Actuator Systems Market Report

Published Date: 03 February 2026 | Report Code: actuator-systems

Actuator Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Actuator Systems market, including insights on market size, growth forecasts, regional analysis, and industry trends from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

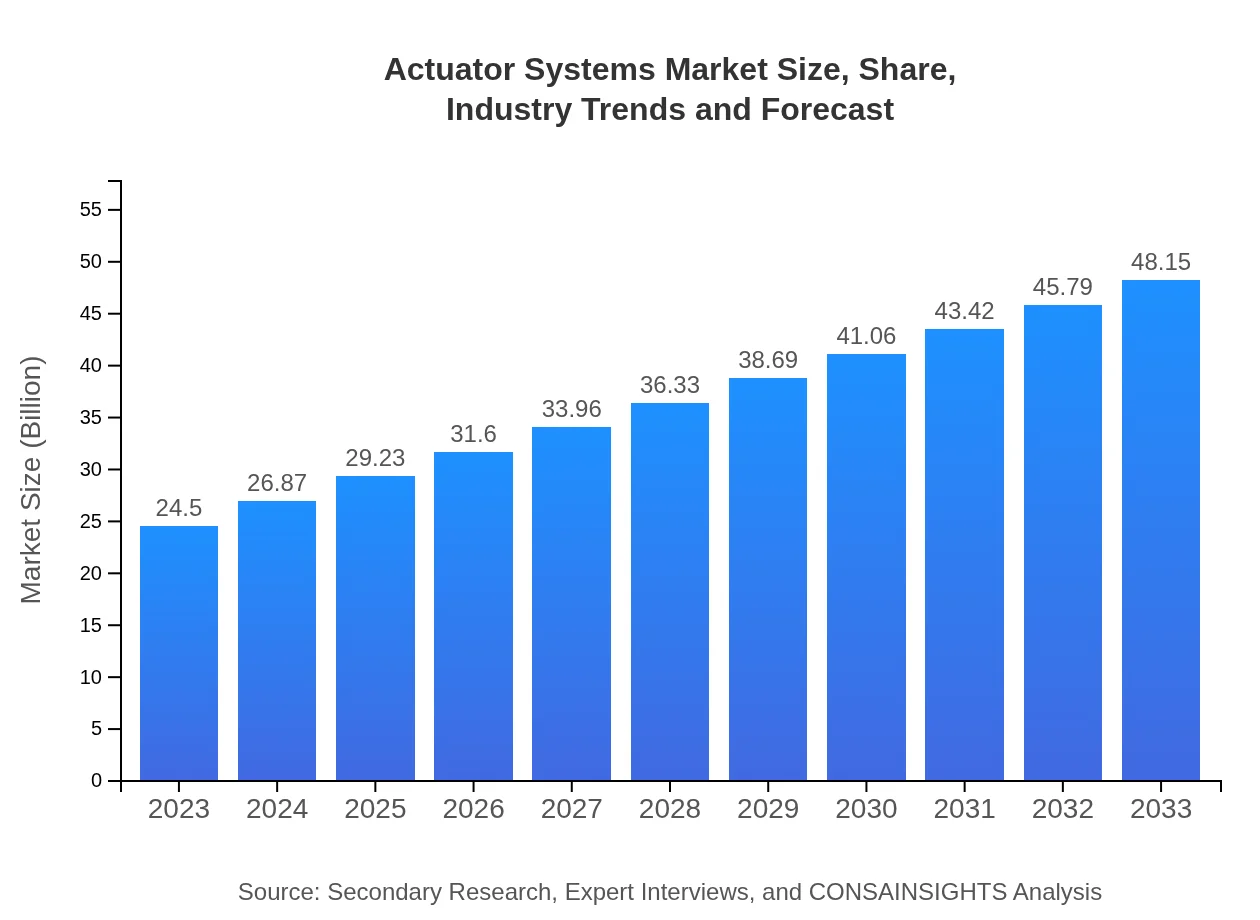

| 2023 Market Size | $24.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $48.15 Billion |

| Top Companies | Parker Hannifin Corporation, Honeywell International, Inc., Schneider Electric, Siemens AG, Moog Inc. |

| Last Modified Date | 03 February 2026 |

Actuator Systems Market Overview

Customize Actuator Systems Market Report market research report

- ✔ Get in-depth analysis of Actuator Systems market size, growth, and forecasts.

