Alumina Trihydrate Market Report

Published Date: 02 February 2026 | Report Code: alumina-trihydrate

Alumina Trihydrate Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Alumina Trihydrate market, examining current trends, market size, and growth forecasts from 2023 to 2033. Insights include regional performance and segmentation details crucial for understanding market dynamics.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

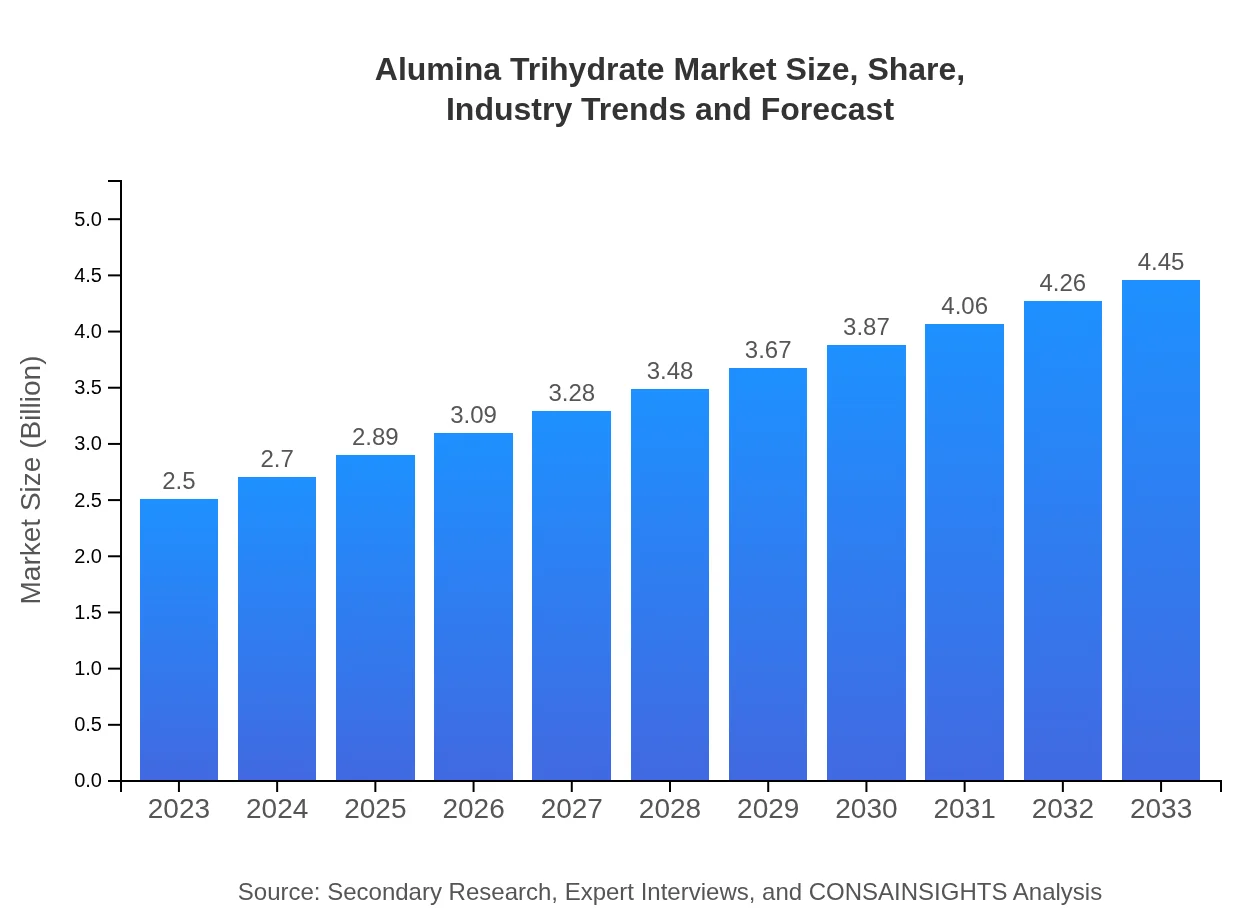

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $4.45 Billion |

| Top Companies | Alcoa Corporation, Hindalco Industries, Nabaltec AG, Alumina Limited, Reliance Industries Limited |

| Last Modified Date | 02 February 2026 |

Alumina Trihydrate Market Overview

Customize Alumina Trihydrate Market Report market research report

- ✔ Get in-depth analysis of Alumina Trihydrate market size, growth, and forecasts.

