Aircraft Paints Market Report

Published Date: 03 February 2026 | Report Code: aircraft-paints

Aircraft Paints Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report analyzes the Aircraft Paints market from 2023 to 2033, focusing on market trends, segmentation, regional analysis, and forecasts. It provides valuable insights into market size, growth rates, and the competitive landscape of key industry players.

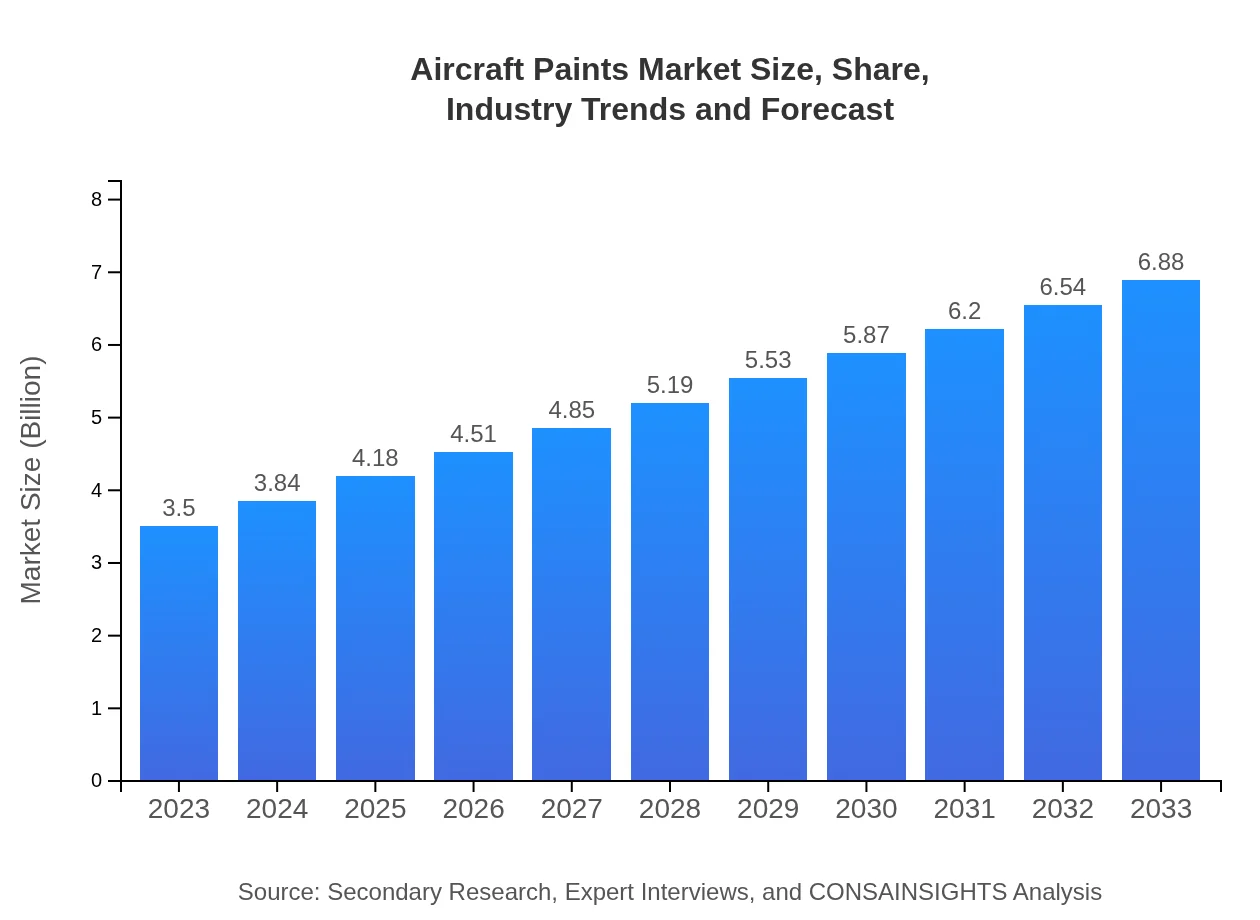

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | PPG Industries, AkzoNobel, BASF, Sherwin-Williams, Hempel |

| Last Modified Date | 03 February 2026 |

Aircraft Paints Market Overview

Customize Aircraft Paints Market Report market research report

- ✔ Get in-depth analysis of Aircraft Paints market size, growth, and forecasts.

