Aircraft Insulation Market Report

Published Date: 03 February 2026 | Report Code: aircraft-insulation

Aircraft Insulation Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Aircraft Insulation market, providing insights from 2023 to 2033. It covers market size, growth rates, segmentation, technology trends, regional analyses, and profiles of key industry players.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

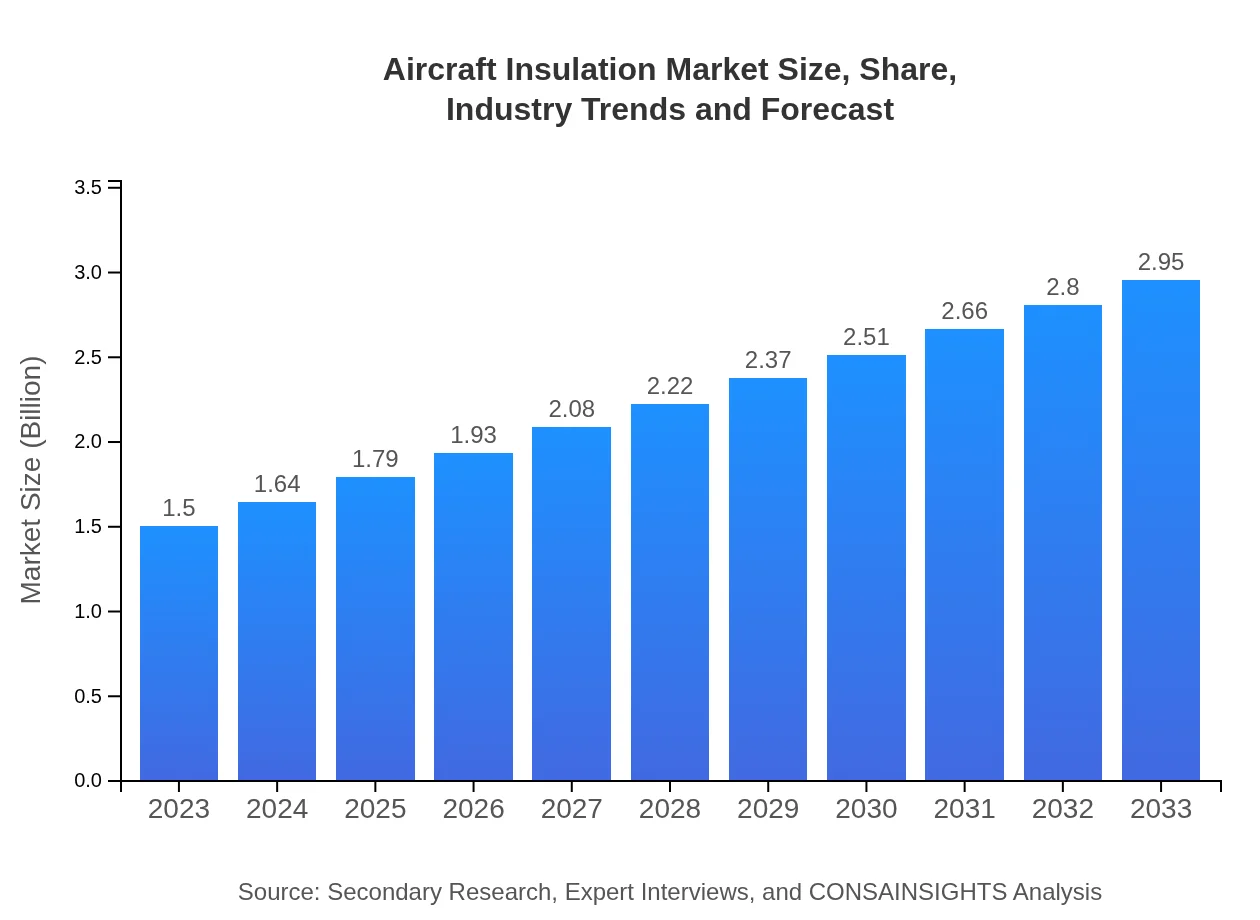

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $2.95 Billion |

| Top Companies | 3M, DuPont, BASF, Rockwool International, Cabot Corporation |

| Last Modified Date | 03 February 2026 |

Aircraft Insulation Market Overview

Customize Aircraft Insulation Market Report market research report

- ✔ Get in-depth analysis of Aircraft Insulation market size, growth, and forecasts.

