Aircraft Seals Market Report

Published Date: 03 February 2026 | Report Code: aircraft-seals

Aircraft Seals Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aircraft Seals market, focusing on market dynamics, trends, and forecasts from 2023 to 2033. Insights include market size, growth factors, segmentation, regional insights, and technology advancements impacting the industry.

| Metric | Value |

|---|---|

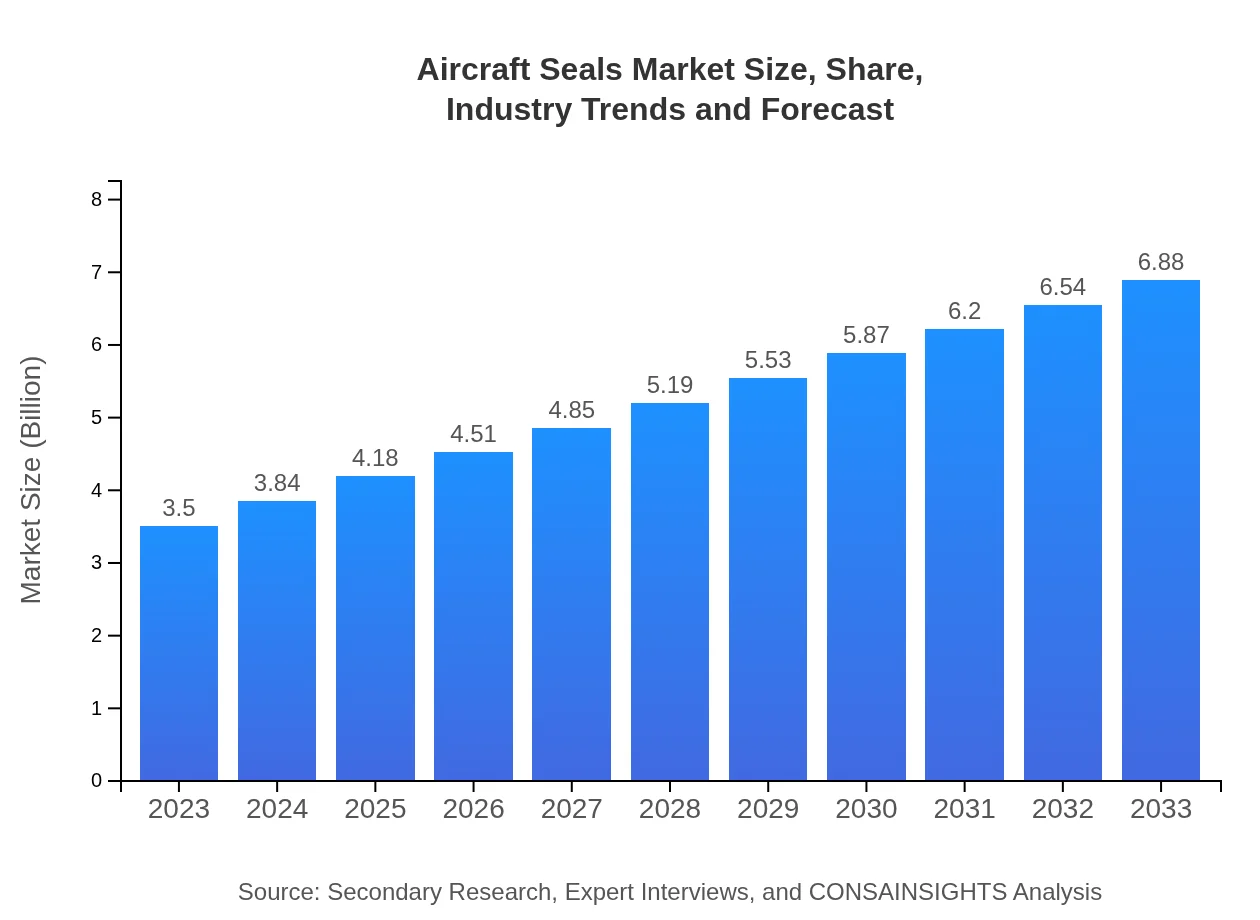

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Honeywell International Inc., W. L. Gore & Associates Inc., Parker Hannifin Corporation, Victaulic Company, Dunlop Aircraft Seating |

| Last Modified Date | 03 February 2026 |

Aircraft Seals Market Overview

Customize Aircraft Seals Market Report market research report

- ✔ Get in-depth analysis of Aircraft Seals market size, growth, and forecasts.