- ✔ Understand Aircraft Paints's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Paints

What is the Market Size & CAGR of Aircraft Paints market in 2023?

Aircraft Paints Industry Analysis

Aircraft Paints Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Paints Market Analysis Report by Region

Europe Aircraft Paints Market Report:

The European market is anticipated to grow from 0.95 billion USD in 2023 to 1.87 billion USD by 2033. Key factors driving this growth include advancements in aviation technologies, collaborations between manufacturers, and government initiatives promoting sustainable practices.Asia Pacific Aircraft Paints Market Report:

In 2023, the Asia Pacific region's Aircraft Paints market is valued at approximately 0.74 billion USD, projected to grow to 1.46 billion USD by 2033. The growth is driven by increasing air travel, a booming aerospace sector, and rising disposable incomes in emerging economies.North America Aircraft Paints Market Report:

North America boasts the largest share of the Aircraft Paints market, valued at 1.24 billion USD in 2023, with a forecast of 2.43 billion USD by 2033. This growth is fueled by the presence of major airlines, a high turnover of aircraft, and strict adherence to aviation safety and aesthetics.South America Aircraft Paints Market Report:

South America's market is relatively small, valued at 0.08 billion USD in 2023, with expectations of reaching 0.16 billion USD by 2033. The growth is largely dependent on the stabilization of the aviation industry and increased demand for regional flights.Middle East & Africa Aircraft Paints Market Report:

In the Middle East and Africa, the market size is projected to increase from 0.49 billion USD in 2023 to 0.95 billion USD by 2033, attributed to investments in aviation infrastructure and a growing preference for regional airlines.Tell us your focus area and get a customized research report.

