Acrylonitrile Butadiene Styrene Abs Resin Market Report

Published Date: 02 February 2026 | Report Code: acrylonitrile-butadiene-styrene-abs-resin

Acrylonitrile Butadiene Styrene Abs Resin Market Size, Share, Industry Trends and Forecast to 2033

This report comprehensively analyzes the Acrylonitrile Butadiene Styrene (ABS) Abs Resin market, providing insights on market size, growth trends, and forecasts from 2023 to 2033, along with a detailed examination of industry segments and regional dynamics.

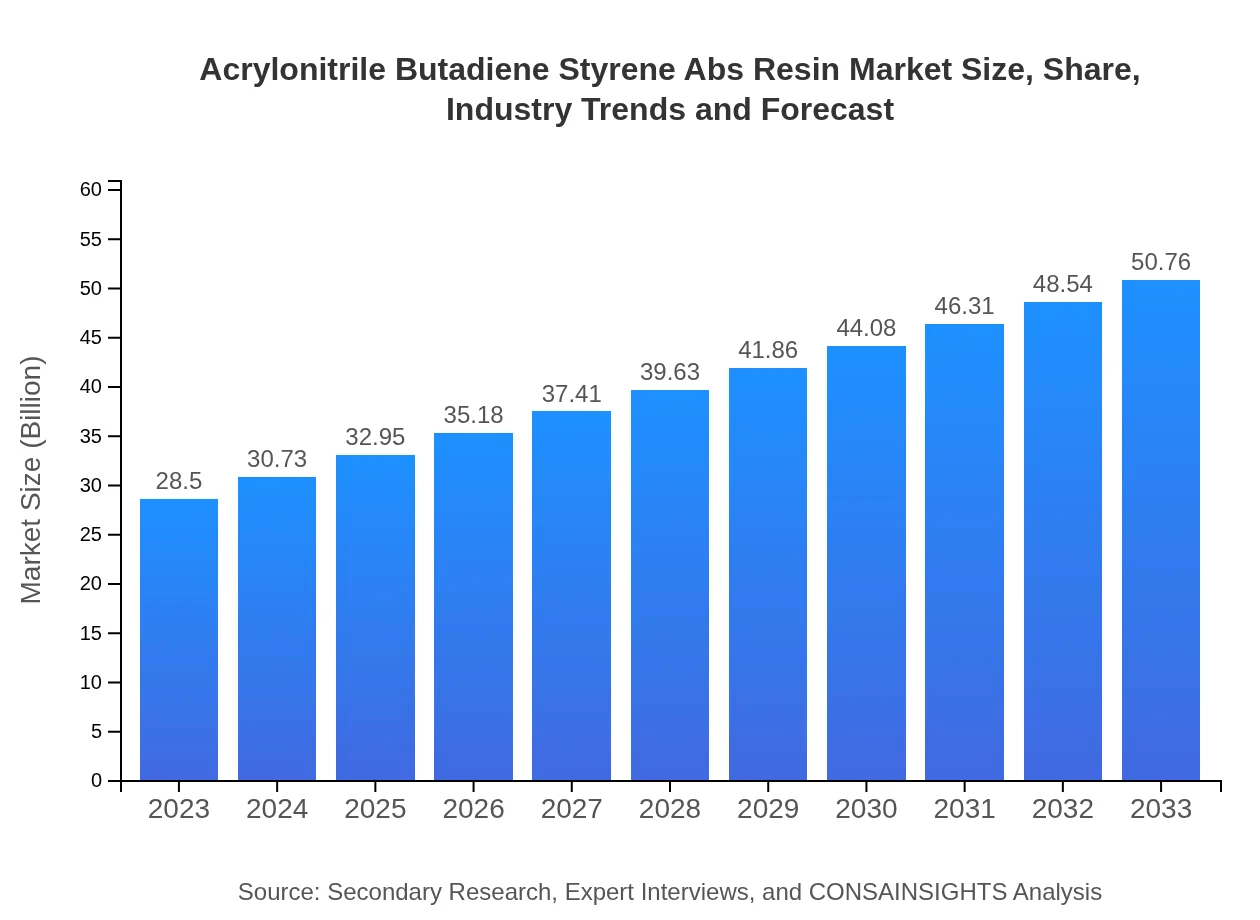

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $28.50 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $50.76 Billion |

| Top Companies | BASF, LG Chem, SABIC |

| Last Modified Date | 02 February 2026 |

Acrylonitrile Butadiene Styrene Abs Resin Market Overview

Customize Acrylonitrile Butadiene Styrene Abs Resin Market Report market research report

- ✔ Get in-depth analysis of Acrylonitrile Butadiene Styrene Abs Resin market size, growth, and forecasts.

