Advanced Composite Materials Market Report

Published Date: 02 February 2026 | Report Code: advanced-composite-materials

Advanced Composite Materials Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Advanced Composite Materials market, covering current trends, future forecasts up to 2033, and insights into market dynamics, segmentation, and regional performance.

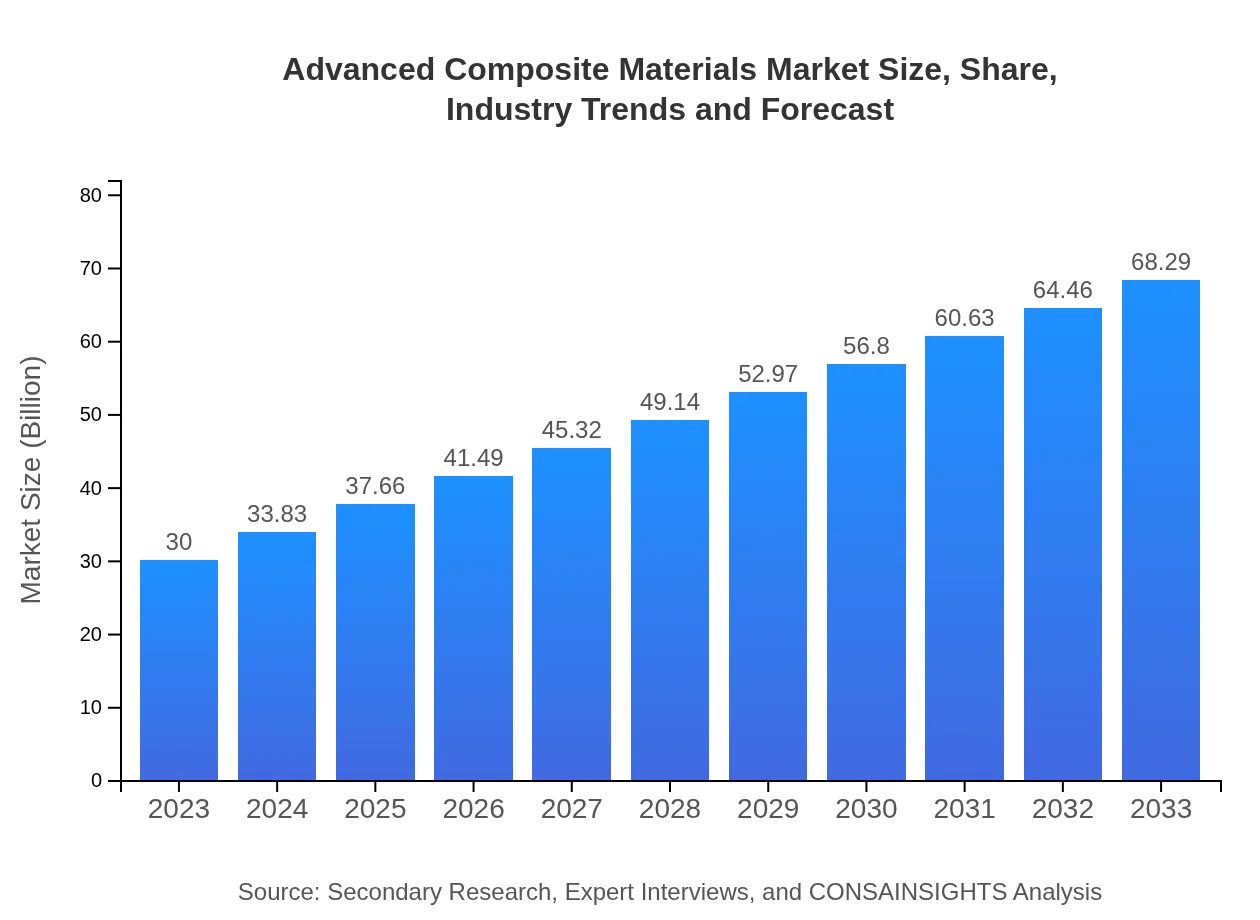

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $30.00 Billion |

| CAGR (2023-2033) | 8.3% |

| 2033 Market Size | $68.29 Billion |

| Top Companies | Toray Industries, Inc., Hexcel Corporation, BASF SE, SABIC |

| Last Modified Date | 02 February 2026 |

Advanced Composite Materials Market Overview

Customize Advanced Composite Materials Market Report market research report

- ✔ Get in-depth analysis of Advanced Composite Materials market size, growth, and forecasts.

