Acrylonitrile Market Report

Published Date: 02 February 2026 | Report Code: acrylonitrile

Acrylonitrile Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the dynamics of the Acrylonitrile market, presenting a comprehensive analysis from 2023 to 2033. It provides insights on market size, segmentation, regional performance, technology trends, and forecasts, empowering stakeholders with data-driven decisions.

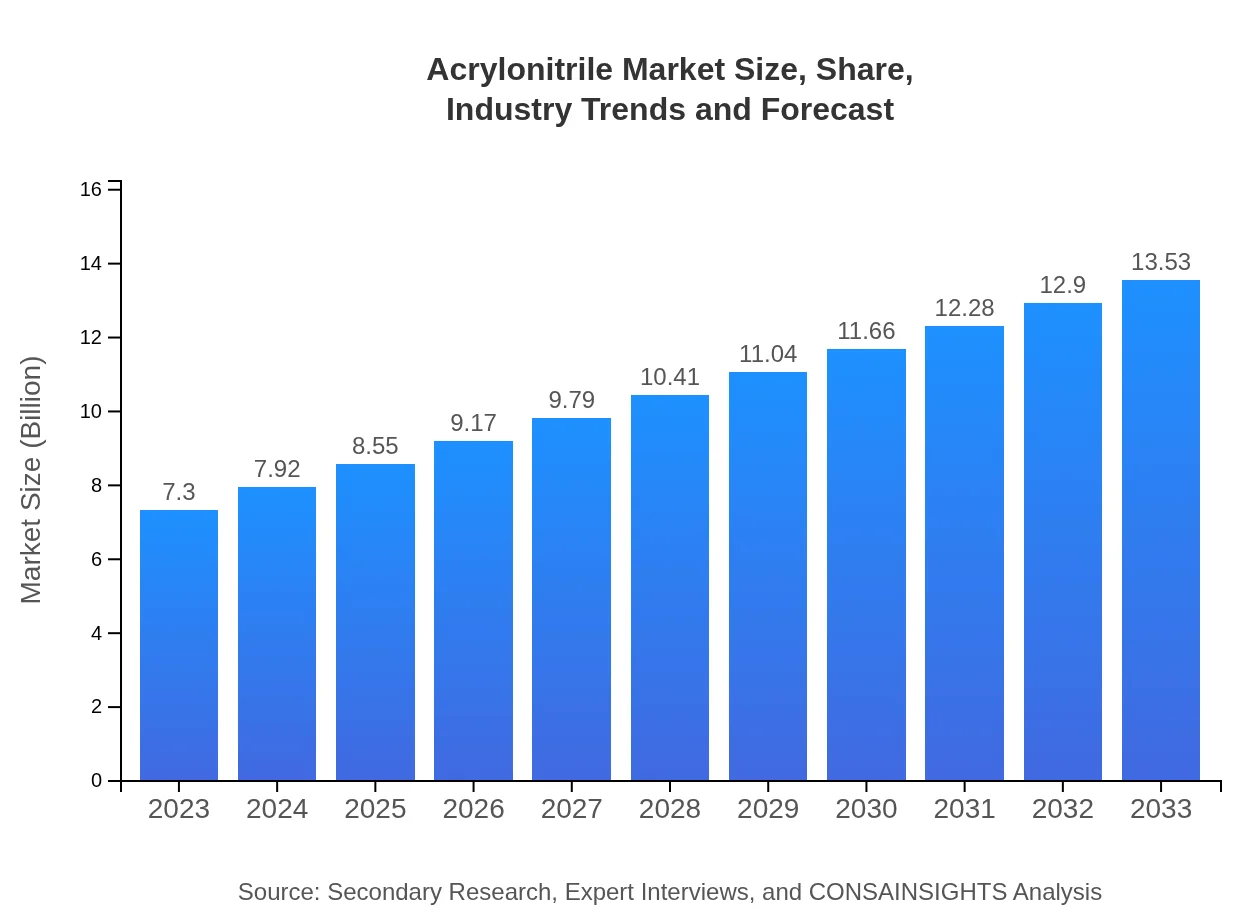

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.30 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $13.53 Billion |

| Top Companies | INEOS, SABIC, Otto Chemie Pvt. Ltd., DOW Chemical |

| Last Modified Date | 02 February 2026 |

Acrylonitrile Market Overview

Customize Acrylonitrile Market Report market research report

- ✔ Get in-depth analysis of Acrylonitrile market size, growth, and forecasts.