- ✔ Understand Alumina Trihydrate's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Alumina Trihydrate

What is the Market Size & CAGR of Alumina Trihydrate market in 2023?

Alumina Trihydrate Industry Analysis

Alumina Trihydrate Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Alumina Trihydrate Market Analysis Report by Region

Europe Alumina Trihydrate Market Report:

Europe's market size is anticipated to grow from $0.60 billion in 2023 to $1.07 billion in 2033, steered by stringent regulations promoting sustainable materials and the region's drive toward environmental conservation.Asia Pacific Alumina Trihydrate Market Report:

The Asia-Pacific region holds a significant share in the Alumina Trihydrate market, with a projected size of $0.97 billion by 2033. The demand is particularly driven by the booming construction and automotive industries in countries like China and India, where infrastructure development is a priority.North America Alumina Trihydrate Market Report:

North America shows robust growth potential with market size projected to reach $1.71 billion by 2033, fueled by advancements in technology and innovation in applications, particularly in coatings and fire protection industries.South America Alumina Trihydrate Market Report:

The South American market for Alumina Trihydrate is expected to double from $0.18 billion in 2023 to $0.32 billion by 2033. The growth is attributed to increased investments in industrialization and the growing demand for eco-friendly materials in the region.Middle East & Africa Alumina Trihydrate Market Report:

The Middle East and Africa market is set to expand from $0.21 billion in 2023 to $0.38 billion by 2033, supported by infrastructural developments and increasing awareness of sustainable building materials.Tell us your focus area and get a customized research report.