- ✔ Understand Advanced Composite Materials's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Advanced Composite Materials

What is the Market Size & CAGR of Advanced Composite Materials market in 2023?

Advanced Composite Materials Industry Analysis

Advanced Composite Materials Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Advanced Composite Materials Market Analysis Report by Region

Europe Advanced Composite Materials Market Report:

Europe's advanced composite materials market is poised to grow from $8.86 billion in 2023 to $20.17 billion by 2033, driven by stringent regulations promoting lightweight materials and sustainability initiatives across various industries.Asia Pacific Advanced Composite Materials Market Report:

The Asia Pacific region, with a market size of $5.40 billion in 2023 projected to reach $12.30 billion by 2033, is driving growth through increasing industrial activities and advancements in manufacturing technology, particularly in China and India.North America Advanced Composite Materials Market Report:

North America leads the market, with a value of $11.29 billion in 2023 and projected to reach $25.70 billion by 2033. The aerospace sector significantly influences growth, underpinned by increasing investments and technological innovation.South America Advanced Composite Materials Market Report:

In South America, the market size in 2023 is $1.20 billion, expected to grow to $2.74 billion by 2033. Growth is being supported by rising demand in the automotive and wind energy sectors.Middle East & Africa Advanced Composite Materials Market Report:

The Middle East and Africa market, valued at $3.24 billion in 2023 and anticipated to reach $7.38 billion by 2033, is benefiting from growth in the construction and automotive sectors.Tell us your focus area and get a customized research report.