- ✔ Understand Aircraft Seals's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aircraft Seals

What is the Market Size & CAGR of Aircraft Seals Market in 2023?

Aircraft Seals Industry Analysis

Aircraft Seals Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aircraft Seals Market Analysis Report by Region

Europe Aircraft Seals Market Report:

Europe's Aircraft Seals market is projected at USD 0.93 billion for 2023, with expectations to reach USD 1.83 billion by 2033. Factors include stringent safety regulations and the increasing trend towards environmentally friendly aircraft solutions.Asia Pacific Aircraft Seals Market Report:

In 2023, the Aircraft Seals market in the Asia Pacific region is valued at approximately USD 0.68 billion, forecasted to reach around USD 1.34 billion by 2033. The substantial growth in this region is fueled by increasing air travel demand and aviation infrastructure development, particularly in China and India.North America Aircraft Seals Market Report:

The North American market stands out with a value of USD 1.36 billion in 2023, projected to escalate to USD 2.67 billion by 2033. Dominated by established aerospace manufacturers, this market benefits from high aircraft activity and continuous technological innovation.South America Aircraft Seals Market Report:

The South American Aircraft Seals market, valued at USD 0.26 billion in 2023, is expected to grow to USD 0.52 billion by 2033. This growth is driven by rising investments in the aviation sector and the need for modernized airport facilities.Middle East & Africa Aircraft Seals Market Report:

In the Middle East and Africa, the market in 2023 is valued at USD 0.27 billion and is expected to double to USD 0.52 billion by 2033. The region's growth is encouraged by emerging aviation markets and rising tourism.Tell us your focus area and get a customized research report.