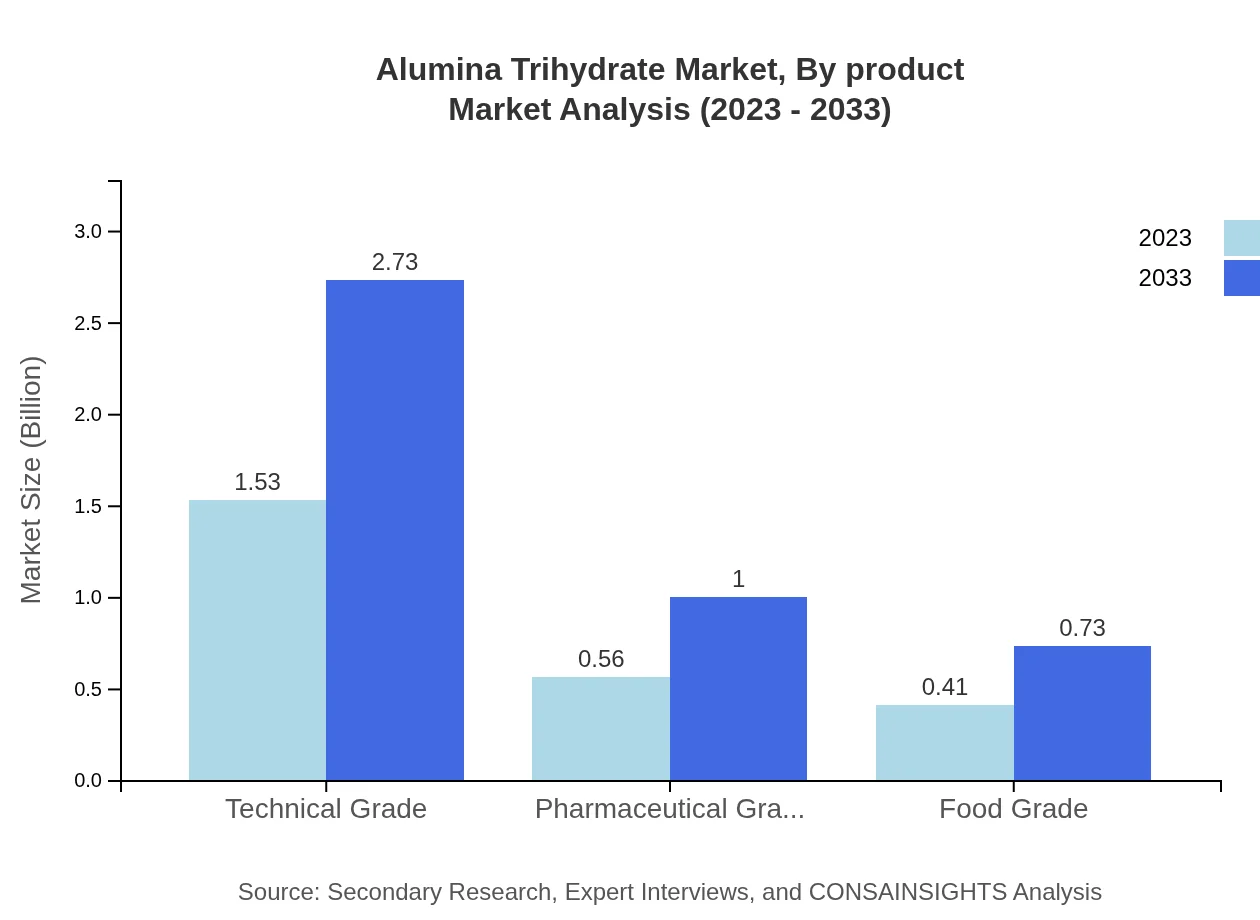

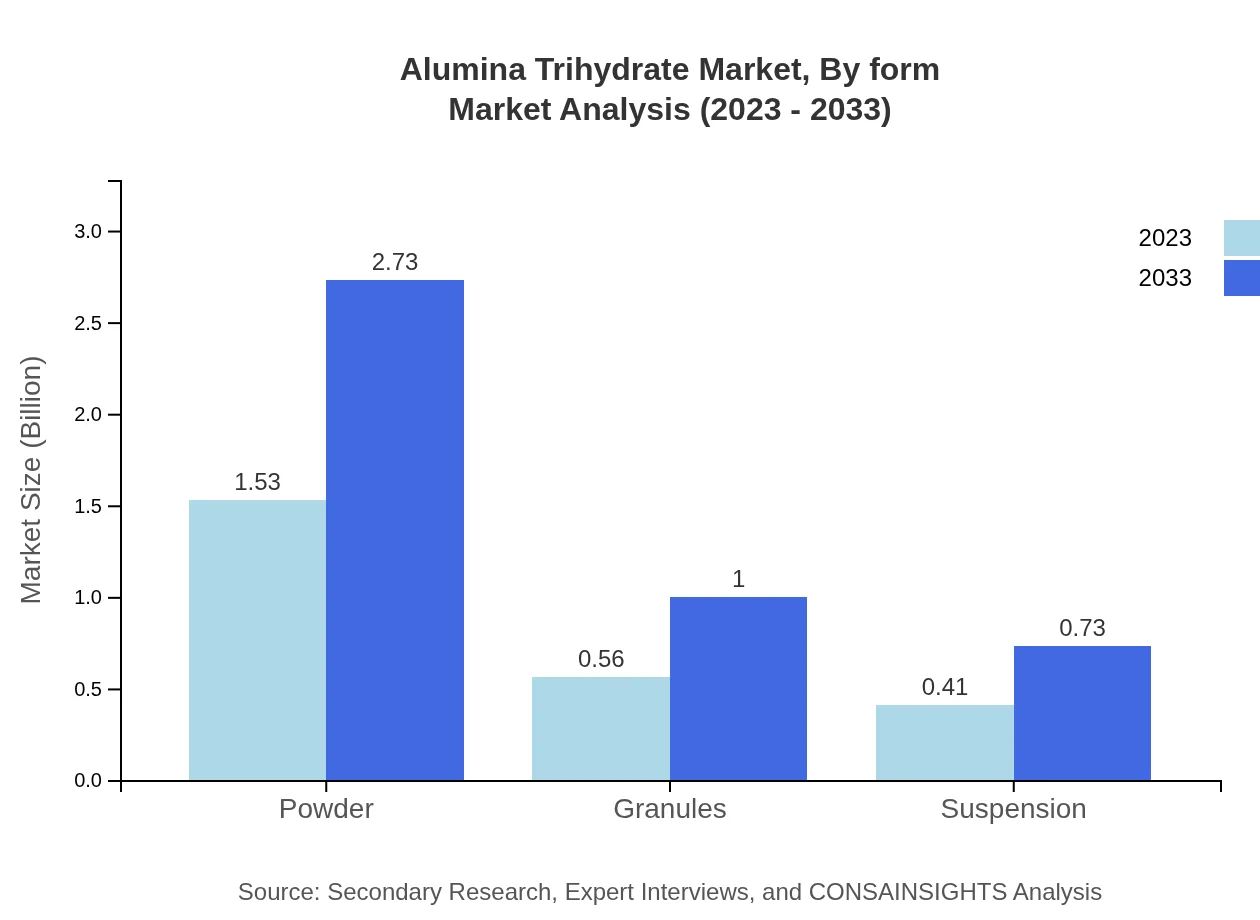

Alumina Trihydrate Market Analysis By Product

In terms of product segmentation, the powder form dominates the market, accounting for the largest share in both revenue and volume. The powder segment is expected to grow from $1.53 billion in 2023 to $2.73 billion in 2033, driven by its versatility in multiple applications. Granules and suspensions also contribute significantly, with granules projected to increase from $0.56 billion to $1.00 billion, while suspension markets will grow from $0.41 billion to $0.73 billion.