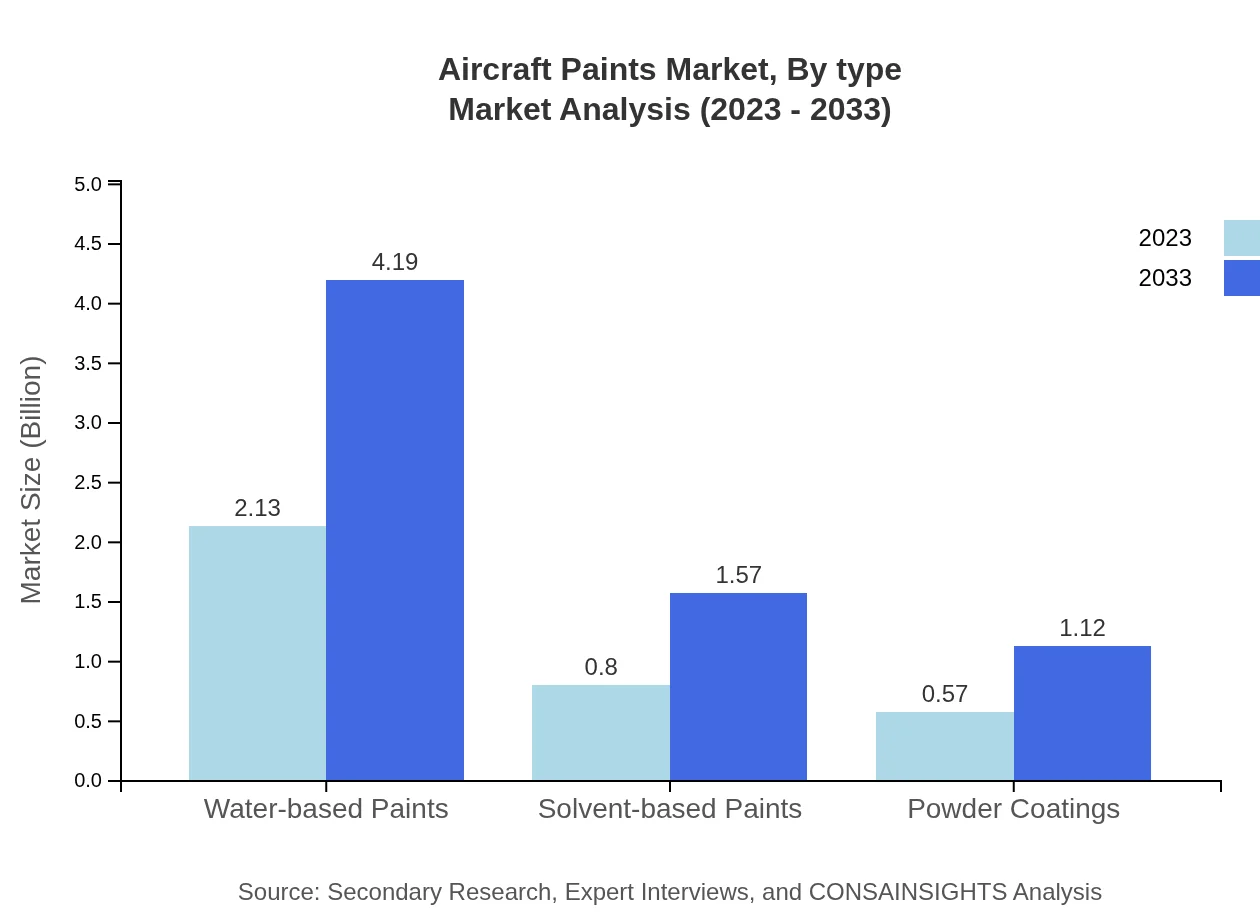

Aircraft Paints Market Analysis By Type

The Aircraft Paints market by type includes water-based paints, solvent-based paints, and powder coatings. Water-based paints dominate the market, with an estimated size of 2.13 billion USD in 2023, expected to reach 4.19 billion USD by 2033, attributed to their low VOC emissions. Solvent-based paints account for 0.80 billion USD of the market in 2023, projected to grow to 1.57 billion USD, while powder coatings start at 0.57 billion USD, expected to reach 1.12 billion USD by 2033.