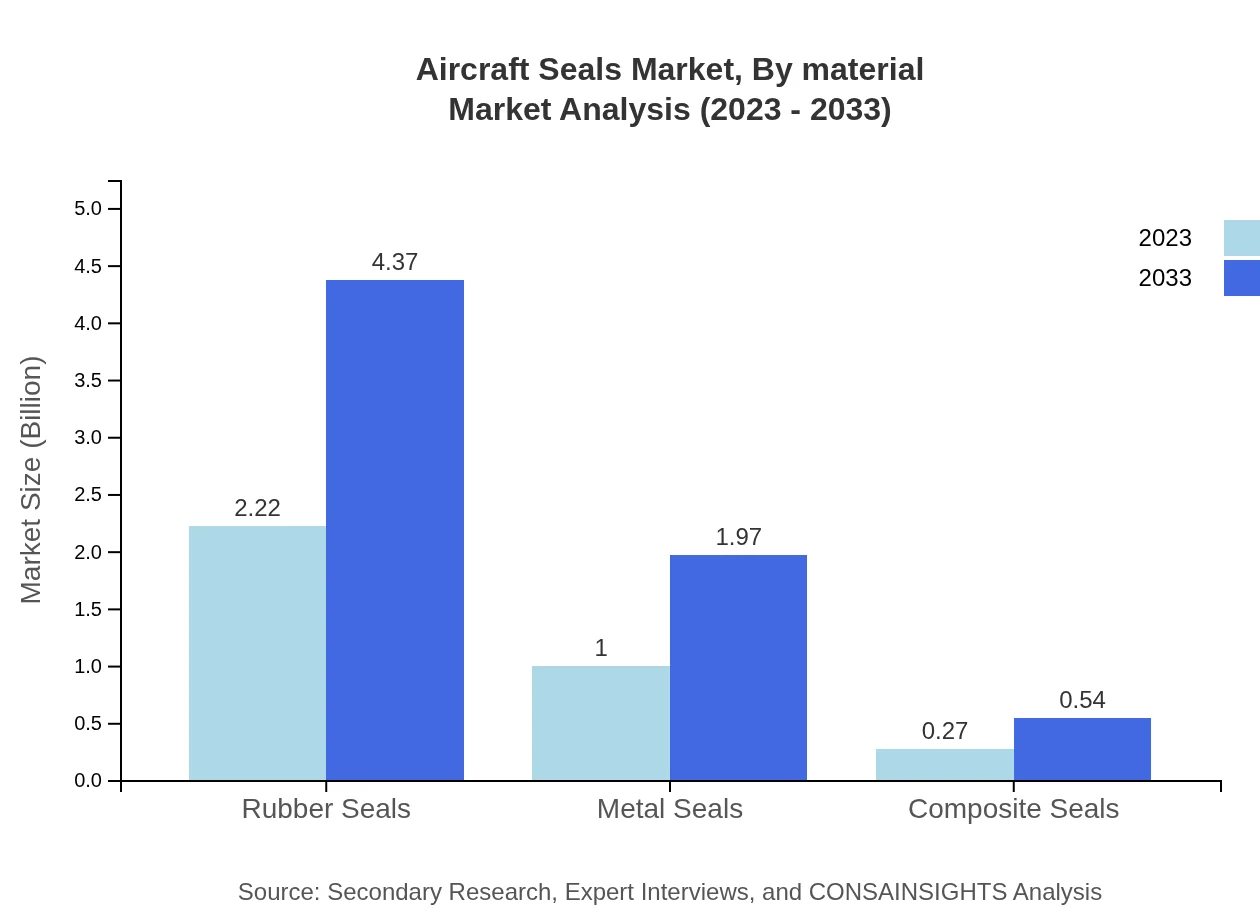

Aircraft Seals Market Analysis By Material

The Aircraft Seals market is categorized by material types such as rubber, metal, and composites. Rubber seals dominate the market with a value of USD 2.22 billion in 2023 and expected growth to USD 4.37 billion by 2033, comprising over 63.48% market share. Metal seals, valued at USD 1.00 billion in 2023, are anticipated to rise to USD 1.97 billion, holding a share of 28.7%. Composite seals are emerging with growth anticipated from USD 0.27 billion to USD 0.54 billion over the same period.

