Adhesive Resin Market Report

Published Date: 02 February 2026 | Report Code: adhesive-resin

Adhesive Resin Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Adhesive Resin market, highlighting market dynamics, size forecasts, segment insights, and regional trends for the period between 2023 and 2033.

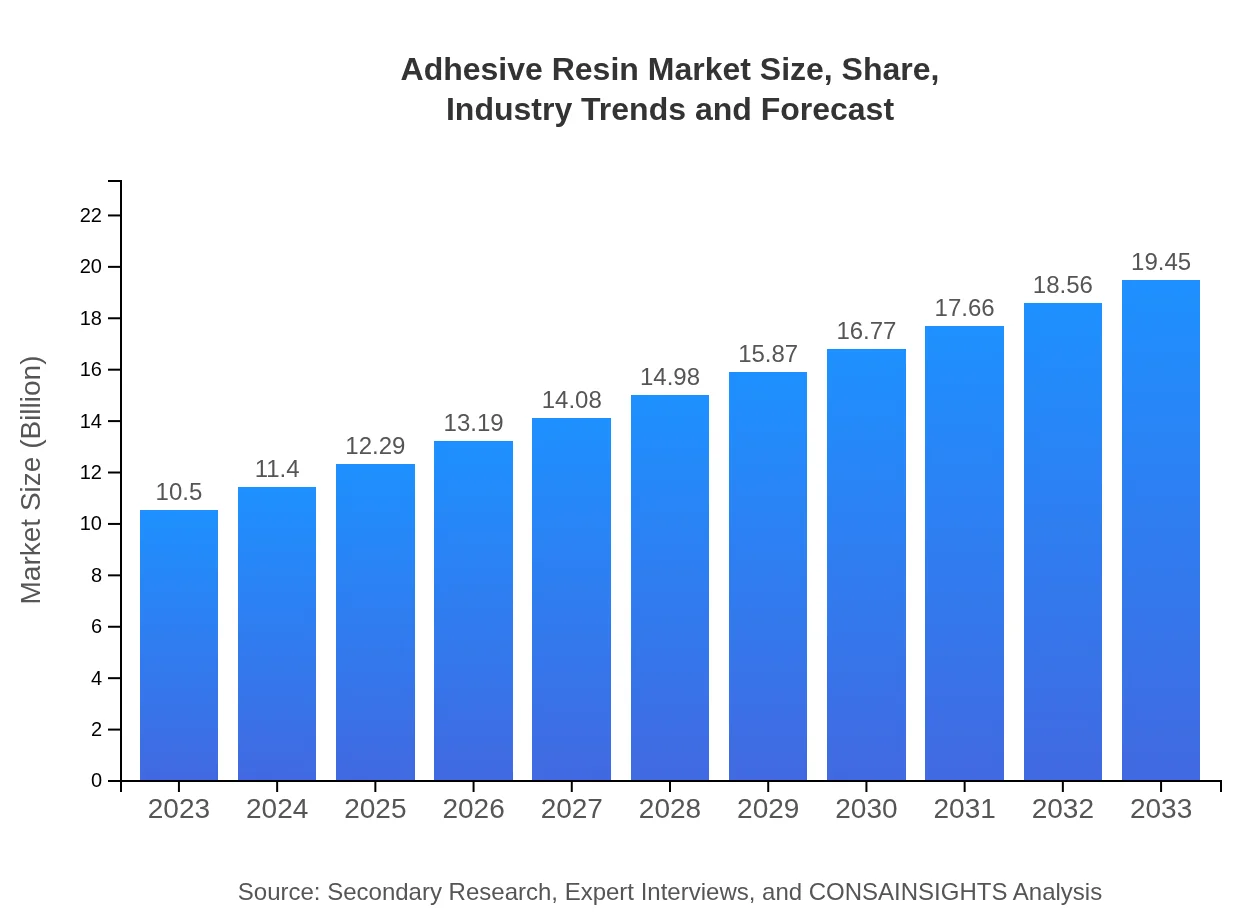

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $19.45 Billion |

| Top Companies | Henkel AG & Co. KGaA, 3M Company, BASF SE, Sika AG, DuPont de Nemours, Inc. |

| Last Modified Date | 02 February 2026 |

Adhesive Resin Market Overview

Customize Adhesive Resin Market Report market research report

- ✔ Get in-depth analysis of Adhesive Resin market size, growth, and forecasts.

