Adhesive Tapes Market Report

Published Date: 02 February 2026 | Report Code: adhesive-tapes

Adhesive Tapes Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Adhesive Tapes market, covering current trends, market dynamics, global leaders, and future forecasts from 2023 to 2033. The insights provided aim to aid stakeholders in making informed decisions.

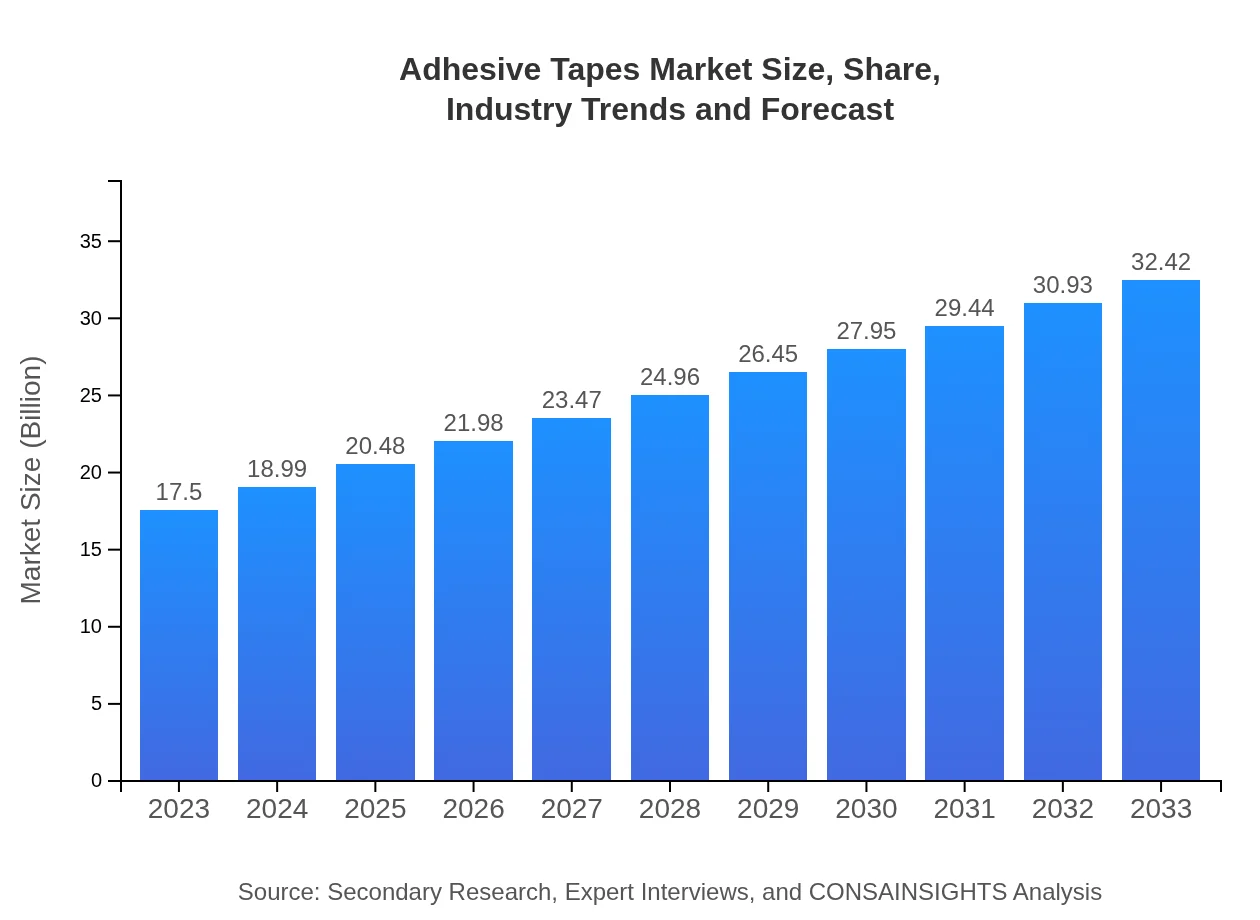

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $17.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $32.42 Billion |

| Top Companies | 3M Company, Avery Dennison Corporation, Henkel AG & Co., Tesa SE, Nitto Denko Corporation |

| Last Modified Date | 02 February 2026 |

Adhesive Tapes Market Overview

Customize Adhesive Tapes Market Report market research report

- ✔ Get in-depth analysis of Adhesive Tapes market size, growth, and forecasts.