- ✔ Understand Acrylonitrile Butadiene Styrene Abs Resin's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylonitrile Butadiene Styrene Abs Resin

What is the Market Size & CAGR of Acrylonitrile Butadiene Styrene Abs Resin market in 2023?

Acrylonitrile Butadiene Styrene Abs Resin Industry Analysis

Acrylonitrile Butadiene Styrene Abs Resin Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis Report by Region

Europe Acrylonitrile Butadiene Styrene Abs Resin Market Report:

Europe's ABS resin market is anticipated to rise from $10.58 billion in 2023 to $18.85 billion by 2033, supported by stringent regulations promoting sustainable materials and innovations in recycling technologies within the polymer industry.Asia Pacific Acrylonitrile Butadiene Styrene Abs Resin Market Report:

The Asia-Pacific region holds a significant share of the ABS resin market, with a market size of approximately $5.19 billion in 2023, expected to grow to $9.25 billion by 2033. Key drivers include rapid industrialization, increased automotive manufacturing, and a growing consumer electronics market.North America Acrylonitrile Butadiene Styrene Abs Resin Market Report:

North America reported a market size of $9.21 billion in 2023, expected to grow to $16.41 billion by 2033. The region's growth is supported by advanced automotive technology employment and a strong demand for electronic applications.South America Acrylonitrile Butadiene Styrene Abs Resin Market Report:

In South America, the market size for ABS resin is projected at $1.60 billion in 2023, with a growth trajectory targeting $2.84 billion by 2033. The region's demand is driven by rising economic activity and urbanization, enhancing the use of synthetic materials in construction and consumer goods.Middle East & Africa Acrylonitrile Butadiene Styrene Abs Resin Market Report:

The Middle East and Africa market size is estimated at $1.92 billion in 2023, growing to $3.41 billion by 2033. Rising investments in infrastructure and growing consumer markets are positioning the region for substantial ABS resin demand.Tell us your focus area and get a customized research report.