- ✔ Understand Adhesive Resin's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Adhesive Resin

What is the Market Size & CAGR of Adhesive Resin market in 2023?

Adhesive Resin Industry Analysis

Adhesive Resin Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Adhesive Resin Market Analysis Report by Region

Europe Adhesive Resin Market Report:

In Europe, the market anticipates growth from $3.25 billion in 2023 to $6.02 billion by 2033. The European adhesive resin sector is driven by stringent regulations favoring sustainable products and the constant evolution of advanced technologies in adhesive formulations.Asia Pacific Adhesive Resin Market Report:

In 2023, the Asia Pacific Adhesive Resin market is valued at approximately $2.07 billion, projected to grow to about $3.84 billion by 2033. Significant growth is driven by rapid industrialization, increased infrastructure projects, and rising demand for packaging materials in countries like China and India.North America Adhesive Resin Market Report:

North America represents a robust market, starting at $3.55 billion in 2023 and anticipated to reach $6.58 billion by 2033. The region's growth is primarily led by advanced manufacturing sectors and the rising adoption of eco-friendly materials across various industries.South America Adhesive Resin Market Report:

The South American market for Adhesive Resins is expected to expand from about $0.95 billion in 2023 to $1.77 billion by 2033. The growth is fueled by the construction sector's recovery post-pandemic and increasing automotive manufacturing activities in the region.Middle East & Africa Adhesive Resin Market Report:

In the Middle East and Africa, the Adhesive Resin market is valued at $0.68 billion in 2023 and is projected at $1.25 billion by 2033. The growth is witnessed due to infrastructural developments, particularly in the Gulf region, accompanied by increased demand in the automotive sector.Tell us your focus area and get a customized research report.

