Adhesive Equipment Market Report

Published Date: 22 January 2026 | Report Code: adhesive-equipment

Adhesive Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Adhesive Equipment market from 2023 to 2033, including insights into market size, growth trends, technological advancements, and competitive landscape.

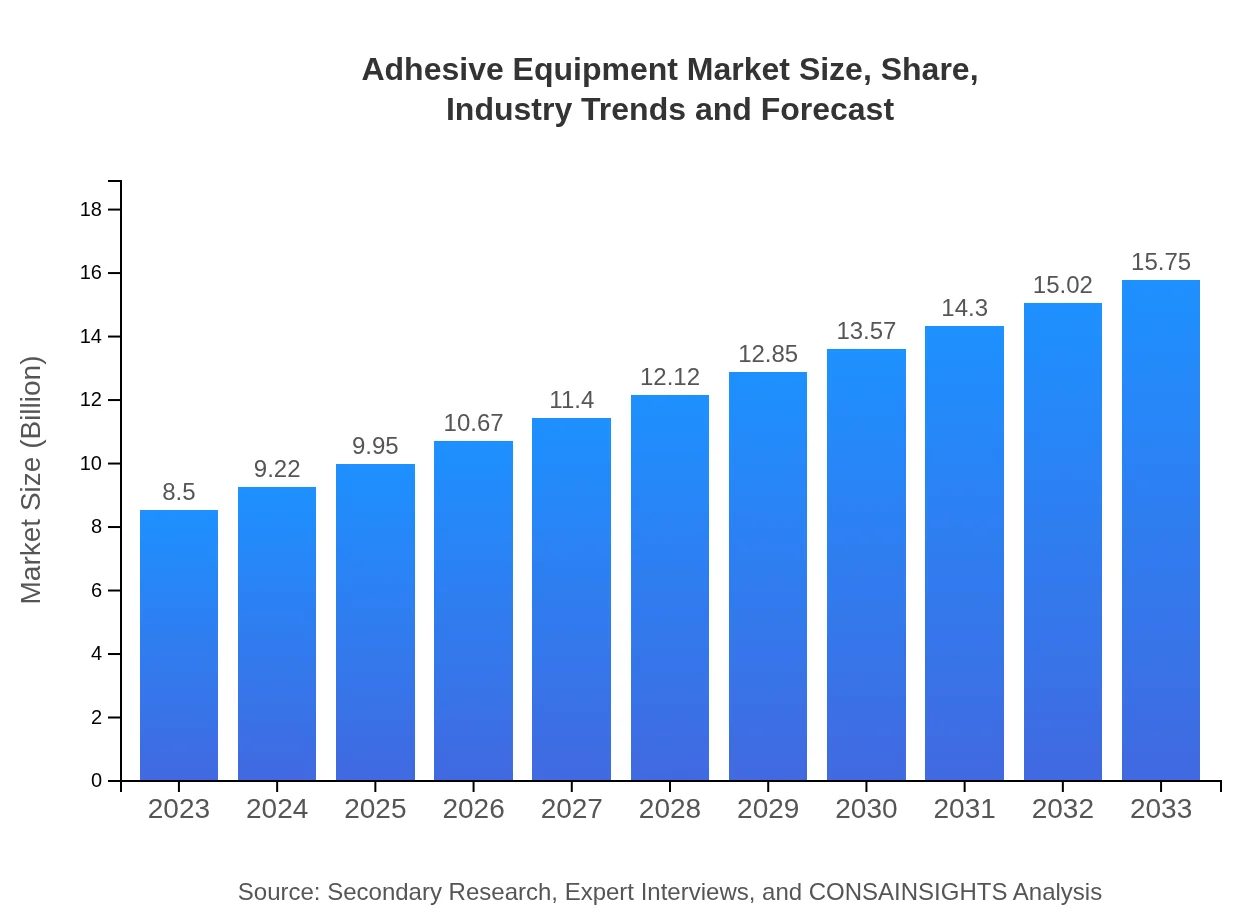

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $8.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $15.75 Billion |

| Top Companies | Henkel AG & Co. KGaA, 3M Company, Sika AG, BASF SE, ITW (Illinois Tool Works) |

| Last Modified Date | 22 January 2026 |

Adhesive Equipment Market Overview

Customize Adhesive Equipment Market Report market research report

- ✔ Get in-depth analysis of Adhesive Equipment market size, growth, and forecasts.