- ✔ Understand Actuator Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Actuator Systems

What is the Market Size & CAGR of Actuator Systems market in 2023?

Actuator Systems Industry Analysis

Actuator Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Actuator Systems Market Analysis Report by Region

Europe Actuator Systems Market Report:

In Europe, the market was valued at 6.02 billion USD in 2023, forecasted to grow to 11.84 billion USD by 2033. Strict regulations regarding emissions and energy efficiency are stimulating the demand for advanced actuator systems in automotive and industrial applications.Asia Pacific Actuator Systems Market Report:

In the Asia Pacific region, the market was valued at approximately 5.36 billion USD in 2023, expected to reach 10.54 billion USD by 2033. Rising industrial activities, along with a shift towards automation in countries like China and India, are major growth drivers in this region.North America Actuator Systems Market Report:

North America, with a market size of 8.35 billion USD in 2023, is anticipated to reach 16.42 billion USD by 2033. The region's strong focus on technological innovation and automation within manufacturing sectors is a key factor propelling growth.South America Actuator Systems Market Report:

The South American market, valued at 1.48 billion USD in 2023, is projected to grow to 2.91 billion USD by 2033. This growth can be attributed to increased investments in infrastructure and automotive industries, enhancing demand for actuator systems.Middle East & Africa Actuator Systems Market Report:

The Middle East and Africa market was valued at 3.28 billion USD in 2023, with expectations to reach 6.45 billion USD by 2033. Growth is driven by infrastructure development and an increasing focus on renewable energy solutions, promoting the use of actuator systems.Tell us your focus area and get a customized research report.