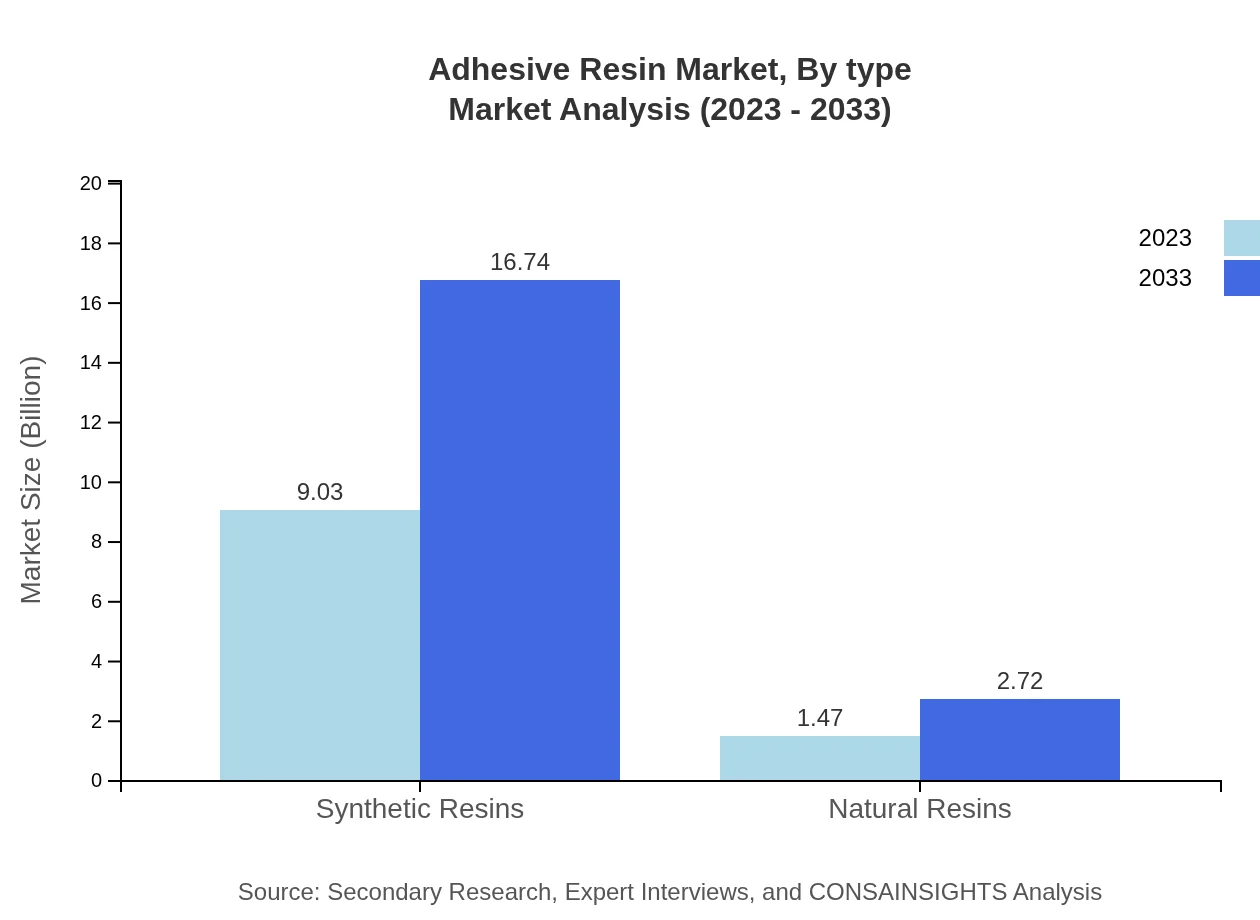

Adhesive Resin Market Analysis By Type

Synthetic resins dominate the Adhesive Resin market in terms of size and share, with a market value of $9.03 billion in 2023 expected to reach $16.74 billion by 2033. Natural resins, although smaller at $1.47 billion in 2023, are projected to grow to $2.72 billion, benefiting from shifts toward sustainable solutions.

