Aircraft Fuel Tanks Market Report

Published Date: 03 February 2026 | Report Code: aircraft-fuel-tanks

Aircraft Fuel Tanks Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aircraft Fuel Tanks market from 2023 to 2033, covering market size, trends, regional insights, and industry dynamics. Key insights include detailed segmentation, forecasts, and competitive landscape analysis to guide stakeholders in making informed decisions.

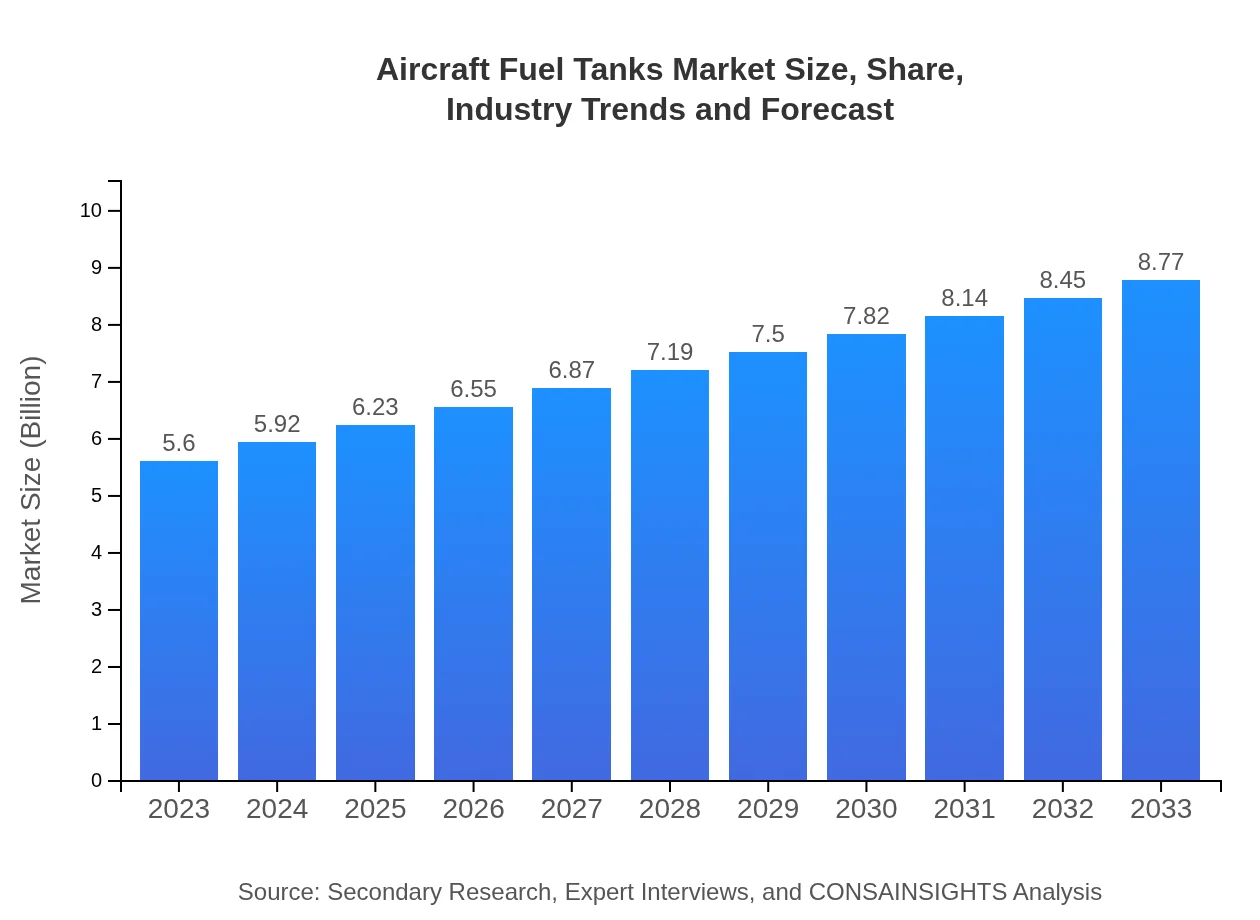

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $8.77 Billion |

| Top Companies | Northrop Grumman, Eaton Corporation, Harrison Aerospace, Boeing , Airbus |

| Last Modified Date | 03 February 2026 |

Aircraft Fuel Tanks Market Overview

Customize Aircraft Fuel Tanks Market Report market research report

- ✔ Get in-depth analysis of Aircraft Fuel Tanks market size, growth, and forecasts.

