Aircraft Pumps Market Report

Published Date: 22 January 2026 | Report Code: aircraft-pumps

Aircraft Pumps Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aircraft Pumps market from 2023 to 2033, offering insights into market size, trends, segmentation, and regional dynamics. It aims to equip stakeholders with valuable data and forecasts to support strategic decision-making.

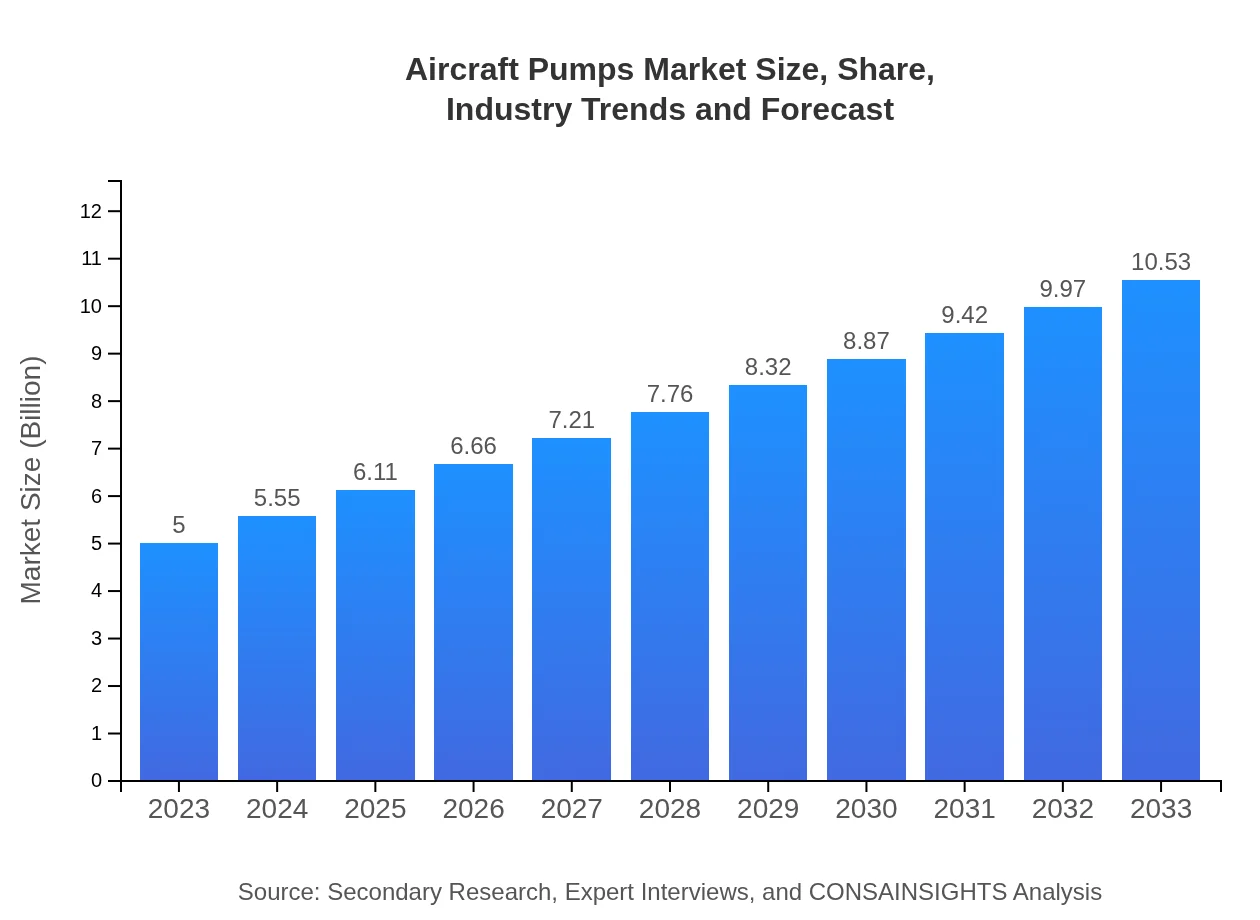

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Parker Hannifin Corporation, Honeywell International Inc., Eaton Corporation, Woodward, Inc., Moog Inc. |

| Last Modified Date | 22 January 2026 |

Aircraft Pumps Market Overview

Customize Aircraft Pumps Market Report market research report

- ✔ Get in-depth analysis of Aircraft Pumps market size, growth, and forecasts.