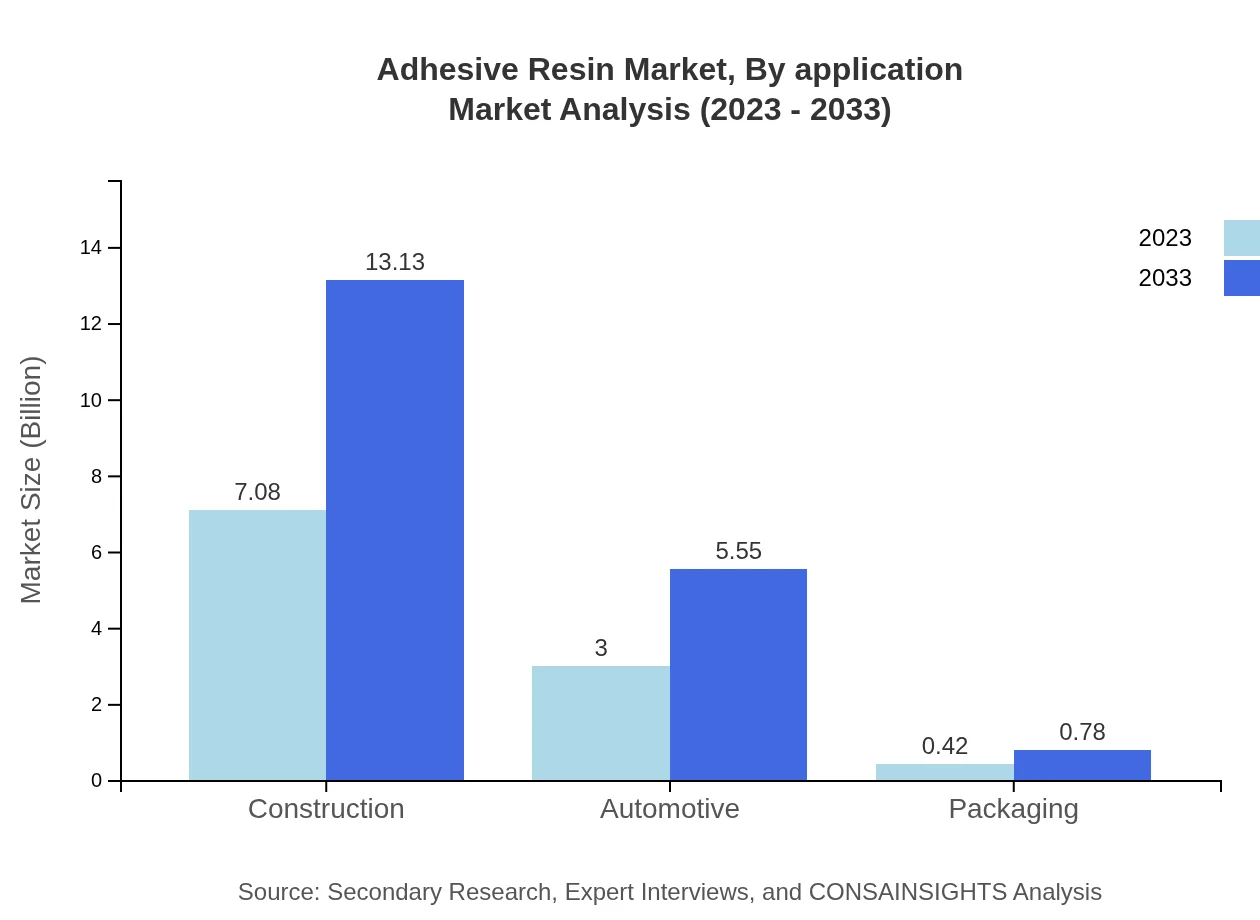

Adhesive Resin Market Analysis By Application

The construction application holds the largest market share, valued at $7.08 billion in 2023 and accelerating to $13.13 billion by 2033. The automotive segment, valued at $3.0 billion in 2023, is expected to grow to $5.55 billion, reflecting the sector’s innovation and demand for advanced adhesives.