- ✔ Understand Aircraft Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Insulation

What is the Market Size & CAGR of Aircraft Insulation market in 2023?

Aircraft Insulation Industry Analysis

Aircraft Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Insulation Market Analysis Report by Region

Europe Aircraft Insulation Market Report:

The European market for Aircraft Insulation is set to grow from $0.45 billion in 2023 to $0.88 billion by 2033. Significant investments in environmental compliance and energy efficiency in aviation propel this market, alongside a strong presence of established aerospace companies.Asia Pacific Aircraft Insulation Market Report:

The Asia Pacific region shows promising growth potential in the Aircraft Insulation market, projected to grow from $0.31 billion in 2023 to $0.61 billion by 2033. This growth is propelled by the increasing air travel demand, expanding airline fleets, and significant investments in aircraft manufacturing across countries such as China and India.North America Aircraft Insulation Market Report:

North America continues to be a leader in the Aircraft Insulation market, expanding from $0.51 billion in 2023 to approximately $1.01 billion by 2033. The region's dominant position is attributed to a sophisticated aerospace industry and a focus on technological advancements in insulation materials and methods.South America Aircraft Insulation Market Report:

In South America, the Aircraft Insulation market is expected to reach $0.07 billion by 2033 from $0.04 billion in 2023. A recovering economy and rising travel demand post-pandemic are key factors driving this growth, alongside regional advancements in aviation infrastructure.Middle East & Africa Aircraft Insulation Market Report:

The Middle East and Africa market is projected to increase from $0.19 billion in 2023 to $0.37 billion by 2033. The rise in air travel demand and investments in aircraft modernization and maintenance fuels the market growth in this region.Tell us your focus area and get a customized research report.