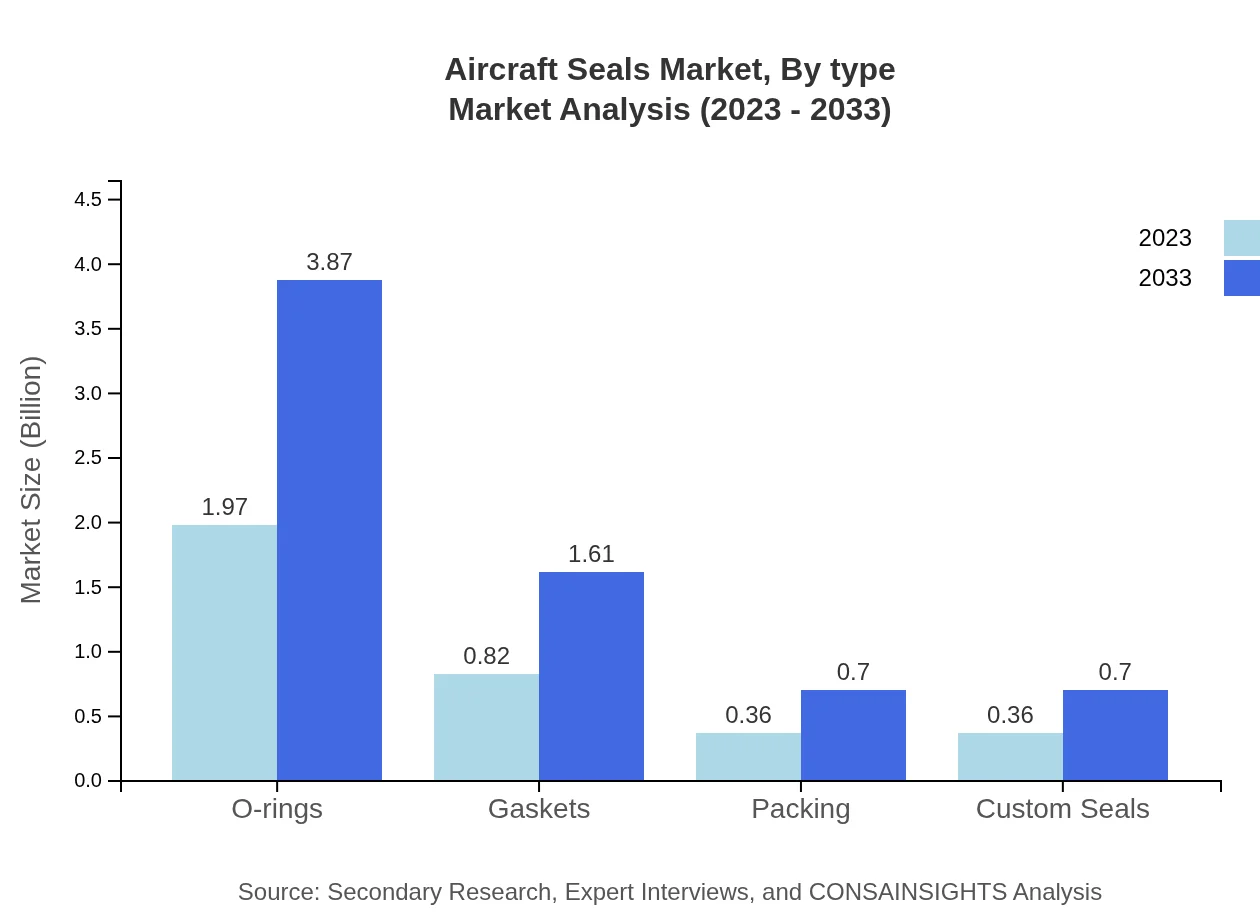

Aircraft Seals Market Analysis By Type

Key segments under type focus on O-rings, gaskets, packing, engine seals, etc. The O-rings category is significant, featuring a market size of USD 1.97 billion in 2023 and expected to reach USD 3.87 billion by 2033. Engine seals also maintain a stable share, contributing USD 1.97 billion in 2023. Each type plays a pivotal role in outfitting different aircraft systems, indicating a well-balanced demand across categories.