- ✔ Understand Adhesive Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Adhesive Equipment

What is the Market Size & CAGR of Adhesive Equipment market in 2023?

Adhesive Equipment Industry Analysis

Adhesive Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Adhesive Equipment Market Analysis Report by Region

Europe Adhesive Equipment Market Report:

Europe is a prominent market for adhesive equipment, projected to grow from $2.98 billion in 2023 to $5.51 billion by 2033. Increased focus on sustainability and high-quality manufacturing in sectors such as automotive and aerospace contribute to this growth, with stringent regulatory standards further driving innovations.Asia Pacific Adhesive Equipment Market Report:

The Asia Pacific region is expected to be a significant market for adhesive equipment, with growth driven by rapid industrialization and increasing consumer demands in countries like China and India. In 2023, the market size is projected at $1.45 billion, with expectations of reaching $2.69 billion by 2033, showcasing a strong CAGR, fueled by the automotive and electronics sectors.North America Adhesive Equipment Market Report:

North America holds a robust position in the adhesive equipment market, driven by technological advancements and strict regulations governing adhesive formulations. The market is valued at $2.85 billion in 2023 and is expected to grow to $5.28 billion by 2033, buoyed by significant developments in automation and manufacturing processes.South America Adhesive Equipment Market Report:

In South America, the adhesive equipment market is emerging, with a 2023 size estimated at $0.54 billion and a forecast of $1.00 billion by 2033. Brazil and Argentina are key markets, with growth supported by advancements in packaging and automotive sectors.Middle East & Africa Adhesive Equipment Market Report:

The Middle East and Africa market for adhesive equipment is witnessing gradual growth, beginning with a size of $0.68 billion in 2023 and expected to reach $1.26 billion by 2033. The expansion in the construction sector, particularly in Gulf Cooperation Council (GCC) countries, is a key driver of this growth.Tell us your focus area and get a customized research report.