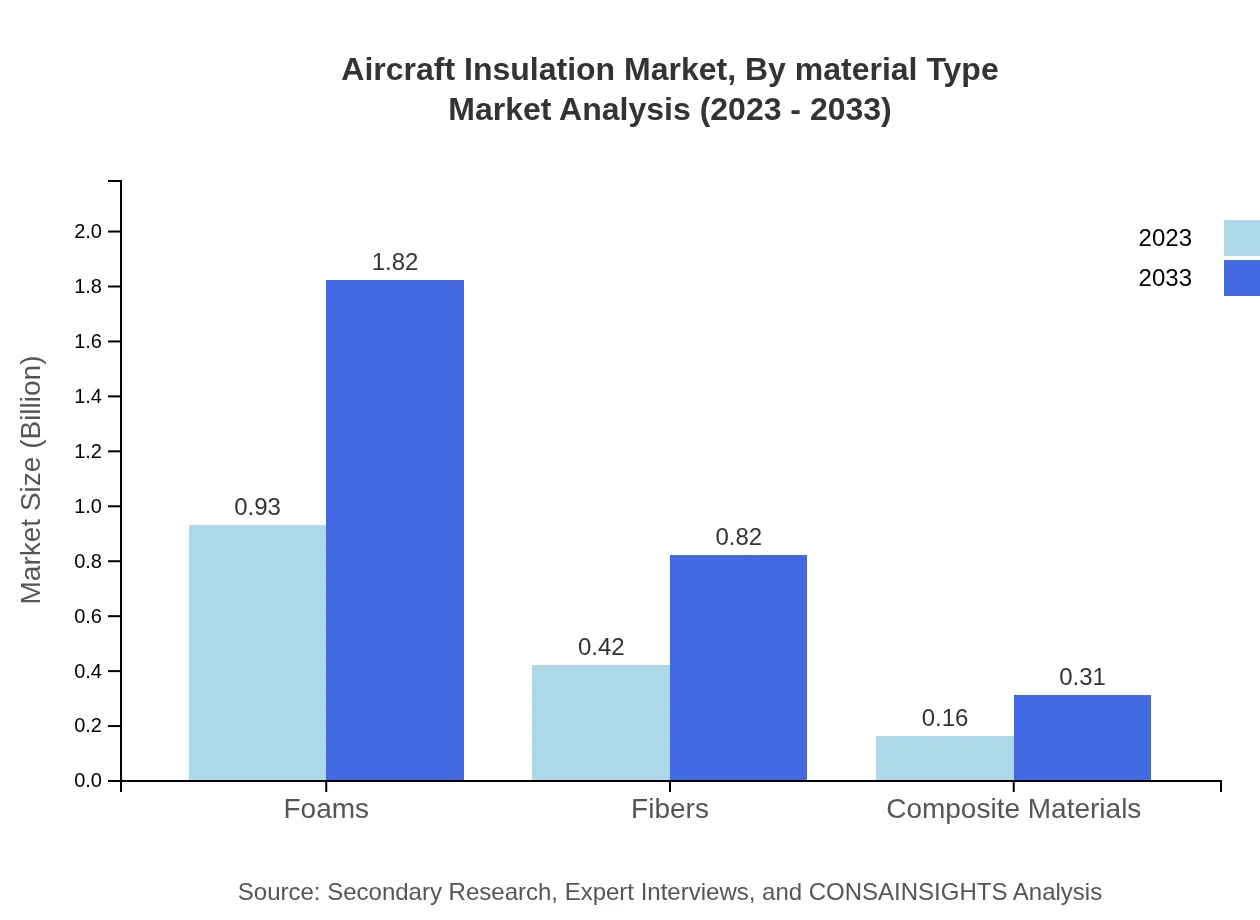

Aircraft Insulation Market Analysis By Material Type

Foams hold a significant share of the Aircraft Insulation market, accounting for $0.93 billion in 2023 and expected to climb to $1.82 billion by 2033, representing 61.67% market share. They are favored for their lightweight properties. Fibers, with a market size of $0.42 billion in 2023, are projected to grow to $0.82 billion, highlighting their relevance in both thermal and acoustic applications. Composite materials also play a crucial role, although with a smaller share of $0.31 billion in 2033.