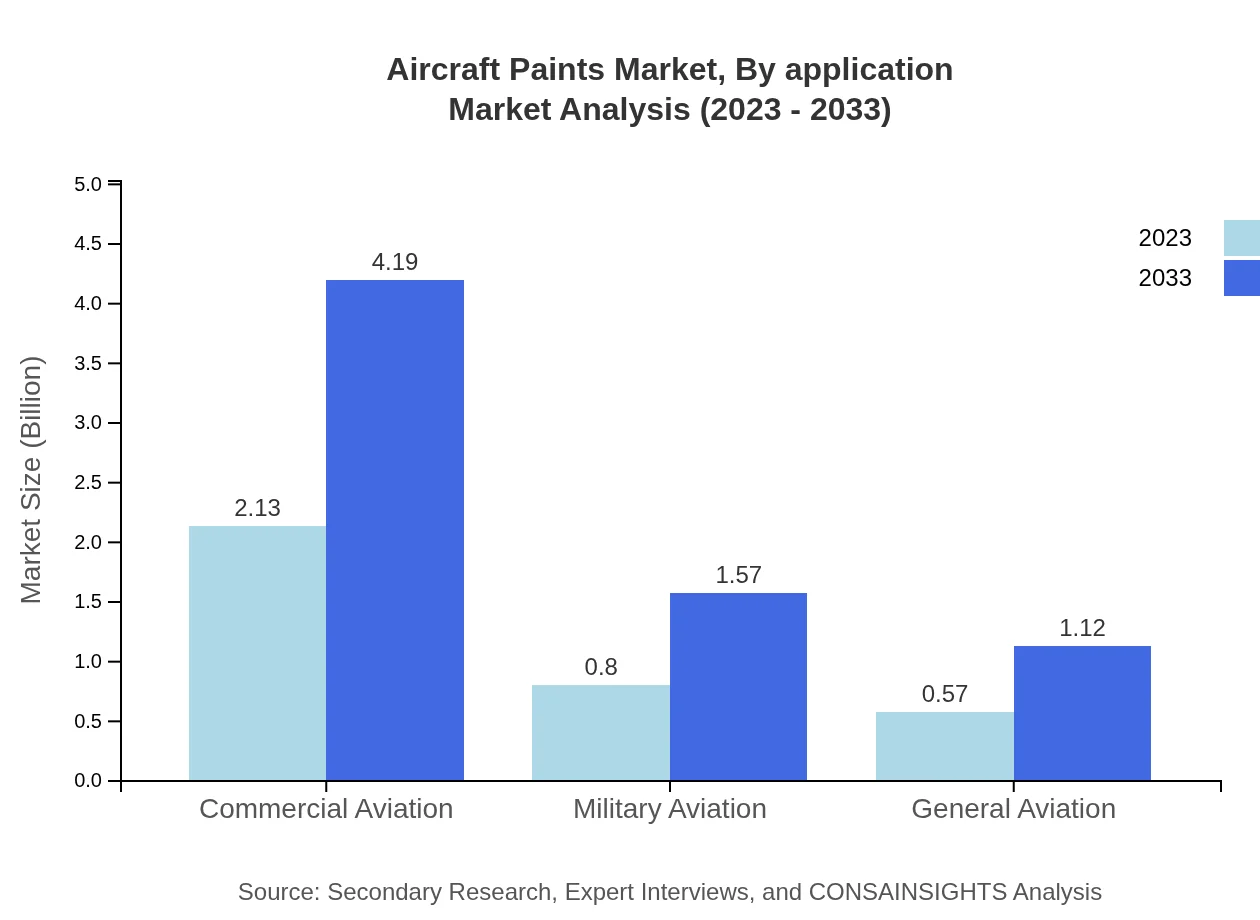

Aircraft Paints Market Analysis By Application

Market segmentation by application reveals commercial aviation dominating with a size of 2.13 billion USD in 2023, growing to 4.19 billion USD by 2033. Military aviation holds 0.80 billion USD, expected to reach 1.57 billion USD, and general aviation starts at 0.57 billion USD, projected to grow to 1.12 billion USD.