- ✔ Understand Aircraft Pumps's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Pumps

What is the Market Size & CAGR of Aircraft Pumps market in 2023?

Aircraft Pumps Industry Analysis

Aircraft Pumps Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Pumps Market Analysis Report by Region

Europe Aircraft Pumps Market Report:

Europe's market is expected to expand from USD 1.27 billion in 2023 to USD 2.67 billion by 2033, supported by stringent environmental regulations driving innovation in fuel efficiency and pump technologies in the aerospace sector.Asia Pacific Aircraft Pumps Market Report:

The Asia Pacific region is projected to see substantial market growth, with sizes estimated to expand from USD 1.05 billion in 2023 to USD 2.21 billion by 2033, driven by rising air travel demand and increasing investments in aircraft manufacturing.North America Aircraft Pumps Market Report:

North America holds the largest share of the Aircraft Pumps market, anticipated to rise from USD 1.78 billion in 2023 to USD 3.75 billion by 2033. The U.S. military's emphasis on modernization and the commercial aviation industry's recovery are key drivers of growth.South America Aircraft Pumps Market Report:

In South America, the Aircraft Pumps market is expected to grow from USD 0.26 billion in 2023 to USD 0.54 billion by 2033. The region's growth is influenced by the expansion of its aviation sector, aided by an increase in domestic and international travel.Middle East & Africa Aircraft Pumps Market Report:

The Middle East and Africa's market is projected to grow from USD 0.64 billion in 2023 to USD 1.36 billion by 2033, given the region's investment in enhancing its aviation infrastructure and services.Tell us your focus area and get a customized research report.