- ✔ Understand Aircraft Fuel Tanks's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Fuel Tanks

What is the Market Size & CAGR of Aircraft Fuel Tanks market in 2023?

Aircraft Fuel Tanks Industry Analysis

Aircraft Fuel Tanks Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Fuel Tanks Market Analysis Report by Region

Europe Aircraft Fuel Tanks Market Report:

Europe's market is projected to rise from $1.73 billion in 2023 to $2.72 billion by 2033. The stringent regulatory standards and increasing focus on aerospace safety are driving innovations in fuel tank manufacturing. The market is also supported by collaborations among leading manufacturers and research institutions.Asia Pacific Aircraft Fuel Tanks Market Report:

The Asia Pacific region is expected to show strong growth, with the market value projected to increase from $1.05 billion in 2023 to $1.64 billion by 2033. Key factors driving this growth include rising air travel demand and increased defense expenditures. Countries like China and India are significant contributors due to their expanding aviation sectors.North America Aircraft Fuel Tanks Market Report:

North America is the largest market, anticipated to grow from $2.05 billion in 2023 to $3.21 billion by 2033. This region benefits from established aerospace manufacturers, advanced technology adoption, and a steady increase in commercial and military aviation activities.South America Aircraft Fuel Tanks Market Report:

In South America, the Aircraft Fuel Tanks market is expected to grow from $0.34 billion in 2023 to $0.53 billion by 2033. This growth is modulated by the regional economic recovery, improving airline capacities, and increased MRO activities.Middle East & Africa Aircraft Fuel Tanks Market Report:

The Middle East and Africa region is expected to expand significantly, with the market value increasing from $0.43 billion in 2023 to $0.68 billion by 2033. Growth drivers include expanding airline networks, increased tourism, and military investments, particularly in the Gulf states.Tell us your focus area and get a customized research report.