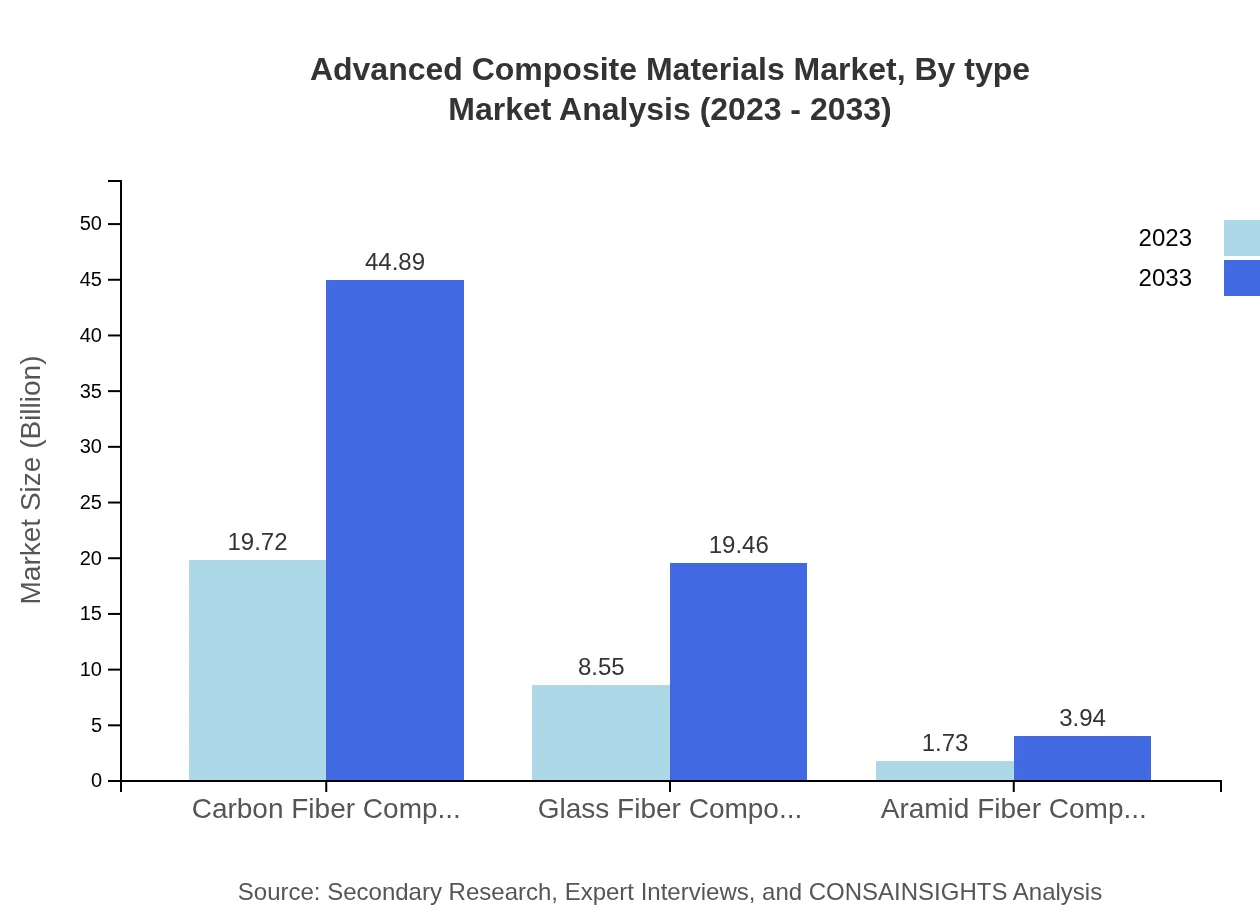

Advanced Composite Materials Market Analysis By Type

In 2023, the Carbon Fiber Composites market size is valued at $19.72 billion, expected to grow to $44.89 billion by 2033, maintaining a market share of 65.74%. Glass Fiber Composites, valued at $8.55 billion in 2023, is anticipated to reach $19.46 billion by 2033 with a market share of 28.49%.