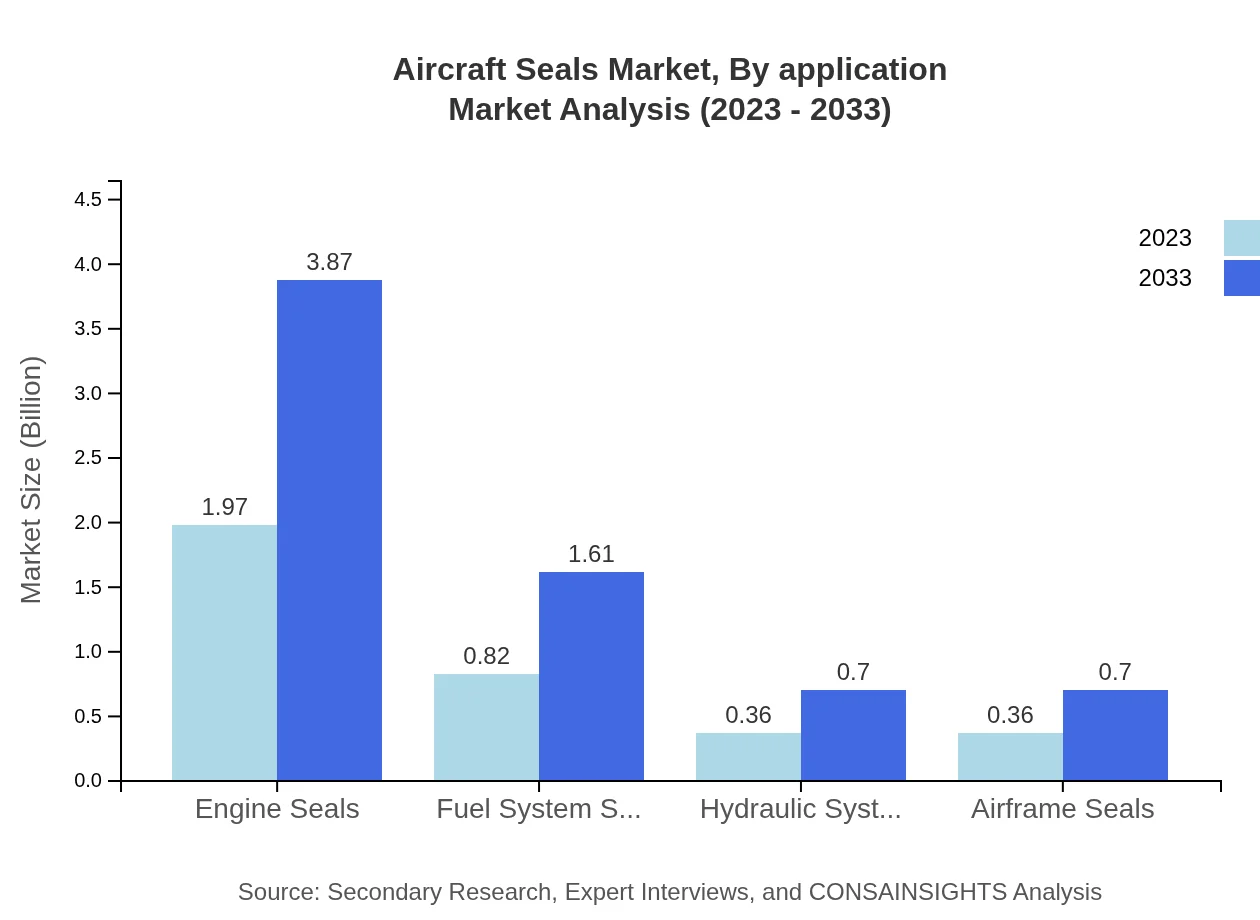

Aircraft Seals Market Analysis By Application

Applications of aircraft seals are prevalent in commercial aviation, military aircraft, and general aviation. Commercial aircraft account for a substantial market share of 56.24% in 2023 with a size of USD 1.97 billion, projected to reach USD 3.87 billion by 2033. Military aircraft also display significant growth potential due to defense expenditure increases, thereby enhancing the demand for reliable sealing solutions across applications.