- ✔ Understand Adhesive Tapes's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Adhesive Tapes

What is the Market Size & CAGR of Adhesive Tapes market in 2023?

Adhesive Tapes Industry Analysis

Adhesive Tapes Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Adhesive Tapes Market Analysis Report by Region

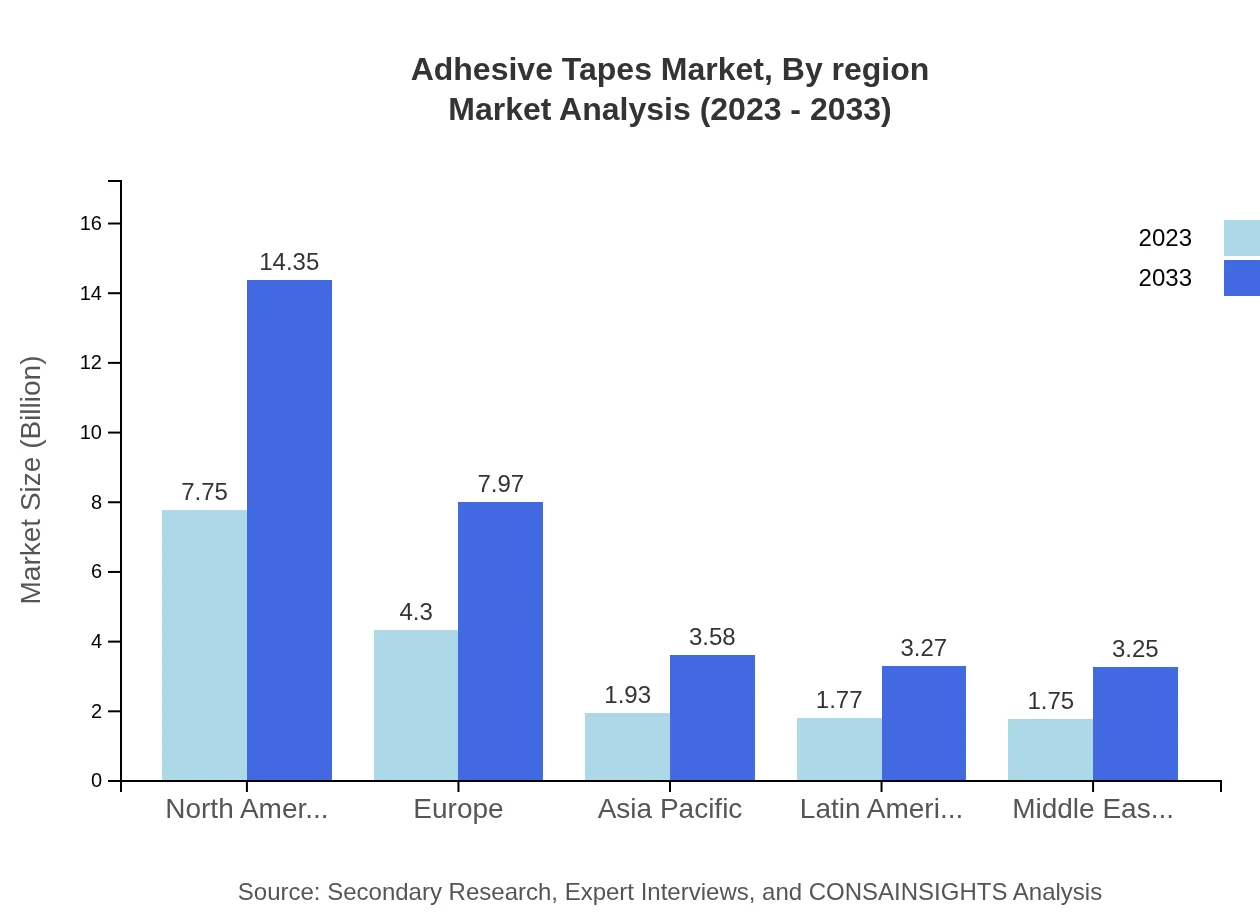

Europe Adhesive Tapes Market Report:

In Europe, the adhesive tapes market is valued at $5.77 billion in 2023, expected to reach $10.69 billion by 2033. The shift towards sustainable products and the stringent regulations surrounding packaging are major factors contributing to this growth.Asia Pacific Adhesive Tapes Market Report:

In 2023, the Asia Pacific adhesive tapes market is valued at $3.28 billion and is expected to grow to $6.07 billion by 2033, marking a significant opportunity driven by expanding manufacturing capabilities and increasing demand in the automotive and electronics sectors.North America Adhesive Tapes Market Report:

North America represents one of the largest adhesive tapes markets, with a valuation of $6.14 billion in 2023 projected to expand to $11.38 billion by 2033. High demand in automotive and healthcare sectors, coupled with a preference for advanced adhesive solutions, fuels this growth.South America Adhesive Tapes Market Report:

The South American market is relatively small, with a valuation of $0.22 billion in 2023, projected to reach $0.41 billion by 2033. Increased construction and packaging activities, alongside adoption of technological advancements, are key growth drivers.Middle East & Africa Adhesive Tapes Market Report:

The Middle East and Africa adhesive tapes market stands at $2.09 billion in 2023, projected to grow to $3.87 billion by 2033. Infrastructure development and increased industrial activity in this region are significant propelling forces for market growth.Tell us your focus area and get a customized research report.