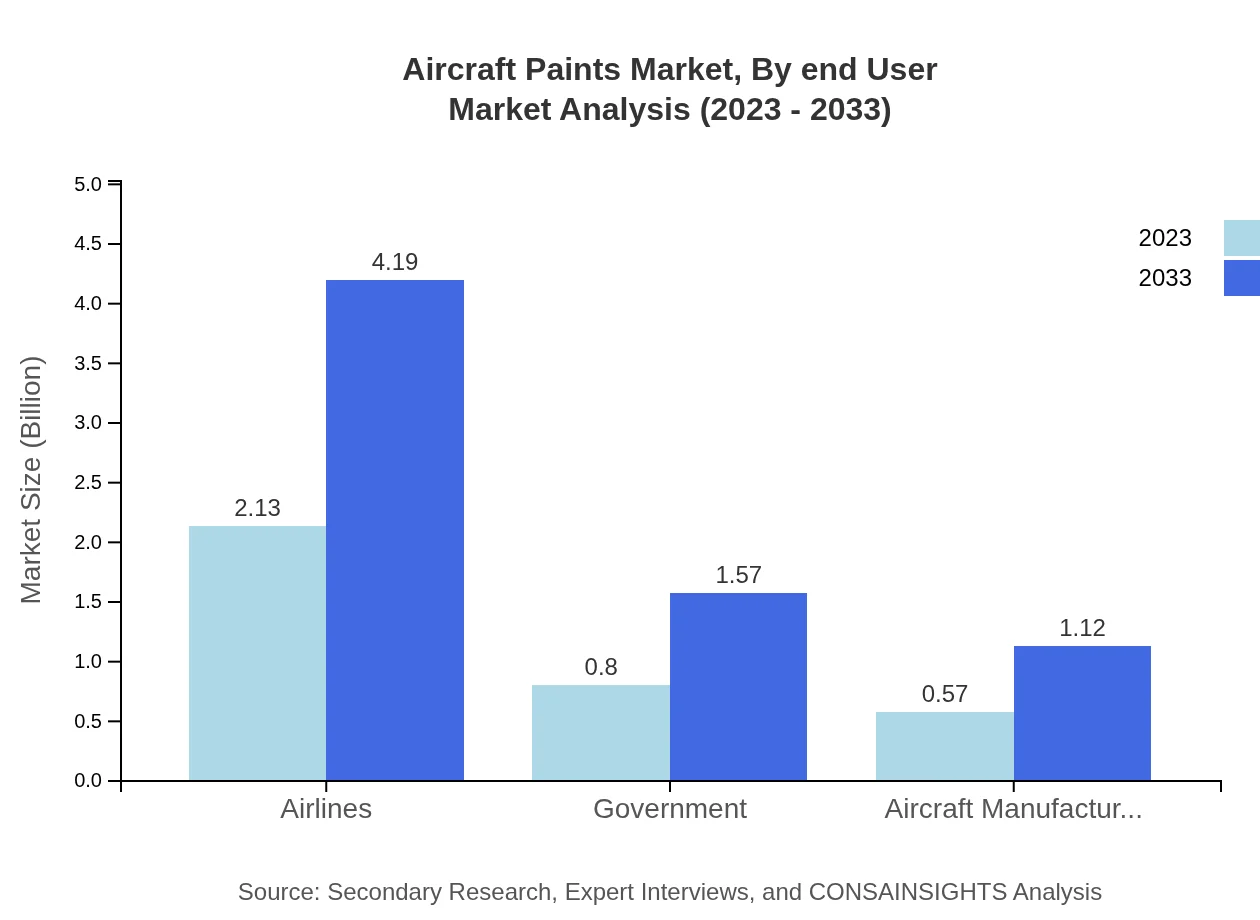

Aircraft Paints Market Analysis By End User

Segmented by end-user, airlines hold the largest market share, valued at 2.13 billion USD in 2023, projected to rise to 4.19 billion USD. Government and private aircraft manufacturers represent markets of 0.80 billion and 0.57 billion USD, respectively, with forecasted growth expected to follow similar trends.