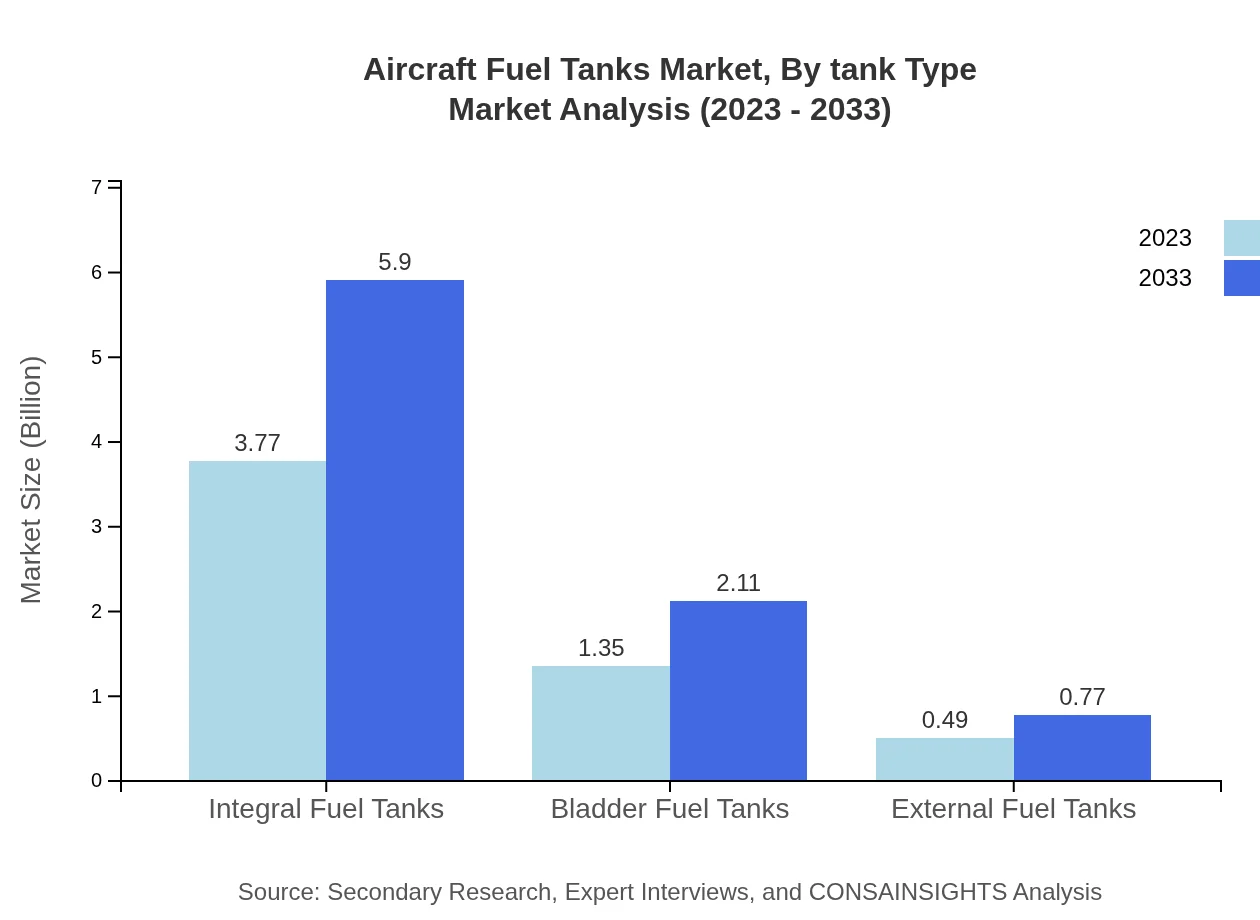

Aircraft Fuel Tanks Market Analysis By Tank Type

Integral fuel tanks represent the largest segment, with market size increasing from $3.77 billion in 2023 to $5.90 billion in 2033, capturing approximately 67.25% of market share. This is followed by bladder fuel tanks and external fuel tanks, which are projected to grow but constitute a smaller market share.