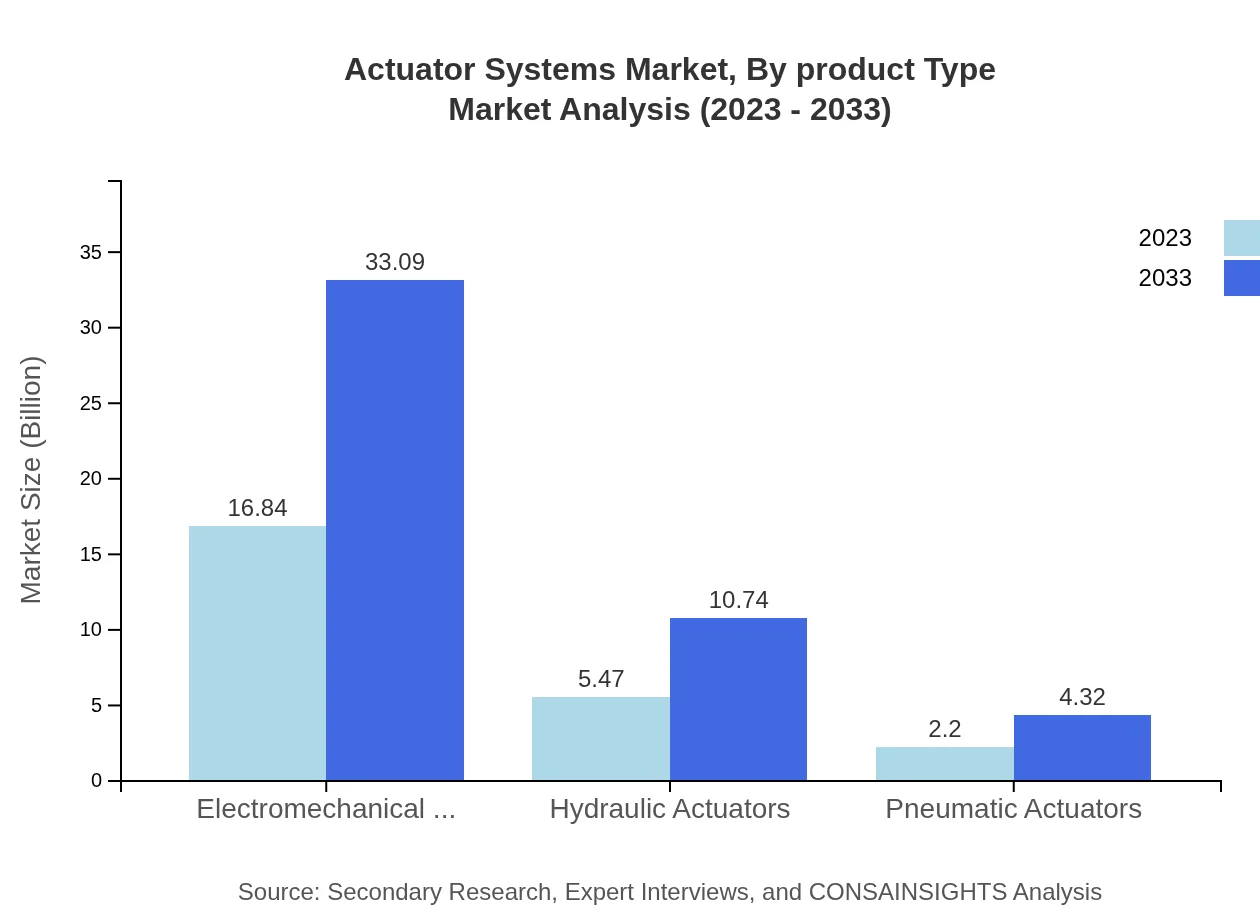

Actuator Systems Market Analysis By Product Type

The Actuator Systems market is segmented by product type into electromechanical, hydraulic, and pneumatic actuators. Electromechanical actuators dominate this segment, with a market size of 16.84 billion USD in 2023, projected to grow to 33.09 billion USD by 2033, holding about 68.72% market share. Hydraulic actuators and pneumatic actuators follow with sizes of 5.47 billion USD and 2.20 billion USD in 2023, respectively. Their sizes are expected to reach 10.74 billion USD and 4.32 billion USD by 2033, showcasing steady growth driven by their respective efficiencies and application versatility.

