Aircraft Control Surfaces Market Report

Published Date: 03 February 2026 | Report Code: aircraft-control-surfaces

Aircraft Control Surfaces Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aircraft Control Surfaces market, highlighting current trends, regional insights, and future forecasts from 2023 to 2033. It encompasses various dimensions including market segmentation, industry analysis, and detailed perspectives from leading players.

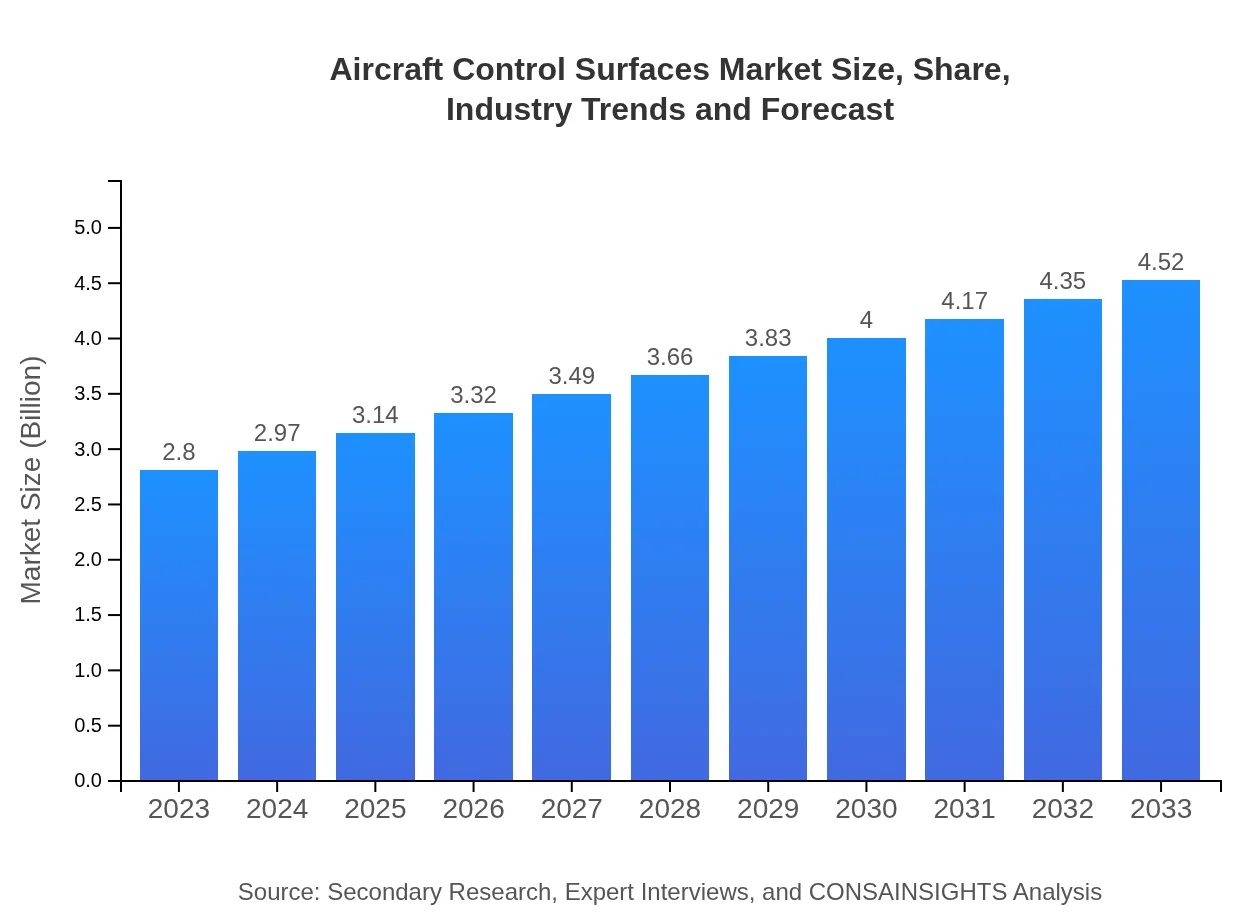

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.80 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $4.52 Billion |

| Top Companies | Boeing , Airbus, Raytheon Technologies, Leonardo S.p.A, Lockheed Martin |

| Last Modified Date | 03 February 2026 |

Aircraft Control Surfaces Market Overview

Customize Aircraft Control Surfaces Market Report market research report

- ✔ Get in-depth analysis of Aircraft Control Surfaces market size, growth, and forecasts.