- ✔ Understand Acrylonitrile's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Acrylonitrile

What is the Market Size & CAGR of Acrylonitrile market in 2023?

Acrylonitrile Industry Analysis

Acrylonitrile Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Acrylonitrile Market Analysis Report by Region

Europe Acrylonitrile Market Report:

The European Market size is poised to increase significantly from $1.90 billion in 2023 to $3.52 billion by 2033. The region's stringent regulatory environment fosters innovation in production processes, especially those prioritizing sustainability.Asia Pacific Acrylonitrile Market Report:

In the Asia Pacific region, the market is projected to grow from $1.41 billion in 2023 to $2.61 billion in 2033. The increasing demand for synthetic textiles and growing automotive production in countries like China and India are contributing factors to this growth.North America Acrylonitrile Market Report:

North America's acrylonitrile market is anticipated to rise from $2.79 billion in 2023 to $5.17 billion in 2033, driven primarily by advancements in the automotive and plastic industries, combined with an increasing focus on sustainable materials.South America Acrylonitrile Market Report:

The South American market is expected to see an increase from $0.38 billion in 2023 to $0.70 billion in 2033. Factors such as the growth in the textile sector and shifting consumption patterns support this mild growth.Middle East & Africa Acrylonitrile Market Report:

The market in the Middle East and Africa is projected to grow from $0.82 billion in 2023 to $1.52 billion in 2033, supported by improvements in the petrochemical sector and rising industrial applications.Tell us your focus area and get a customized research report.