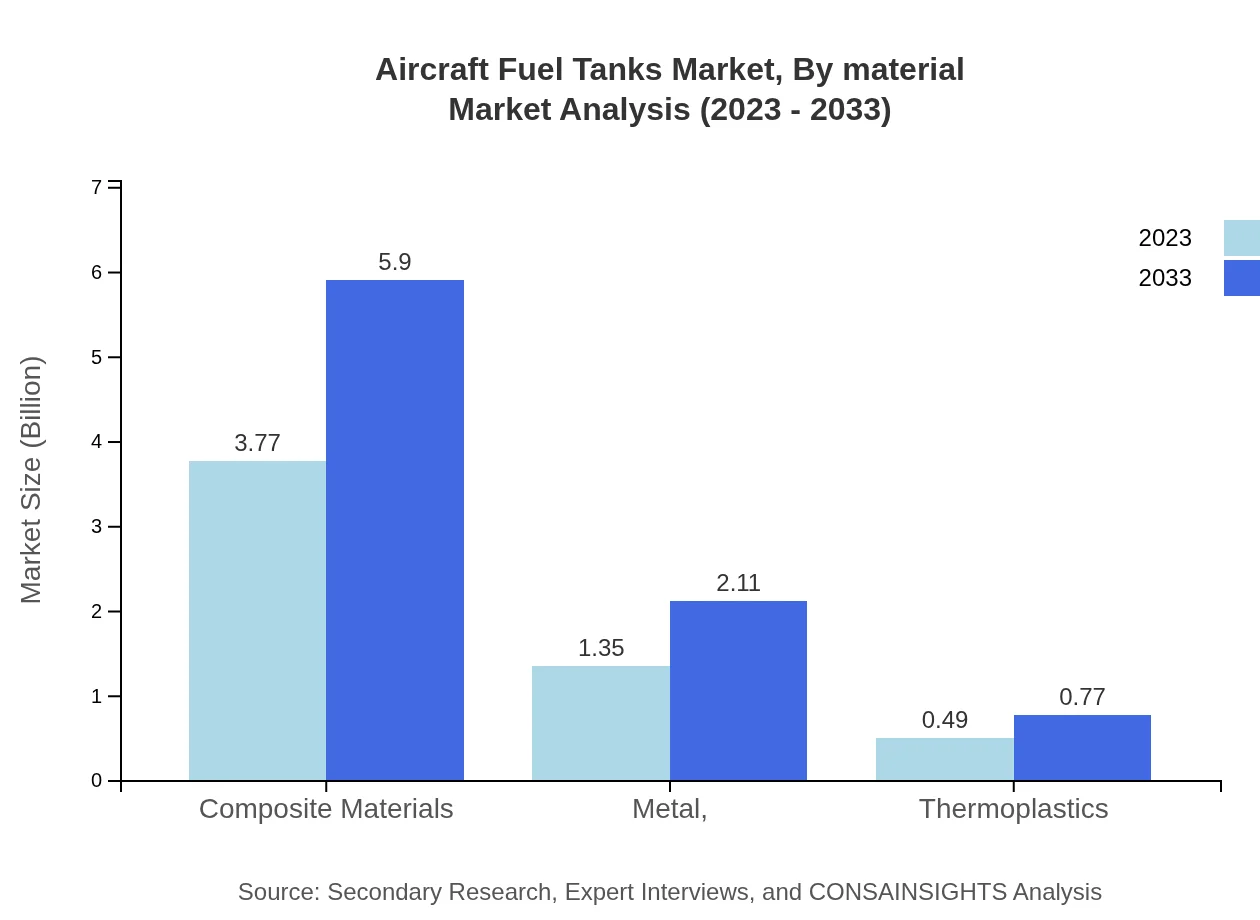

Aircraft Fuel Tanks Market Analysis By Material

In terms of materials, composites dominate with a market size of $3.77 billion in 2023, expected to reach $5.90 billion by 2033, holding a 67.25% market share. Metals represent 24.02%, while thermoplastics hold 8.73%, indicating a notable trend towards lightweight composite materials in tank design.