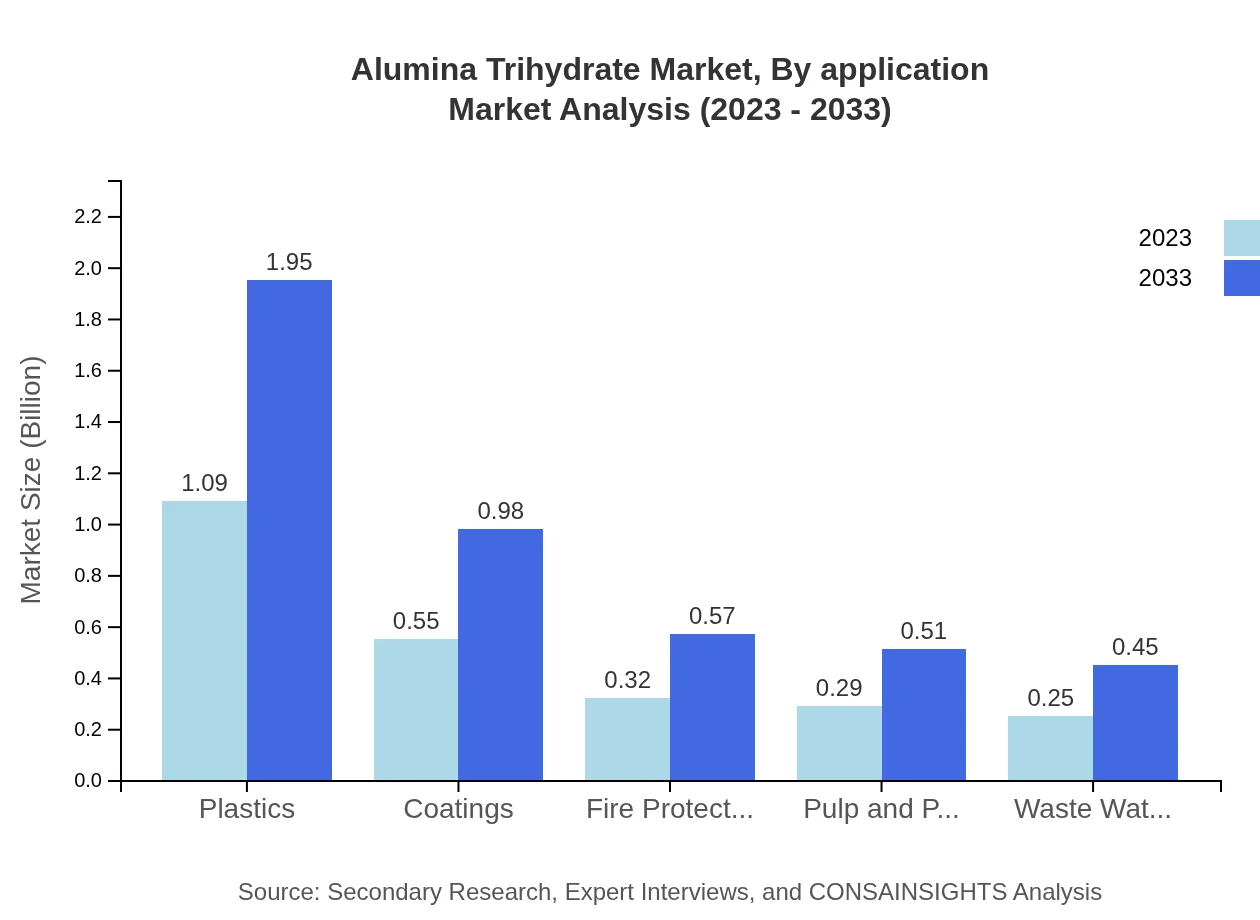

Alumina Trihydrate Market Analysis By Application

Applications of Alumina Trihydrate are broad, ranging from coatings to fire protection materials. The coatings segment holds crucial importance, showing growth, driven by demand for high-performance coating products. The construction application is particularly significant, with a market size increase from $1.27 billion to $2.27 billion, indicating its role in sustainable building practices.