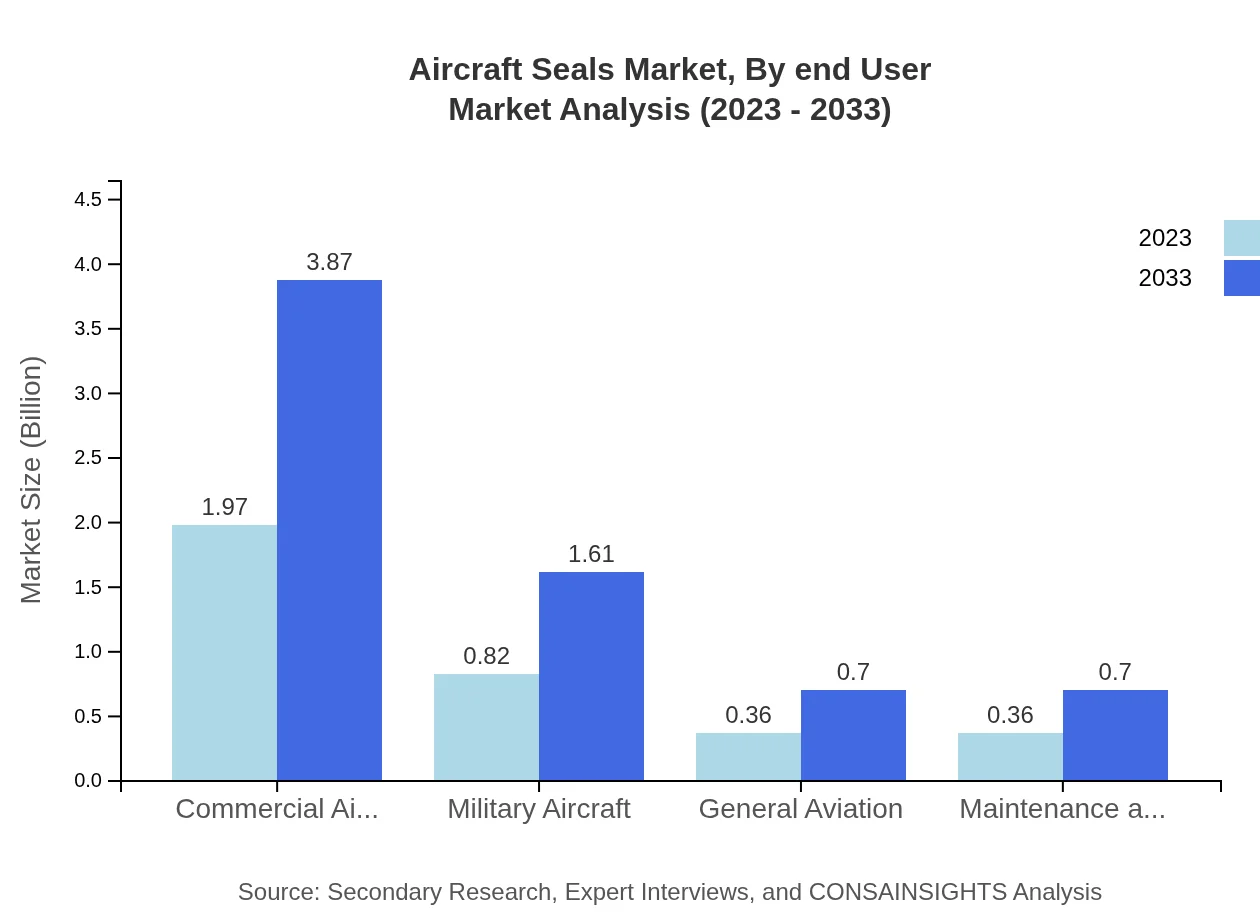

Aircraft Seals Market Analysis By End User

End-users of aircraft seals span manufacturers, maintenance, and repair operations. The maintenance and repair segment contributes significantly, reflected by its market size of USD 0.36 billion in 2023, estimated to reach USD 0.70 billion by 2033, emphasizing the importance of durable seals in prolonging aircraft longevity.