- ✔ Understand Aircraft Control Surfaces's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Control Surfaces

What is the Market Size & CAGR of Aircraft Control Surfaces market in 2023?

Aircraft Control Surfaces Industry Analysis

Aircraft Control Surfaces Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Control Surfaces Market Analysis Report by Region

Europe Aircraft Control Surfaces Market Report:

Europe is expected to grow its market size from USD 0.98 billion in 2023 to USD 1.59 billion by 2033 due to rising regulations around aviation safety and the increasing production of fuel-efficient aircraft.Asia Pacific Aircraft Control Surfaces Market Report:

The Asia Pacific region is expected to witness significant growth in the Aircraft Control Surfaces market, projecting an increased market size from USD 0.50 billion in 2023 to USD 0.80 billion by 2033. Factors driving this growth include rising air travel demand, increasing investments in new aircraft, and advancements in aviation technologies.North America Aircraft Control Surfaces Market Report:

North America remains the largest market, projected to expand from USD 0.91 billion in 2023 to USD 1.46 billion by 2033. This growth is fueled by the presence of major aerospace manufacturers and technological innovations in aircraft design.South America Aircraft Control Surfaces Market Report:

In South America, the market is anticipated to grow from USD 0.14 billion in 2023 to USD 0.23 billion by 2033. The growth is supported by increasing regional air traffic, and government initiatives to enhance privately owned aircraft sectors.Middle East & Africa Aircraft Control Surfaces Market Report:

The Middle East and Africa region is also seeing a market expansion from USD 0.27 billion in 2023 to USD 0.44 billion by 2033, largely driven by military projects and airline expansions in the region.Tell us your focus area and get a customized research report.

