Aerospace Tapes Market Report

Published Date: 03 February 2026 | Report Code: aerospace-tapes

Aerospace Tapes Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aerospace Tapes market, detailing industry dynamics, market sizing, segmentation, and forecasts from 2023 to 2033. Key insights include current trends, regional analysis, and leading players within the market.

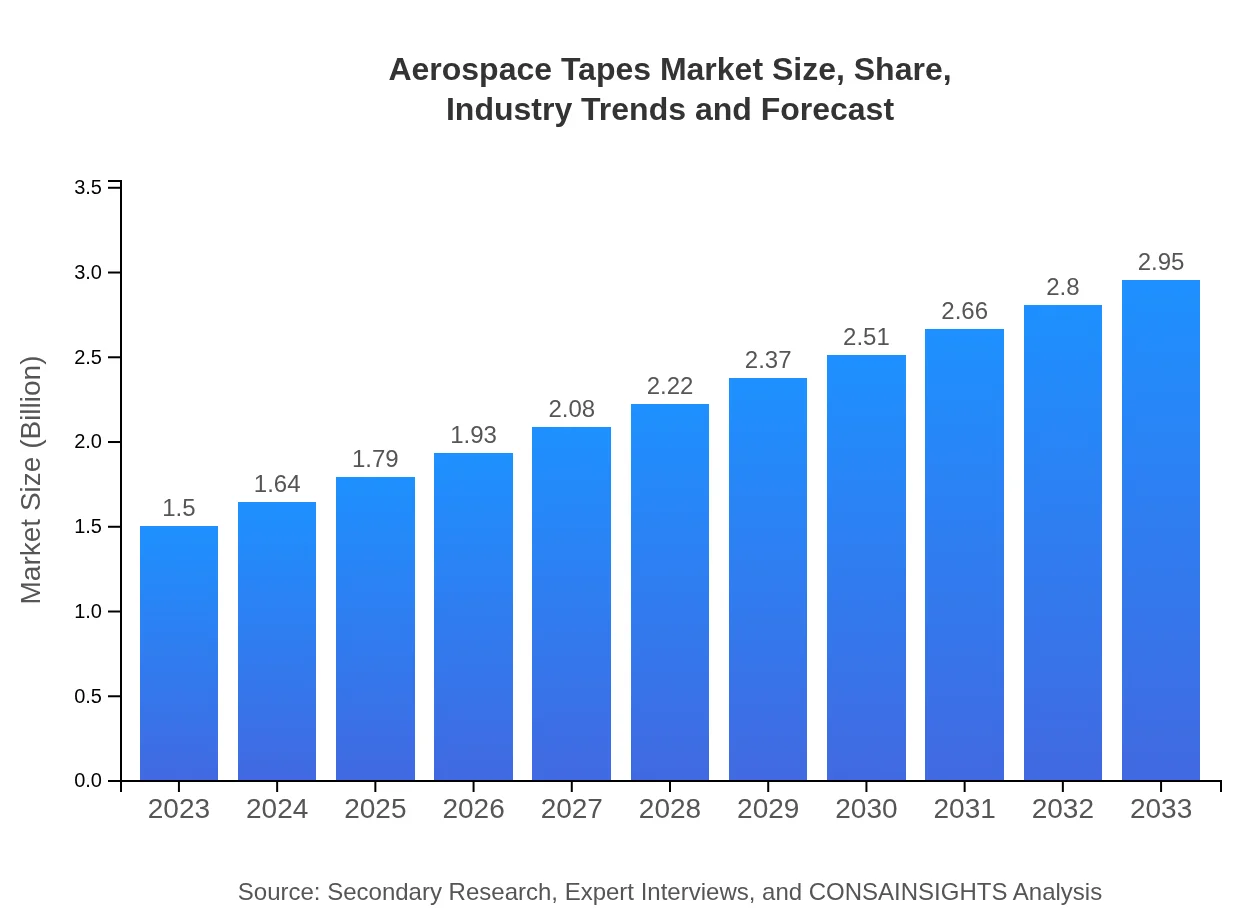

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $2.95 Billion |

| Top Companies | 3M Company, Avery Dennison Corporation, Henkel AG & Co., Scapa Group PLC |

| Last Modified Date | 03 February 2026 |

Aerospace Tapes Market Overview

Customize Aerospace Tapes Market Report market research report

- ✔ Get in-depth analysis of Aerospace Tapes market size, growth, and forecasts.