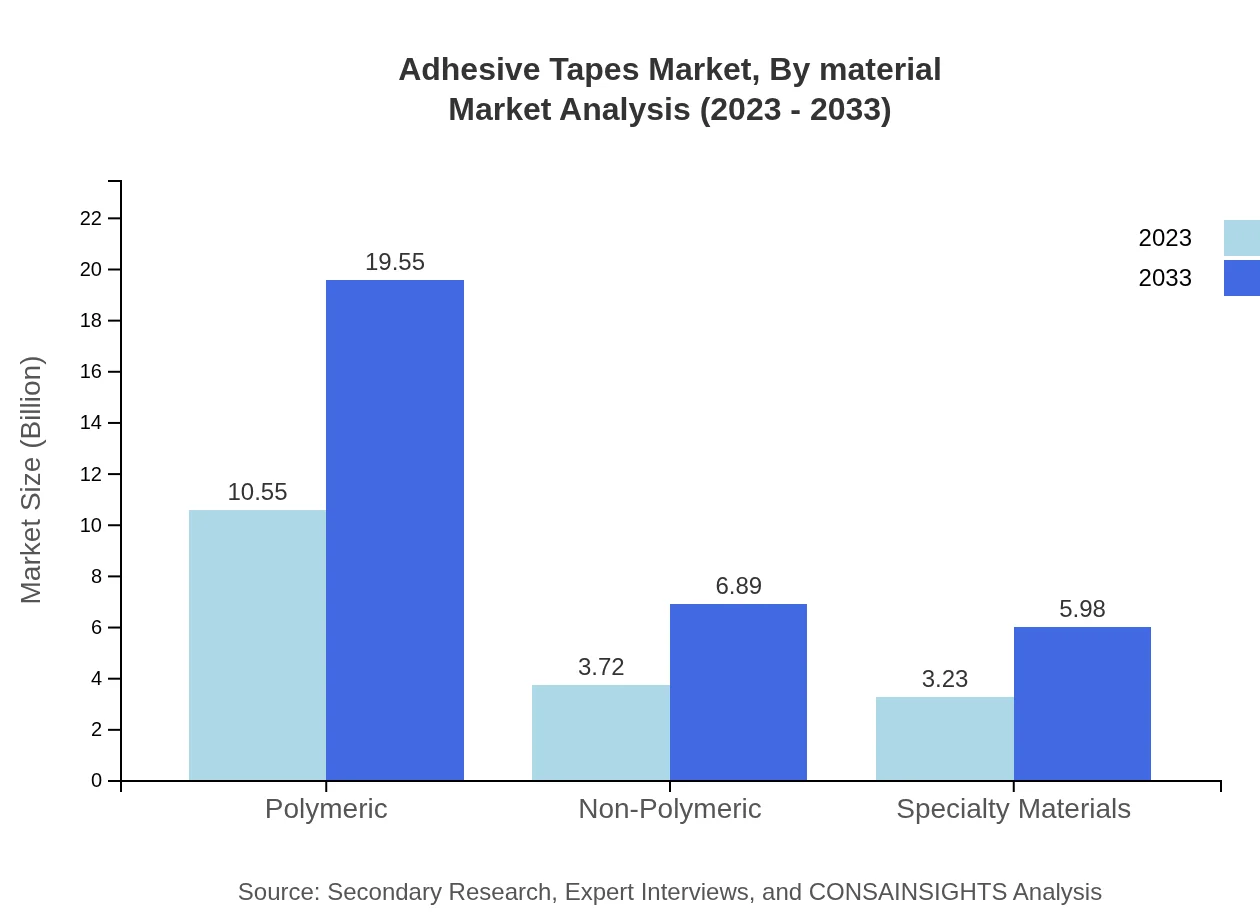

Adhesive Tapes Market Analysis By Material

The adhesive tapes market by material is primarily categorized into polymeric, non-polymeric, and specialty materials. In 2023, polymeric materials dominate the market, holding a substantial share due to their versatility and superior bonding capabilities. The trend is expected to continue, with polymeric tapes projected to reach a size of $19.55 billion by 2033.