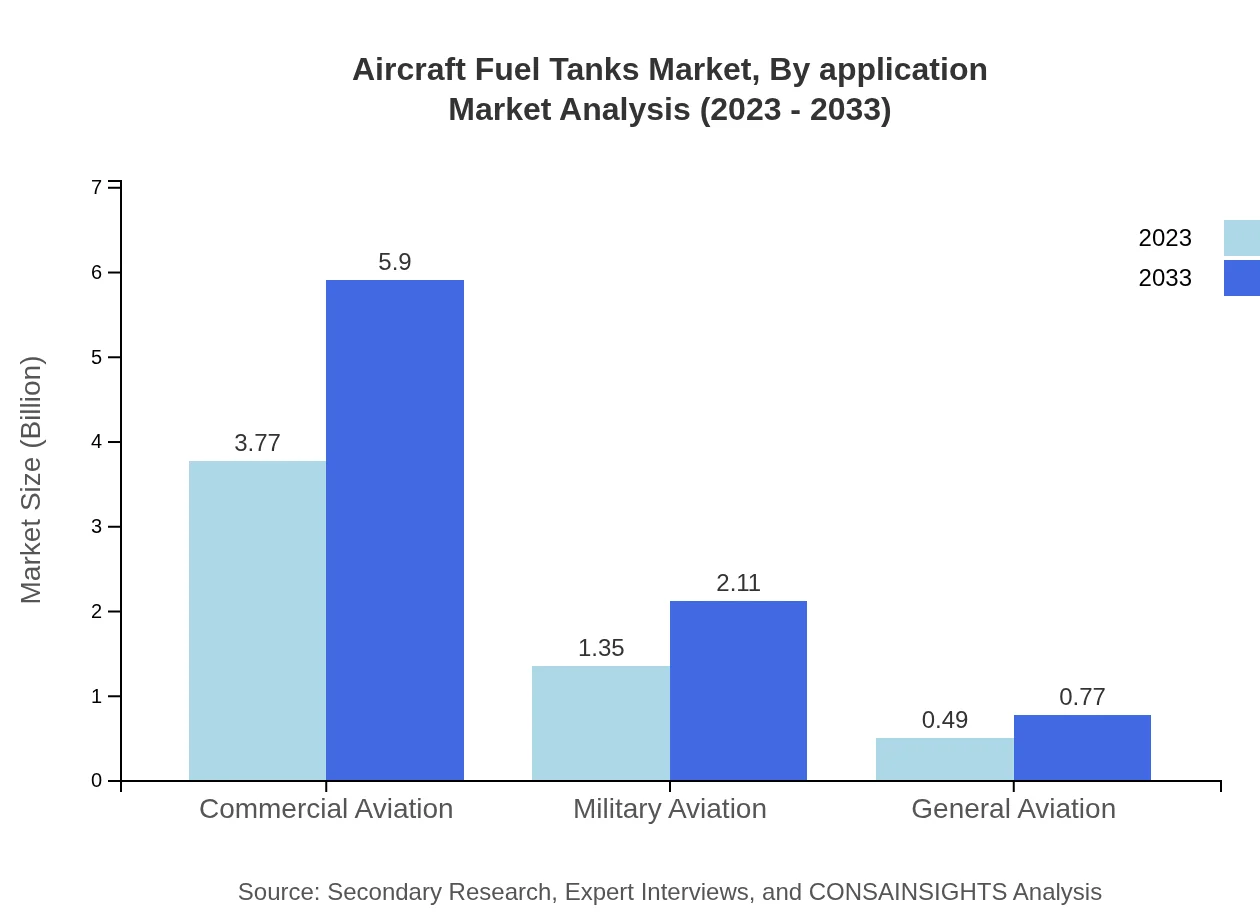

Aircraft Fuel Tanks Market Analysis By Application

The commercial aviation segment leads with a market size rising from $3.77 billion in 2023 to $5.90 billion by 2033, accounting for 67.25% of the market share. Military aviation follows with 24.02%, reflecting the ongoing military modernization efforts globally.