Aircraft Insulation Market Analysis By Application

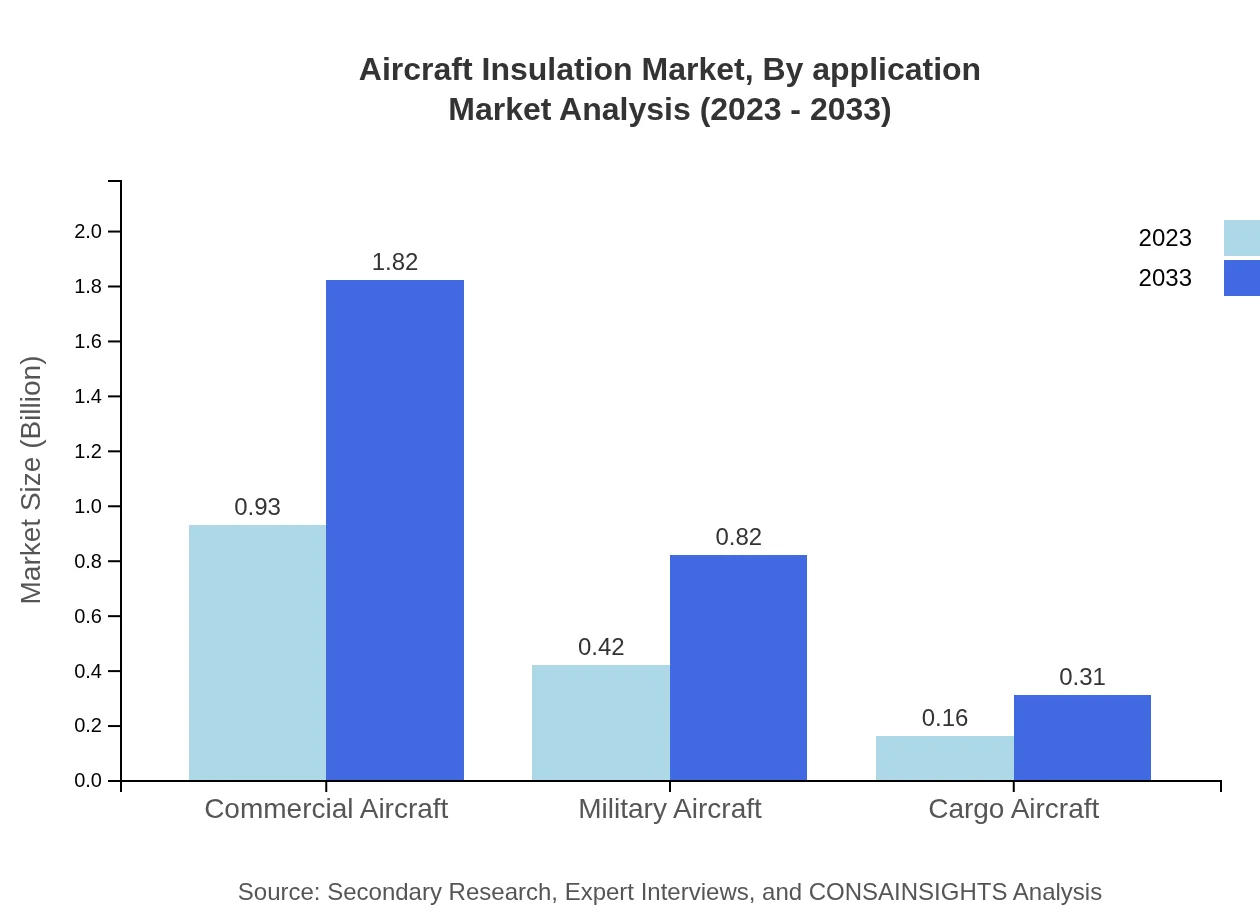

The commercial aircraft segment dominates the Aircraft Insulation market, accounting for $0.93 billion in 2023, set to rise to $1.82 billion by 2033, driven by increasing passenger traffic and fleet expansions. Military aircraft, with a predicted growth from $0.42 billion to $0.82 billion in the same period, reflects defense spending increases. The cargo aircraft segment, albeit smaller, is also forecasted to double to $0.31 billion by 2033 as global trade increases.