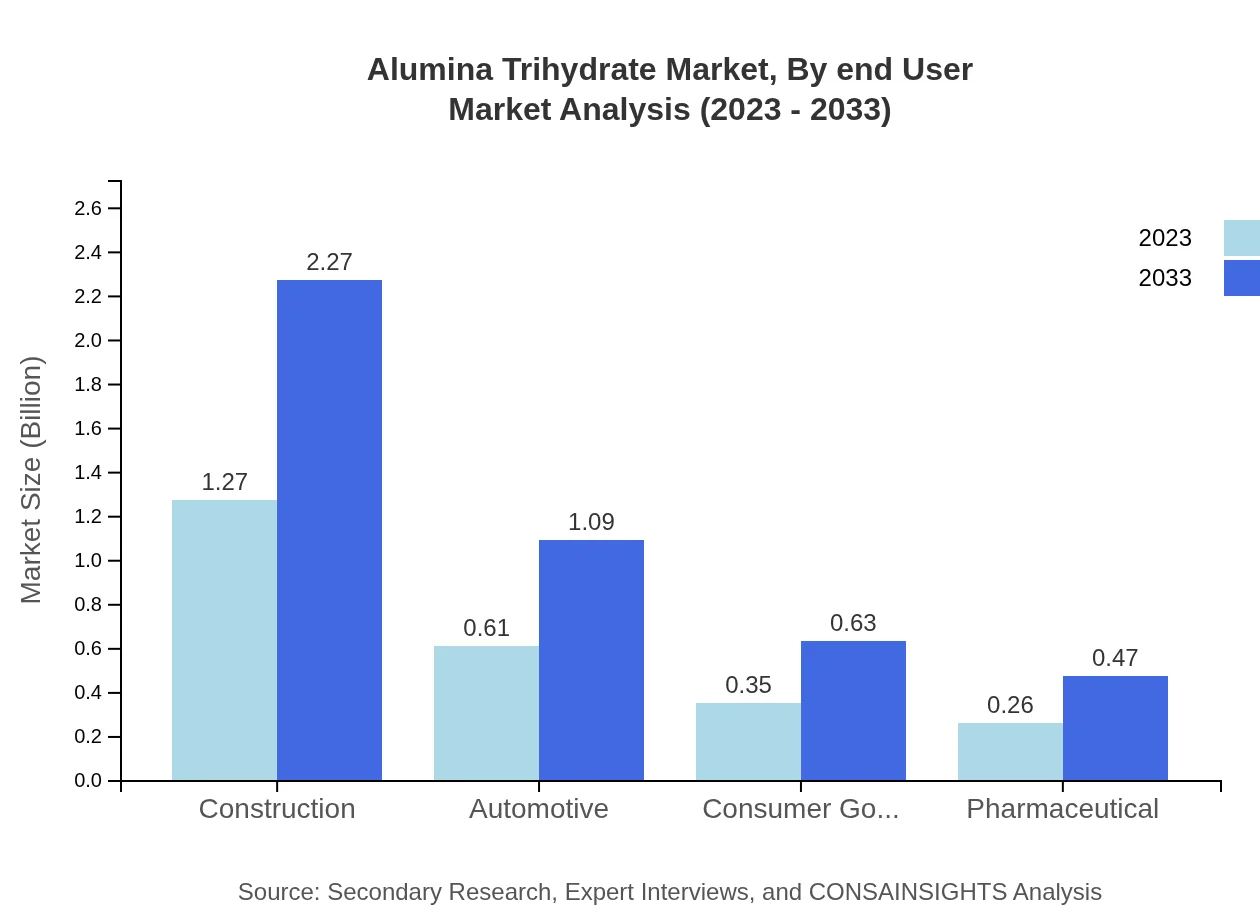

Alumina Trihydrate Market Analysis By End User

The end-user industries using Alumina Trihydrate include construction, automotive, consumer goods, pharmaceuticals, and coatings. The construction sector is a leading user, signaling strong future demand for environmentally sustainable building materials and insulation products. Automotive industries are also significant due to the focused shift toward lightweight materials.

Alumina Trihydrate Market Analysis By Form

Alumina Trihydrate is primarily categorized into powder, granules, and suspension forms. The powder segment, with a 61.23% share in 2023, is expected to remain dominant, while granules (22.4%) and suspensions (16.37%) present significant growth opportunities in niche markets.