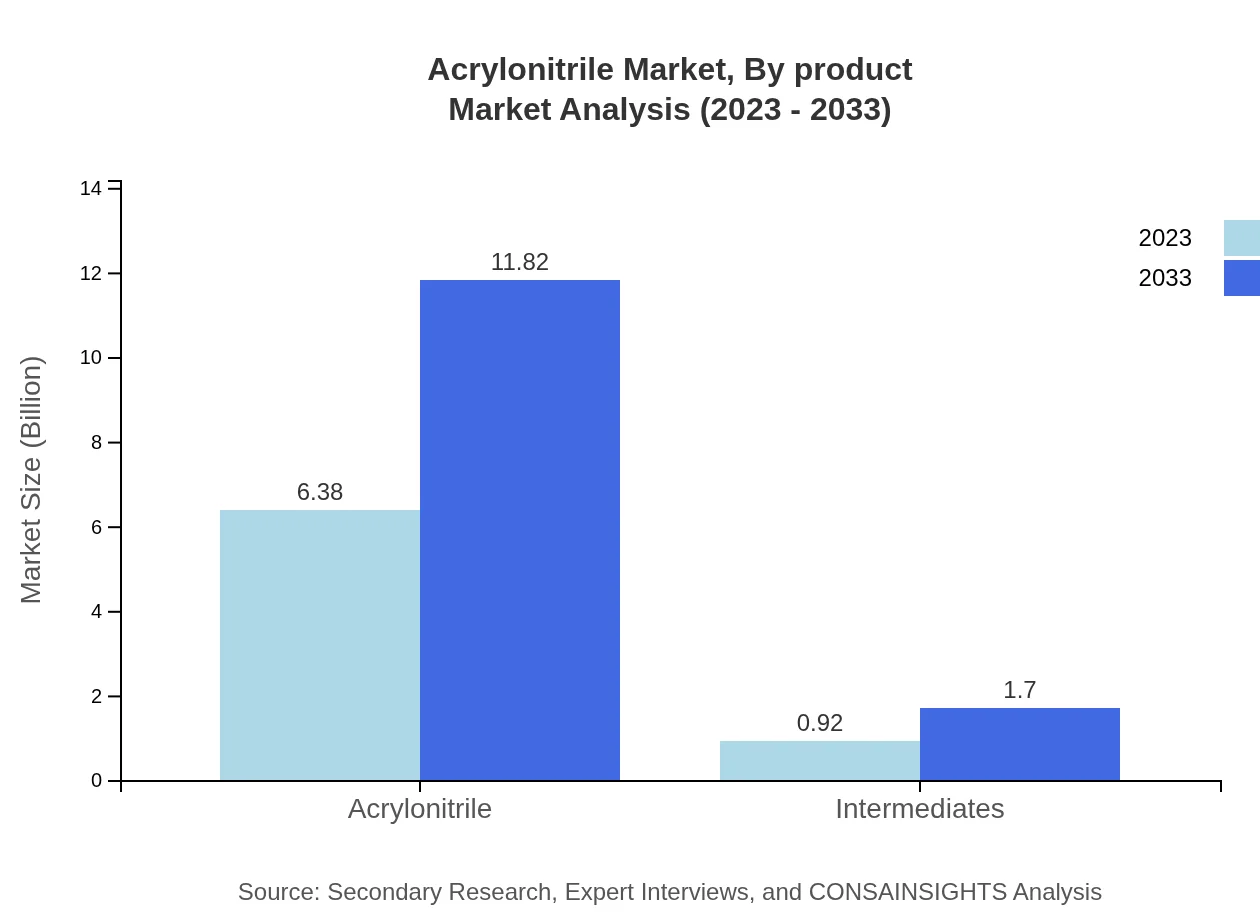

Acrylonitrile Market Analysis By Product

The acrylonitrile market by product segment indicates that the primary products include acrylic fiber, ABS, and latex. The acrylic fiber segment dominates, contributing approximately $4.13 billion in 2023, projected to reach $7.65 billion by 2033. ABS continues to gain traction, driven by demand in the automotive and electronics sectors.