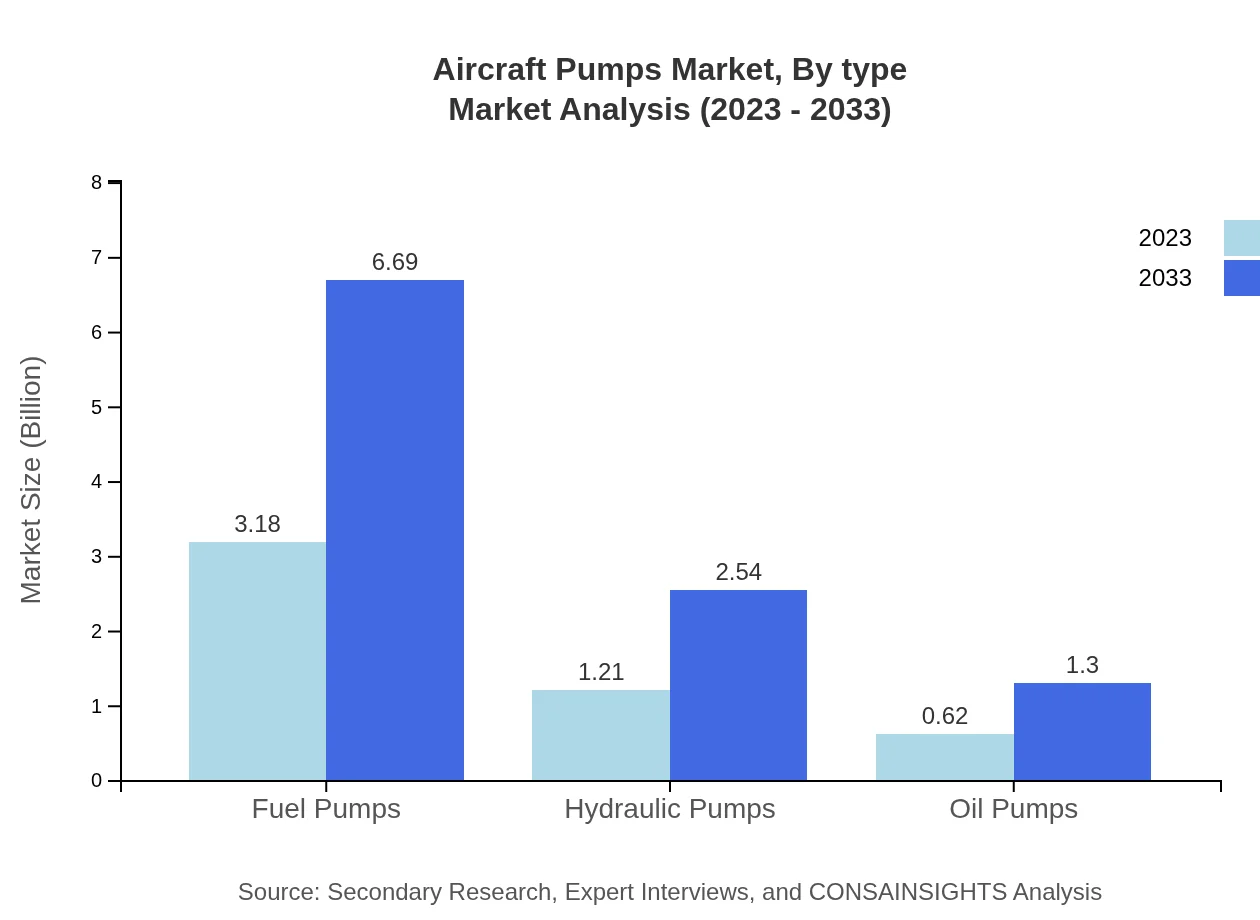

Aircraft Pumps Market Analysis By Type

Fuel Pumps dominate the market, expected to increase from USD 3.18 billion in 2023 to USD 6.69 billion by 2033, holding a market share of 63.54%. Hydraulic Pumps follow, growing from USD 1.21 billion to USD 2.54 billion, with a 24.12% share, while Oil Pumps will expand from USD 0.62 billion to USD 1.30 billion, owning 12.34% of the market.