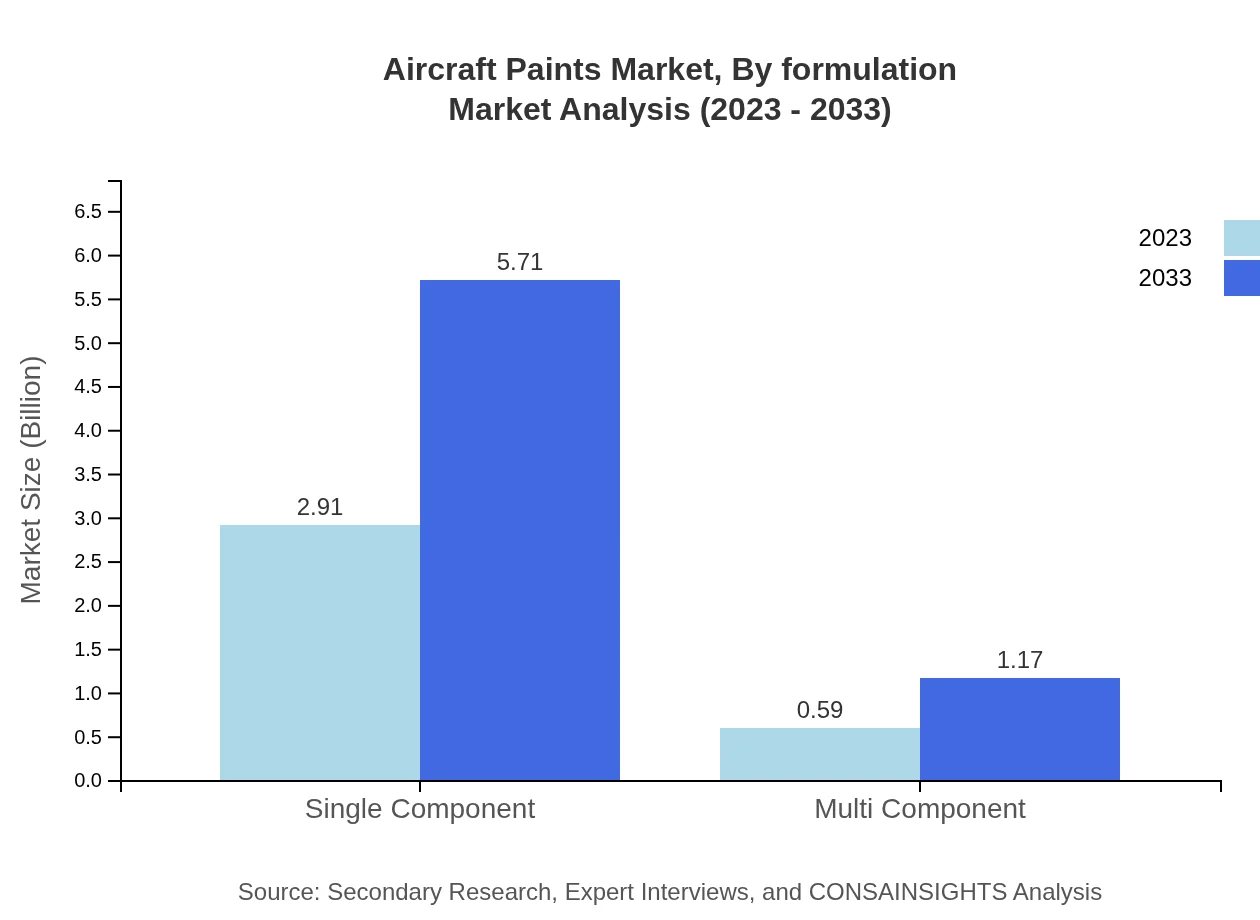

Aircraft Paints Market Analysis By Formulation

In terms of formulation, single component paints lead the market with a value of 2.91 billion USD in 2023 and a projected size of 5.71 billion USD. Multi-component formulations are currently at 0.59 billion USD, with expectations of reaching 1.17 billion USD by 2033.

