Aerospace Interior Adhesive Market Report

Published Date: 03 February 2026 | Report Code: aerospace-interior-adhesive

Aerospace Interior Adhesive Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aerospace Interior Adhesive market, focusing on trends, growth opportunities, and forecasts for the period 2023 to 2033. It encompasses market size, segmentation, regional insights, and an overview of key players.

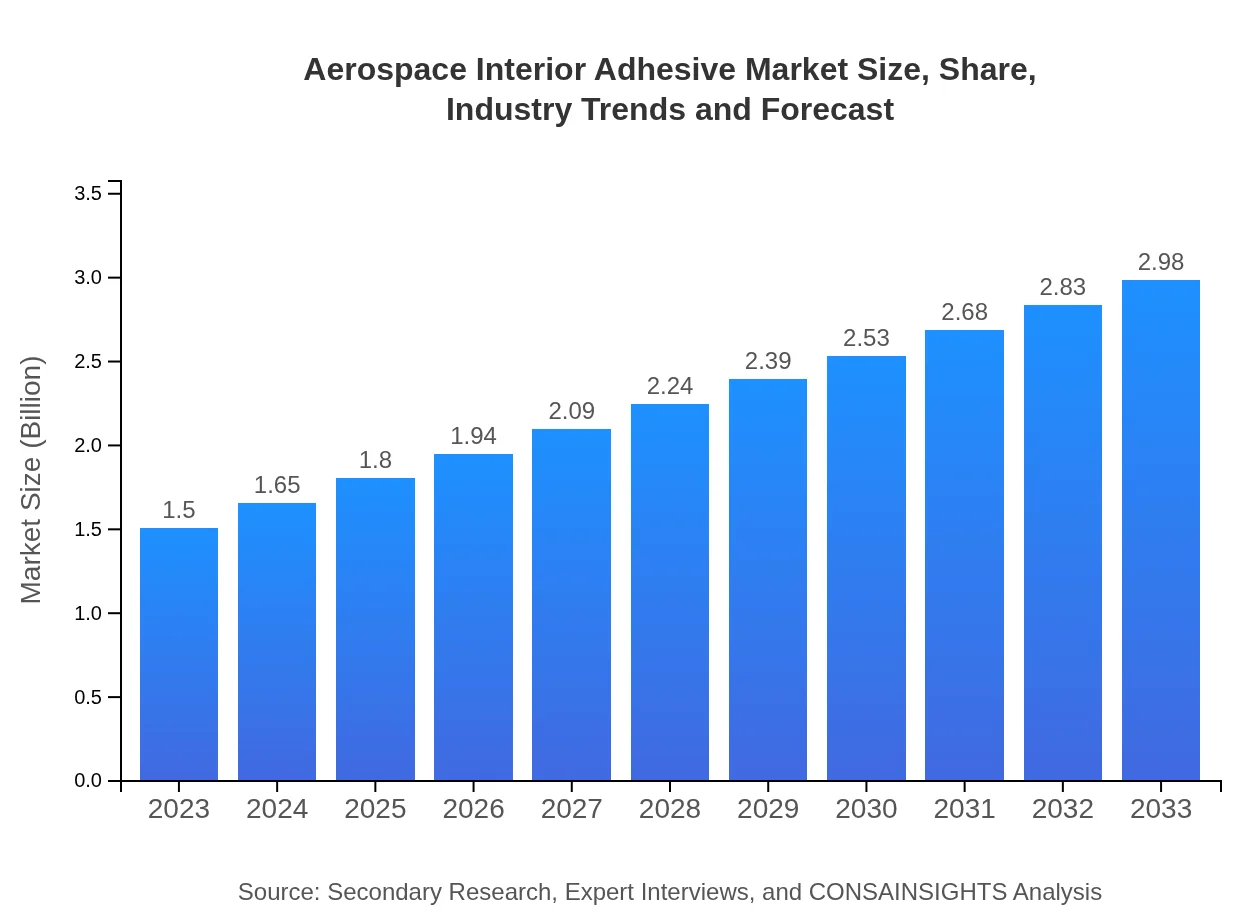

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.9% |

| 2033 Market Size | $2.98 Billion |

| Top Companies | 3M Company, Henkel AG & Co., H.B. Fuller Company, Momentive Performance Materials |

| Last Modified Date | 03 February 2026 |

Aerospace Interior Adhesive Market Overview

Customize Aerospace Interior Adhesive Market Report market research report

- ✔ Get in-depth analysis of Aerospace Interior Adhesive market size, growth, and forecasts.