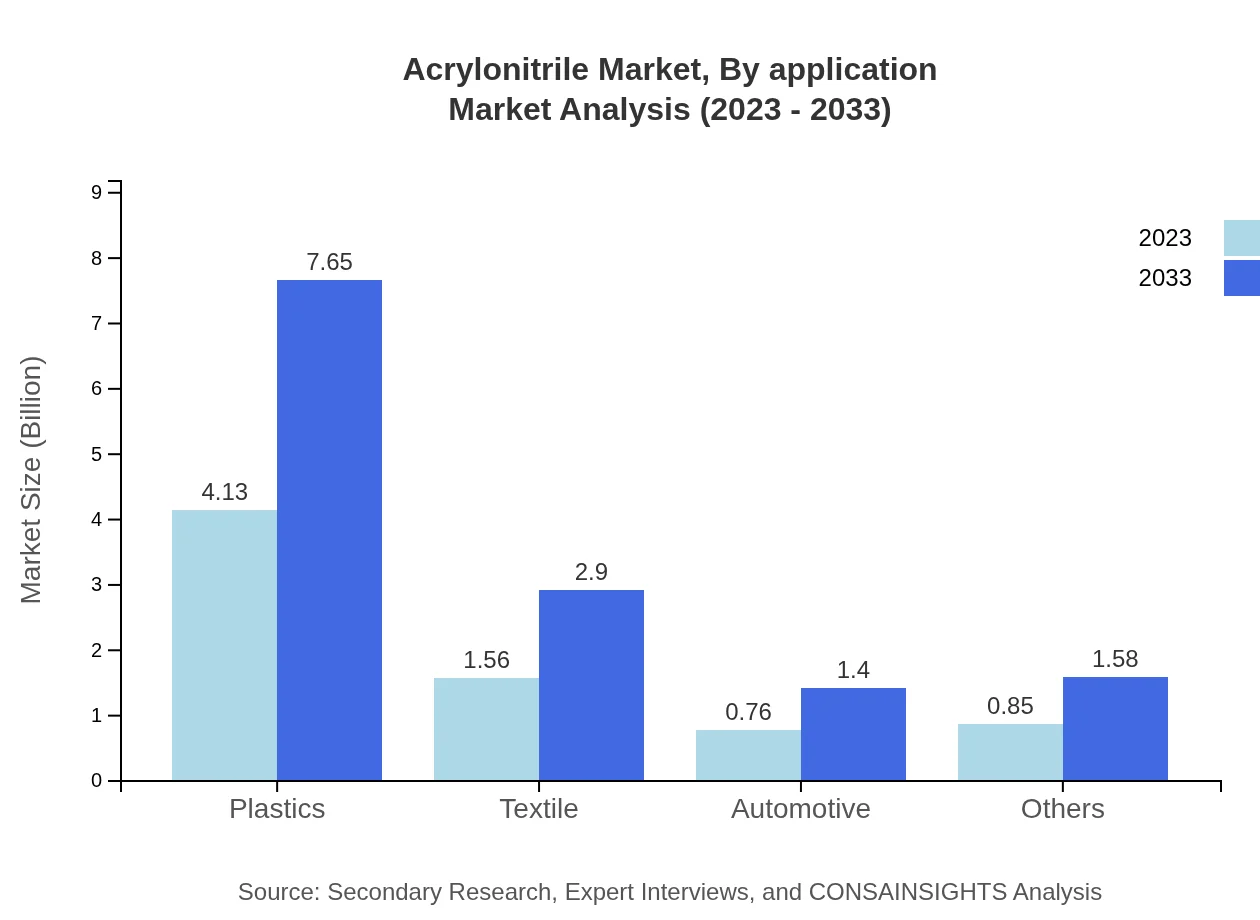

Acrylonitrile Market Analysis By Application

Key applications include textiles, plastics, automotive, and others, with textiles leading the market share. As of 2023, the textile segment accounted for about 21.43% of the total market share. The automotive sector is also notable, expected to expand significantly as electric vehicle production ramps up.