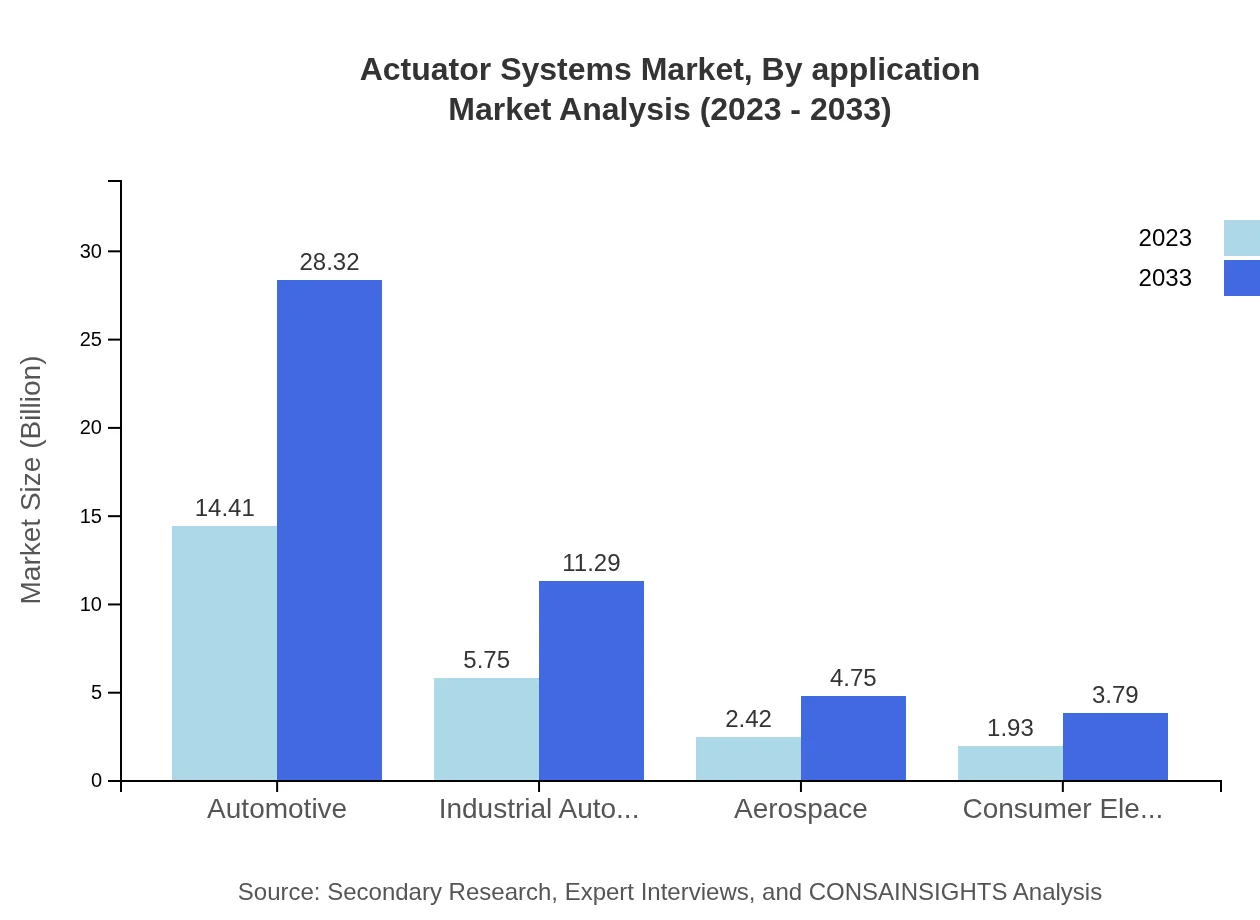

Actuator Systems Market Analysis By Application

Actuator Systems are utilized in multiple applications, significantly in automotive, industrial automation, aerospace, and consumer electronics. In 2023, automotive applications comprise approximately 58.81% market share, valued at 14.41 billion USD, expected to grow to 28.32 billion USD by 2033. Industrial automation applications follow, with a market size of 5.75 billion USD in 2023, projected to reach 11.29 billion USD by 2033, representing a 23.45% share.