- ✔ Understand Aerospace Interior Adhesive's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aerospace Interior Adhesive

What is the Market Size & CAGR of Aerospace Interior Adhesive market in 2023 and 2033?

Aerospace Interior Adhesive Industry Analysis

Aerospace Interior Adhesive Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aerospace Interior Adhesive Market Analysis Report by Region

Europe Aerospace Interior Adhesive Market Report:

The European market for Aerospace Interior Adhesives is anticipated to grow from $0.49 billion in 2023 to $0.96 billion by 2033. Stringent regulations promoting safety and environmental sustainability are driving the adoption of advanced adhesive solutions in the region.Asia Pacific Aerospace Interior Adhesive Market Report:

The Asia Pacific region has emerged as a significant market for Aerospace Interior Adhesives, estimated to grow from $0.28 billion in 2023 to $0.56 billion by 2033. Increased air travel and rising aircraft production in countries like China and India are key growth drivers. Additionally, investments in aerospace infrastructure are likely to bolster market expansion.North America Aerospace Interior Adhesive Market Report:

North America continues to be a leading region in the Aerospace Interior Adhesive market, with an expected rise from $0.51 billion in 2023 to $1.02 billion by 2033. The strong presence of major aerospace manufacturers and continuous technological advancements are key contributors to this growth trajectory.South America Aerospace Interior Adhesive Market Report:

In South America, the Aerospace Interior Adhesive market is projected to increase from $0.05 billion in 2023 to $0.09 billion by 2033. The growth is primarily supported by the expansion of the aviation sector and the increasing demand for innovative materials in aircraft manufacturing.Middle East & Africa Aerospace Interior Adhesive Market Report:

The Middle East and Africa have seen growth in the Aerospace Interior Adhesive market from $0.18 billion in 2023 to $0.35 billion by 2033. Increasing air travel and investments in upgrading airport facilities and fleet maintenance are crucial factors supporting market growth in this region.Tell us your focus area and get a customized research report.