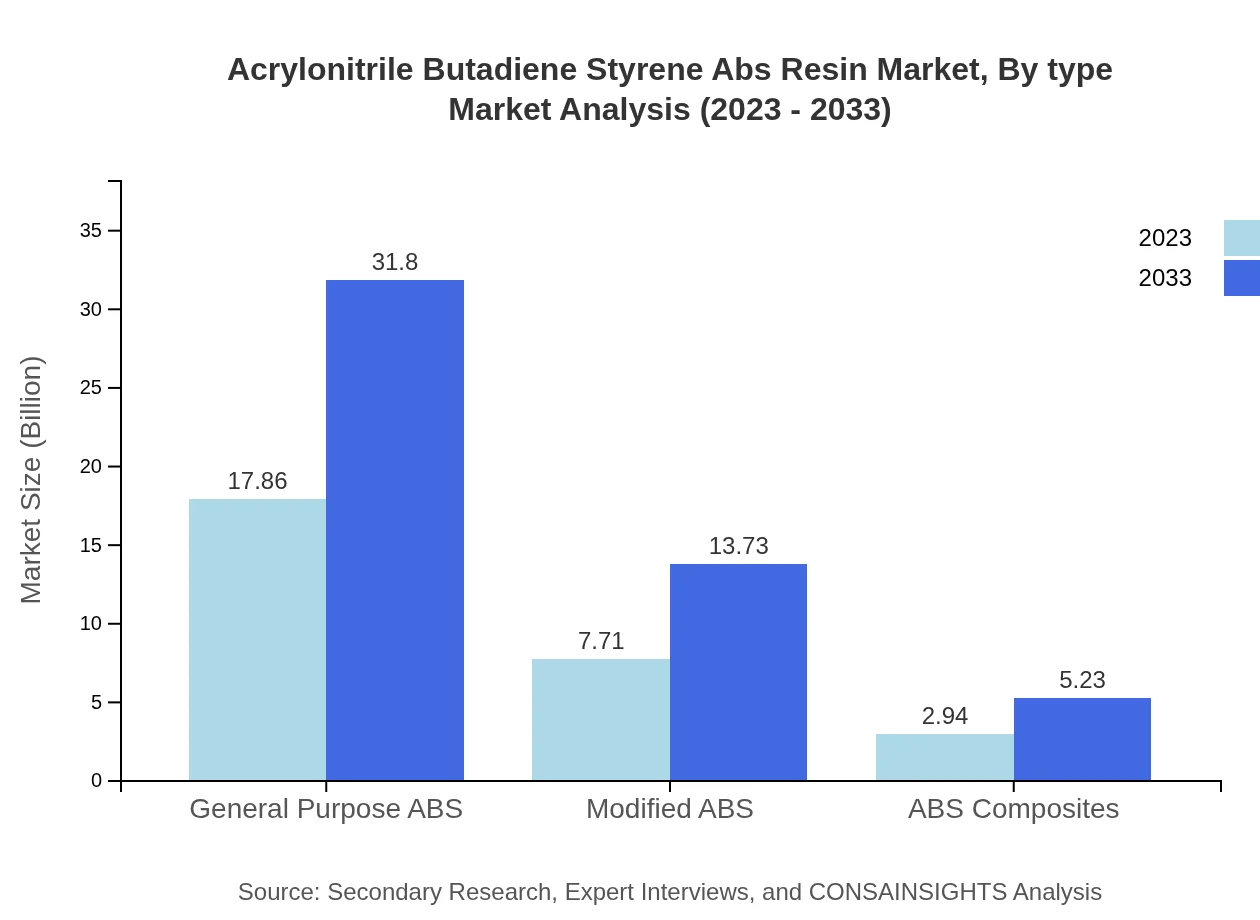

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis By Type

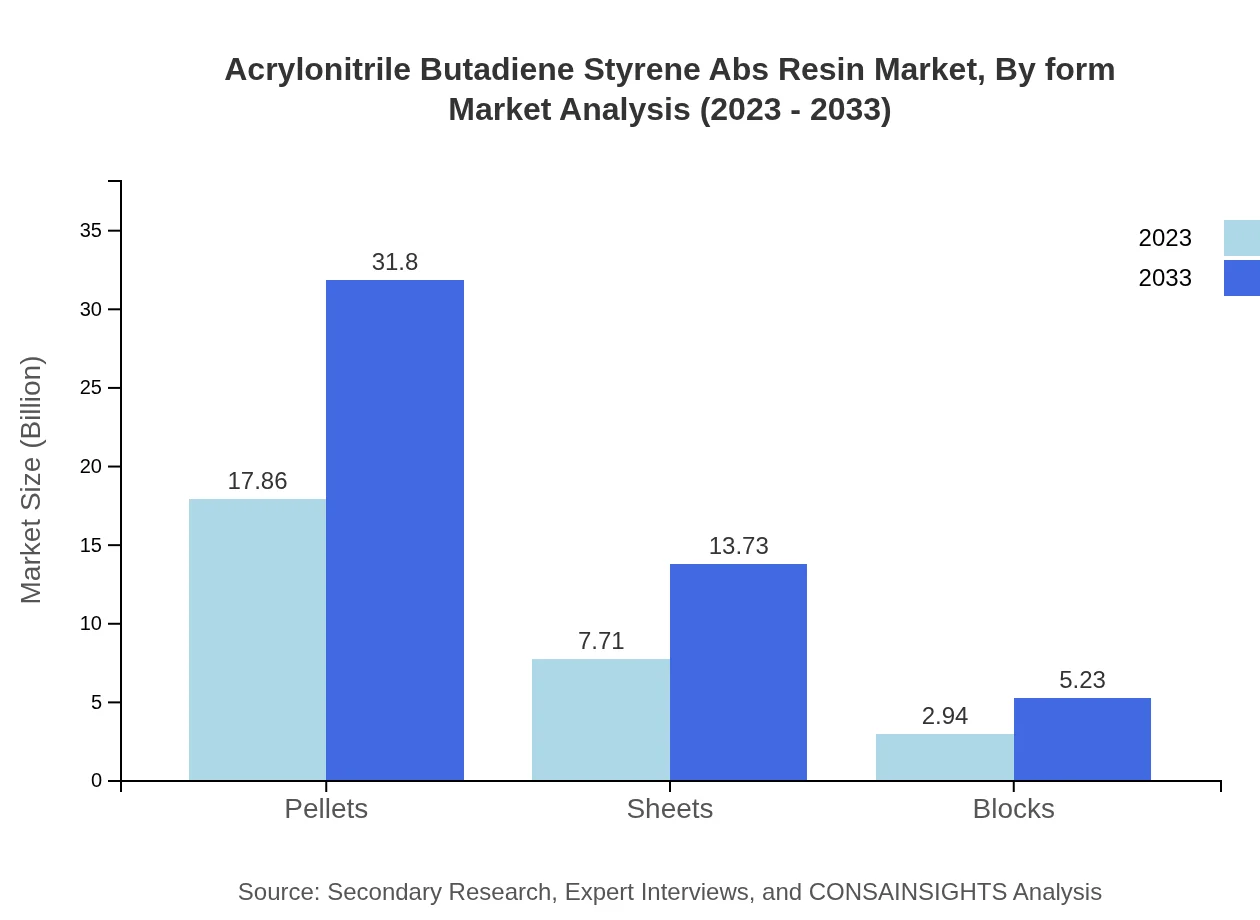

In 2023, the Pellets segment dominates the ABS market with a size of $17.86 billion, expected to reach $31.80 billion by 2033, maintaining a market share of 62.65%. The Sheets segment accounts for $7.71 billion, projected to grow to $13.73 billion. Blocks and composites segments have a market size of $2.94 billion, showing significant growth potential as these materials are favored for specific applications.