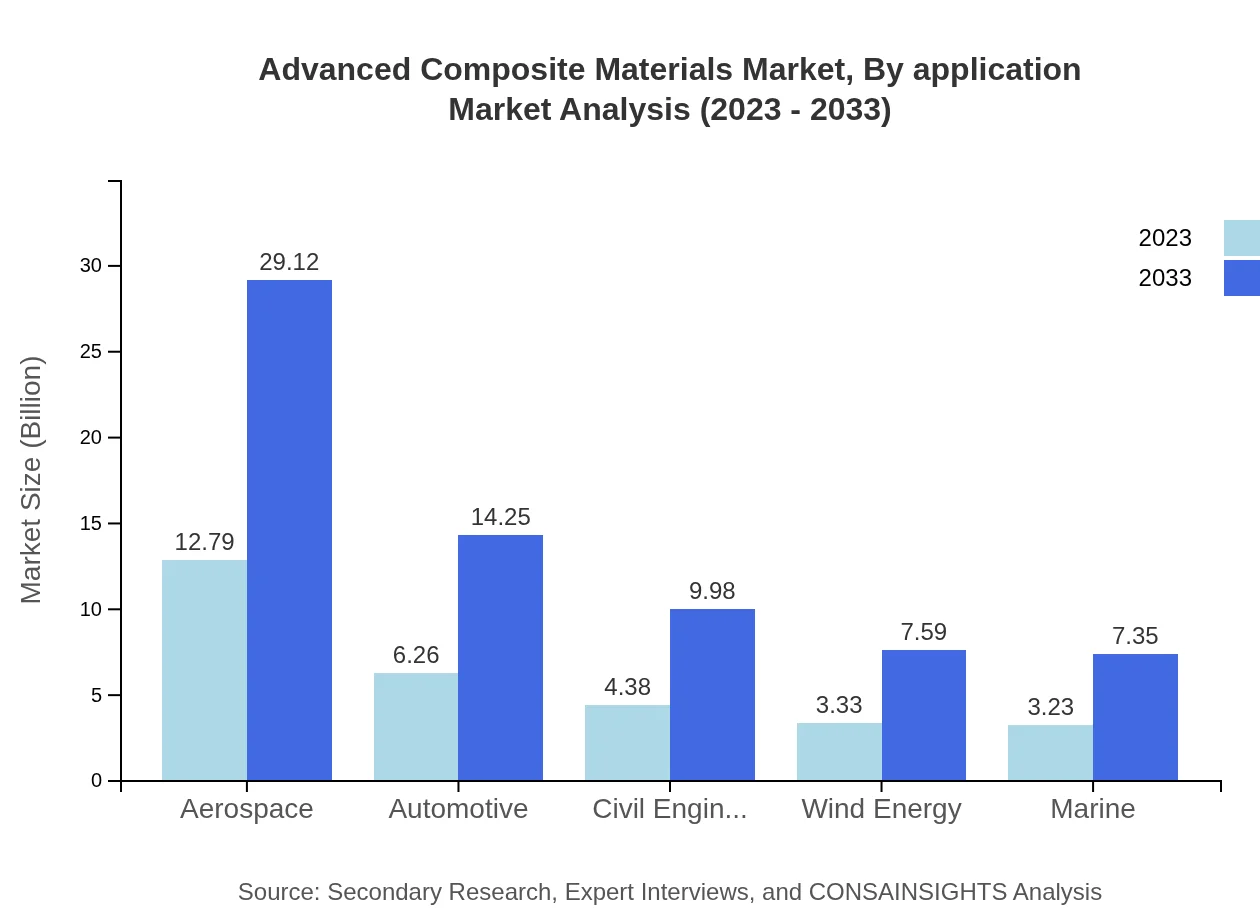

Advanced Composite Materials Market Analysis By Application

The aerospace sector holds a substantial market share at 42.64% in 2023, growing from $12.79 billion to $29.12 billion by 2033. The automotive sector, valued at $6.26 billion in 2023, is projected to expand to $14.25 billion, with a share of 20.87%.