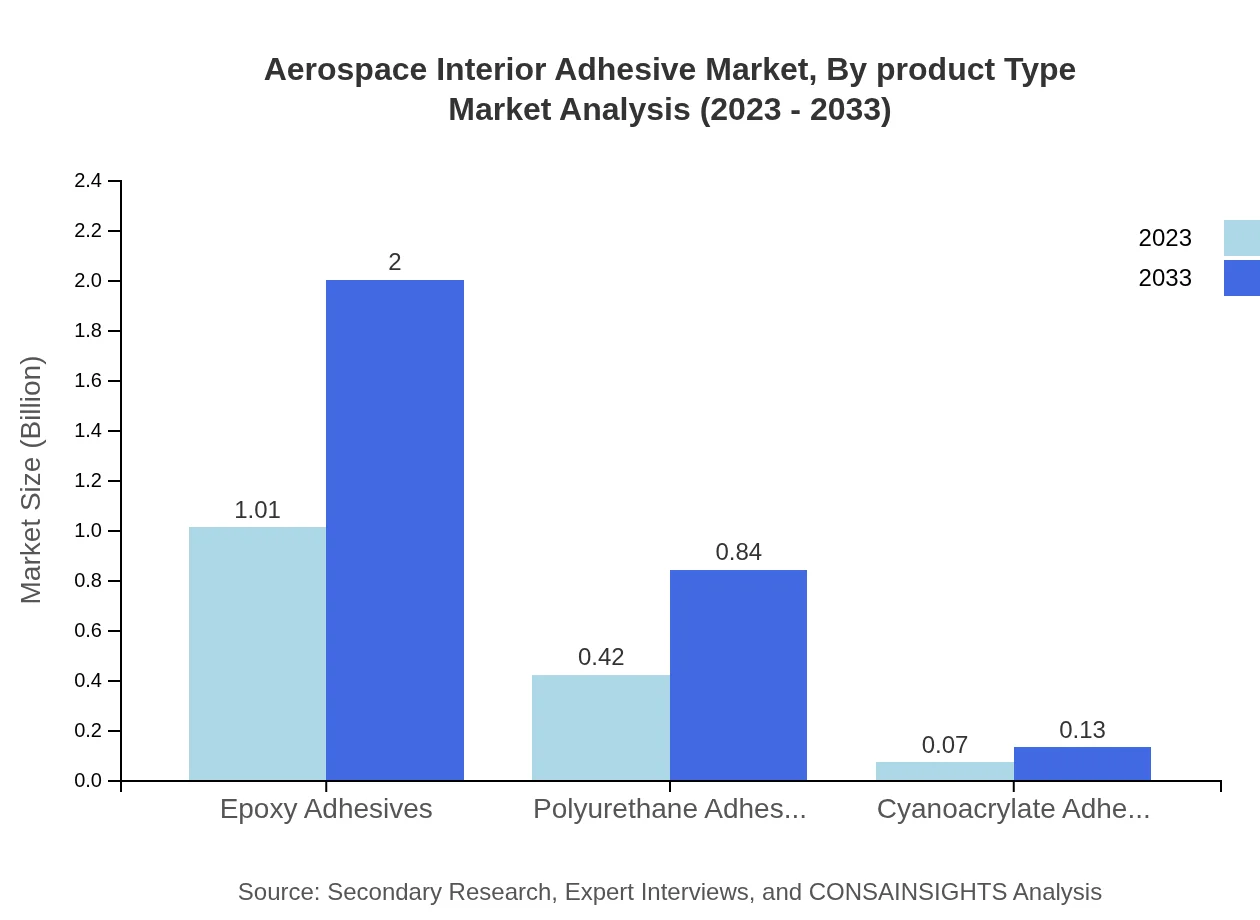

Aerospace Interior Adhesive Market Analysis By Product Type

The Aerospace Interior Adhesive market is divided into several product types, including Solvent-Based Adhesives, Water-Based Adhesives, Epoxy Adhesives, Polyurethane Adhesives, and Hot Melt Adhesives. Solvent-Based Adhesives dominate the market with a share of 67.23%, growing from $1.01 billion in 2023 to $2.00 billion by 2033. Water-Based and Epoxy Adhesives hold significant market shares at 28.28% and 67.23%, respectively, highlighting the shift toward more environmentally friendly options.