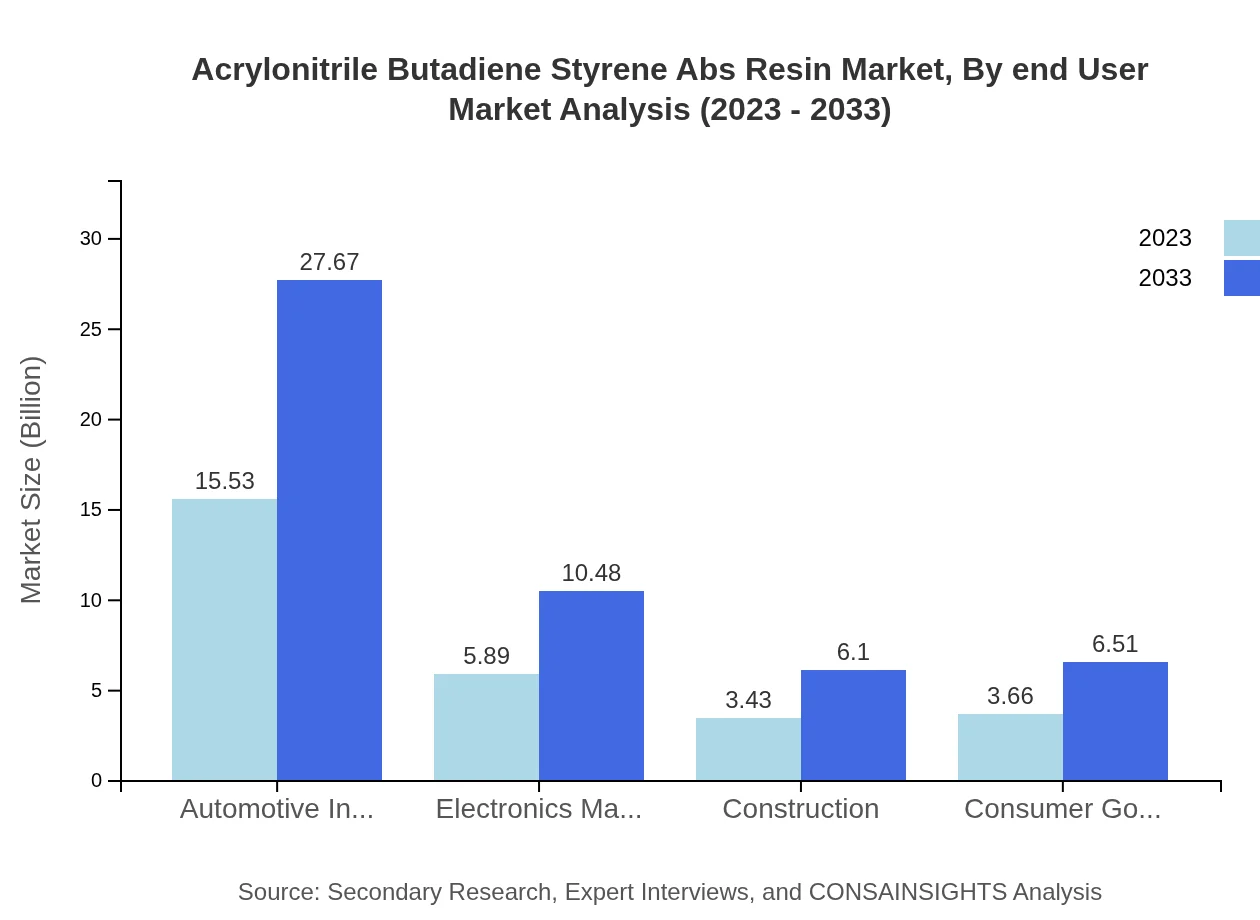

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis By Application

The automotive sectors dominate the application spectrum, with $15.53 billion in 2023, expected to increase to $27.67 billion by 2033. Electronics manufacturing contributes $5.89 billion, underscoring the compact and durable requirement in products. Construction and consumer goods applications are equally significant in driving ABS resin demand.