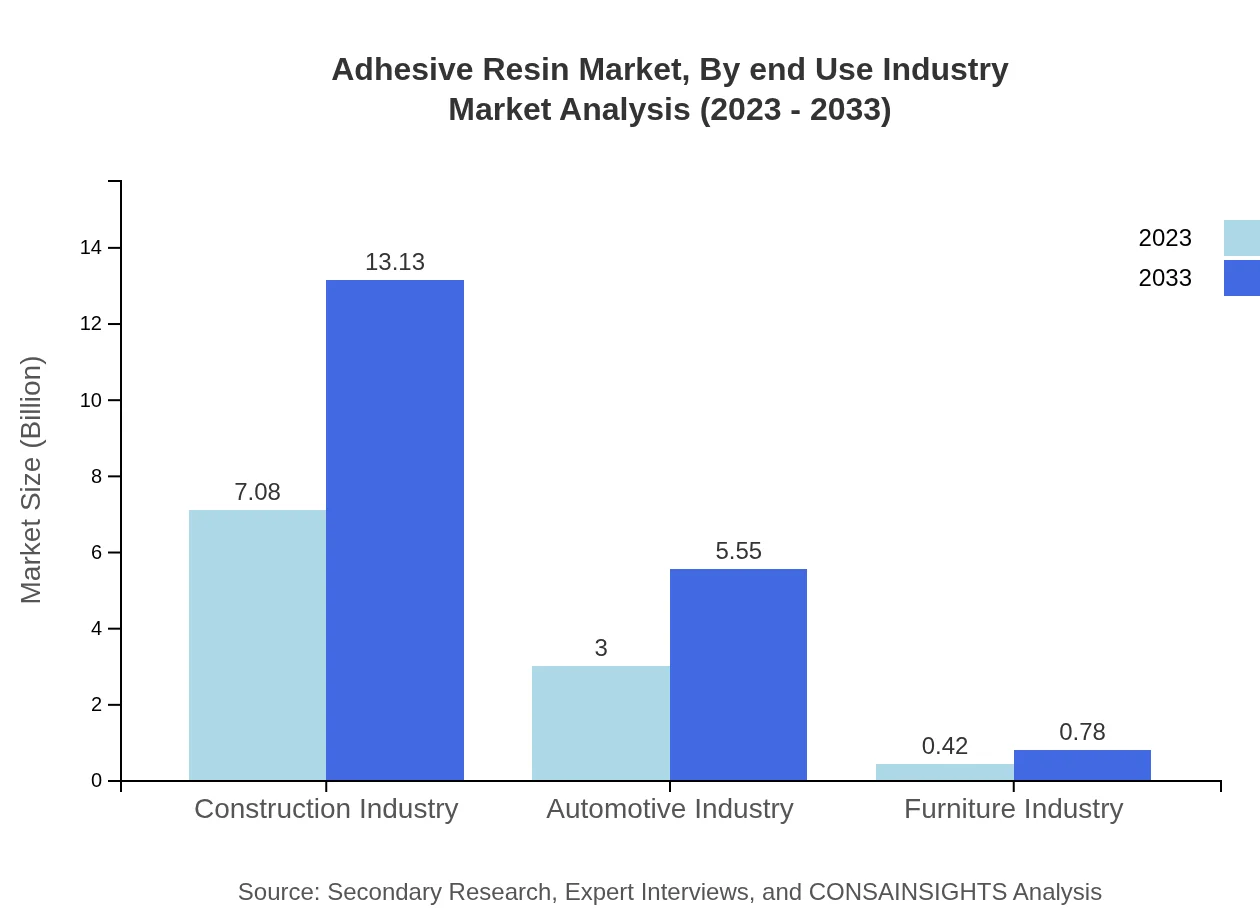

Adhesive Resin Market Analysis By End Use Industry

Focusing on end-use industries, the construction industry represents a significant portion, making up 67.47% of the total market share in 2023. The automotive industry contributes around 28.53%, indicating robust growth prospects as electric vehicles gain traction.