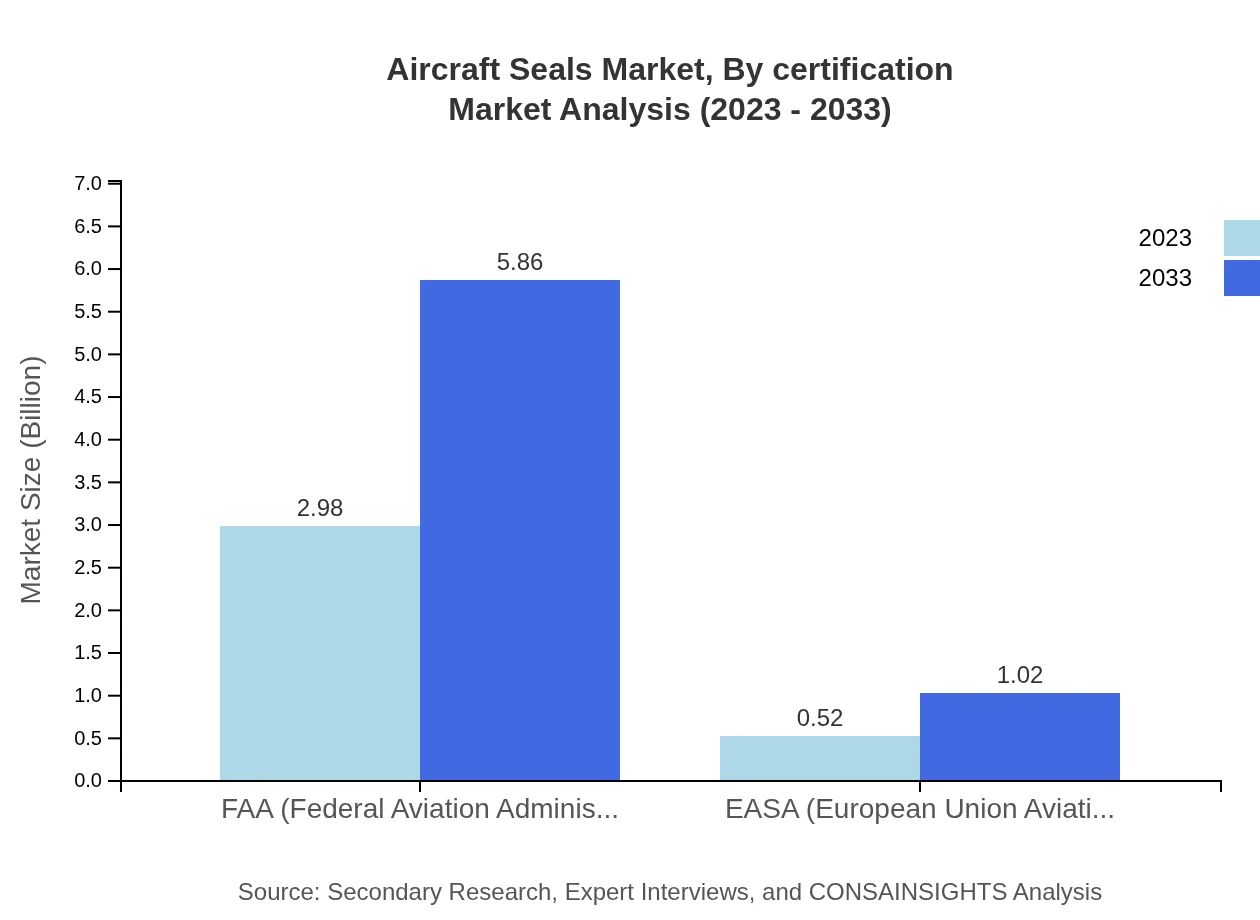

Aircraft Seals Market Analysis By Certification

Certification plays a critical role in quality assurance, with FAA approved seals leading the market at USD 2.98 billion in 2023 and expected to grow to USD 5.86 billion by 2033. EASA certification is also significant with USD 0.52 billion in 2023 projected to reach USD 1.02 billion by 2033, reinforcing the criticality of approved materials in enhancing safety and compliance in the aviation sector.

Aircraft Seals Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aircraft Seals Industry

Honeywell International Inc.:

A key player in aeronautics and manufacturing, Honeywell offers advanced sealing solutions and innovations in material technology that ensure the safety and efficiency of aircraft.W. L. Gore & Associates Inc.:

Known for its high-performance sealing products, W. L. Gore is a leader in the aerospace sector, providing unique solutions that meet stringent aviation standards.Parker Hannifin Corporation:

Specializing in motion and control technologies, Parker Hannifin produces a range of seals that enhance the reliability and performance of aviation applications.Victaulic Company:

Victaulic is notable for its innovative seal technologies, driving engineering advancements in commercial and military aircraft.Dunlop Aircraft Seating:

Dunlop specializes in aviation seating solutions, with integrated sealing systems that ensure the safety and comfort of passengers.We're grateful to work with incredible clients.

FAQs

What is the market size of aircraft seals?

The aircraft seals market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 6.8%. By 2033, the market is expected to expand significantly, reflecting growing demand within the aerospace industry.

What are the key market players or companies in the aircraft seals industry?

Key players in the aircraft seals industry include major manufacturers like Parker Hannifin, Zodiac Aerospace, and Eaton Corporation. These companies are known for their innovative sealing solutions and play a pivotal role in driving market growth.

What are the primary factors driving the growth in the aircraft seals industry?

Growth drivers in the aircraft seals market include increasing air travel demand, advancements in aerospace technology, and a rise in aircraft production. Additionally, regulatory requirements for safety standards boost the need for high-quality sealing solutions.

Which region is the fastest Growing in the aircraft seals market?

The Asia Pacific region is witnessing rapid growth in the aircraft seals market, with a market size expected to grow from $0.68 billion in 2023 to $1.34 billion by 2033, benefiting from rising air travel and infrastructure developments.

Does ConsaInsights provide customized market report data for the aircraft seals industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the aircraft seals industry. This includes insights, forecasts, and analysis focused on particular market segments or geographical regions.

What deliverables can I expect from this aircraft seals market research project?

Deliverables from the aircraft seals market research project typically include comprehensive market analysis reports, growth forecasts, regional insights, competitive landscape analysis, and segment data to support strategic decision-making.

What are the market trends of aircraft seals?

Current trends in the aircraft seals market include a shift towards advanced materials for enhanced performance, increasing adoption of sustainable practices, and innovations in designs to meet evolving industry standards and regulatory requirements.