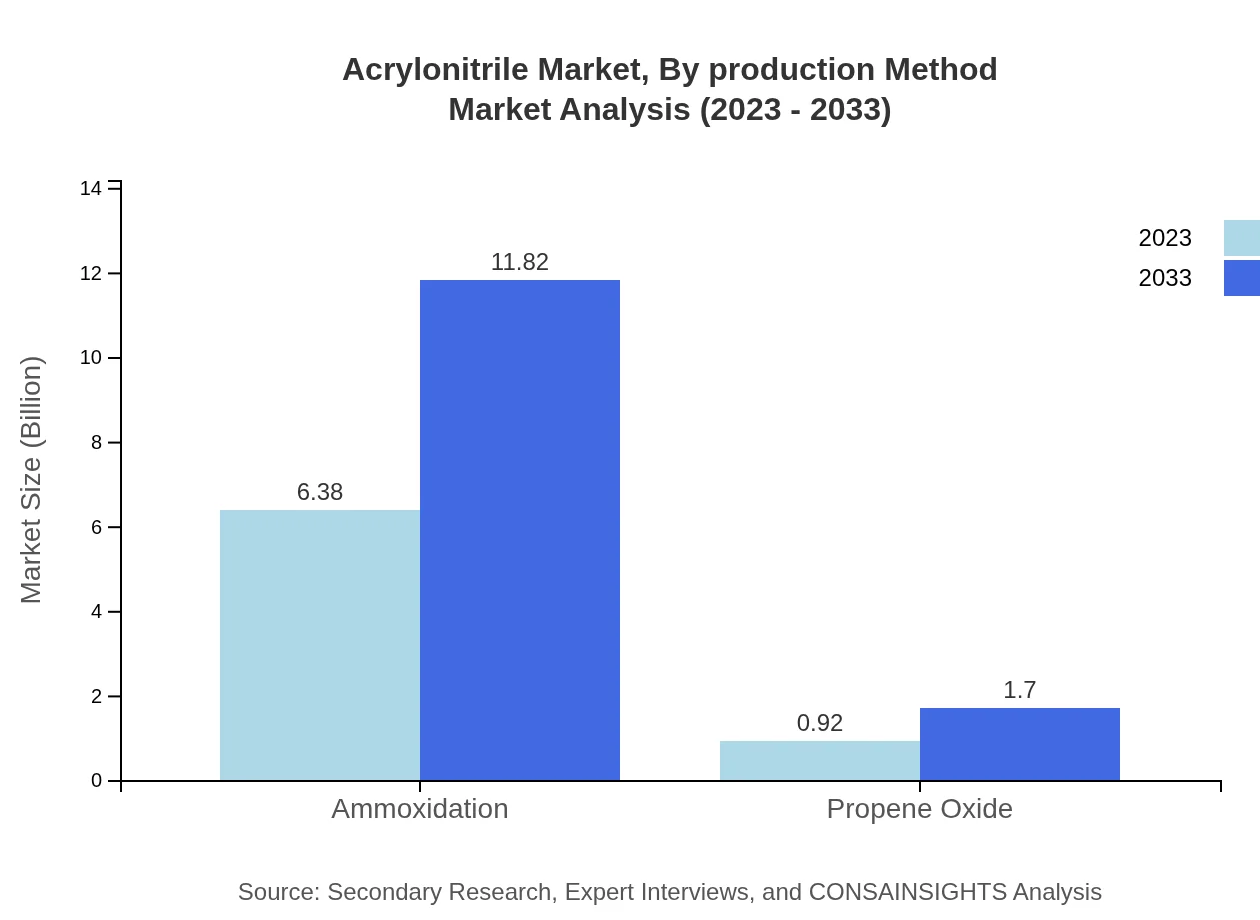

Acrylonitrile Market Analysis By Production Method

The primary production method employed in the manufacture of acrylonitrile is the ammoxidation process. This accounts for approximately 87.41% of the market share and is anticipated to remain the dominant method due to its efficiency and cost-effectiveness compared to other production routes.