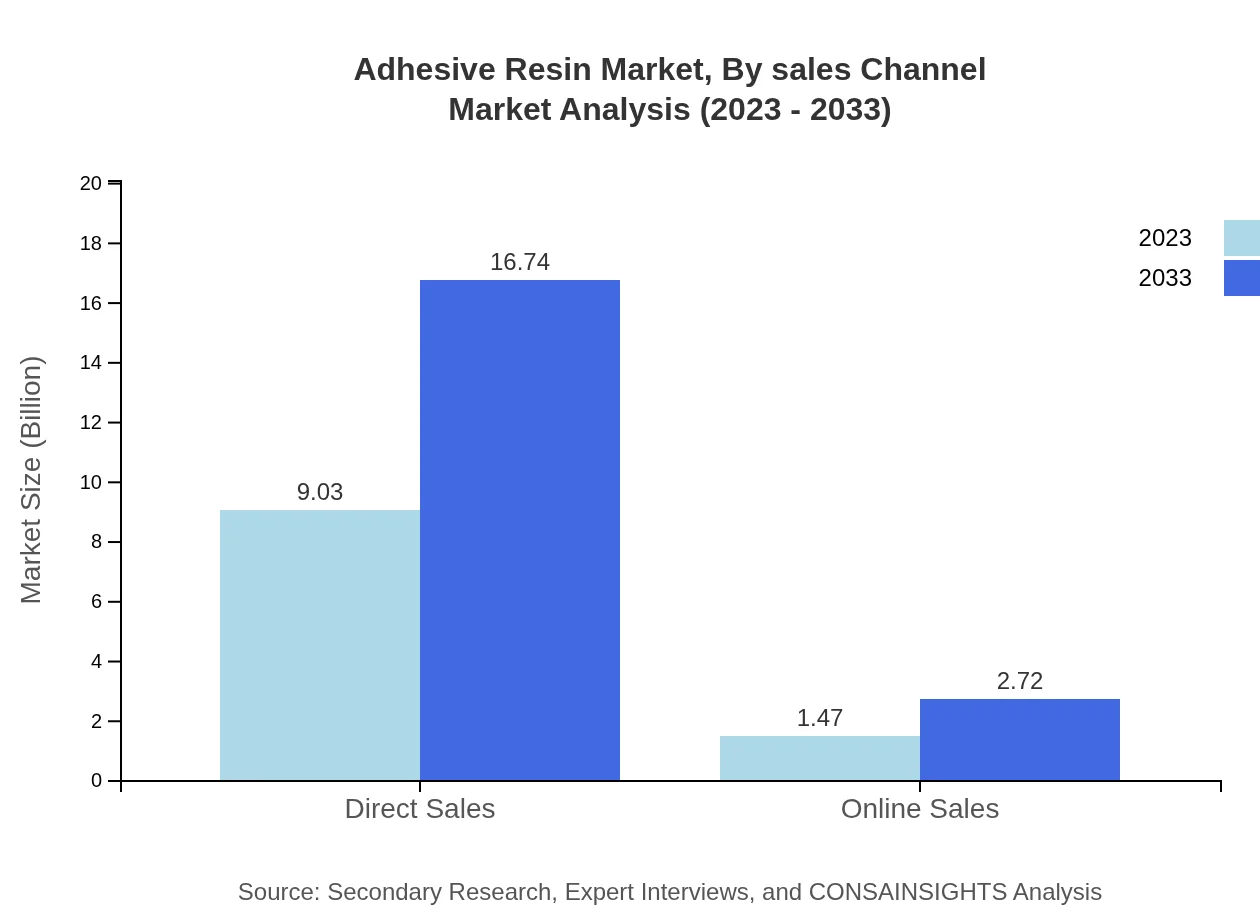

Adhesive Resin Market Analysis By Sales Channel

Direct sales control a significant share of the market, valued at $9.03 billion in 2023 and projected to mirror growth to $16.74 billion by 2033. Online sales, while smaller at $1.47 billion, are anticipated to increase to $2.72 billion as digital platforms gain more prevalence.

Adhesive Resin Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Adhesive Resin Industry

Henkel AG & Co. KGaA:

A global leader in adhesives, sealants, and surface treatments, Henkel is known for its innovation in adhesive technologies catering to the automotive, industrial, and consumer markets.3M Company:

3M is recognized for its vast array of adhesive solutions, advancing technologies across various sectors including healthcare, automotive, and electronics.BASF SE:

BASF is a prominent player offering high-performance resins and adhesive solutions, focusing on sustainable products and innovations in polymer chemistry.Sika AG:

Sika specializes in construction materials, including adhesives and sealants, with a strong emphasis on providing solutions that enhance building performance.DuPont de Nemours, Inc.:

DuPont’s diverse portfolio includes advanced adhesives and resins with applications in automotive, electronics, and construction sectors, emphasizing R&D innovation.We're grateful to work with incredible clients.

FAQs

What is the market size of adhesive Resin?

The adhesive resin market size is valued at approximately $10.5 billion in 2023, with a projected CAGR of 6.2%. This growth indicates a strong demand in diverse applications across various industries.

What are the key market players or companies in the adhesive Resin industry?

Key players in the adhesive resin industry include companies like Henkel AG & Co. KGaA, 3M Company, BASF SE, and H.B. Fuller. These companies drive innovation and market growth through their extensive product portfolios.

What are the primary factors driving the growth in the adhesive Resin industry?

The growth in the adhesive resin industry is driven by increasing demand from construction, automotive, and packaging sectors. Innovations in adhesive technology and a shift towards eco-friendly resins further contribute to market expansion.

Which region is the fastest Growing in the adhesive Resin?

The fastest-growing region for adhesive resins is projected to be North America, with market growth from $3.55 billion in 2023 to $6.58 billion by 2033, indicating a growing industrial application and infrastructure expansion.

Does ConsaInsights provide customized market report data for the adhesive Resin industry?

Yes, ConsaInsights offers customized market report data, tailored to meet specific research needs, including detailed insights into market size, trends, and competitive analysis within the adhesive resin industry.

What deliverables can I expect from this adhesive Resin market research project?

Deliverables from the adhesive-resin market research project include comprehensive reports, data on market size, segmentation analysis, trends, and forecasts, along with actionable insights for strategic decision-making.

What are the market trends of adhesive Resin?

Current market trends in adhesive resins include a rise in synthetic resin applications, sustainability drives, growing online sales channels, and advancements in adhesive manufacturing technologies that enhance performance.