- ✔ Understand Aerospace Tapes's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aerospace Tapes

What is the Market Size & CAGR of Aerospace Tapes market in 2023?

Aerospace Tapes Industry Analysis

Aerospace Tapes Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aerospace Tapes Market Analysis Report by Region

Europe Aerospace Tapes Market Report:

In Europe, the market is expected to grow from $0.37 billion in 2023 to $0.73 billion by 2033, driven by robust regulations that sustain high-quality standards in aircraft manufacturing, supported by established players focused on R&D to advance aerospace technologies.Asia Pacific Aerospace Tapes Market Report:

The Asia Pacific region is estimated to be valued at $0.29 billion in 2023 and is expected to grow to $0.56 billion by 2033. Growth drivers include the expanding aerospace sector in countries like China and India, focusing on both domestic and international air travel, coupled with increased investments in new fleet acquisitions.North America Aerospace Tapes Market Report:

North America remains the largest market for Aerospace Tapes, with an estimated value of $0.55 billion in 2023 projected to reach $1.08 billion by 2033. This region is characterized by the presence of leading companies and advancements in aircraft technology fueled by a resilient aerospace manufacturing industry.South America Aerospace Tapes Market Report:

South America shows a considerable growth potential, with a market projected to rise from $0.12 billion in 2023 to $0.24 billion in 2033. The growth in the aerospace sector in Brazil and Argentina is notable, influenced by rising demand for air travel and potential shifts in aerospace manufacturing bases.Middle East & Africa Aerospace Tapes Market Report:

The Middle East and Africa region has a market value predicted to grow from $0.18 billion in 2023 to $0.34 billion by 2033, as an influx of investments in aviation infrastructure, particularly in the Gulf States and sustained growth in air travel, encourages boosting aerospace activities in this region.Tell us your focus area and get a customized research report.

