Alpha Methylstyrene Market Report

Published Date: 02 February 2026 | Report Code: alpha-methylstyrene

Alpha Methylstyrene Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Alpha Methylstyrene market, covering market size, growth projections, regional insights, and competitive landscape from 2023 to 2033. It offers valuable insights into trends, technology advancements, and market segmentation.

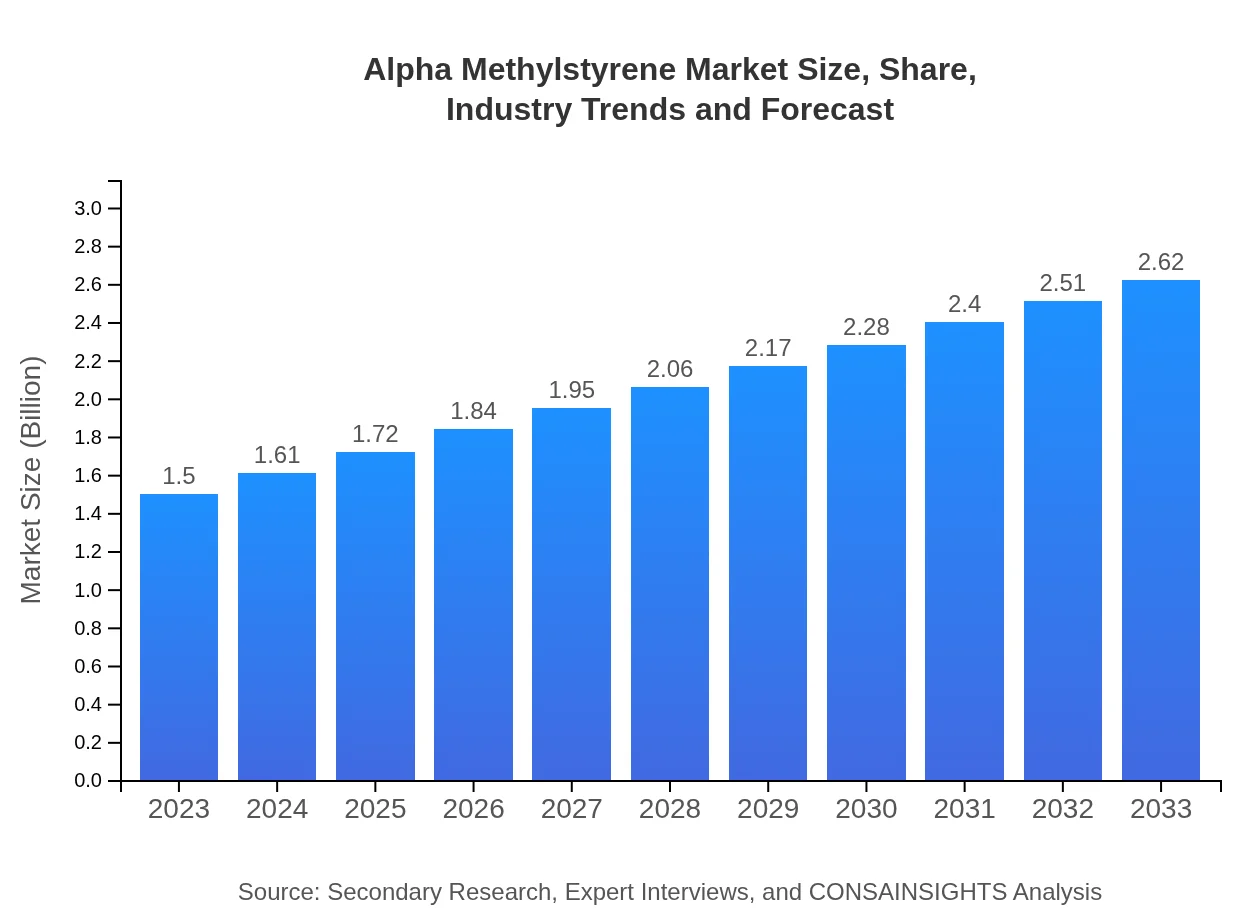

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 5.6% |

| 2033 Market Size | $2.62 Billion |

| Top Companies | BASF SE, ExxonMobil Chemical, SABIC, INEOS |

| Last Modified Date | 02 February 2026 |

Alpha Methylstyrene Market Overview

Customize Alpha Methylstyrene Market Report market research report

- ✔ Get in-depth analysis of Alpha Methylstyrene market size, growth, and forecasts.