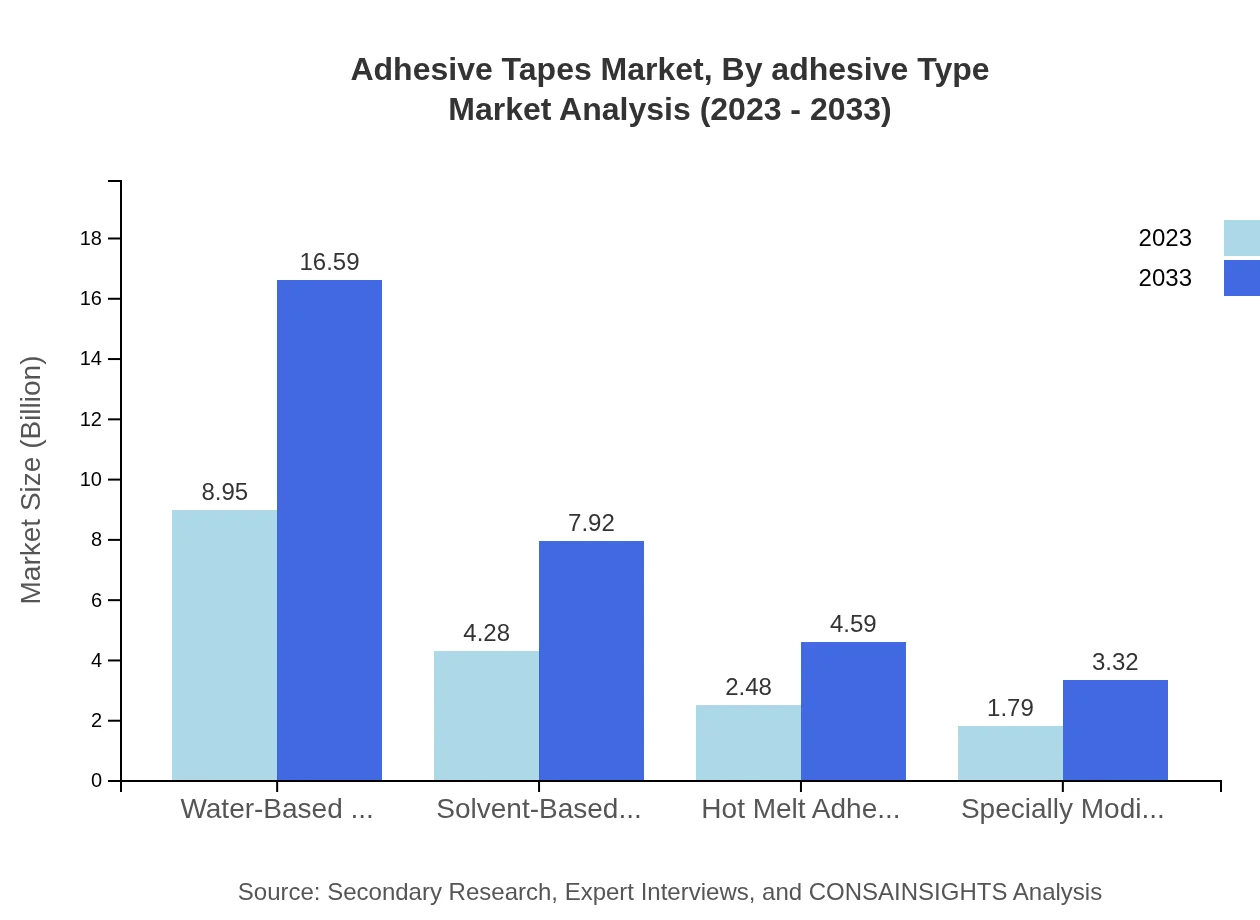

Adhesive Tapes Market Analysis By Adhesive Type

By adhesive type, the market is segmented into water-based, solvent-based, hot melt, and specially modified adhesives. Water-based adhesives account for a significant share, valued at $8.95 billion in 2023 and forecasted to grow to $16.59 billion by 2033, underlining the shift towards eco-friendly solutions.