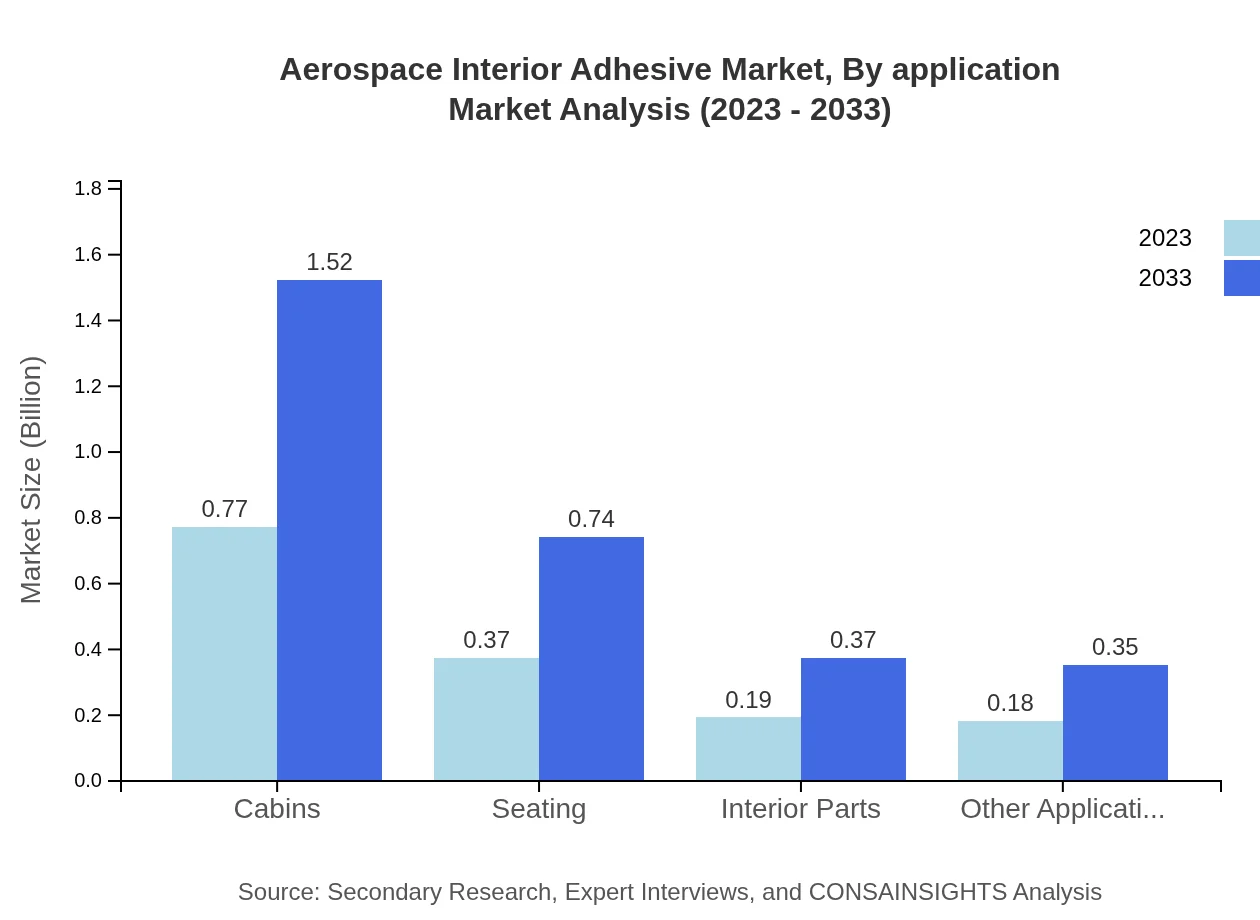

Aerospace Interior Adhesive Market Analysis By Application

The key applications of Aerospace Interior Adhesives include Cabins, Seating, and Interior Parts. The cabins segment is expected to maintain a significant market share, growing from $0.77 billion in 2023 to $1.52 billion by 2033, exhibiting its critical role in aircraft safety and performance. Other applications also show promising growth, particularly due to innovations in adhesive technologies.