- ✔ Understand Alpha Methylstyrene's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Alpha Methylstyrene

What is the Market Size & CAGR of Alpha Methylstyrene market in 2023 and 2033?

Alpha Methylstyrene Industry Analysis

Alpha Methylstyrene Market Segmentation and Scope

Tell us your focus area and get a customized research report.

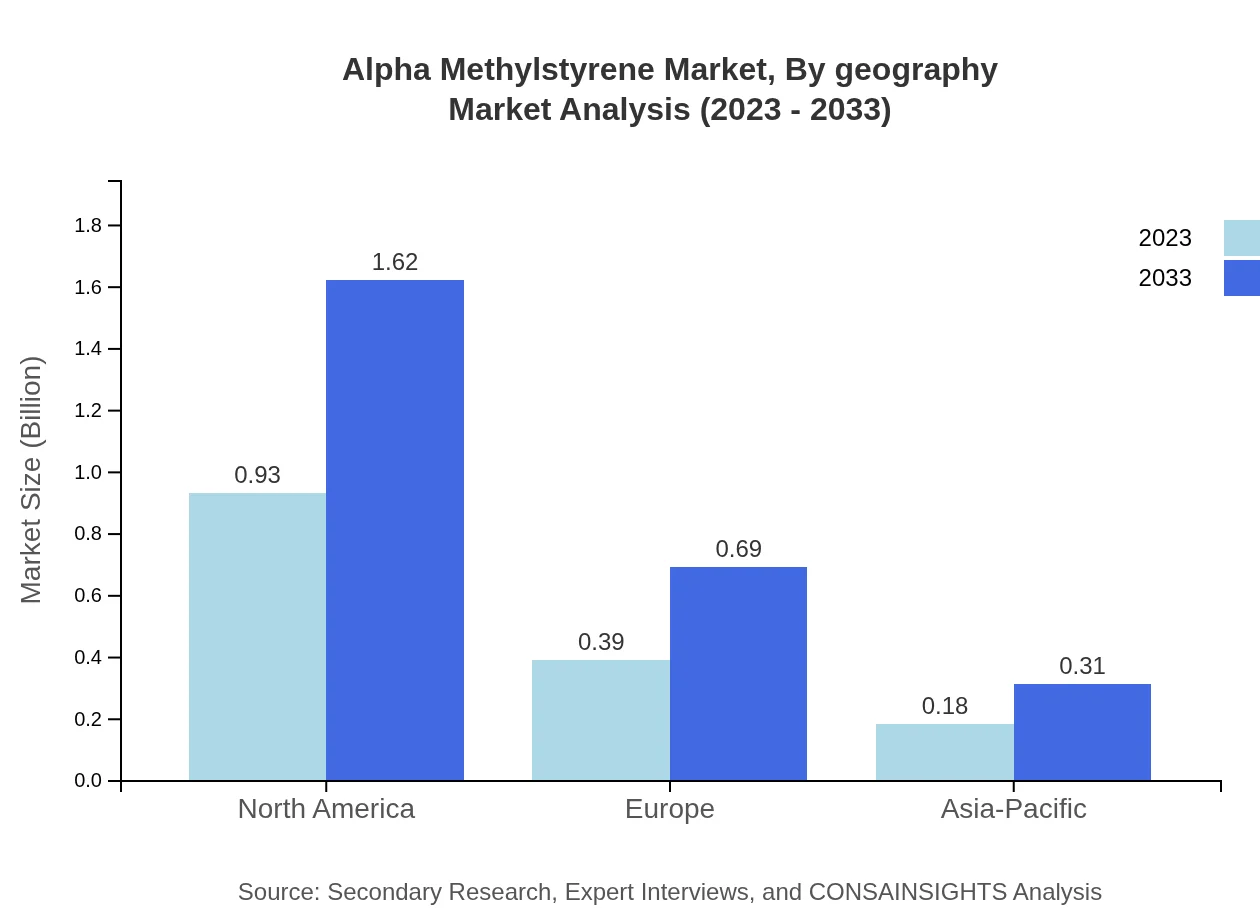

Alpha Methylstyrene Market Analysis Report by Region

Europe Alpha Methylstyrene Market Report:

The European market for Alpha Methylstyrene is projected to expand from $0.38 billion in 2023 to $0.67 billion in 2033. The region's focus on sustainable production and innovative polymers ties closely to regulatory standards and eco-friendly initiatives.Asia Pacific Alpha Methylstyrene Market Report:

In the Asia Pacific region, the Alpha Methylstyrene market is set to grow from $0.31 billion in 2023 to $0.54 billion in 2033. This increase is stimulated by rapid industrialization, growing automotive production, and rising demands for consumer goods and electronics.North America Alpha Methylstyrene Market Report:

North America holds a significant share of the market, with an expected growth from $0.58 billion in 2023 to $1.01 billion by 2033. The primary drivers include advancements in automotive manufacturing and a robust consumer goods market.South America Alpha Methylstyrene Market Report:

In South America, the market is projected to rise from $0.09 billion in 2023 to $0.16 billion in 2033. The growth is mainly supported by developments in infrastructure, construction activities, and rising domestic consumption of polymers and adhesives.Middle East & Africa Alpha Methylstyrene Market Report:

The Middle East and Africa region anticipates growth from $0.14 billion in 2023 to $0.24 billion in 2033. This growth is mainly driven by increased oil refining capacities, development in the chemical industry, and expanding local markets.Tell us your focus area and get a customized research report.