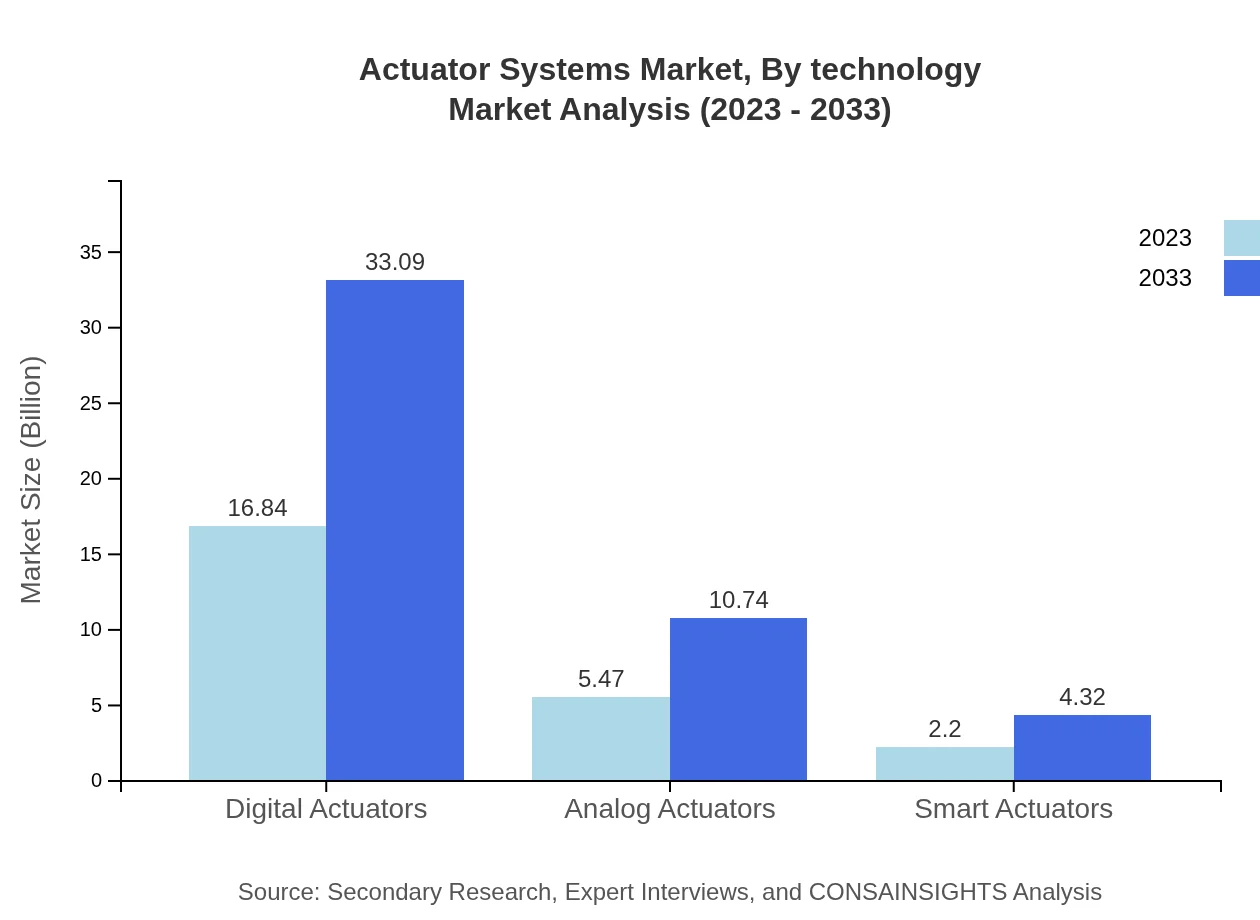

Actuator Systems Market Analysis By Technology

The technology segment includes traditional and smart actuators. Smart actuators, which incorporate IoT technology, are becoming increasingly popular due to their advantages in monitoring and automation capabilities. Traditional actuators still hold a significant market size, but the shift towards smart technology is profoundly influencing the market trends, with smart actuators expected to grow from 2.20 billion USD in 2023 to 4.32 billion USD by 2033.