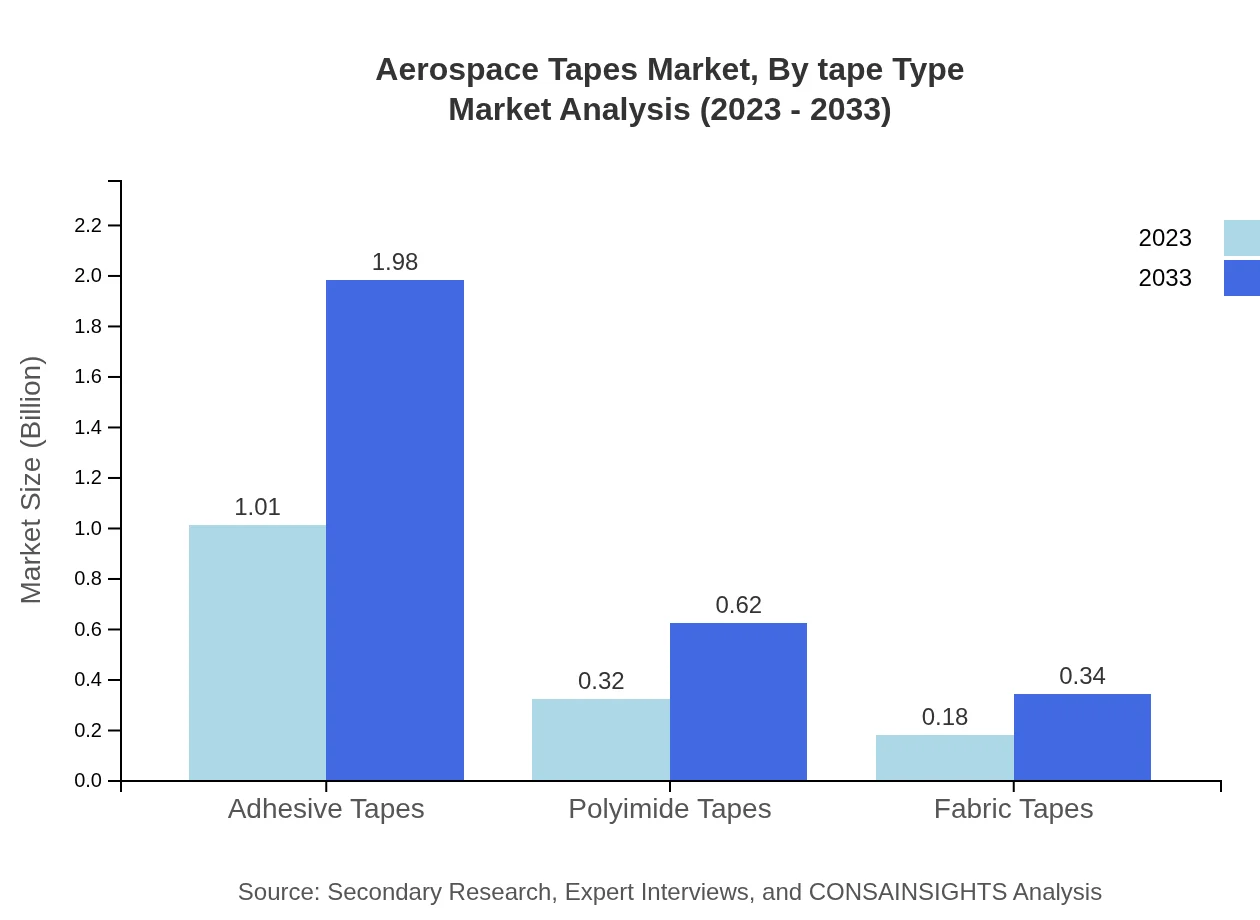

Aerospace Tapes Market Analysis By Tape Type

The growth of tape types within the Aerospace Tapes market is notable, with acrylic tapes leading the segment, expected to increase from $1.01 billion in 2023 to $1.98 billion by 2033, maintaining a market share of 67.12%. Polyimide tapes account for significant demand, projected to grow from $0.32 billion to $0.62 billion, while silicone and fluoropolymer tapes also play crucial roles owing to their unique properties beneficial in aerospace applications.