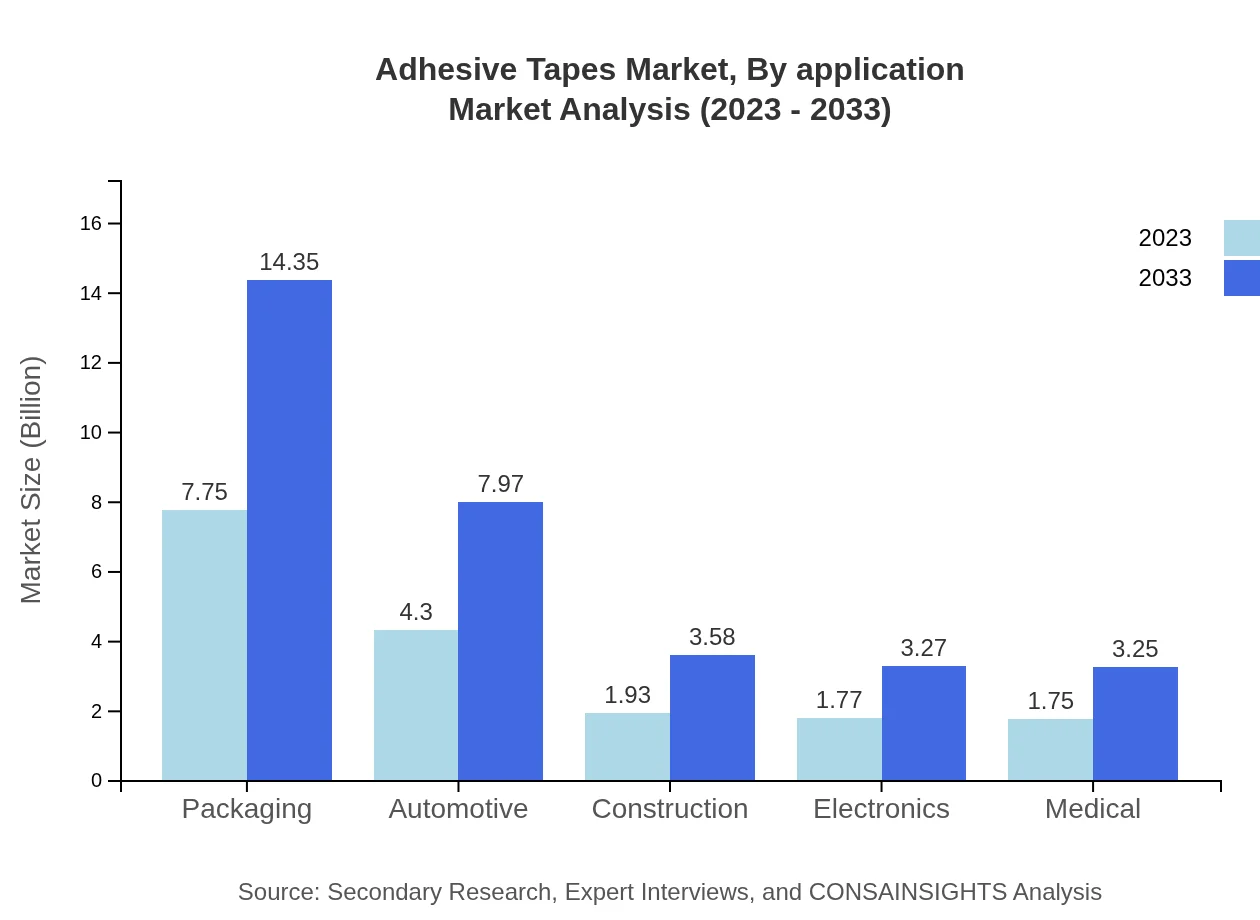

Adhesive Tapes Market Analysis By Application

The application of adhesive tapes is categorized into packaging, automotive, electronics, construction, and medical sectors. In 2023, packaging accounts for the largest segment valued at $7.75 billion, expected to reach $14.35 billion by 2033, driven by increased retail and shipping needs.