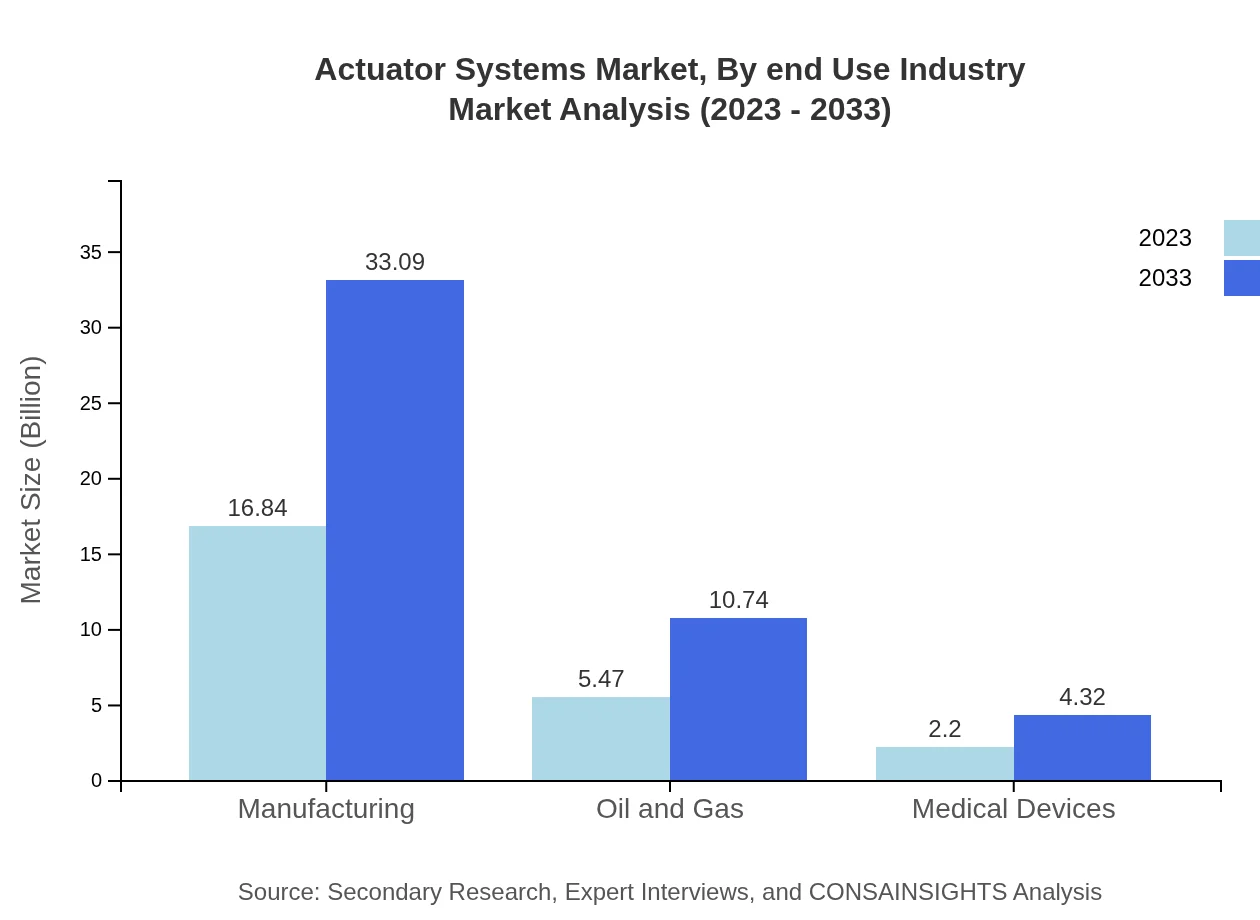

Actuator Systems Market Analysis By End Use Industry

Different end-use industries include automotive, manufacturing, oil and gas, aerospace, medical devices, and consumer electronics. Automotive applications are currently leading the market, while emerging sectors like renewable energy and smart manufacturing are rapidly gaining traction. The manufacturing industry is also a major consumer of actuator systems, accounting for a significant portion of the market share.