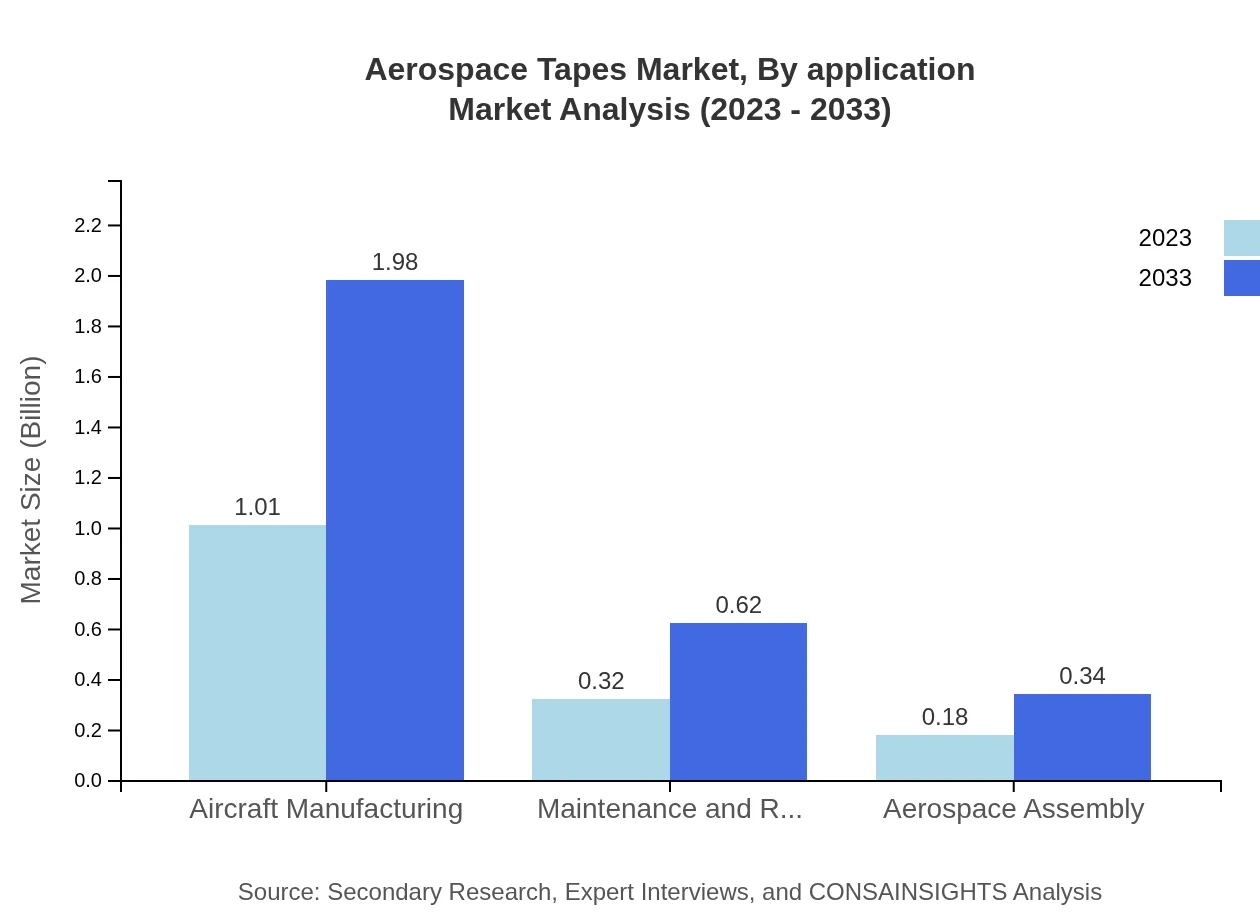

Aerospace Tapes Market Analysis By Application

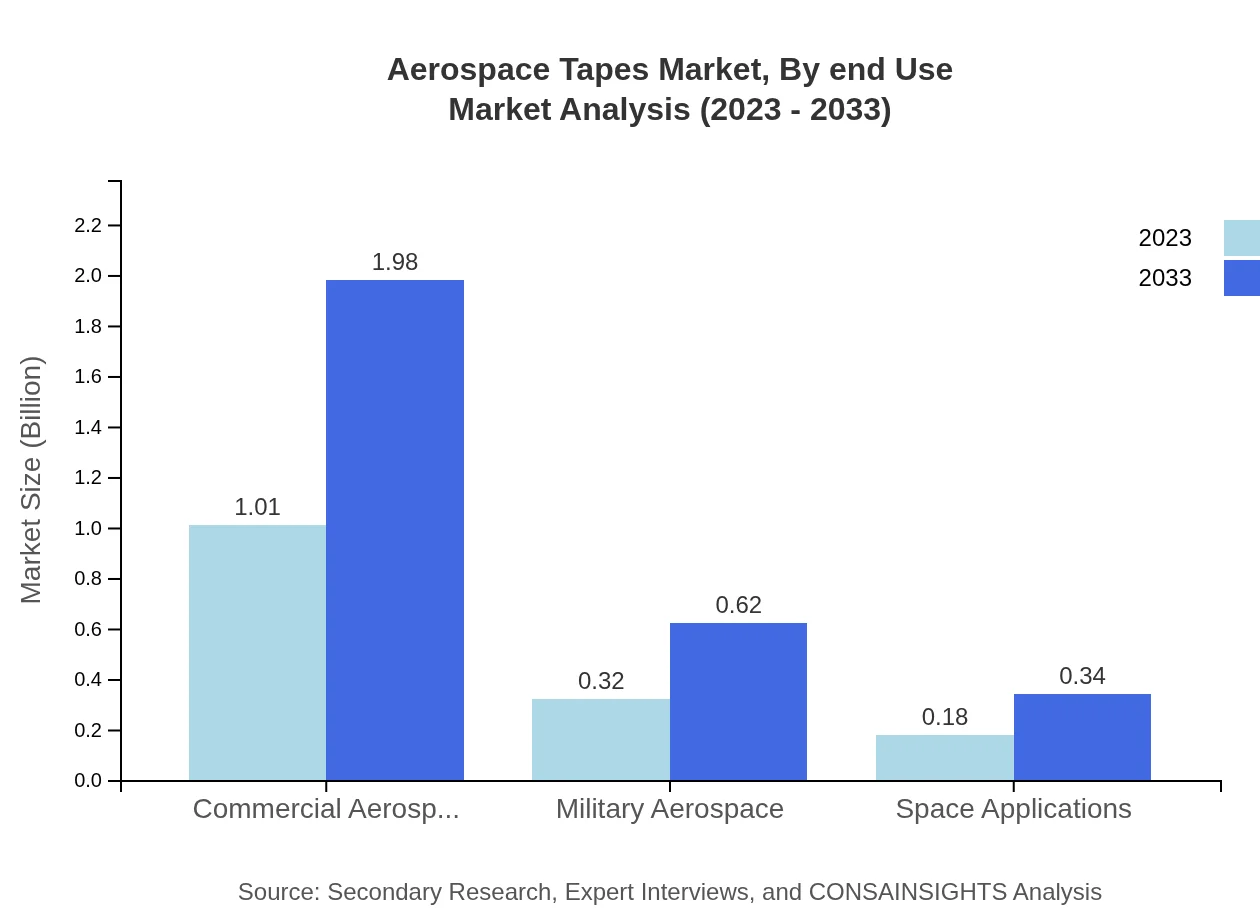

The application segment reflects significant growth in the commercial aerospace sector, estimated to make up 67.12% of the market in 2023, with an anticipated growth from $1.01 billion to $1.98 billion by 2033. Military aerospace and space applications are also crucial segments, with military tapes growing from $0.32 billion to $0.62 billion and space applications from $0.18 billion to $0.34 billion.

