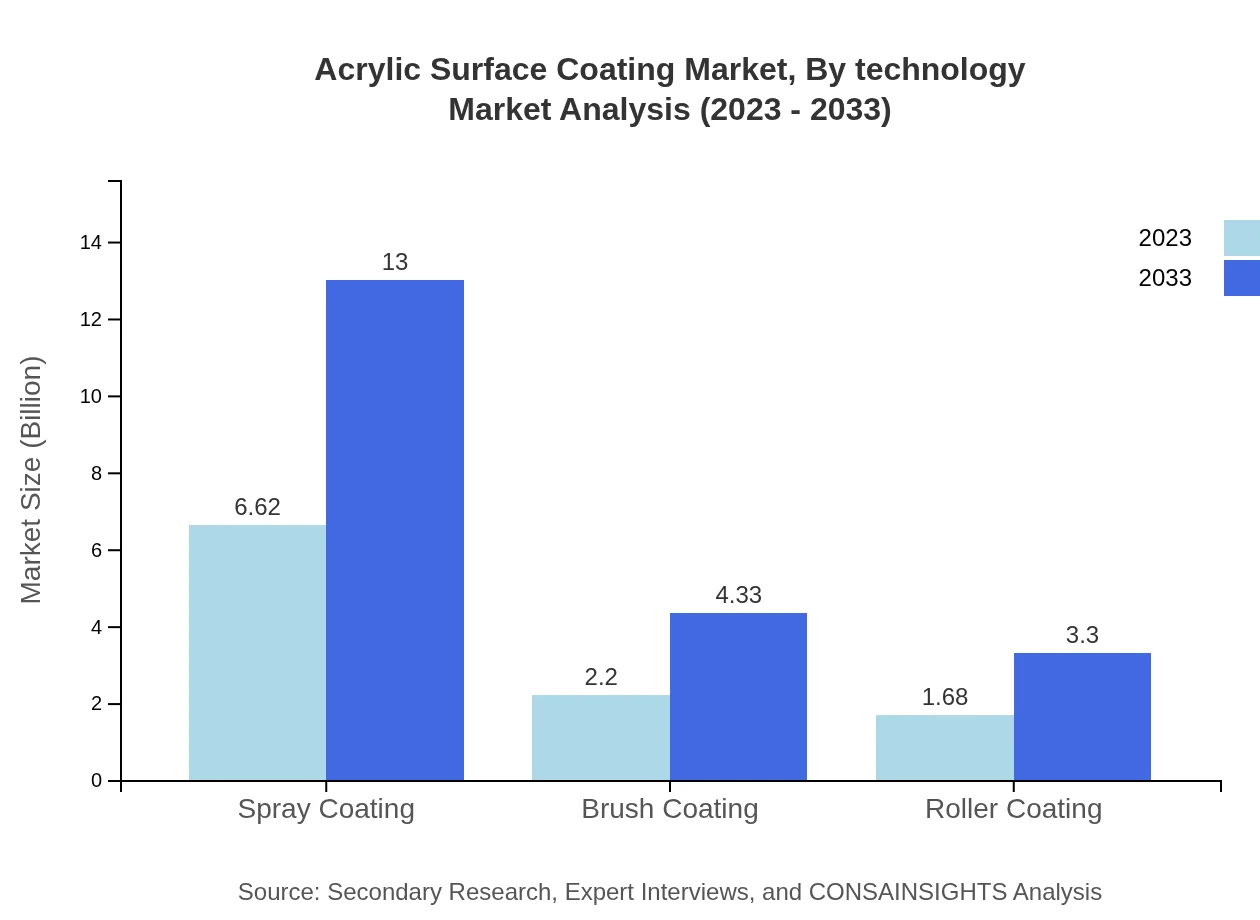

Acrylic Surface Coating Market Analysis By Technology

Spray coating technology is the most preferred method, accounting for significant market share of63.01% in 2023. Brush and roller coatings also play vital roles depending on end-user requirements, although spray techniques are more efficient for large surface applications.

Acrylic Surface Coating Market Analysis By End User

Leading sectors utilizing acrylic surface coatings include automotive, with substantial growth projected due to rising vehicle production. The construction segment follows, driven by new infrastructure projects and renovations, cultivating a strong market for acrylic applications.

Acrylic Surface Coating Market Analysis By Region

Regional analysis indicates North America and Europe as strong markets, while Asia-Pacific offers rapid growth potential. Understanding regional specifics aids companies in strategizing their market entry and expansion.

Acrylic Surface Coating Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylic Surface Coating Industry

Axalta Coating Systems:

A global leader in coatings with a diverse portfolio, dedicated to innovative solutions for automotive and industrial applications.BASF SE:

One of the largest chemical companies worldwide, focusing on sustainable development and advanced coatings technology.PPG Industries:

A major player in the paint and coatings market, PPG offers a wide range of products with a strong emphasis on research and innovation.Sherwin-Williams:

A leader in coatings and finishes, providing high-performance products and committed to sustainability.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylic Surface Coating?

The global acrylic surface coating market size is anticipated to reach approximately $10.5 billion by 2033, growing at a CAGR of 6.8%. This growth reflects increasing demand across various sectors, underlining the market's extensive potential.

What are the key market players or companies in this acrylic Surface Coating industry?

Key players in the acrylic surface coating industry include major companies like PPG Industries, Sherwin-Williams, BASF, AkzoNobel, and Dow. These companies drive innovation and competition, shaping industry standards and delivering diverse product offerings.

What are the primary factors driving the growth in the acrylic Surface Coating industry?

Growth in the acrylic surface coating industry is primarily driven by the rising demand for sustainable and environmentally friendly coatings, increasing investments in the construction and automotive sectors, and technological advances enhancing product performance and application methods.

Which region is the fastest Growing in the acrylic Surface Coating?

The fastest-growing region in the acrylic surface coating market is projected to be North America, showing significant growth from $3.88 billion in 2023 to $7.62 billion by 2033. This growth is fueled by advancements in the automotive and construction industries.

Does ConsaInsights provide customized market report data for the acrylic Surface Coating industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the acrylic surface coating industry, allowing businesses to gather insights relevant to their market strategies and competitive analysis.

What deliverables can I expect from this acrylic Surface Coating market research project?

From this market research project, you can expect comprehensive reports including market size estimates, growth forecasts, competitive landscape analyses, trends, and valuable insights about critical segments and regional performance within the acrylic surface coating industry.

What are the market trends of acrylic Surface Coating?

Current market trends in the acrylic surface coating industry include rising demand for eco-friendly formulations, innovation in application techniques, and enhanced product functionalities, as well as a growing emphasis on durability and sustainability across various market segments.