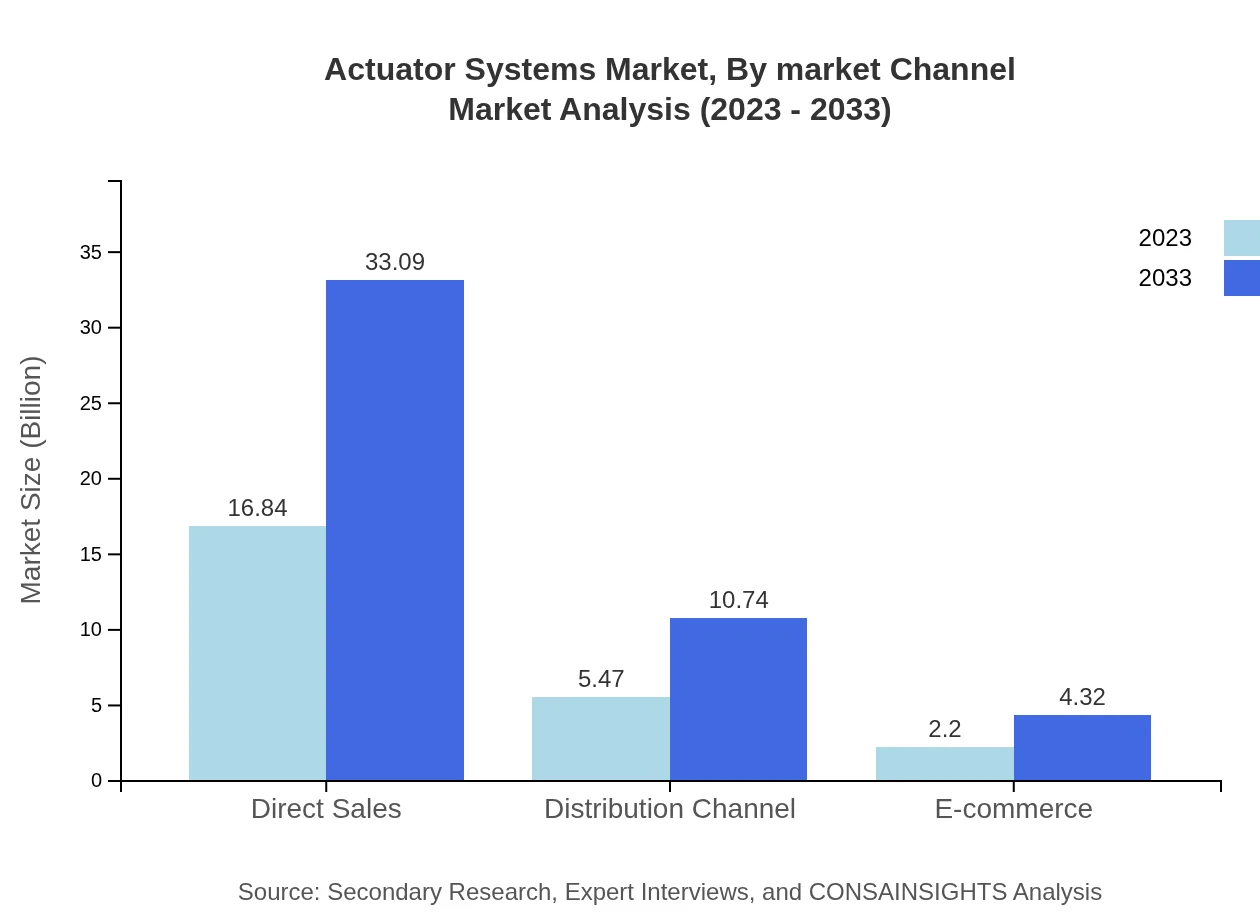

Actuator Systems Market Analysis By Market Channel

The market channels include direct sales, distribution channels, and e-commerce platforms. Direct sales dominate with a 68.72% share, valued at 16.84 billion USD in 2023, expected to rise to 33.09 billion USD by 2033. E-commerce is also making notable inroads, growing from 2.20 billion USD to 4.32 billion USD in the same period.

Actuator Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Actuator Systems Industry

Parker Hannifin Corporation:

A global leader in motion and control technologies, Parker Hannifin offers a broad range of actuator systems for various industries, known for their reliability and innovation.Honeywell International, Inc.:

Honeywell provides advanced actuator solutions, focusing on connectivity and smart technology integration, enhancing automation across numerous applications.Schneider Electric:

Schneider Electric, a leader in digital transformation, offers innovative actuator solutions that promote energy efficiency and automation.Siemens AG:

Siemens is a key player in the actuator systems market, emphasizing automation and control solutions to meet evolving industrial demands.Moog Inc.:

Moog specializes in high-performance actuator systems, primarily serving the aerospace and defense sectors, enhancing operational precision and reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of actuator Systems?

The actuator systems market is valued at $24.5 billion in 2023, with a projected CAGR of 6.8% through 2033, indicating significant growth driven by advancements in automation and control systems.

What are the key market players or companies in this actuator Systems industry?

Key players in the actuator systems market include major companies like Siemens, Honeywell, and Emerson Electric, known for their innovative solutions and substantial market presence, contributing to various sectors including industrial and automotive applications.

What are the primary factors driving the growth in the actuator systems industry?

Growth in the actuator systems market is primarily driven by increasing demand for automation, advancements in technology, and the rising need for efficient energy management in industries such as manufacturing and automotive.

Which region is the fastest Growing in the actuator systems?

North America is the fastest-growing region in the actuator systems market, projected to expand from $8.35 billion in 2023 to $16.42 billion by 2033, highlighting significant investment in smart automation technologies.

Does Consainsights provide customized market report data for the actuator systems industry?

Yes, Consainsights offers customized market report data for the actuator systems industry, allowing businesses to gain insights tailored to their specific needs and strategic goals, facilitating informed decision-making.

What deliverables can I expect from this actuator Systems market research project?

Expect comprehensive deliverables including in-depth market analysis, segmentation insights, competitive landscape assessment, and detailed regional forecasts, enabling strategic planning and market entry strategies.

What are the market trends of actuator systems?

Key trends in the actuator systems market include the rise of digital actuators, integration of smart technology, increased automation in industrial processes, and a push towards environmentally sustainable solutions.