Aircraft Insulation Market Analysis By Insulation Type

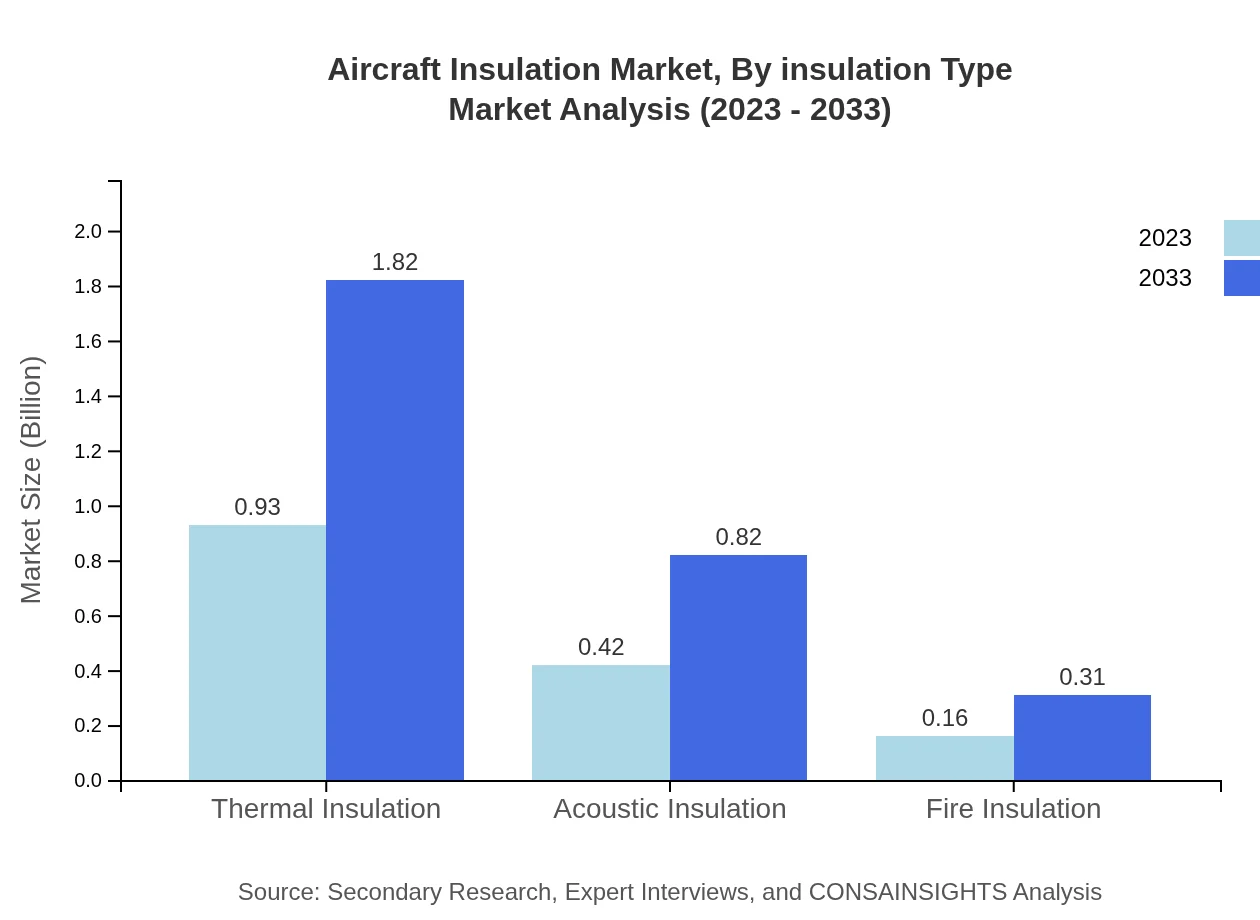

Thermal insulation, with a market size of $0.93 billion in 2023, is essential for ensuring efficiency and safety in aircraft operations, projected to increase to $1.82 billion by 2033. Acoustic insulation is also critical, showing significant growth potential especially in commercial applications, climbing from $0.42 billion to $0.82 billion. Fire insulation, though a smaller share currently at $0.16 billion, is expected to grow, reflecting evolving safety regulations.