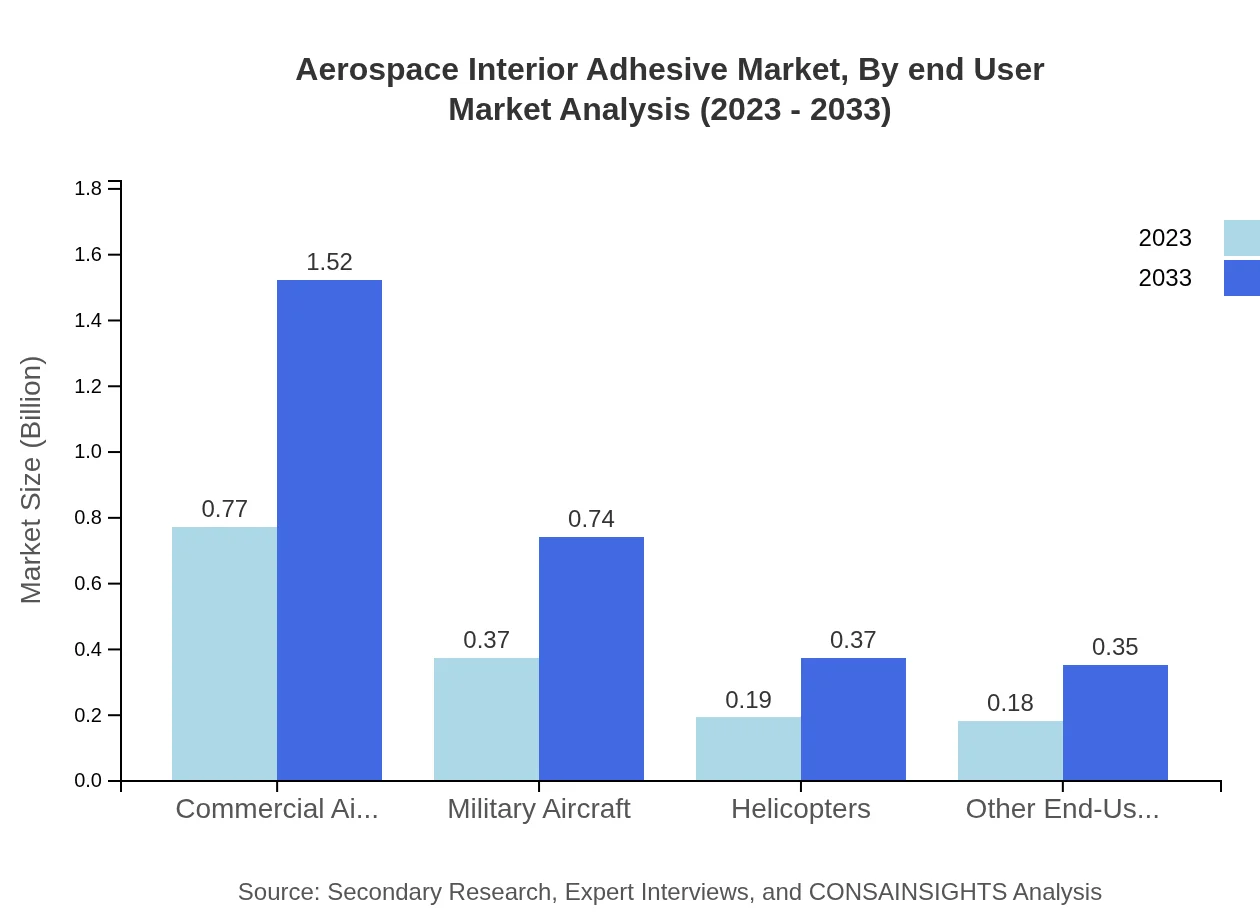

Aerospace Interior Adhesive Market Analysis By End User

The end-user segments include Commercial Aircraft, Military Aircraft, and Helicopters. The Commercial Aircraft sector leads the market, with a value of $0.77 billion in 2023, expected to double by 2033. Military applications are also significant, reflecting defense spending and modernization initiatives in various countries.