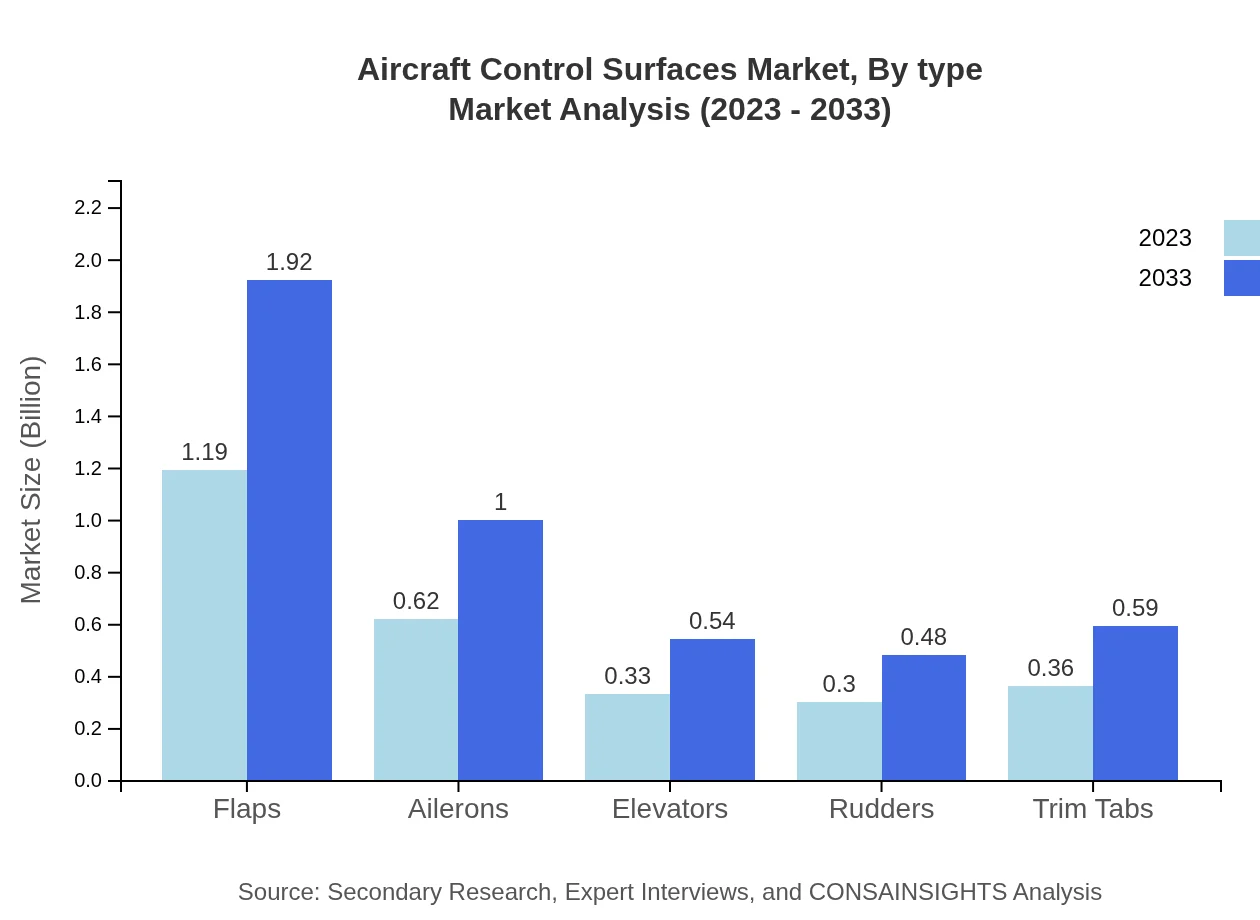

Aircraft Control Surfaces Market Analysis By Type

The Aircraft Control Surfaces market by type is dominated by Flaps, which account for a substantial segment. In 2023, Flaps are valued at USD 1.19 billion and are expected to rise to USD 1.92 billion by 2033. Other components such as Ailerons and Elevators also show robust growth potential.