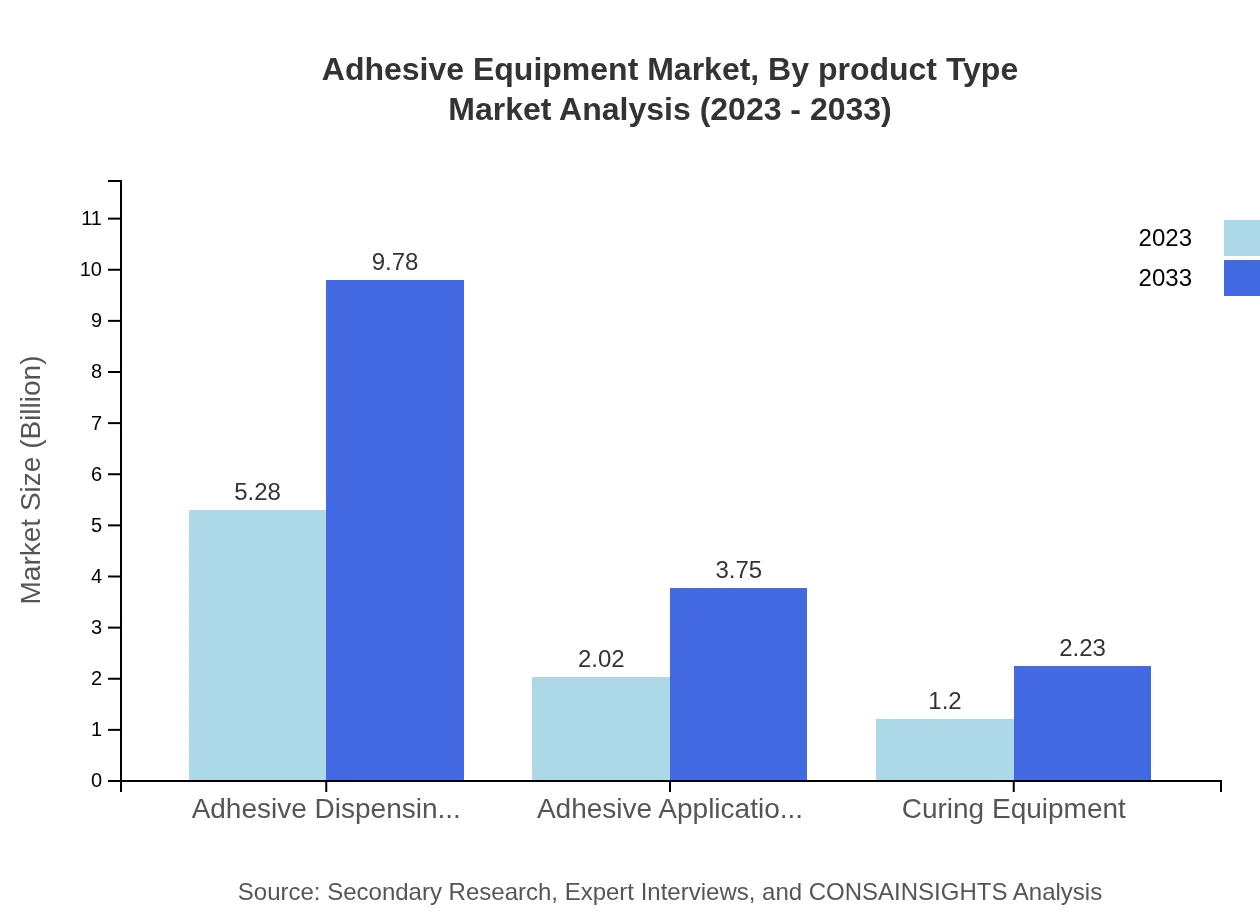

Adhesive Equipment Market Analysis By Product Type

The adhesive equipment market by product type showcases diverse segments including adhesive dispensing equipment, adhesive application systems, and curing equipment. In 2023, adhesive dispensing equipment leads with $5.28 billion, while adhesive application systems and curing equipment generate revenues of $2.02 billion and $1.20 billion, respectively. By 2033, these segments are expected to grow considerably, with adhesive dispensing equipment projected at $9.78 billion, indicating its critical role across various industries.