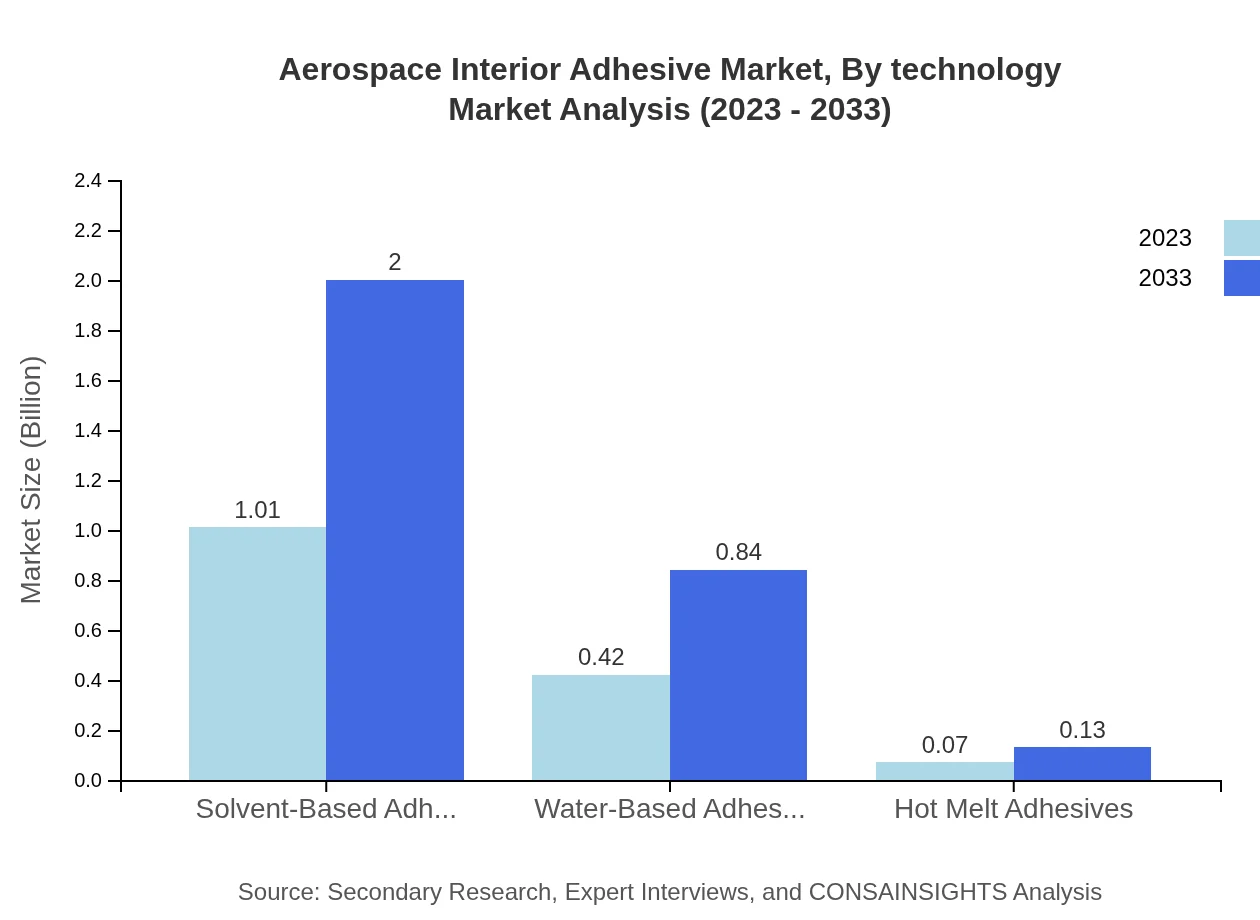

Aerospace Interior Adhesive Market Analysis By Technology

Innovations in adhesive technologies have led to the development of new formulations that enhance performance while reducing environmental impact. The focus is on advancements that promote sustainability, such as bio-based adhesives, which are gaining traction in the aerospace industry due to their eco-friendly attributes.