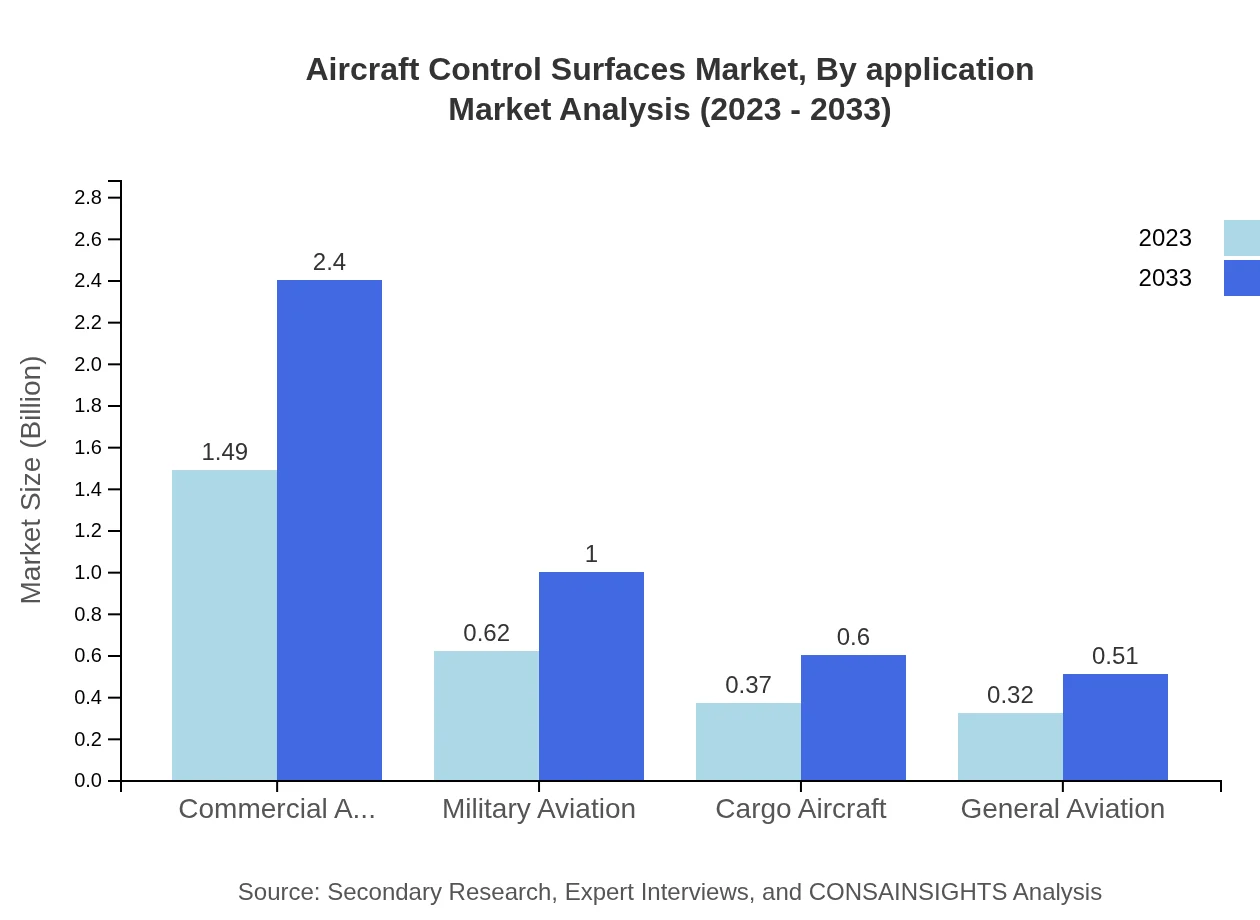

Aircraft Control Surfaces Market Analysis By Application

The Commercial Aviation segment holds the largest market share, with a value of USD 1.49 billion in 2023, anticipated to reach USD 2.40 billion by 2033, driven by increasing passenger travel. Military Aviation follows closely with consistent demand for updated aircraft technology.