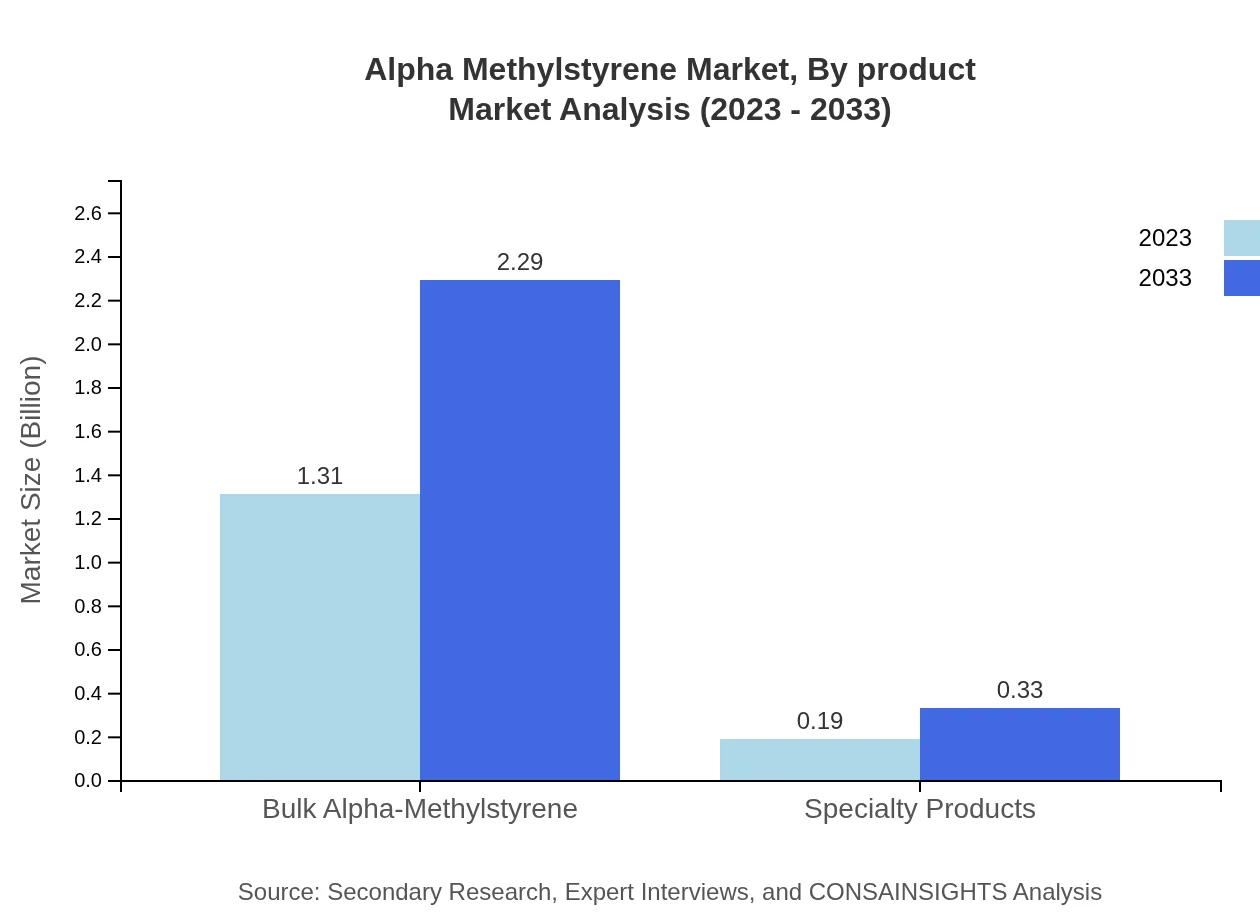

Alpha Methylstyrene Market Analysis By Product

The Alpha Methylstyrene market can be analyzed by product type, where bulk Alpha-Methylstyrene dominates the market size, growing from $1.31 billion in 2023 to $2.29 billion in 2033, holding an 87.42% market share throughout the forecast period. Specialty products, while smaller, are also expected to grow from $0.19 billion to $0.33 billion, maintaining a 12.58% share.