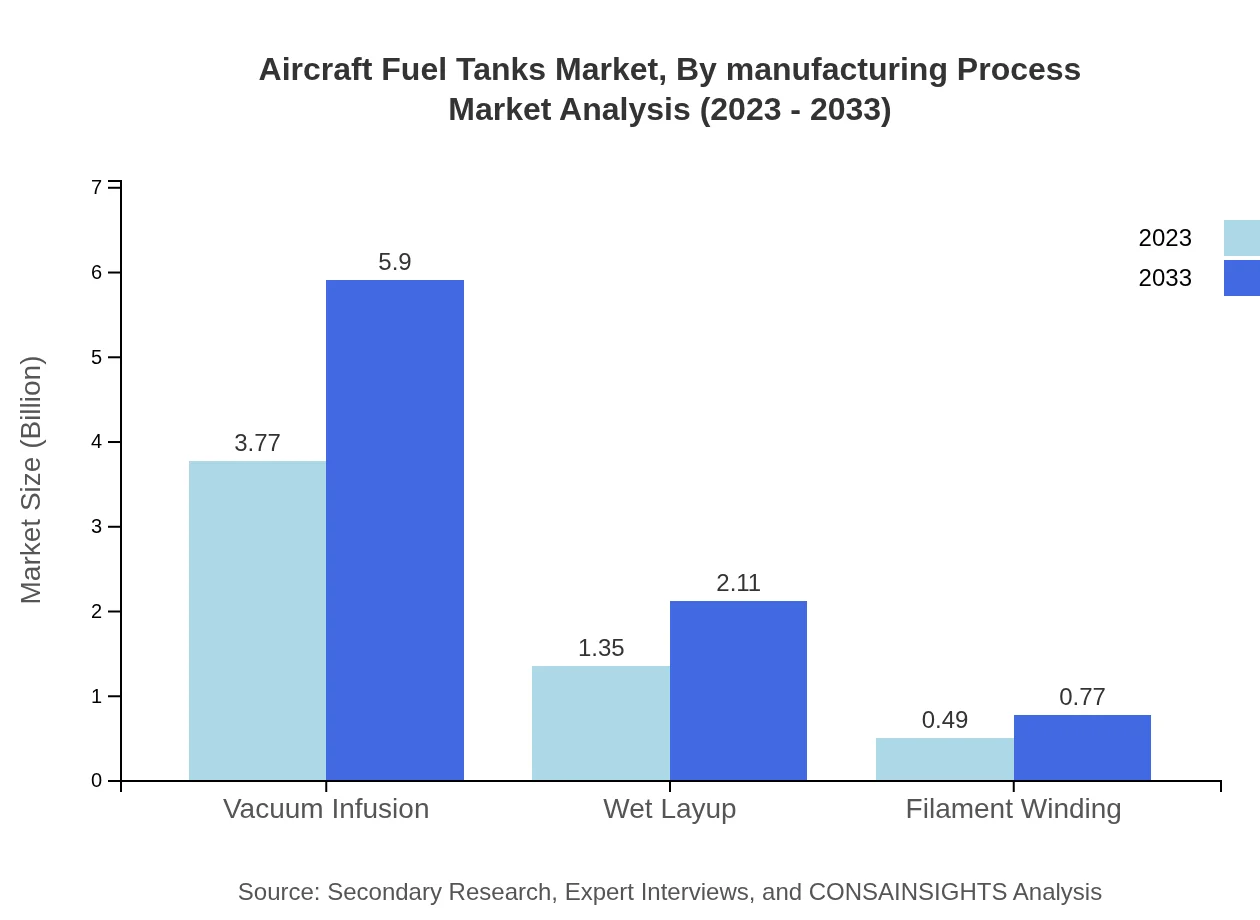

Aircraft Fuel Tanks Market Analysis By Manufacturing Process

Vacuum Infusion remains a preferred process for manufacturing aircraft fuel tanks, projected to hold a 67.25% market share, while the Wet Layup method is also significant at 24.02%. Innovations in these processes are enhancing production efficiencies.