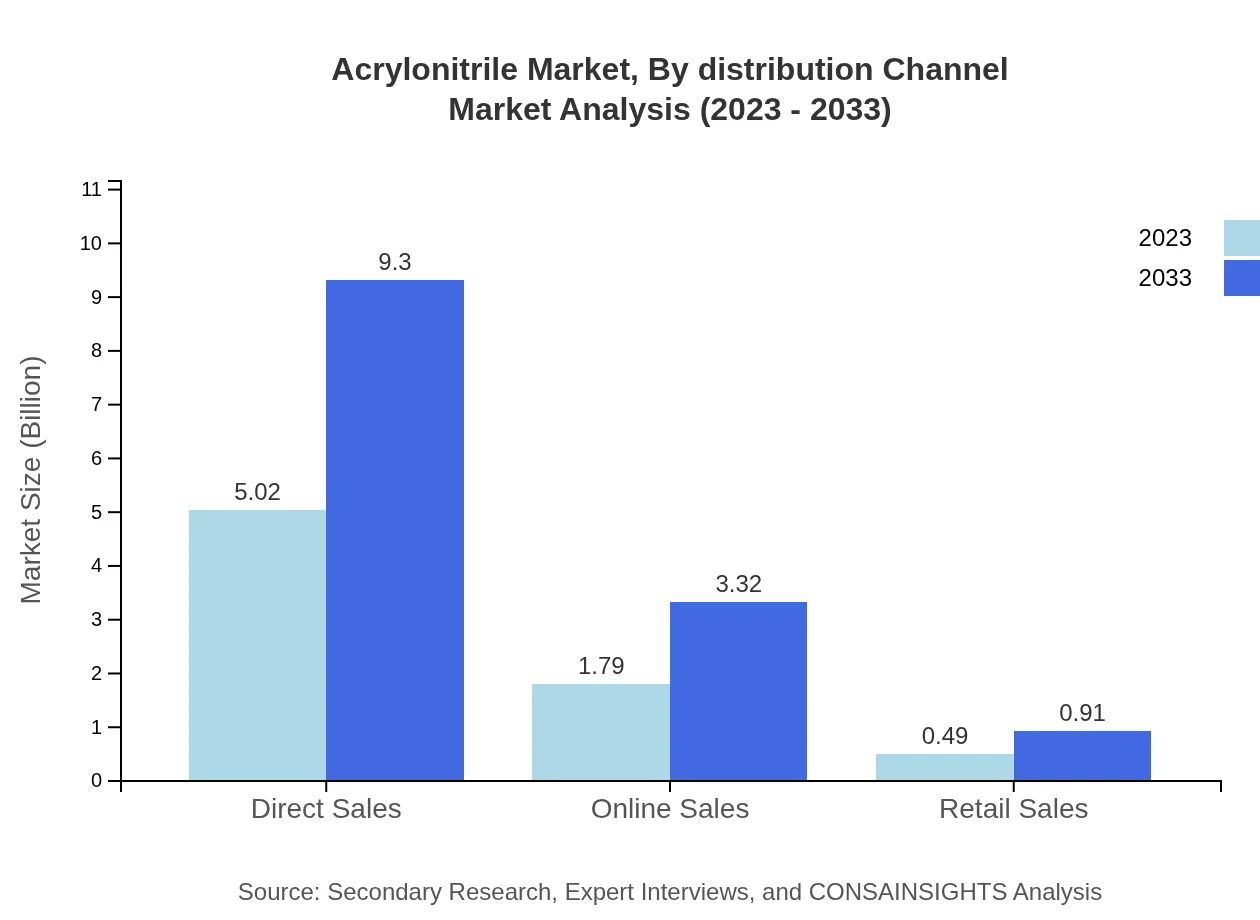

Acrylonitrile Market Analysis By Distribution Channel

Distribution channels for acrylonitrile products include direct sales, online sales, and retail sales. Direct sales dominate with 68.74% market share in 2023, as industries prefer bulk procurement directly from manufacturers.

Acrylonitrile Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Acrylonitrile Industry

INEOS:

A global leader in the chemicals sector, INEOS produces acrylonitrile with a strong focus on R&D and sustainability.SABIC:

SABIC is a multinational corporation involved in petrochemicals and is a significant player in the acrylonitrile market, specializing in advanced materials.Otto Chemie Pvt. Ltd.:

A rising player distinguished for its focus on specialty chemicals and innovative acrylonitrile applications.DOW Chemical:

Known for its diversification in chemical products, DOW Chemical produces acrylonitrile with an emphasis on high-performance applications.We're grateful to work with incredible clients.

FAQs

What is the market size of acrylonitrile?

The acrylonitrile market is valued at approximately $7.3 billion in 2023, with a projected CAGR of 6.2% from 2023 to 2033. This growth trajectory indicates significant demand and expansion in various applications and industries utilizing acrylonitrile.

What are the key market players or companies in the acrylonitrile industry?

Key players in the acrylonitrile market include major chemical manufacturers globally, focusing on production and distribution, innovative application developments, and expansions in emerging markets, further fueling the industry's growth and advancements.

What are the primary factors driving the growth in the acrylonitrile industry?

Growth in the acrylonitrile industry is driven by increasing demand for plastics and fibers in various sectors such as automotive, construction, and textiles, alongside advancements in production technology enhancing efficiency and sustainability.

Which region is the fastest Growing in the acrylonitrile market?

The North American region is the fastest-growing market for acrylonitrile, expected to grow from $2.79 billion in 2023 to $5.17 billion by 2033, showcasing a notable increase driven by industrial and consumer applications.

Does ConsaInsights provide customized market report data for the acrylonitrile industry?

Yes, ConsaInsights offers customized market report data tailored specifically to clients' needs in the acrylonitrile industry, ensuring comprehensive insights aligning with their business strategies and targets.

What deliverables can I expect from this acrylonitrile market research project?

Deliverables from the acrylonitrile market research project include detailed market analysis reports, growth forecasts, competitive landscape assessments, segmented data insights, and tailored recommendations to enhance strategic planning.

What are the market trends of acrylonitrile?

Current market trends in acrylonitrile indicate a strong shift towards sustainable production practices, increased recycling efforts in plastics, and growing applications in advanced materials, catering to diverse industrial needs.