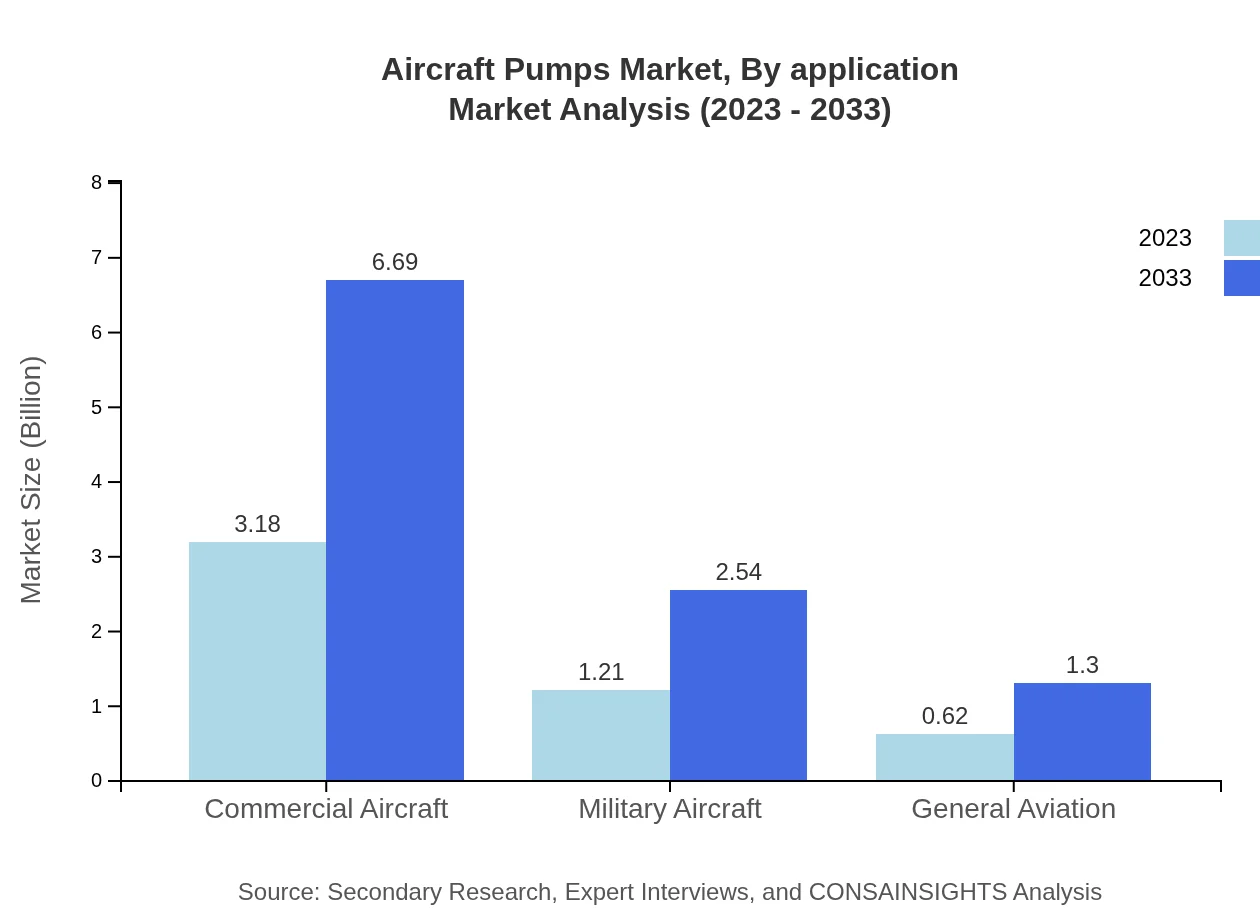

Aircraft Pumps Market Analysis By Application

The Commercial Aircraft application leads the segment, growing from USD 3.18 billion in 2023 to USD 6.69 billion by 2033, with a consistent share of 63.54%. Military Aircraft is also expected to expand, contributing to a share of 24.12% with a growth from USD 1.21 billion to USD 2.54 billion, while General Aviation is projected to rise from USD 0.62 billion to USD 1.30 billion.