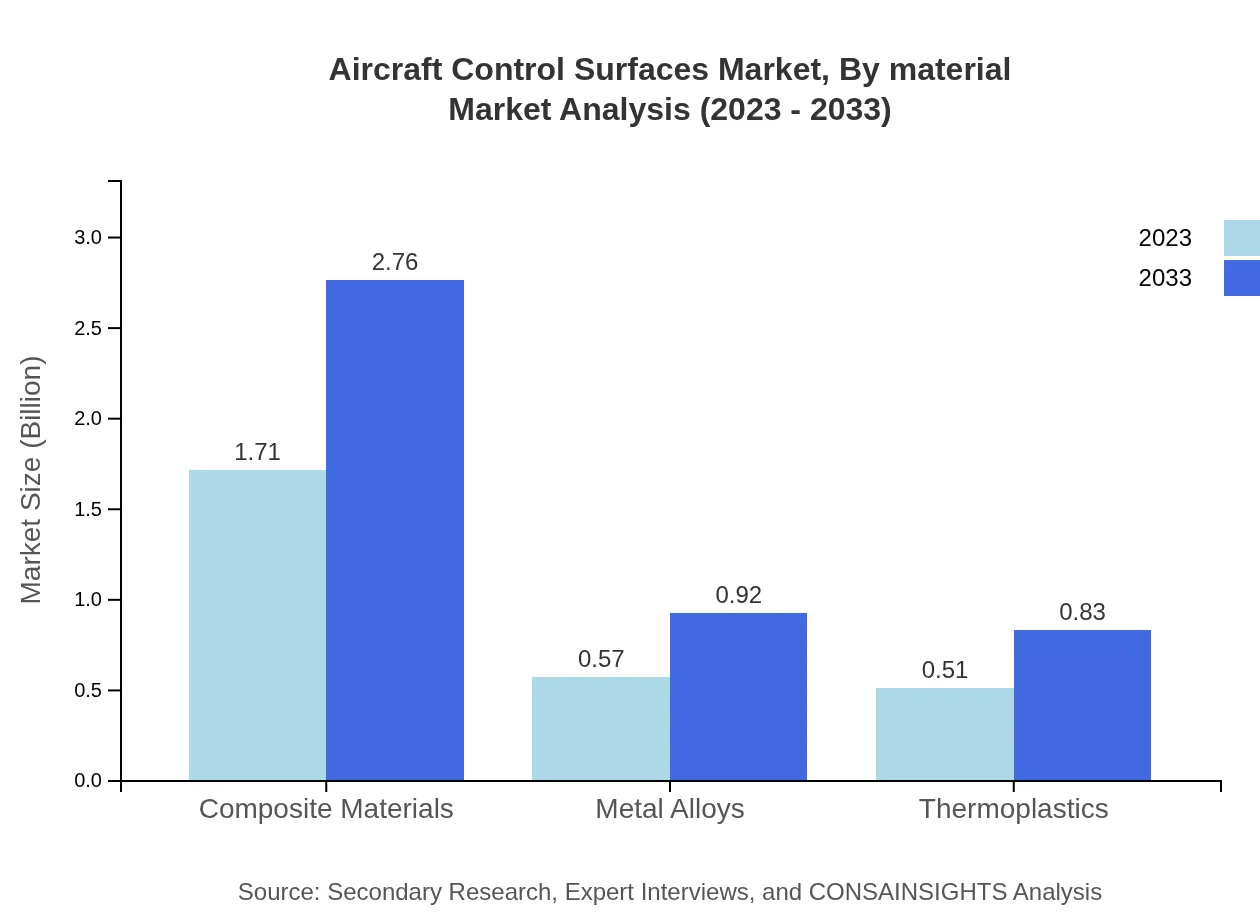

Aircraft Control Surfaces Market Analysis By Material

Composite Materials dominate the market, holding a share of 61.18% in 2023 with a projection to grow from USD 1.71 billion to USD 2.76 billion by 2033. This growth is propelled by the need for lightweight and durable aircraft components.