Aircraft Paints Market Analysis By Compliance

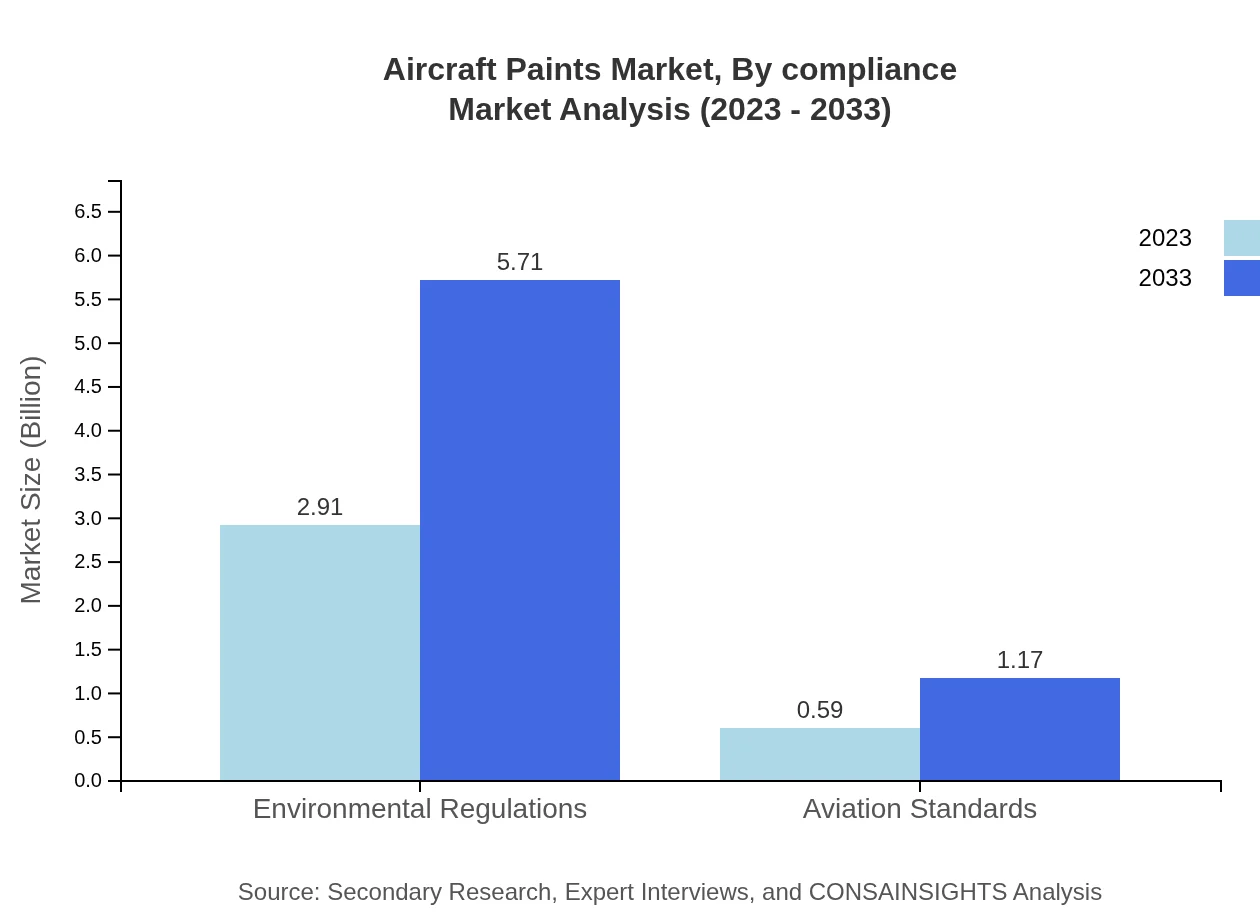

Compliance with environmental regulations is critical, with a market size of 2.91 billion USD in 2023, reaching 5.71 billion USD by 2033, affirming the industry's rapid adaptation to regulatory demands and standards in aviation.

Aircraft Paints Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Paints Industry

PPG Industries:

A leading supplier of aircraft coating products, offering innovative and sustainable solutions tailored to the needs of airlines and manufacturers.AkzoNobel:

Known for its extensive portfolio of paints and coatings, AkzoNobel focuses on developing eco-friendly products that meet the stringent requirements of the aviation sector.BASF:

A global chemical company that provides advanced paint solutions for the aircraft industry, emphasizing research and development for performance improvement.Sherwin-Williams:

A prominent paint manufacturer, Sherwin-Williams specializes in high-quality coatings for aerospace applications, leveraging technology to enhance product durability.Hempel:

Hempel is recognized for its innovative coating solutions and is committed to sustainable practices in the aerospace coatings market.We're grateful to work with incredible clients.

FAQs

What is the market size of aircraft Paints?

The global aircraft paints market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 6.8% from 2023 to 2033, indicating robust growth in the industry.

What are the key market players or companies in the aircraft Paints industry?

Key players in the aircraft-paints market include major manufacturers that provide various coatings and solutions tailored for both commercial and military aircraft applications.

What are the primary factors driving the growth in the aircraft Paints industry?

The growth in the aircraft-paints industry is driven by increasing air travel demand, advancements in paint technologies, and stringent environmental regulations enhancing product performance and sustainability.

Which region is the fastest Growing in the aircraft Paints market?

Asia Pacific is the fastest-growing region for aircraft paints, expected to rise from $0.74 billion in 2023 to $1.46 billion in 2033 due to expanding aviation sectors and rising demand for new aircraft.

Does ConsaInsights provide customized market report data for the aircraft Paints industry?

Yes, ConsaInsights offers customized market reports that can be tailored to specific requirements, providing in-depth analysis and insights on various aspects of the aircraft-paints market.

What deliverables can I expect from this aircraft Paints market research project?

Deliverables include detailed market analysis, trend reports, competitive landscape assessments, and forecasts segmented by region and type, ensuring comprehensive insights into the aircraft-paints market.

What are the market trends of aircraft Paints?

Market trends indicate a shift towards water-based paints, environmentally friendly solutions, and innovations in coating technologies, enhancing durability and performance for various aviation applications.