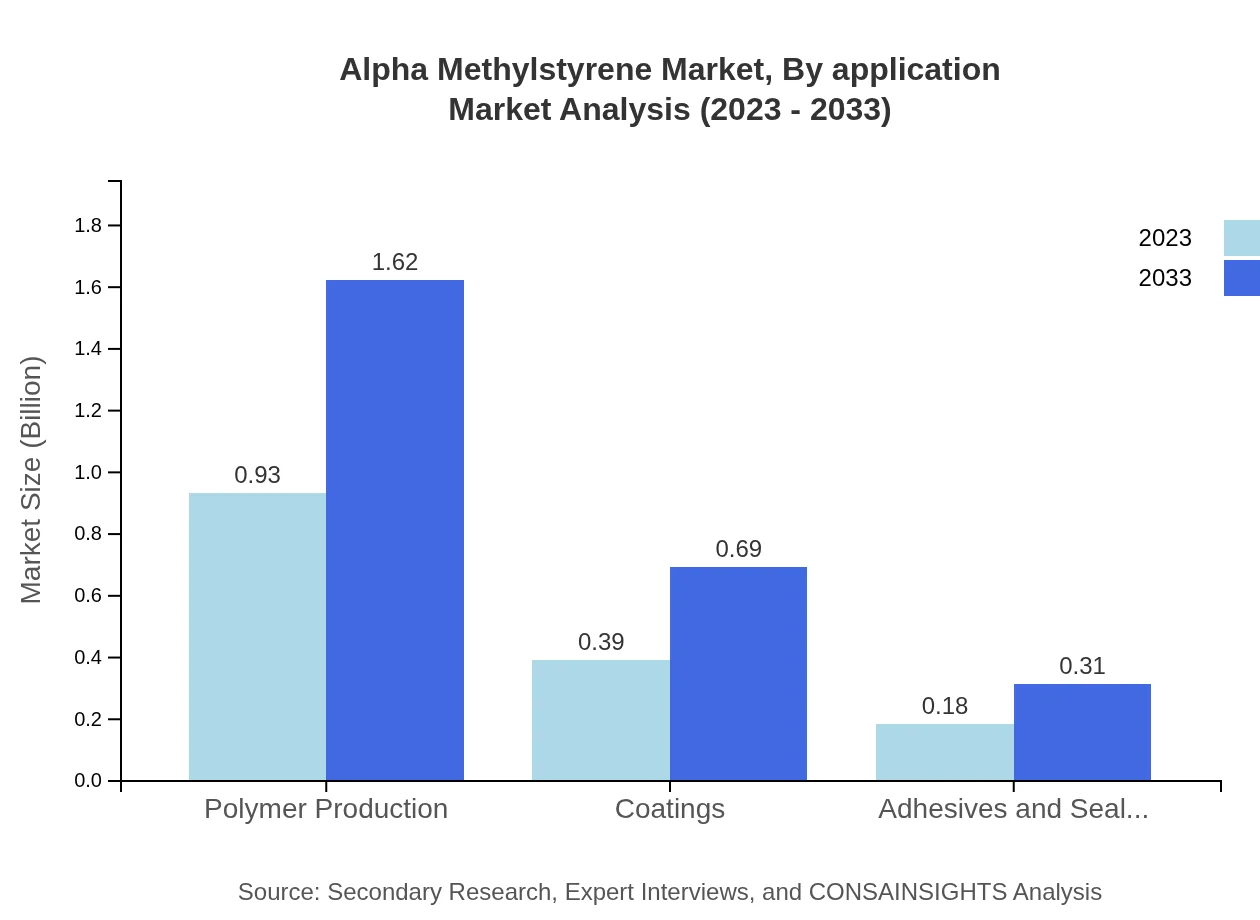

Alpha Methylstyrene Market Analysis By Application

Applications of Alpha Methylstyrene span across various sectors, prominently in polymer production, coatings, and adhesives. Polymer production remains the dominant application, with market sizes expected to grow from $0.93 billion to $1.62 billion. Coatings and adhesives also show substantial growth, contributing to the overall demand.