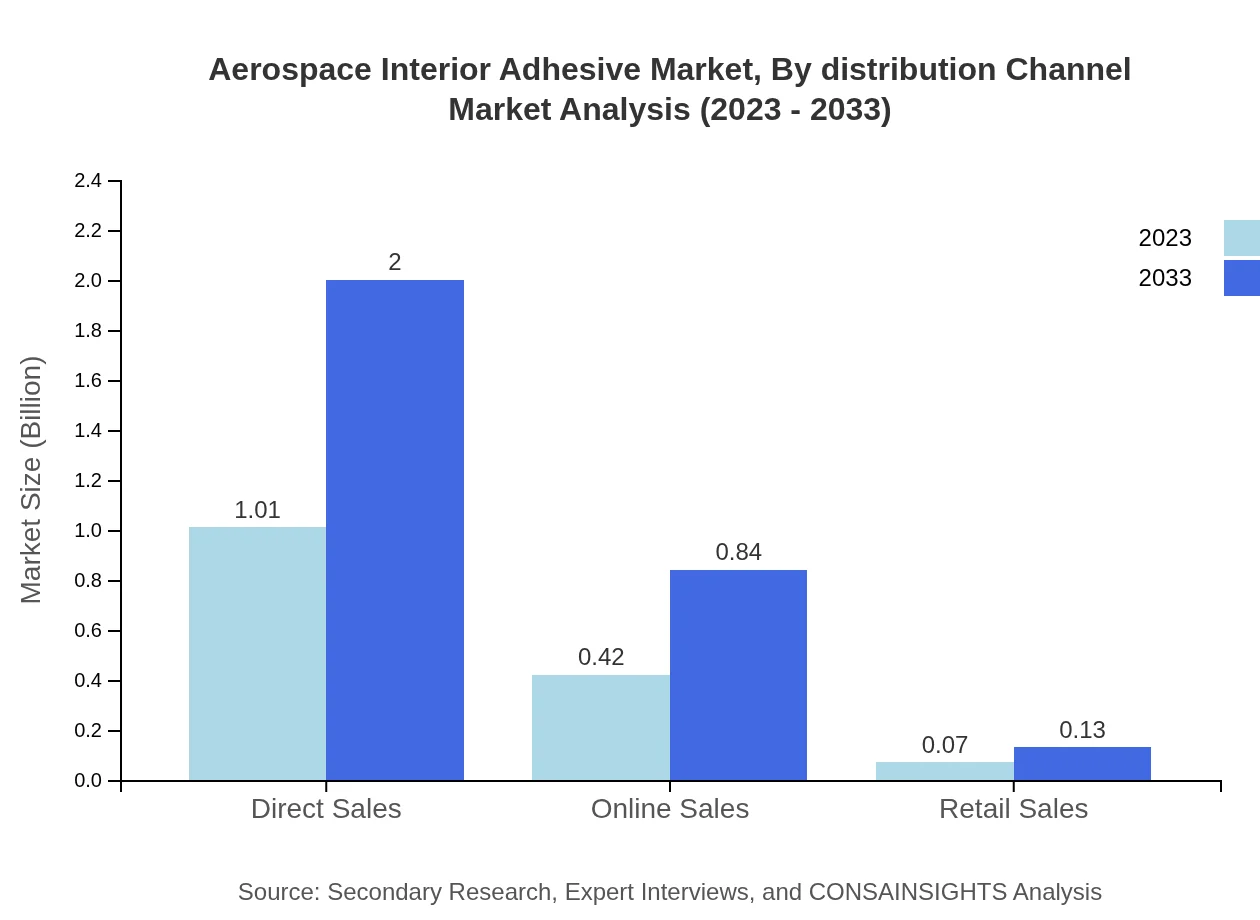

Aerospace Interior Adhesive Market Analysis By Distribution Channel

The Aerospace Interior Adhesive market distribution channels encompass Direct Sales, Online Sales, and Retail Sales. Direct Sales dominate the market, accounting for 67.23% share in 2023, as manufacturers often prefer direct engagement with customers to provide tailored solutions and maintain quality control.

Aerospace Interior Adhesive Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aerospace Interior Adhesive Industry

3M Company:

A leader in adhesive technology, 3M produces a diverse range of high-performance adhesives utilized in various aerospace applications, emphasizing safety and efficiency.Henkel AG & Co.:

Henkel is known for its extensive portfolio of adhesives, sealants, and surface treatments for the aerospace industry, focusing on technological innovation and sustainability.H.B. Fuller Company:

H.B. Fuller specializes in adhesives and has tailored solutions for aerospace applications, delivering performance products that meet regulatory compliance.Momentive Performance Materials:

Momentive offers advanced adhesive and sealant solutions, particularly for the aerospace sector, emphasizing high durability and environmental safety.We're grateful to work with incredible clients.

FAQs

What is the market size of aerospace Interior Adhesive?

The aerospace interior adhesive market is currently valued at approximately $1.5 billion in 2023. It is projected to grow at a CAGR of 6.9% over the next decade, reaching substantial growth by 2033.

What are the key market players or companies in this aerospace Interior Adhesive industry?

Key companies in the aerospace interior adhesive industry include major manufacturers such as 3M, Henkel AG, H.B. Fuller, and Lord Corporation. These players are known for their innovative adhesive technologies tailored for aerospace applications.

What are the primary factors driving the growth in the aerospace Interior Adhesive industry?

Growth in the aerospace interior adhesive market is driven by increased demand for lightweight materials, technological advancements in adhesive formulations, and the rising production of commercial and military aircraft adapting to stricter environmental regulations.

Which region is the fastest Growing in the aerospace Interior Adhesive?

North America holds the position as the fastest-growing region in the aerospace interior adhesive market, projected to grow from $0.51 billion in 2023 to $1.02 billion by 2033, driven by robust aerospace manufacturing and maintenance activities.

Does ConsaInsights provide customized market report data for the aerospace Interior Adhesive industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the aerospace interior adhesive industry, providing detailed market insights, trends, and forecasts based on individual client requirements.

What deliverables can I expect from this aerospace interior adhesive market research project?

From the aerospace interior adhesive market research project, clients can expect comprehensive reports, data visualizations, market forecasts, competitor analysis, and insights on regulatory trends and consumer preferences.

What are the market trends of aerospace Interior Adhesive?

Key trends in the aerospace interior adhesive market include a shift towards eco-friendly adhesive solutions, increased R&D investments in advanced adhesive technologies, and a growing adoption of automation in manufacturing processes.