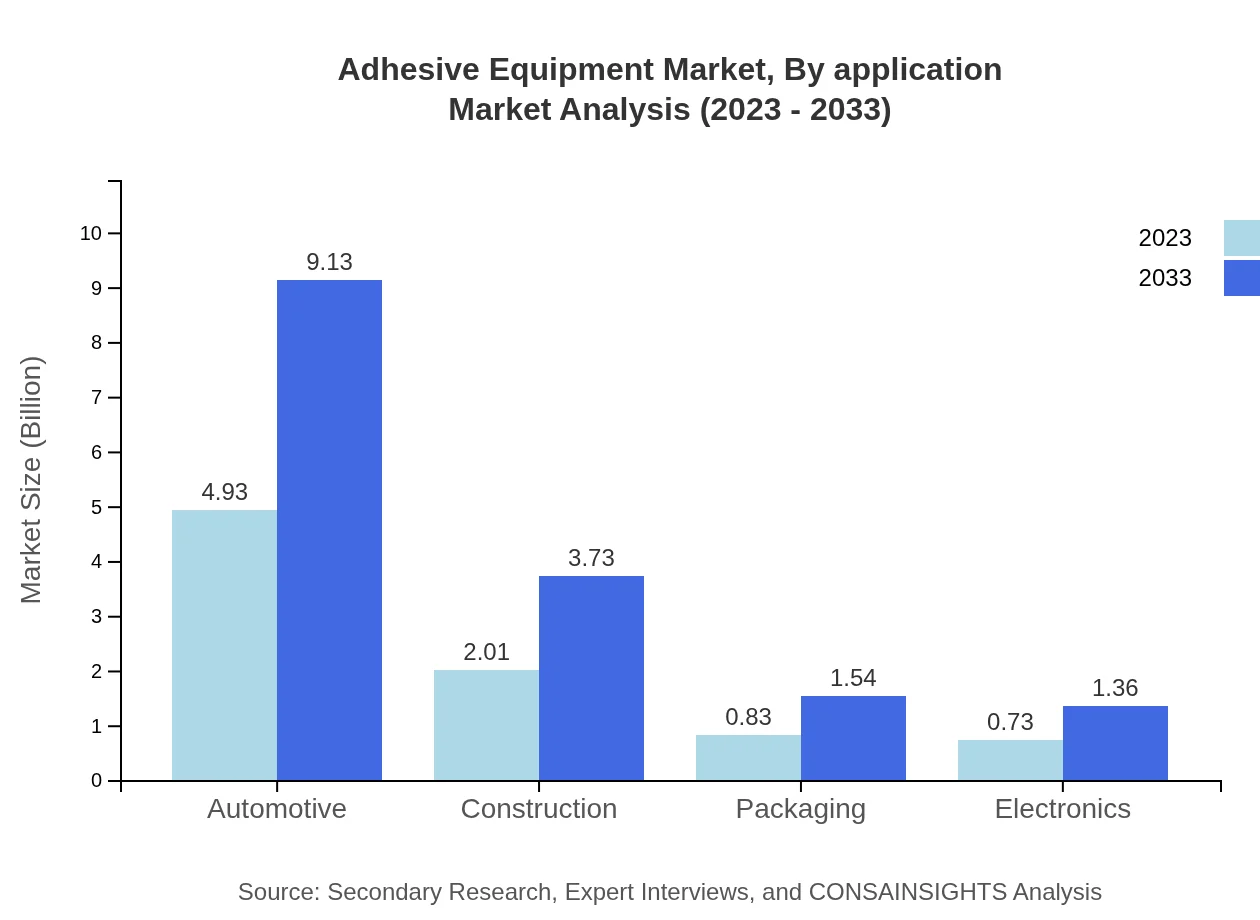

Adhesive Equipment Market Analysis By Application

Applications for adhesive equipment span various industries, including automotive, construction, packaging, and electronics. Automotive applications dominate the segment, valued at $4.93 billion in 2023, due to the increasing demand for lightweight, durable bonding solutions. The construction sector follows with $2.01 billion. By 2033, growth in automotive applications is expected to continue, reaching $9.13 billion, as more automotive manufacturers embrace adhesive solutions to enhance vehicle performance and design.