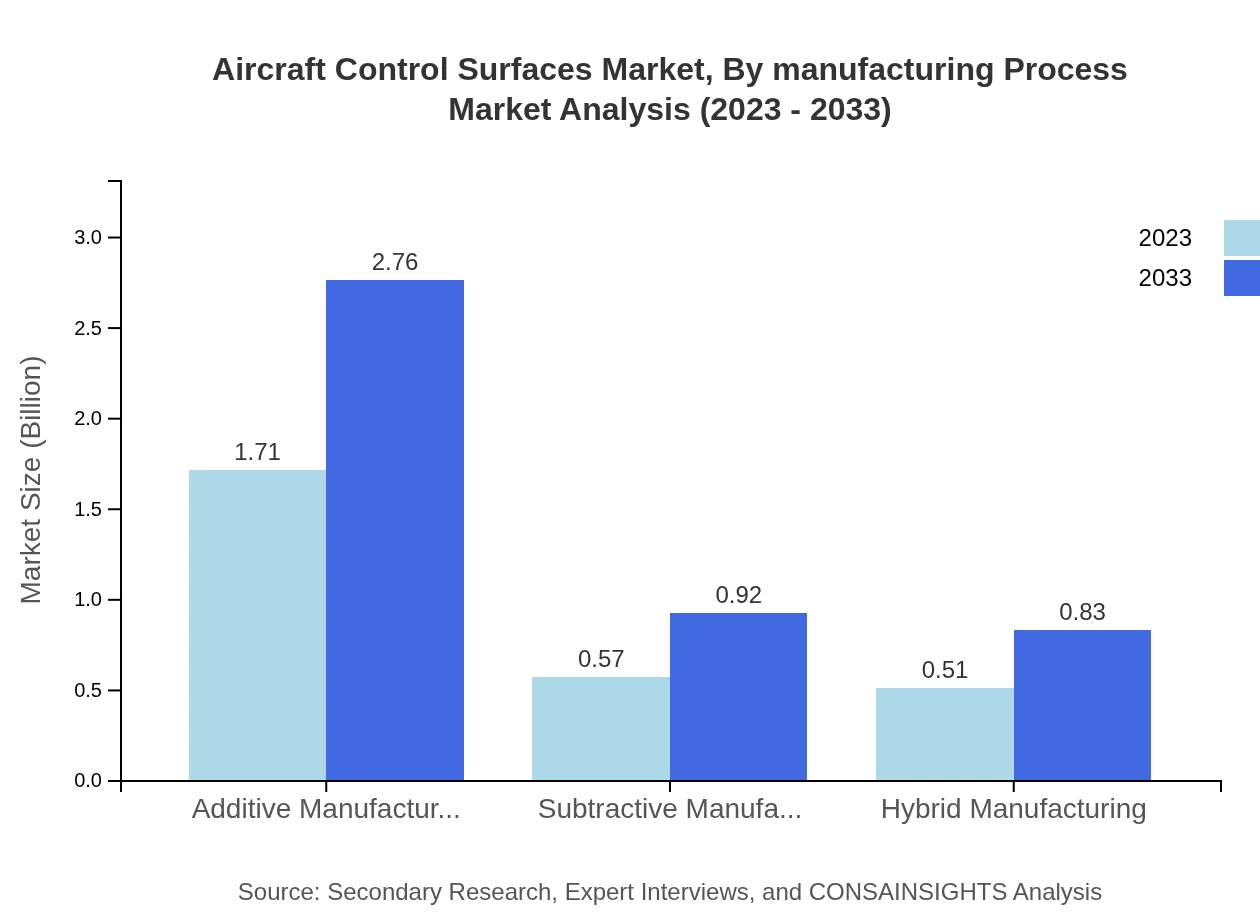

Aircraft Control Surfaces Market Analysis By Manufacturing Process

Additive Manufacturing has become a significant player in the market, contributing approximately 61.18% of the segment share in 2023, highlighting its relevance in making customized parts for aircraft appurtenances.