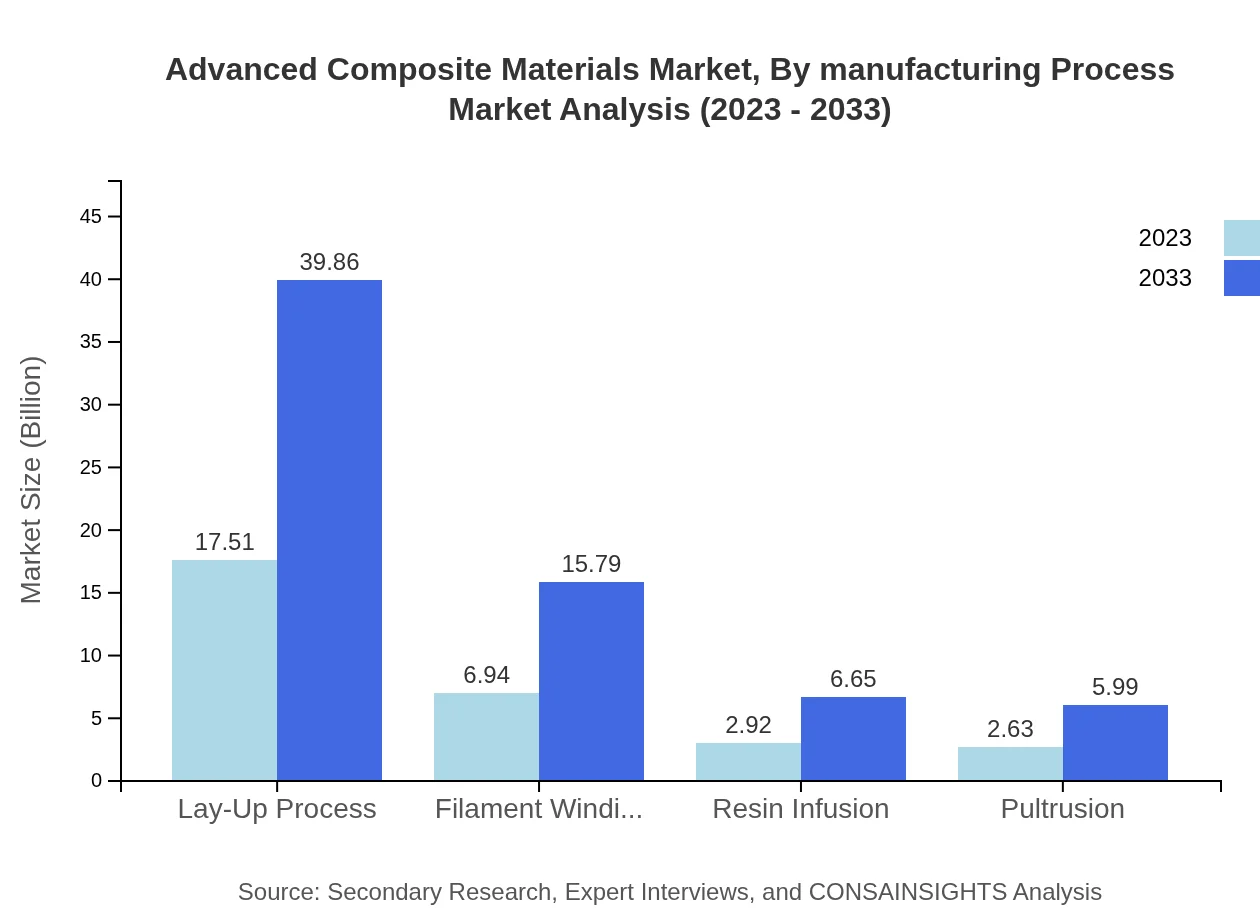

Advanced Composite Materials Market Analysis By Manufacturing Process

The Lay-Up Process dominates the manufacturing sector with a market size of $17.51 billion in 2023, set to grow to $39.86 billion. The Filament Winding process is also significant, expanding from $6.94 billion to $15.79 billion.