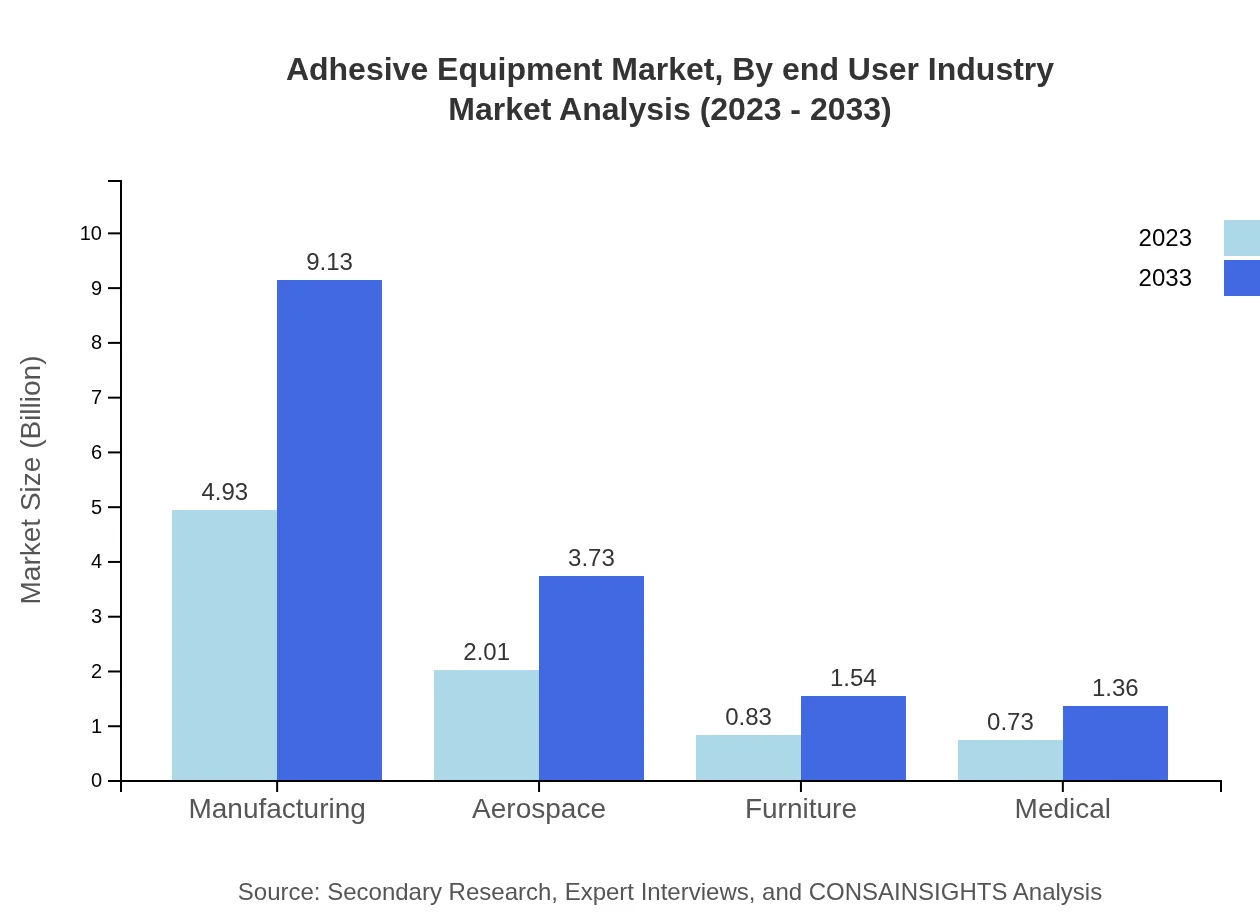

Adhesive Equipment Market Analysis By End User Industry

The adhesive equipment market's end-user industries are vital for growth analysis, encompassing automotive, construction, packaging, electronics, aerospace, and medical sectors. The automotive industry remains the largest consumer, with a market size of $4.93 billion in 2023, driven by the need for precision bonding. The construction and packaging industries, collectively valued at $2.01 billion and $0.83 billion respectively in 2023, also play crucial roles as industries increasingly utilize adhesives for efficient assembly processes and product integrity.