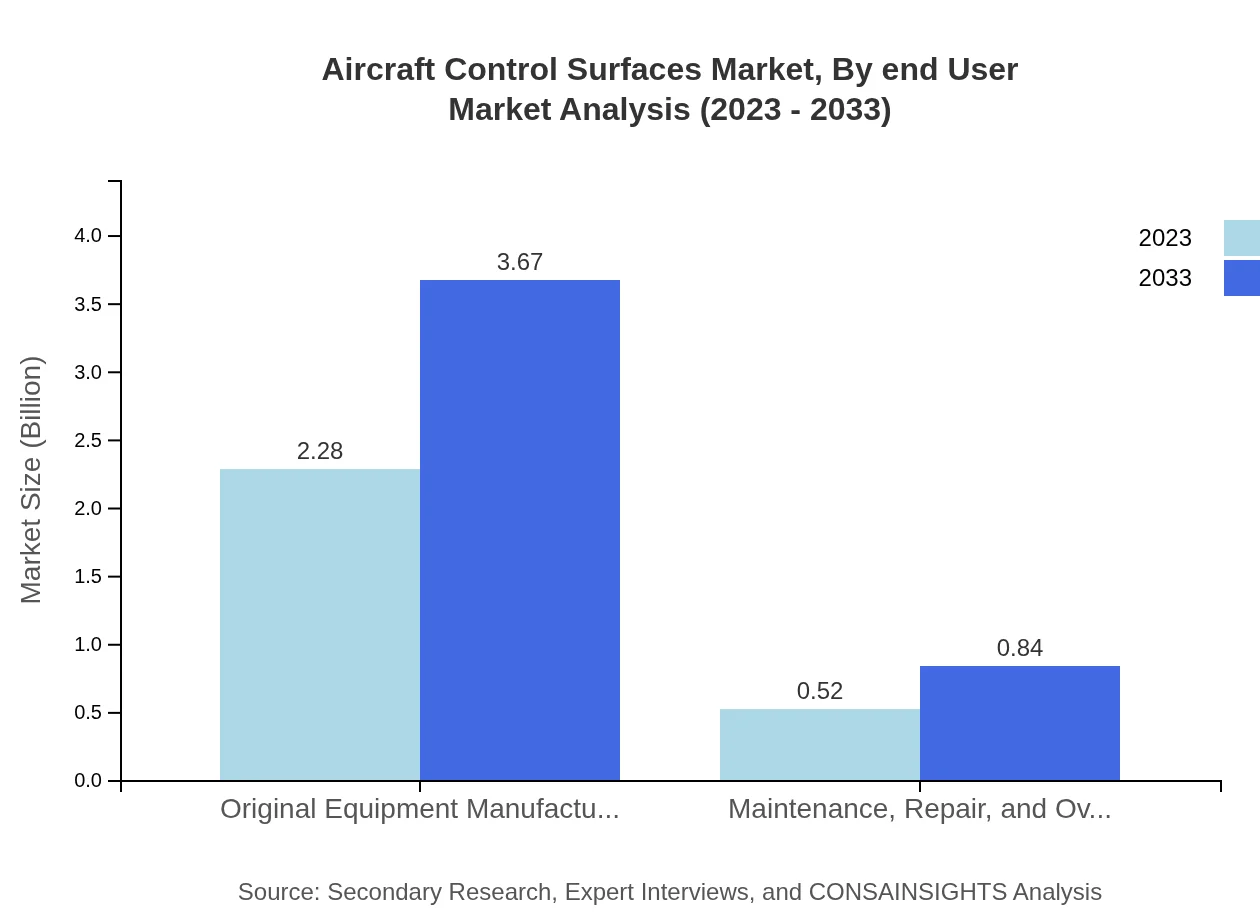

Aircraft Control Surfaces Market Analysis By End User

OEMs maintain dominance in the end-user category, constituting 81.31% of the market share in 2023. This trend underscores the importance of developing innovative manufacturing solutions that meet the rising demand for aircraft.

Aircraft Control Surfaces Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Control Surfaces Industry

Boeing :

Boeing is a leading manufacturer of commercial and military aircraft, investing heavily in advanced technologies for control surface production.Airbus:

Airbus is a major player in the aviation industry, known for innovative designs in control surfaces that enhance aerodynamics and efficiency.Raytheon Technologies:

Raytheon Technologies specializes in aerospace systems and manufactures critical components for aircraft including control surfaces.Leonardo S.p.A:

Leonardo is an Italian multinational company, focusing on aerospace, defense, and security, providing integrated solutions including aircraft control surfaces.Lockheed Martin:

Lockheed Martin is involved in aerospace and defense, noted for their advanced aircraft manufacturing and related technologies including control surfaces.We're grateful to work with incredible clients.

FAQs

What is the market size of aircraft control surfaces?

The global aircraft control surfaces market is valued at approximately $2.8 billion in 2023, with a projected CAGR of 4.8%, indicating steady growth anticipated over the coming decade.

What are the key market players or companies in the aircraft control surfaces industry?

Key players in the aircraft control surfaces industry include major OEMs, suppliers, and manufacturers who consistently drive innovations and improvements, ensuring competitiveness and quality in aerospace applications.

What are the primary factors driving the growth in the aircraft control surfaces industry?

Growth in the aircraft control surfaces market is primarily driven by the expanding aerospace sector, increasing air travel demand, technological advancements, and a focus on enhancing aircraft performance and fuel efficiency.

Which region is the fastest Growing in the aircraft control surfaces?

The Asia Pacific region is experiencing the fastest growth in the aircraft control surfaces sector, transitioning from $0.50 billion in 2023 to $0.80 billion by 2033, driven by rising manufacturing and demand for advanced aircraft.

Does ConsaInsights provide customized market report data for the aircraft control surfaces industry?

Yes, ConsaInsights offers customized market report data, tailored specifically to the aircraft control surfaces industry, enabling businesses to access targeted insights and detailed analytics based on unique needs.

What deliverables can I expect from this aircraft control surfaces market research project?

Deliverables from the aircraft control surfaces market research project typically include comprehensive market analysis, trends, segment data, regional insights, and forecasts, enabling informed strategic decision-making.

What are the market trends of aircraft control surfaces?

Current trends in the aircraft control surfaces market include increased adoption of composite materials, advancements in manufacturing technologies, and a growing emphasis on sustainable practices within the aerospace industry.