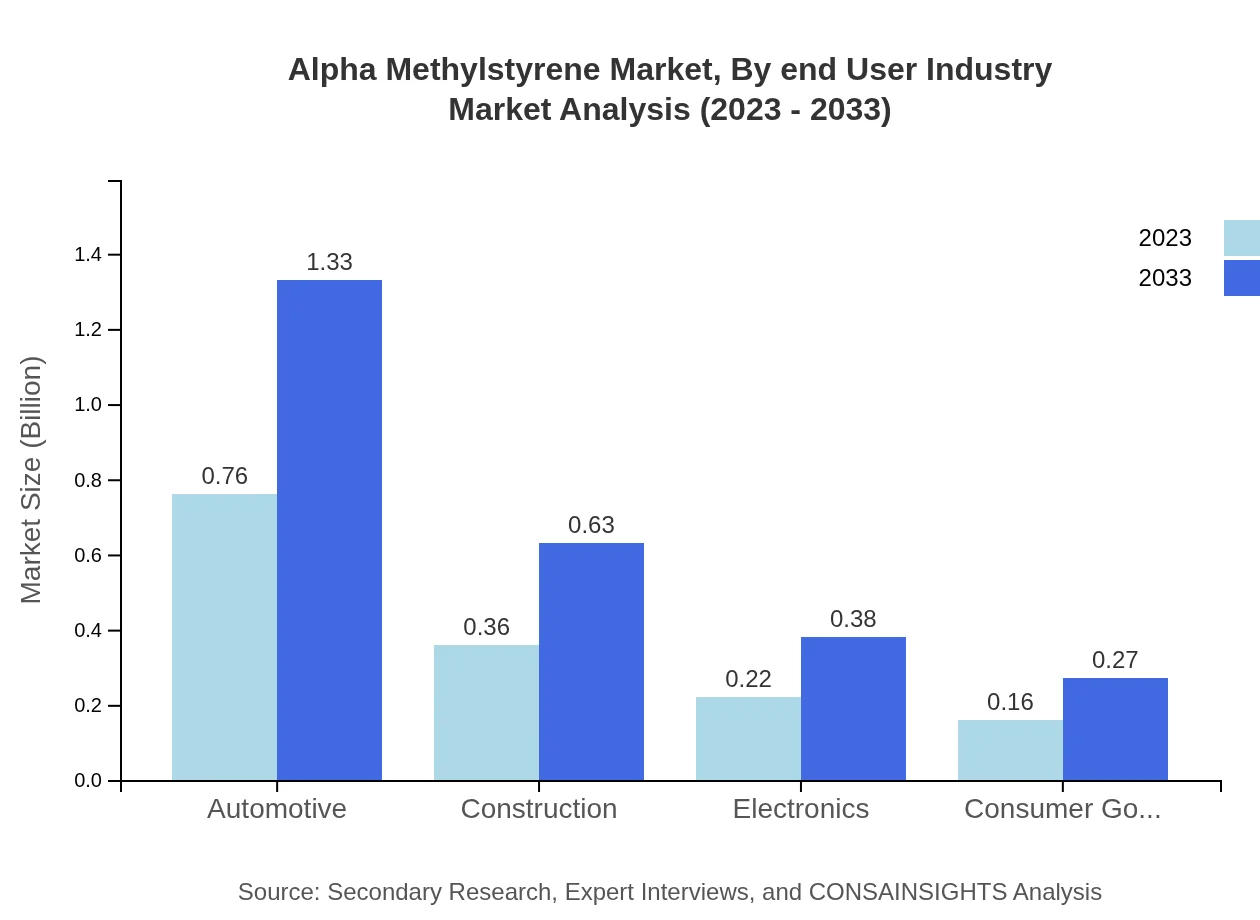

Alpha Methylstyrene Market Analysis By End User Industry

The automotive industry remains a significant consumer of Alpha Methylstyrene, evolving from a market size of $0.76 billion in 2023 to $1.33 billion in 2033. Other vital sectors include construction, electronics, and consumer goods, all contributing actively to the market dynamics.

Alpha Methylstyrene Market Analysis By Geography

Geographical segmentation reveals varied dynamics, with North America, Europe, and Asia Pacific leading. North America and Europe account for substantial market shares, driven by extensive industrial applications and innovation, while Asia Pacific shows the highest growth rate due to increased manufacturing and consumer base.

Alpha Methylstyrene Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Alpha Methylstyrene Industry

BASF SE:

A leading global chemical company offering a wide range of products, including Alpha Methylstyrene, with a strong emphasis on sustainability and innovation.ExxonMobil Chemical:

A major player in the petrochemical industry producing Alpha Methylstyrene, known for extensive production capacities and a broad product portfolio.SABIC:

One of the largest petrochemical manufacturers, SABIC has a strong foothold in developing and commercializing Alpha Methylstyrene technologies.INEOS:

Footprint in the chemical sector with cutting-edge production processes for Alpha Methylstyrene and strong global market presence.We're grateful to work with incredible clients.

FAQs

What is the market size of alpha Methylstyrene?

The alpha-methylstyrene market was valued at approximately $1.5 billion in 2023 and is projected to grow at a CAGR of 5.6% through 2033. This growth reflects rising demand across various applications.

What are the key market players or companies in the alpha Methylstyrene industry?

Key players in the alpha-methylstyrene market include major chemical manufacturers such as BASF, Repsol, and LyondellBasell. These companies dominate through innovation and extensive distribution networks, offering high-quality products.

What are the primary factors driving the growth in the alpha Methylstyrene industry?

Growth in the alpha-methylstyrene market is driven by the increasing demand from polymer production, particularly in automotive and construction sectors. Other factors include technological advancements and rising usage in coatings and adhesives.

Which region is the fastest Growing in the alpha Methylstyrene market?

North America is the fastest-growing region for alpha-methylstyrene, with a market valuation projected to rise from $0.58 billion in 2023 to $1.01 billion by 2033, driven by robust demand in manufacturing and automotive sectors.

Does ConsaInsights provide customized market report data for the alpha Methylstyrene industry?

Yes, ConsaInsights offers customized market data reports tailored to specific needs in the alpha-methylstyrene industry, enabling businesses to access detailed market insights and analysis pertinent to their strategic objectives.

What deliverables can I expect from this alpha Methylstyrene market research project?

From the alpha-methylstyrene market research project, you can expect comprehensive reports detailing market size, growth forecasts, competitive landscape, regional analysis, and insights into key trends impacting the industry.

What are the market trends of alpha Methylstyrene?

Market trends for alpha-methylstyrene include increased adoption in industrial applications, a shift towards sustainable production practices, and a rise in innovation leading to advanced product formulations within coatings and sealants.