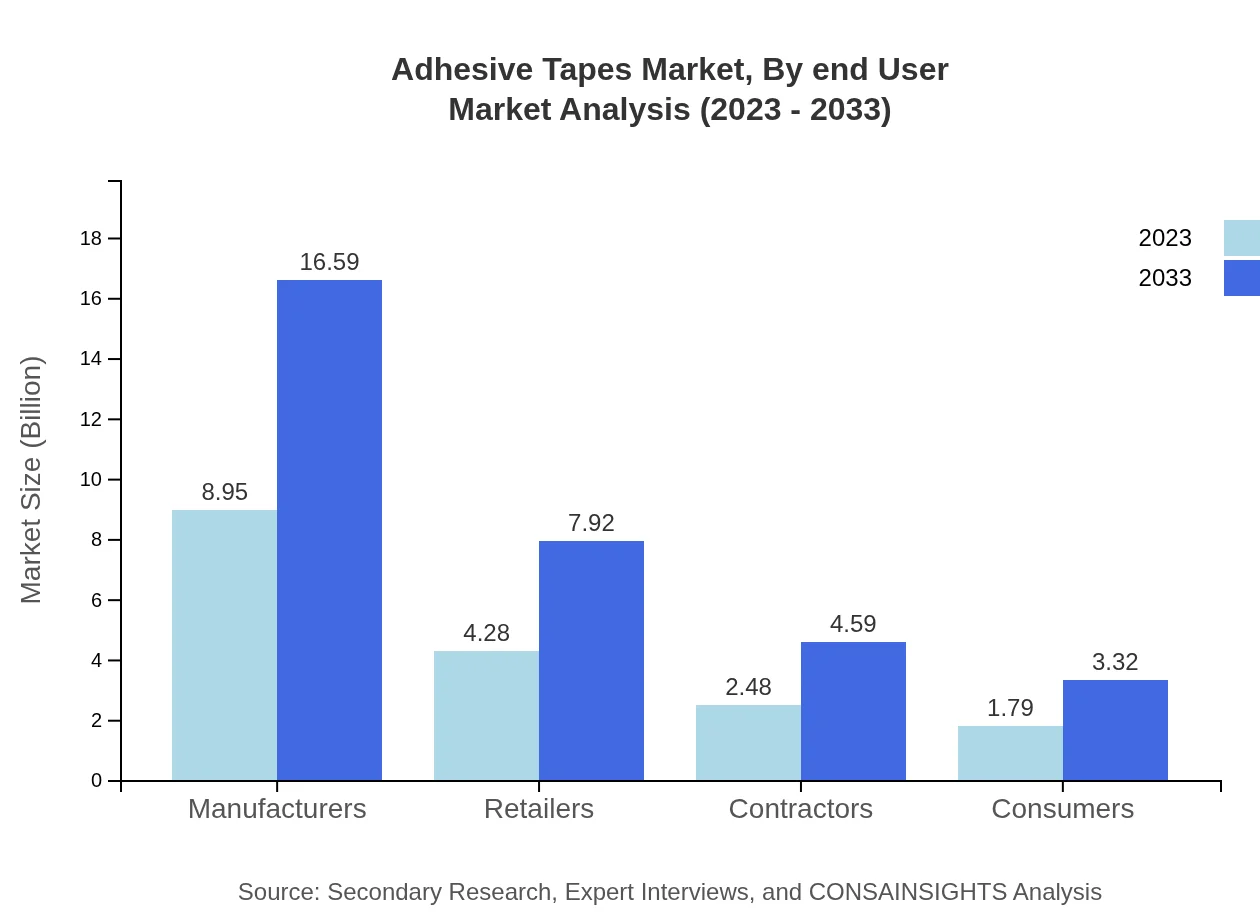

Adhesive Tapes Market Analysis By End User

End-user industries include manufacturers, retailers, contractors, and consumers of adhesive tapes. The manufacturing sector drives demand with a market size of $8.95 billion in 2023, anticipated to expand to $16.59 billion by 2033, showcasing the essential role of adhesive tapes in production processes.

Adhesive Tapes Market Analysis By Region

Regional market analysis indicates differing dynamics across continents. North America and Europe dominate the market due to technological advancements and high purchasing power, while the Asia Pacific shows the fastest growth motivated by booming industries and rising economic development.

Adhesive Tapes Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Adhesive Tapes Industry

3M Company:

A global leader in adhesive tapes, known for innovative products that cater to various industries, including automotive, healthcare, and electronics.Avery Dennison Corporation:

Specializes in labeling and packaging materials, their adhesive tapes are widely used in consumer products and industrial applications.Henkel AG & Co.:

A major player in adhesive technologies, offering a broad portfolio of industrial and consumer adhesive tapes that emphasize high performance.Tesa SE:

Known for their innovative adhesive solutions, Tesa provides high-quality adhesive tapes for both industrial and consumer markets.Nitto Denko Corporation:

A leader in advanced adhesive technologies, Nitto produces specialized adhesive tapes catering to various high-tech applications.We're grateful to work with incredible clients.

FAQs

What is the market size of adhesive Tapes?

The adhesive tapes market is estimated to be valued at $17.5 billion in 2023, with a projected CAGR of 6.2%, potentially reaching significant sizes over the next decade as demand across various applications continues to rise.

What are the key market players or companies in this adhesive Tapes industry?

Key players in the adhesive-tapes market include manufacturers such as 3M, Avery Dennison, and Nitto Denko. These companies dominate through innovations in adhesive technology and expanding their product portfolios to cater to diverse industries.

What are the primary factors driving the growth in the adhesive Tapes industry?

Growth drivers for the adhesive-tapes industry include increased demand from the packaging sector, technological advancements in adhesive formulations, and the rising need for sustainable materials that are being adopted in various applications.

Which region is the fastest Growing in the adhesive Tapes?

In the adhesive-tapes market, the fastest-growing region is expected to be Europe, with market growth from $5.77 billion in 2023 to $10.69 billion by 2033, reflecting strong industrial growth and innovation trends.

Does Consainsights provide customized market report data for the adhesive Tapes industry?

Yes, Consainsights offers customized market report data tailored to specific needs, allowing clients to gain insights based on unique parameters and requirements relevant to the adhesive-tapes market.

What deliverables can I expect from this adhesive Tapes market research project?

Deliverables from the adhesive-tapes market research project include comprehensive market analysis, segmentation data, regional insights, competitor analysis, and market forecasts aimed at helping businesses make informed decisions.

What are the market trends of adhesive Tapes?

Current market trends in adhesive-tapes include a shift toward eco-friendly products, increased use of specialty tapes in various applications, and a focus on high-performance adhesive solutions to enhance product efficacy in diverse industries.