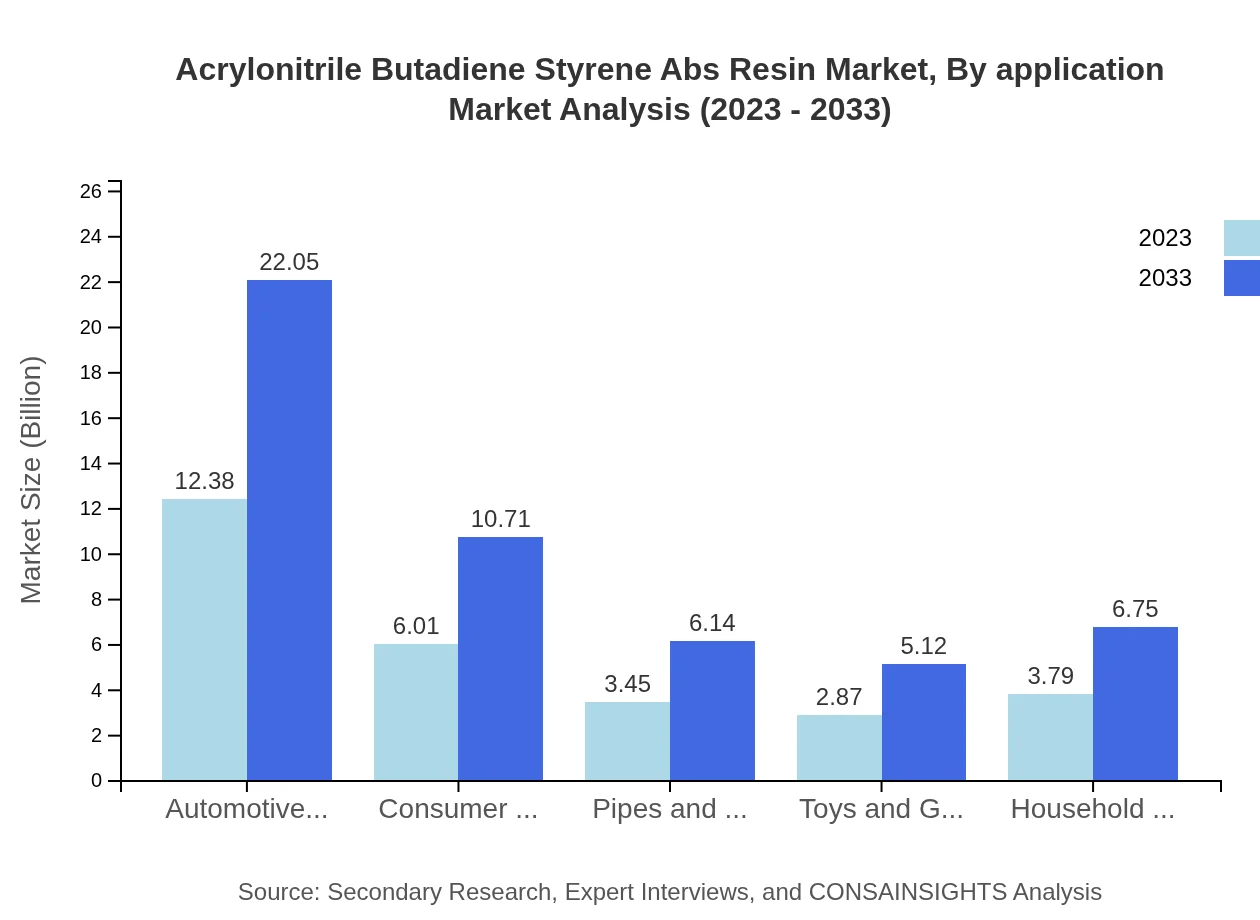

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis By End User

The automotive components segment, valued at $12.38 billion in 2023, shows a robust forecast of $22.05 billion by 2033. Consumer electronics and household goods also provide substantial contributions, with market sizes reflecting the sector's shift towards renewable materials and sustainability.