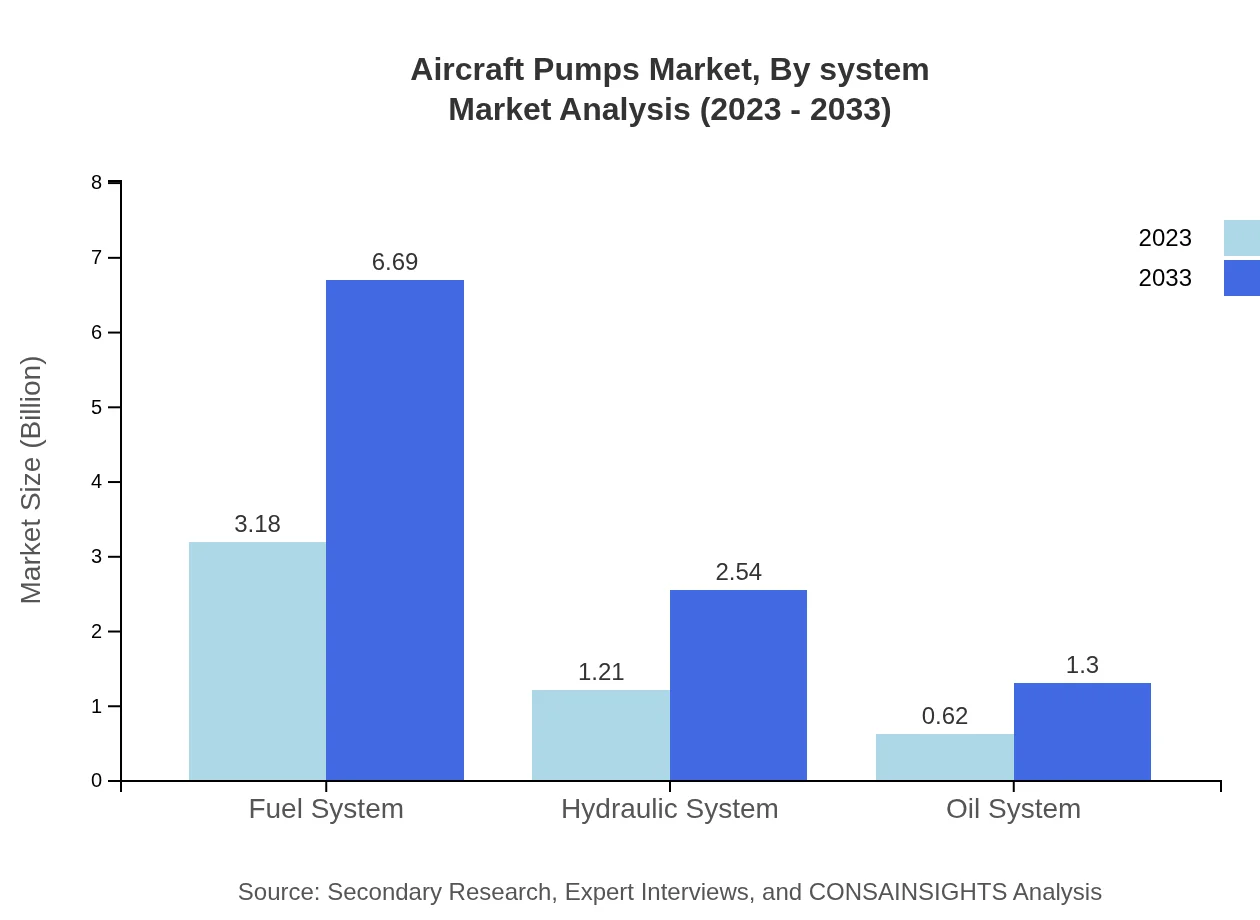

Aircraft Pumps Market Analysis By System

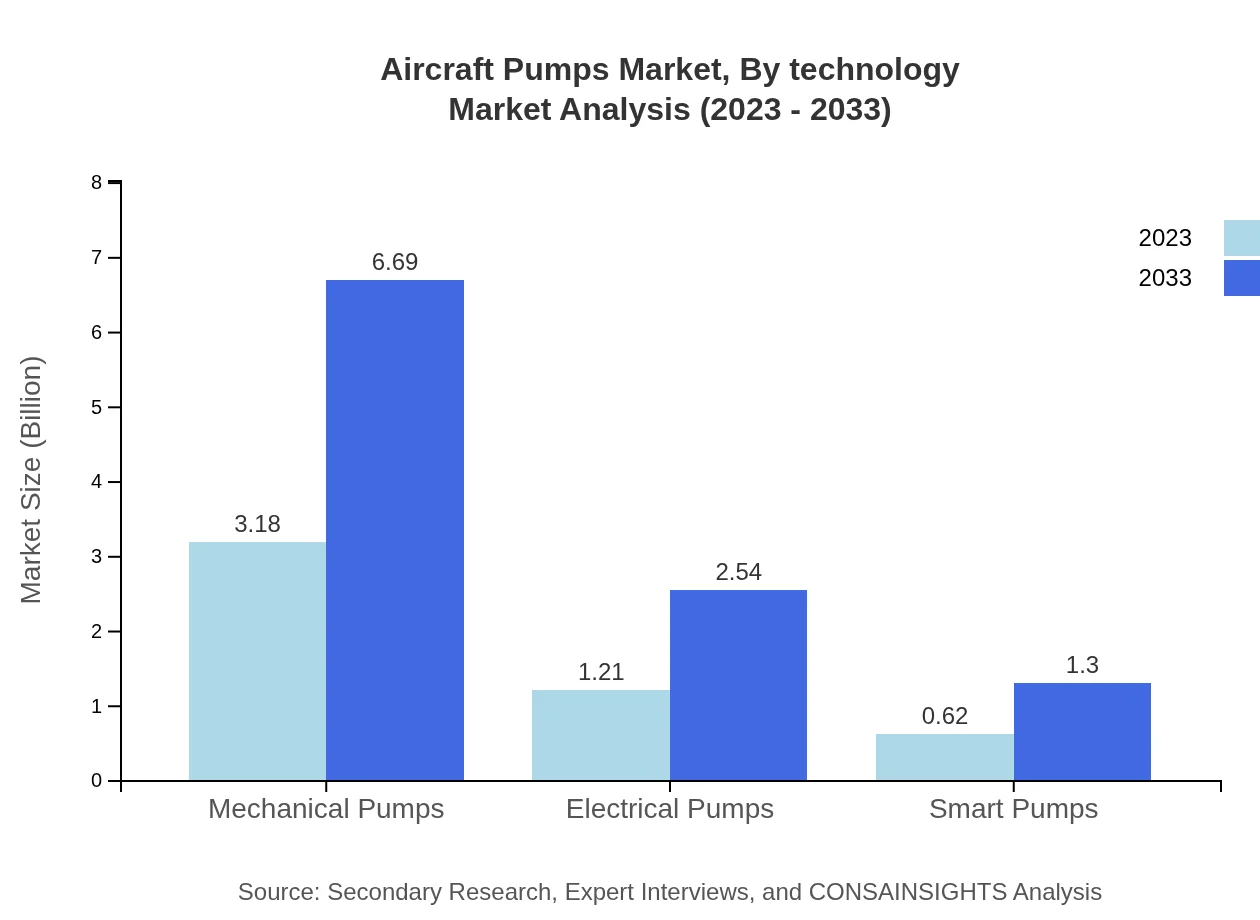

Mechanical Pumps dominate the system segment, expected to grow from USD 3.18 billion to USD 6.69 billion by 2033, representing 63.54% of the market. Electrical Pumps, with a 24.12% share, will increase in size from USD 1.21 billion to USD 2.54 billion. Smart Pumps, leveraging advanced technology, will see growth from USD 0.62 billion to USD 1.30 billion.