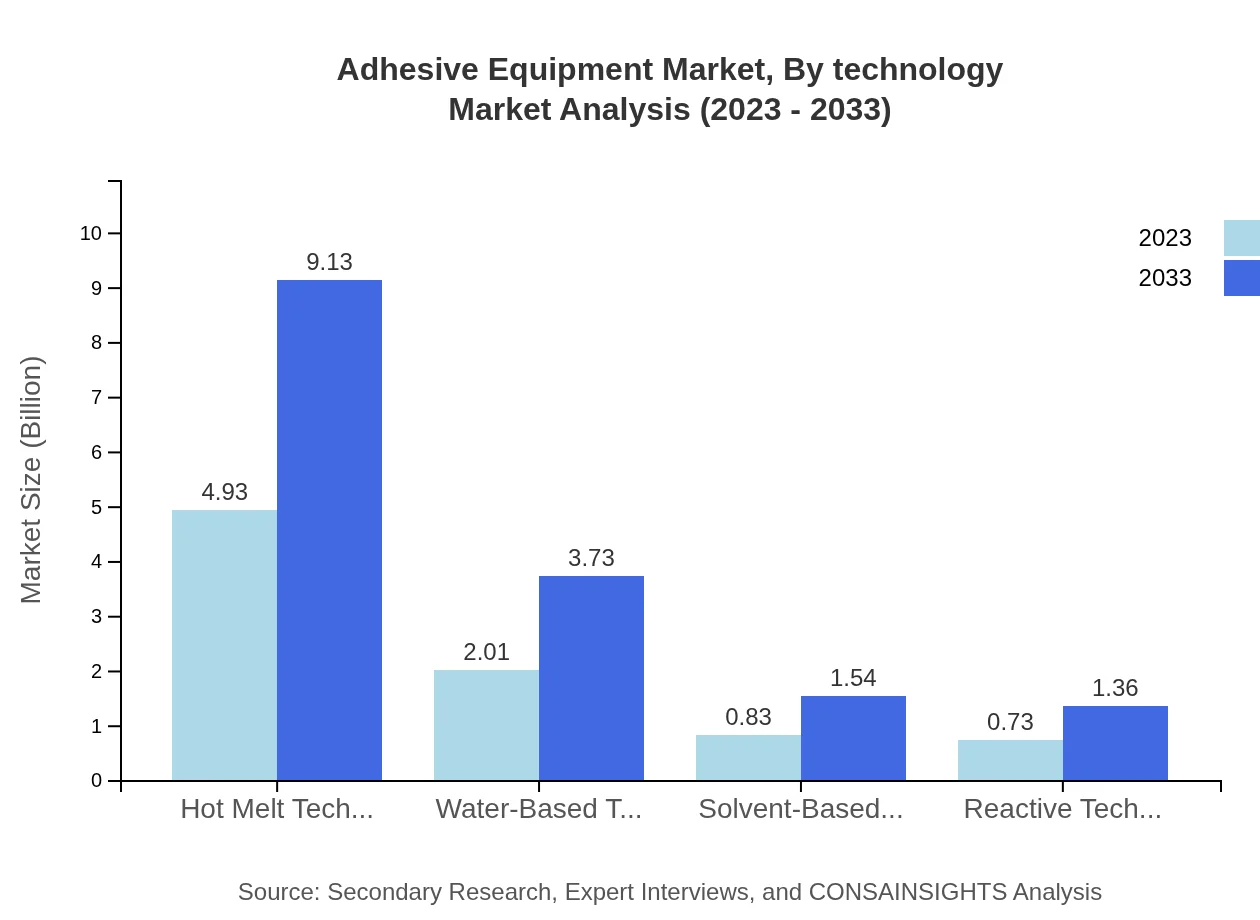

Adhesive Equipment Market Analysis By Technology

Examining the market by technology reveals segments including hot melt, water-based, solvent-based, and reactive adhesives. Hot melt technology dominates, accounting for $4.93 billion in 2023 and anticipated to expand to $9.13 billion by 2033, showcasing its preference for quick-setting applications. Water-based and solvent-based technologies are also significant, valued at $2.01 billion and $0.83 billion respectively in 2023, with reactive technology projected to grow considerably due to increasing demand for durable, long-lasting bonds.

Adhesive Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Adhesive Equipment Industry

Henkel AG & Co. KGaA:

A global leader in adhesives, Henkel offers innovative adhesive solutions for diverse applications, continuously enhancing its product range through R&D investments.3M Company:

3M is renowned for its adhesive technologies, providing high-performance products for industrial, automotive, and consumer markets, emphasizing sustainability and efficiency.Sika AG:

Sika is a leading manufacturer of specialty chemicals, including adhesive solutions for construction and industrial applications, known for their high quality and durability.BASF SE:

BASF provides a comprehensive array of adhesive products developed to meet the needs of various industries, focusing on innovative and environmentally friendly solutions.ITW (Illinois Tool Works):

ITW specializes in industrial adhesives, offering a broad range of products for the automotive, packaging, and construction sectors, backed by technological innovation.We're grateful to work with incredible clients.

FAQs

What is the market size of adhesive Equipment?

The global adhesive equipment market is valued at $8.5 billion in 2023, and it is expected to grow at a CAGR of 6.2%, reaching substantial expansion by 2033.

What are the key market players or companies in this adhesive Equipment industry?

Key players in the adhesive equipment market include manufacturers specializing in adhesive application systems, curing equipment, and dispensing technologies, contributing to advancements and innovations driving market growth.

What are the primary factors driving the growth in the adhesive Equipment industry?

The growth drivers in the adhesive equipment industry include increased demand in automotive, construction, and packaging sectors, as well as technological advancements in adhesive formulations and automated application processes.

Which region is the fastest Growing in the adhesive Equipment?

The Asia-Pacific region is projected as the fastest-growing market in adhesive equipment, with a market size increasing from $1.45 billion in 2023 to $2.69 billion by 2033.

Does ConsaInsights provide customized market report data for the adhesive Equipment industry?

Yes, ConsaInsights offers customized market reports for the adhesive equipment industry to cater to specific client needs, including tailored data analysis and forecasts.

What deliverables can I expect from this adhesive Equipment market research project?

Deliverables typically include comprehensive market analysis reports, covering market size, growth forecasts, competitive landscape, segment data, and regional insights in the adhesive equipment sector.

What are the market trends of adhesive Equipment?

Current market trends in the adhesive equipment industry include increasing automation in application processes, rising sustainability concerns driving eco-friendly adhesives, and innovative product developments catering to diverse industrial applications.