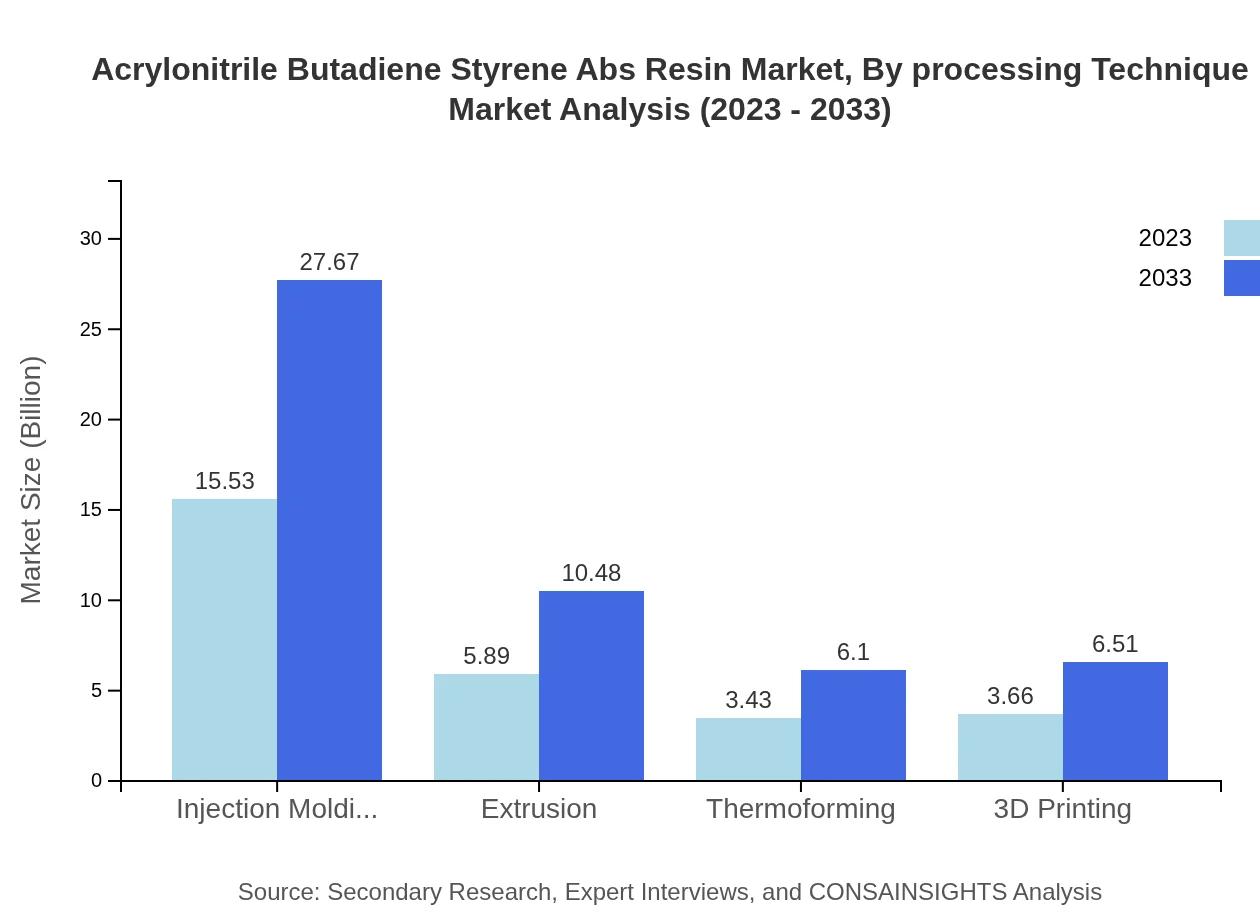

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis By Processing Technique

Injection molding dominates the processing technique sector with a market size of $15.53 billion in 2023, capturing a 54.5% market share. Extrusion and thermoforming are also essential processes, with projected growth linked to increased demand in rapid prototyping and industrial design sectors.

Acrylonitrile Butadiene Styrene Abs Resin Market Analysis By Form

The ABS resin market is also analyzed by form, with pellets and sheets leading in consumption. Their extensive use in various industries reflects the versatility and adaptability of ABS as a manufacturing material, increasing its market relevance.

Acrylonitrile Butadiene Styrene Abs Resin Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylonitrile Butadiene Styrene Abs Resin Industry

BASF:

BASF is one of the world's largest chemical producers, offering a broad range of ABS products tailored for automotive, consumer goods, and electronics applications, focusing on sustainability and innovation.LG Chem:

A leading chemical company from South Korea known for its high-performance ABS products, LG Chem emphasizes technological advancement and environmentally friendly manufacturing processes.SABIC:

Saudi Basic Industries Corporation produces a wide range of ABS resins, contributing to major markets in automotive and construction, with a strong focus on operational excellence and sustainable product development.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylonitrile Butadiene Styrene Abs Resin?

The global acrylonitrile-butadiene-styrene (ABS) resin market is valued at approximately $28.5 billion in 2023, with a projected CAGR of 5.8% through 2033, indicating significant growth opportunities in the sector.

What are the key market players or companies in this acrylonitrile Butadiene Styrene Abs Resin industry?

Key players in the ABS resin market include companies such as BASF, LG Chem, and SABIC. These companies dominate through innovation, production capacity, and global distribution, influencing market trends and pricing.

What are the primary factors driving the growth in the acrylonitrile Butadiene Styrene Abs Resin industry?

Growth in the ABS resin market is driven by increased demand in automotive and electronics industries, innovation in manufacturing processes, and rising consumer preferences for durable, lightweight materials, enhancing its application range.

Which region is the fastest Growing in the acrylonitrile Butadiene Styrene Abs Resin?

The fastest-growing region for ABS resin is Europe, with a market size expected to grow from $10.58 billion in 2023 to $18.85 billion by 2033, fueled by expanding automotive and electronics sectors.

Does ConsaInsights provide customized market report data for the acrylonitrile Butadiene Styrene Abs Resin industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the ABS resin industry, providing insights into market trends, forecasts, and regional analyses for informed decision-making.

What deliverables can I expect from this acrylonitrile Butadiene Styrene Abs Resin market research project?

Expect deliverables such as comprehensive market reports, detailed segment analysis, growth forecasts, competitive landscapes, and insights into regional and global trends, ensuring an in-depth understanding of the ABS resin market.

What are the market trends of acrylonitrile Butadiene Styrene Abs Resin?

Current market trends include a shift towards environmentally friendly materials, increased adoption in 3D printing, and innovations in product formulations, which are fostering new applications in diverse industries.