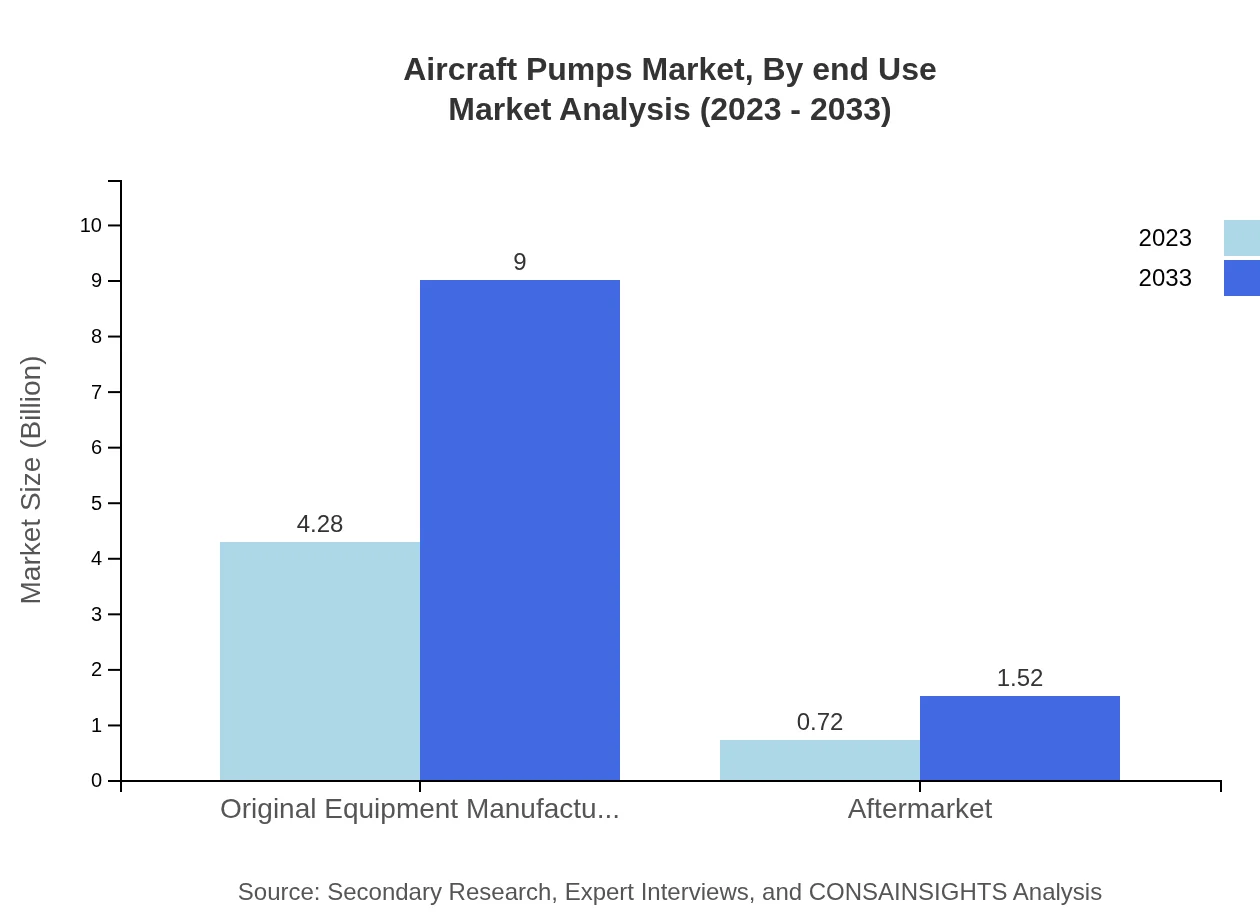

Aircraft Pumps Market Analysis By End Use

The Original Equipment Manufacturers (OEMs) segment is the largest, expected to grow from USD 4.28 billion in 2023 to USD 9.00 billion by 2033, maintaining a share of 85.54%. The Aftermarket segment will also increase from USD 0.72 billion to USD 1.52 billion, representing 14.46% of the market.

Aircraft Pumps Market Analysis By Technology

The technology segment comprises traditional and advanced smart pumping solutions. The shift from mechanical to electric and smart pumps reflects the industry's move toward precision and automation. This segment is expected to adapt with technological advancements and regulatory pressures, enhancing fuel efficiency and operational reliability.

Aircraft Pumps Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Pumps Industry

Parker Hannifin Corporation:

A leading global manufacturer of motion and control technologies, Parker Hannifin provides advanced pump solutions for civilian and military aviation.Honeywell International Inc.:

Honeywell is a prominent player in aerospace technology, offering aircraft pumps and systems that enhance safety, performance, and efficiency.Eaton Corporation:

Eaton is known for its wide range of hydraulic and fuel pumps, contributing significantly to the Aircraft Pumps market with innovative technologies.Woodward, Inc.:

Specializes in control solutions for aircraft engines and systems, providing advanced fuel pumps and other critical aircraft components.Moog Inc.:

Moog provides high-performance hydraulic pumps and fuel systems, serving both commercial and military aircraft segments.We're grateful to work with incredible clients.

FAQs

What is the market size of Aircraft Pumps?

The Aircraft Pumps market reached a size of $5 billion in 2023, and is projected to grow at a CAGR of 7.5% over the next ten years to reach an estimated market size in 2033.

What are the key market players or companies in the Aircraft Pumps industry?

Key players in the Aircraft Pumps industry include major manufacturers, suppliers, and OEMs. They contribute significantly to market growth by offering advanced pumps and systems tailored for the aviation sector.

What are the primary factors driving the growth in the Aircraft Pumps industry?

Major growth drivers include increased air travel demand, technological advancements in pump design, and a rise in aircraft production. This growth is also fueled by the need for efficient fuel systems in modern aircraft.

Which region is the fastest Growing in the Aircraft Pumps market?

The fastest-growing region is North America, anticipated to expand from $1.78 billion in 2023 to $3.75 billion by 2033, driven by robust aerospace manufacturing and higher defense budgets.

Does ConsaInsights provide customized market report data for the Aircraft Pumps industry?

Yes, ConsaInsights offers tailored market research reports for the Aircraft Pumps industry, enabling clients to obtain specific insights and data relevant to their business needs.

What deliverables can I expect from this Aircraft Pumps market research project?

Deliverables typically include market size analysis, growth forecasts, competitive landscape overview, segment analysis, and regional insights for the Aircraft Pumps market research project.

What are the market trends of Aircraft Pumps?

Current trends in the Aircraft Pumps market include the increasing adoption of smart pump technologies and a shift toward more efficient fuel systems in aircraft, adapting to stricter regulatory requirements and sustainability goals.