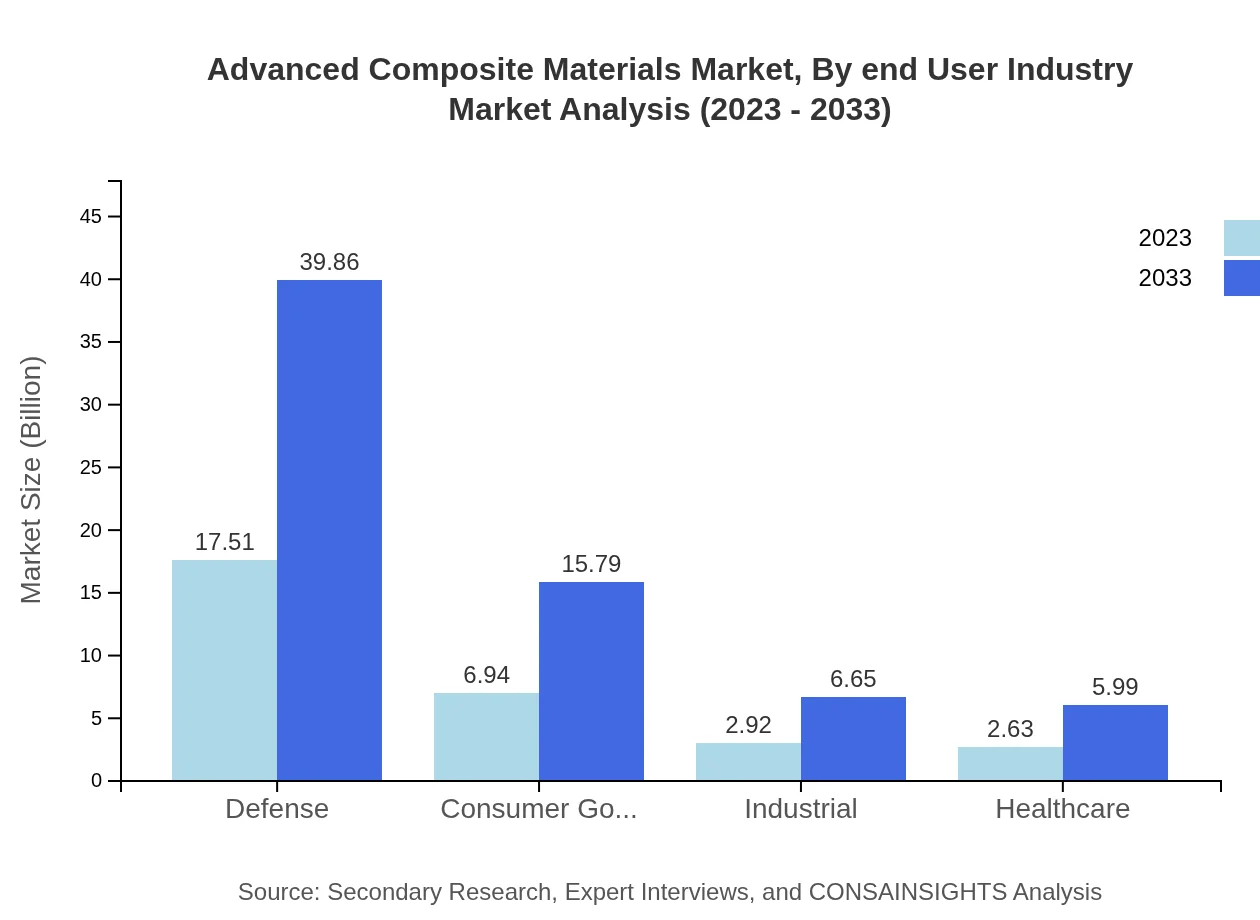

Advanced Composite Materials Market Analysis By End User Industry

In 2023, the Defense sector is a leading end-user with a market size of $17.51 billion, expected to rise to $39.86 billion by 2033, while Consumer Goods stands at $6.94 billion with a similar growth trajectory.

Advanced Composite Materials Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Advanced Composite Materials Industry

Toray Industries, Inc.:

A leading manufacturer of carbon fiber polymers and composites, Toray focuses on advanced materials to serve automotive and aerospace industries.Hexcel Corporation:

Specializes in advanced composite materials, including carbon and aramid fibers, primarily for the aerospace and defense sectors.BASF SE:

A global chemical company that produces composite materials and resins for various industries, promoting sustainable and innovative solutions.SABIC:

A global leader in diversified chemicals, SABIC manufactures high-performance materials for diverse applications, including automotive and healthcare.We're grateful to work with incredible clients.

FAQs

What is the market size of advanced Composite Materials?

The advanced composite materials market is projected to grow from $30 billion in 2023 to approximately $65 billion by 2033, reflecting a CAGR of 8.3%. This growth emphasizes the increasing demand across various industries.

What are the key market players or companies in this advanced Composite Materials industry?

Key players in the advanced composite materials industry include Hexcel Corporation, Toray Industries, Teijin Limited, and Owens Corning. These companies are at the forefront, driving innovation and shaping market trends through constant research and development.

What are the primary factors driving the growth in the advanced Composite Materials industry?

Factors driving growth in the advanced composite materials industry include increasing demand for lightweight materials, advancements in manufacturing technologies, and rising applications in aerospace, automotive, and construction, bolstered by energy efficiency requirements.

Which region is the fastest Growing in the advanced Composite Materials?

North America stands out as the fastest-growing region for advanced composite materials, with a market expected to grow from $11.29 billion in 2023 to $25.70 billion by 2033, fueled by aerospace and automotive sector demands.

Does ConsaInsights provide customized market report data for the advanced Composite Materials industry?

Yes, ConsaInsights offers tailored market reports specifically for the advanced composite materials industry, enabling stakeholders to obtain precise insights aligned with their strategic needs and market objectives.

What deliverables can I expect from this advanced Composite Materials market research project?

Deliverables from the advanced composite materials market research project include detailed market analysis reports, industry trends, competitive landscape assessments, and actionable insights tailored for strategic decision-making.

What are the market trends of advanced Composite Materials?

Current trends in the advanced composite materials market include a shift towards eco-friendly materials, increased automation in manufacturing processes, and a growing focus on research for enhanced strength-to-weight ratios for improved performance.