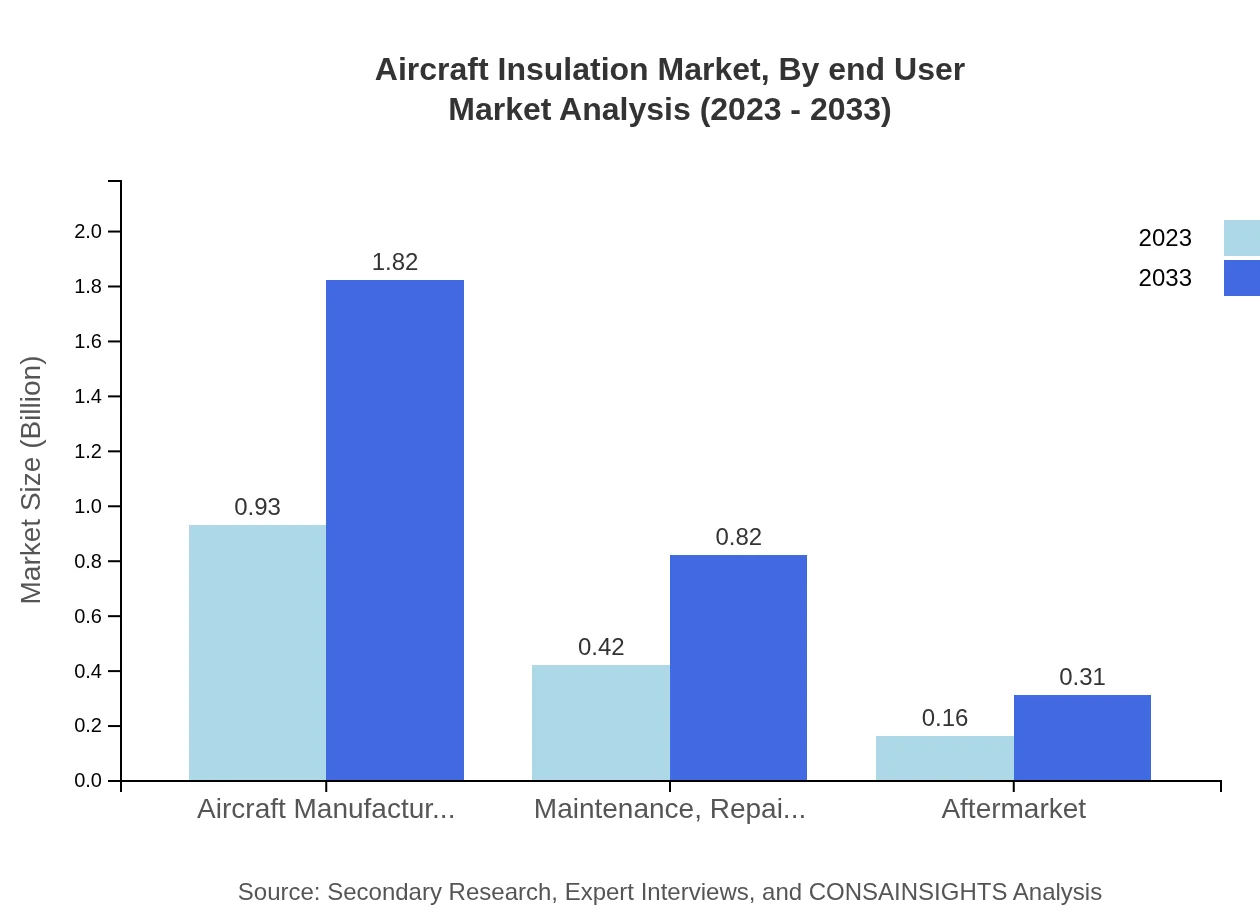

Aircraft Insulation Market Analysis By End User

The Aircraft Manufacturers segment is the largest end-user, growing from $0.93 billion in 2023 to $1.82 billion by 2033, indicating a strong relationship with the rising production of aircraft. The Maintenance, Repair, and Overhaul (MRO) segment is vital as well, with a size expanding from $0.42 billion to $0.82 billion. The aftermarket segment, while smaller, reflects product sustainability trends and is set to grow from $0.16 billion to $0.31 billion.

Aircraft Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Insulation Industry

3M:

A technology company known for its innovative insulation solutions utilizing aerogel technologies to enhance thermal protection and fire resistance in aircraft.DuPont:

DuPont produces high-performance insulation materials that are lightweight and provide optimal thermal and acoustic insulation, crucial for modern aerospace applications.BASF:

BASF focuses on providing advanced insulation solutions including foams and composites, emphasizing sustainability and performance in aircraft manufacturing.Rockwool International:

Rockwool specializes in stone wool insulation that offers exceptional fire resistance and durability, widely used in various aircraft insulation applications.Cabot Corporation:

Cabot is known for its advanced specialty chemicals and materials, producing insulation products that ensure compliance with stringent aviation regulations.We're grateful to work with incredible clients.

FAQs

What is the market size of aircraft insulation?

The global aircraft insulation market is valued at approximately $1.5 billion in 2023 and is projected to grow at a CAGR of 6.8%. By 2033, the market size is expected to expand significantly, reflecting the growing demand in the aviation industry.

What are the key market players or companies in the aircraft insulation industry?

Key players in the aircraft insulation market include Zotefoams, BASF, 3M, and DuPont. These companies dominate the industry due to their innovative product offerings and commitment to enhancing aircraft performance and passenger comfort.

What are the primary factors driving the growth in the aircraft insulation industry?

The growth in the aircraft insulation market is driven by increased air travel, rising demand for fuel-efficient aircraft, and advancements in insulation materials that improve thermal and acoustic performance. Regulatory requirements for noise reduction also contribute to market expansion.

Which region is the fastest Growing in the aircraft insulation market?

The North America region is the fastest-growing segment in the aircraft insulation market. With a projected market growth from $0.51 billion in 2023 to $1.01 billion in 2033, it showcases a strong demand driven by major aerospace manufacturers and increasing air travel.

Does ConsaInsights provide customized market report data for the aircraft insulation industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the aircraft insulation industry. Clients can request detailed insights based on unique requirements and market dynamics.

What deliverables can I expect from this aircraft insulation market research project?

Clients can expect comprehensive deliverables, including detailed market reports, data analytics, trend analysis, and forecasts on market size and segments. Tailored insights on specific regions and manufacturers will also be provided.

What are the market trends of aircraft insulation?

Current trends in the aircraft insulation market include a shift toward lightweight materials, eco-friendly alternatives, and enhanced acoustic performance designs. There is a growing emphasis on thermal insulation to improve energy efficiency in aircraft.