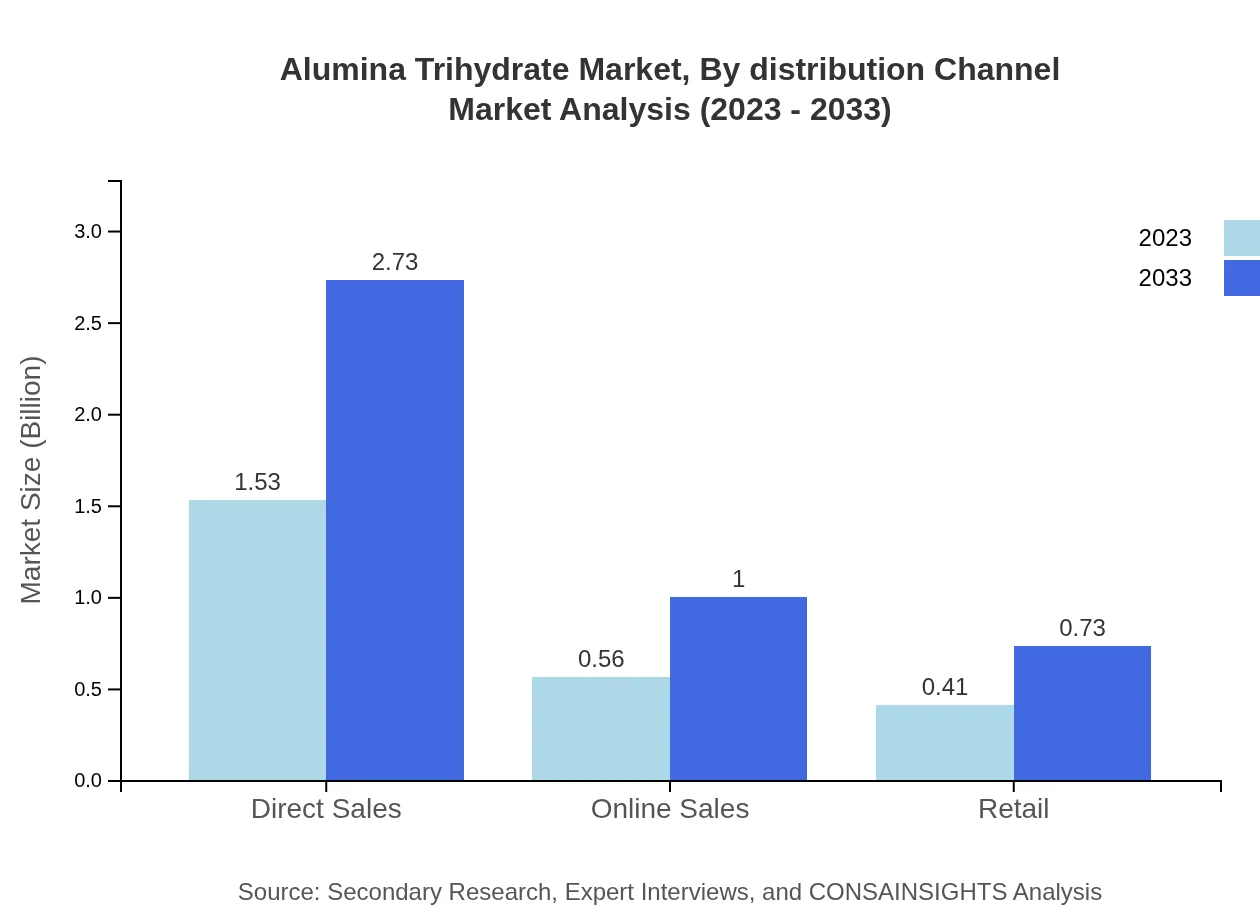

Alumina Trihydrate Market Analysis By Distribution Channel

The distribution of Alumina Trihydrate is conducted through various channels, including direct sales, online sales, and retail. Direct sales currently dominate the market due to established relationships between manufacturers and distributors, holding a market share of 61.23%, with online and retail sales growing substantially, driven by e-commerce trends.

Alumina Trihydrate Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Alumina Trihydrate Industry

Alcoa Corporation:

A leading producer of alumina and aluminum products, Alcoa has a strong presence in the market, emphasizing sustainability and innovative aluminum solutions.Hindalco Industries:

Part of the Aditya Birla Group, Hindalco is a significant player in the alumina sector, focusing on expanding its product portfolio and enhancing production capacities.Nabaltec AG:

Specializes in high-quality inorganic and ceramic products, Nabaltec has been instrumental in developing innovative Alumina Trihydrate applications, particularly in the fire protection sector.Alumina Limited:

With a global footprint, Alumina Limited is a prominent player focused on alumina refining, and it plays an essential role in the production of Alumina Trihydrate.Reliance Industries Limited:

As one of the largest conglomerates, Reliance is diversifying into the chemicals sector, including the production of alumina, prioritizing sustainable materials.We're grateful to work with incredible clients.

FAQs

What is the market size of alumina Trihydrate?

The global alumina trihydrate market was valued at approximately $2.5 billion in 2023 and is projected to grow at a CAGR of 5.8%, reaching significant growth by 2033.

What are the key market players or companies in this alumina Trihydrate industry?

Key players in the alumina trihydrate market include companies like CRS Chemicals, Almatis, and AkzoNobel, who contribute to production capacities and technological advancements within the industry.

What are the primary factors driving the growth in the alumina Trihydrate industry?

The growth in the alumina trihydrate industry is driven by increasing demand in construction, automotive, and plastics, alongside technological innovations and a rising emphasis on sustainable materials.

Which region is the fastest Growing in the alumina Trihydrate?

The fastest-growing region for alumina trihydrate is North America, projected to expand from $0.96 billion in 2023 to $1.71 billion by 2033, indicating strong demand across various sectors.

Does ConsaInsights provide customized market report data for the alumina Trihydrate industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the alumina trihydrate industry, enabling businesses to make informed strategic decisions.

What deliverables can I expect from this alumina Trihydrate market research project?

Deliverables from the alumina trihydrate market research project include comprehensive reports, analytical insights, and forecasts covering market trends, competitive landscape, and regional breakdowns.

What are the market trends of alumina Trihydrate?

Current market trends for alumina trihydrate include increased adoption in fire protection materials and wastewater treatment, as well as a growing focus on sustainability and eco-friendly products in various industries.