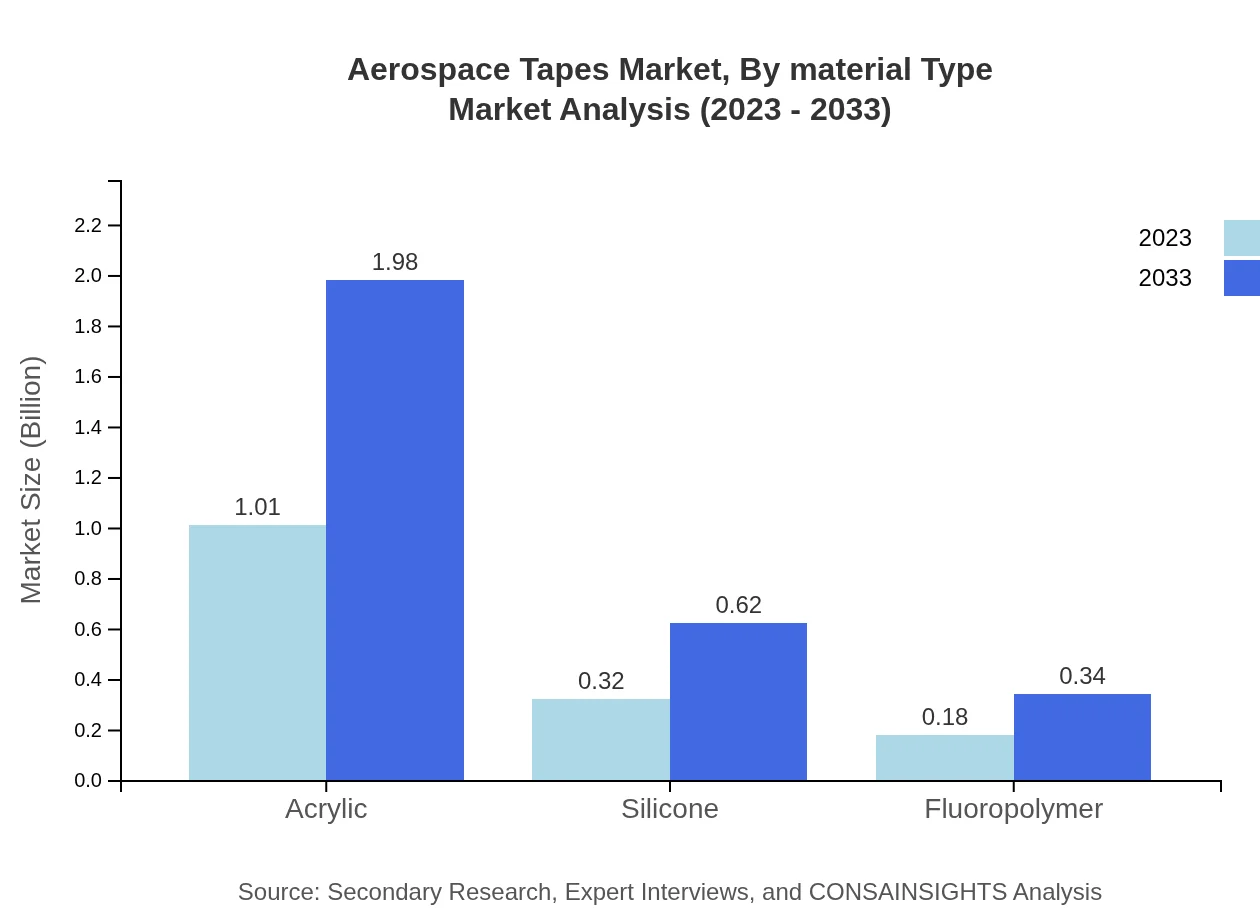

Aerospace Tapes Market Analysis By Material Type

Various material types underline the resilience of the Aerospace Tapes market, where the adhesive tapes segment maintains a commanding share of 67.12%, and grows consistently; the polyimide and silicone tapes also demonstrate steady growth patterns throughout the forecast period, responding to specific needs in aerospace engineering.

Aerospace Tapes Market Analysis By End Use

Focusing on end-use, the aircraft manufacturing industry dominates, expected to sustain a market share of 67.12%, growing from $1.01 billion to $1.98 billion by 2033. The maintenance and repair sector also stands significant, projected to boost market size from $0.32 billion in 2023 to $0.62 billion, reflecting the ongoing investments in fleet upgrades and repairs.