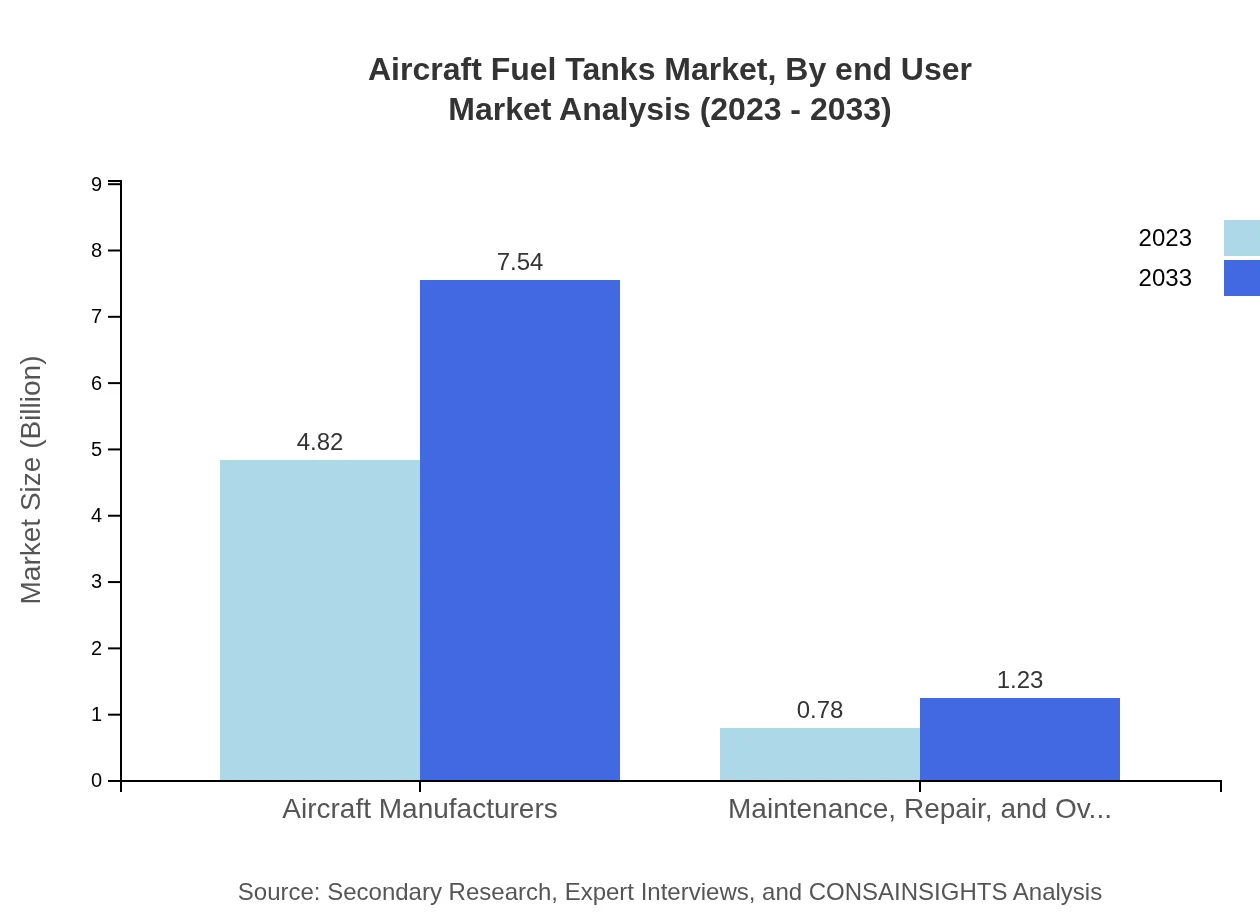

Aircraft Fuel Tanks Market Analysis By End User

Aircraft manufacturers dominate the end-user segment with a market size of $4.82 billion in 2023, projected to increase to $7.54 billion by 2033, representing 86.02% of the overall market. MRO services hold a crucial but smaller share.

Aircraft Fuel Tanks Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Fuel Tanks Industry

Northrop Grumman:

A leader in aerospace and defense technology, Northrop Grumman specializes in advanced fuel tank systems for military and commercial applications.Eaton Corporation:

Eaton provides innovative fuel management systems, ensuring safety and efficiency across aviation applications.Harrison Aerospace:

Known for its state-of-the-art manufacturing techniques, Harrison Aerospace develops fuel tanks that meet rigorous industry standards.Boeing :

A major player in the aerospace sector, Boeing designs and integrates advanced fuel systems for its aircraft portfolio.Airbus:

Airbus focuses on creating lightweight and efficient fuel tank solutions, leveraging sustainable materials and advanced engineering.We're grateful to work with incredible clients.

FAQs

What is the market size of Aircraft Fuel Tanks?

The global Aircraft Fuel Tanks market is valued at approximately $5.6 billion in 2023 and is projected to grow at a CAGR of 4.5% from 2023 to 2033.

What are the key market players or companies in the Aircraft Fuel Tanks industry?

Key players in the Aircraft Fuel Tanks market include prominent companies such as Safran, Collins Aerospace, and Zodiac Aerospace, specializing in innovative fuel tank designs and technologies.

What are the primary factors driving the growth in the Aircraft Fuel Tanks industry?

Growth drivers in the Aircraft Fuel Tanks industry include increasing air travel demand, advancements in fuel efficiency, and the rising trend of lightweight materials to enhance aircraft performance.

Which region is the fastest Growing in the Aircraft Fuel Tanks market?

North America is the fastest-growing region, with the market projected to grow from $2.05 billion in 2023 to $3.21 billion in 2033, driven by high aviation activity and technology adoption.

Does ConsaInsights provide customized market report data for the Aircraft Fuel Tanks industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs, ensuring that clients get relevant insights for the Aircraft Fuel Tanks industry.

What deliverables can I expect from this Aircraft Fuel Tanks market research project?

Deliverables include comprehensive market analysis, segment data, competitive landscape, forecasts, and customized insights relevant to the Aircraft Fuel Tanks market.

What are the market trends of Aircraft Fuel Tanks?

Current trends in the Aircraft Fuel Tanks market include increased adoption of composite materials for fuel tanks and advancements in integrated fuel tank designs, enhancing safety and efficiency.