Aerospace Tapes Market Analysis By Distribution Channel

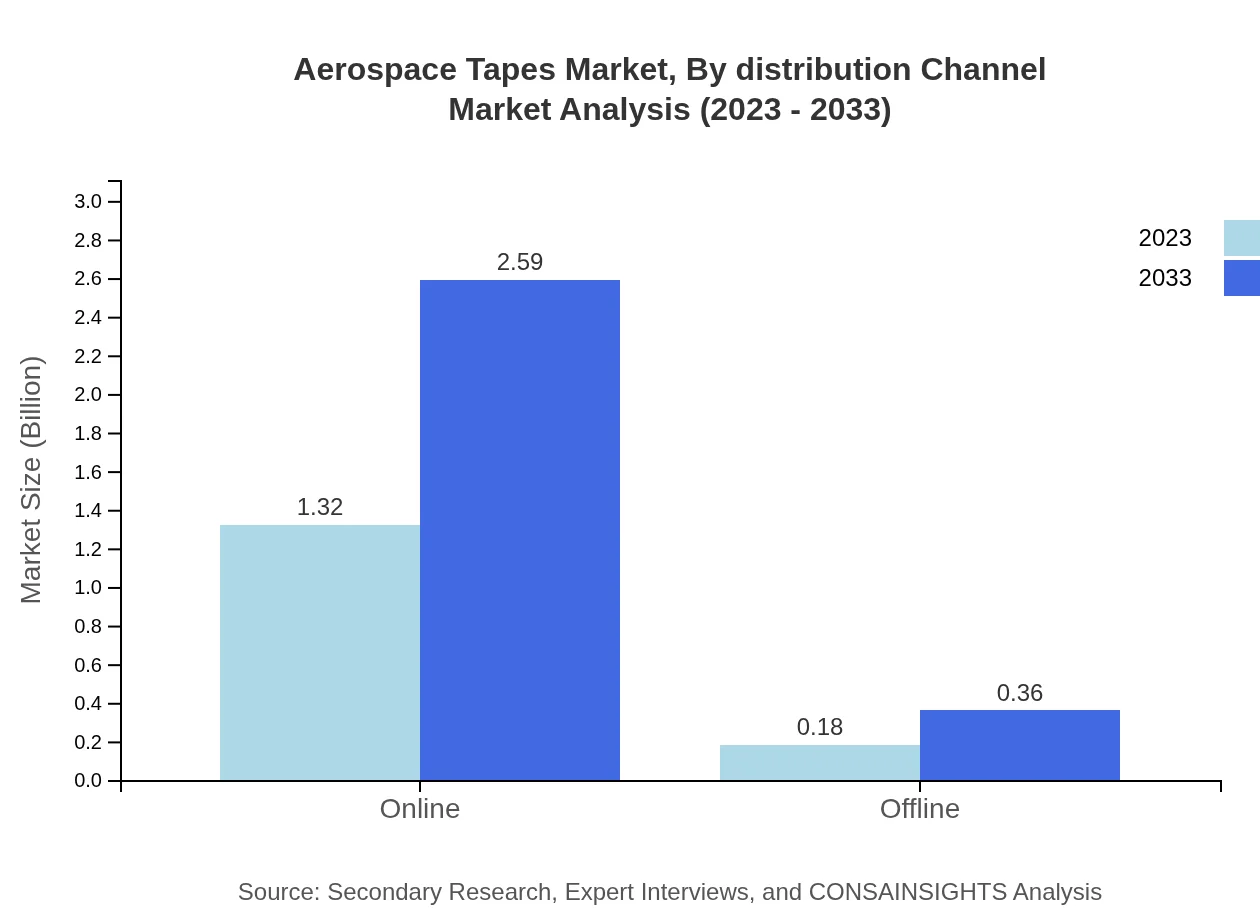

The distribution landscape reveals an increase towards online sales channels with a remarkable share of 87.86%, indicating a shift in purchasing behavior towards convenience and access to a broader product range. Offline sales, while still relevant, are forecasted to grow steadily, reflecting ongoing traditional market engagement.

Aerospace Tapes Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aerospace Tapes Industry

3M Company:

A global leader in adhesive technologies, 3M develops innovative aerospace tapes with properties tailored for high-performance applications in aviation.Avery Dennison Corporation:

Known for its adhesive solutions, Avery Dennison offers a variety of aerospace tapes designed to facilitate safer, lighter, and more cost-effective aerospace applications.Henkel AG & Co.:

Henkel provides advanced adhesives and taping solutions, with a strong commitment to sustainability and innovation in aerospace manufacturing.Scapa Group PLC:

Specializing in bonding solutions, Scapa designs aerospace tapes focusing on niche applications and optimized performance across various aerospace sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of aerospace Tapes?

The aerospace tapes market was valued at approximately $1.5 billion in 2023, with a projected CAGR of 6.8%. By 2033, it is expected to grow significantly, demonstrating the industry's robust expansion potential.

What are the key market players or companies in this aerospace Tapes industry?

Key players in the aerospace tapes market include leading manufacturers and suppliers specializing in tape solutions. These companies are essential in driving innovation, maintaining market growth, and meeting industry-specific requirements.

What are the primary factors driving the growth in the aerospace Tapes industry?

Growth is primarily driven by rising aircraft production rates, technological advancements in aerospace materials, and increasing demands for lightweight, durable, and efficient adhesive solutions in commercial and military aviation sectors.

Which region is the fastest Growing in the aerospace Tapes?

North America is the fastest-growing region in the aerospace-tapes market, projected to expand from $0.55 billion in 2023 to $1.08 billion in 2033, driven by significant aerospace activities and innovations in the region.

Does ConsaInsights provide customized market report data for the aerospace Tapes industry?

Yes, ConsaInsights specializes in creating customized market reports. Tailored analyses are available to address specific research needs, providing in-depth insights into particular segments of the aerospace-tapes industry.

What deliverables can I expect from this aerospace Tapes market research project?

Deliverables typically include a comprehensive report with market size estimates, forecasts, segment analysis, competitive landscape evaluations, and insights into emerging trends and market dynamics within the aerospace-tapes industry.

What are the market trends of aerospace Tapes?

Current trends include a rise in demand for eco-friendly materials, innovations in adhesive technologies, and increased use of aerospace tapes in varied applications like maintenance, repair, and advanced aircraft manufacturing processes.