Aluminum Electrolyte Capacitors Market Report

Published Date: 22 January 2026 | Report Code: aluminum-electrolyte-capacitors

Aluminum Electrolyte Capacitors Market Size, Share, Industry Trends and Forecast to 2033

This report conducts a comprehensive analysis of the Aluminum Electrolyte Capacitors market, focusing on market developments, trends, technological advancements, and region-specific insights. It covers the forecast period from 2023 to 2033, providing key market size, growth rates, and future projections.

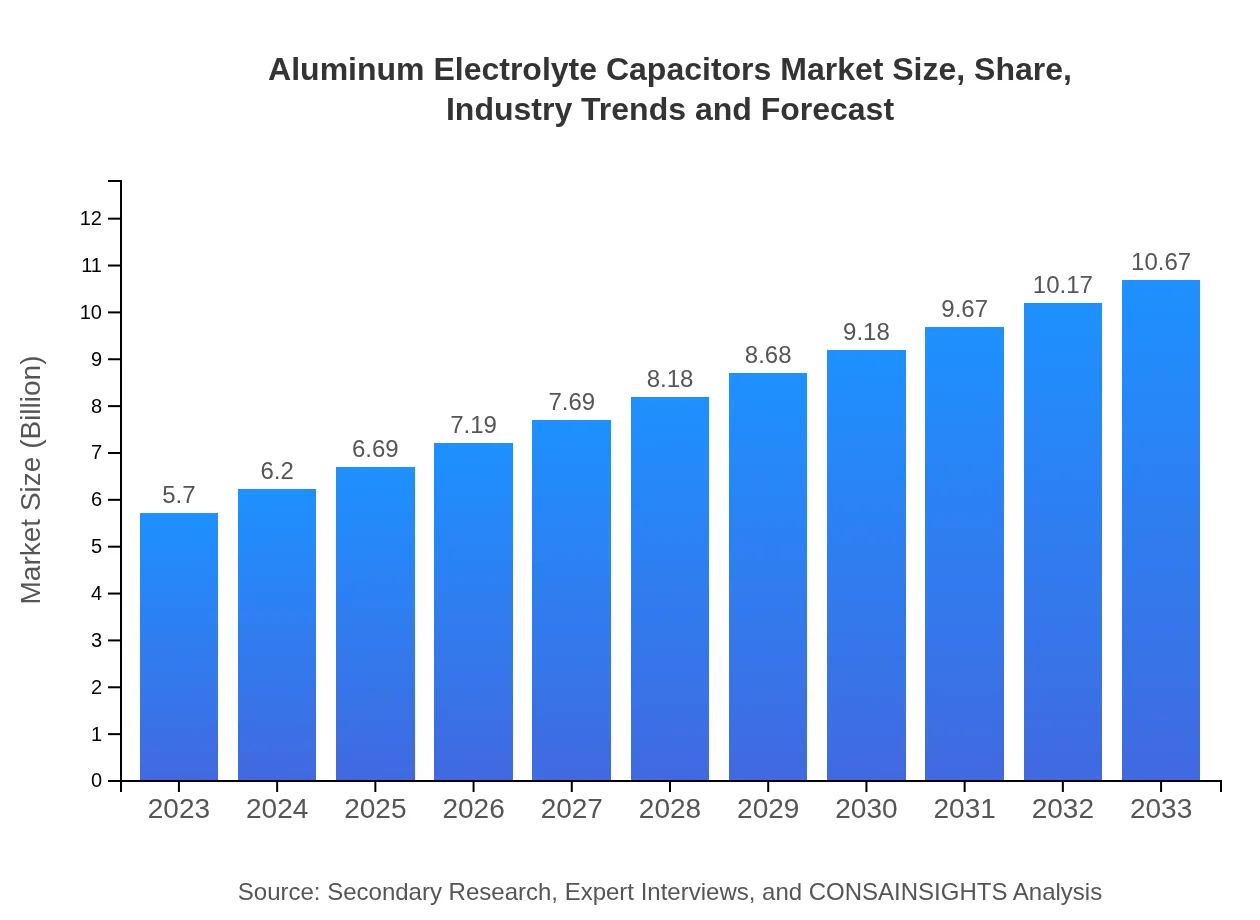

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.70 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $10.67 Billion |

| Top Companies | Panasonic Corporation, Nichicon Corporation, Rubicon Technology, KEMET Corporation, Vishay Intertechnology |

| Last Modified Date | 22 January 2026 |

Aluminum Electrolyte Capacitors Market Overview

Customize Aluminum Electrolyte Capacitors Market Report market research report

- ✔ Get in-depth analysis of Aluminum Electrolyte Capacitors market size, growth, and forecasts.

- ✔ Understand Aluminum Electrolyte Capacitors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aluminum Electrolyte Capacitors

What is the Market Size & CAGR of Aluminum Electrolyte Capacitors market in 2023?

Aluminum Electrolyte Capacitors Industry Analysis

Aluminum Electrolyte Capacitors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aluminum Electrolyte Capacitors Market Analysis Report by Region

Europe Aluminum Electrolyte Capacitors Market Report:

Europe’s market is set to increase from $2.03 billion in 2023 to $3.79 billion by 2033. The region's strong automotive industry and stringent energy efficiency regulations are boosting demand for electrolytic capacitors.Asia Pacific Aluminum Electrolyte Capacitors Market Report:

The Asia Pacific region is projected to witness significant growth, with a market size of $2.02 billion by 2033, up from $1.08 billion in 2023. This growth is attributed to rapid industrialization and the rising electronics manufacturing sector, primarily in countries like China, Japan, and South Korea.North America Aluminum Electrolyte Capacitors Market Report:

The North American market is expected to grow from $1.96 billion in 2023 to $3.66 billion by 2033. Factors such as the development of electric vehicles and advanced consumer electronics are propelling this growth.South America Aluminum Electrolyte Capacitors Market Report:

In South America, the market is expected to grow from $0.12 billion in 2023 to $0.23 billion by 2033. Increasing investments in renewable energy and consumer electronics are driving the demand for aluminum electrolyte capacitors.Middle East & Africa Aluminum Electrolyte Capacitors Market Report:

The Middle East and Africa market is projected to rise from $0.51 billion in 2023 to $0.96 billion by 2033, driven by expanding telecommunications infrastructure and increasing investment in renewable energy technologies.Tell us your focus area and get a customized research report.

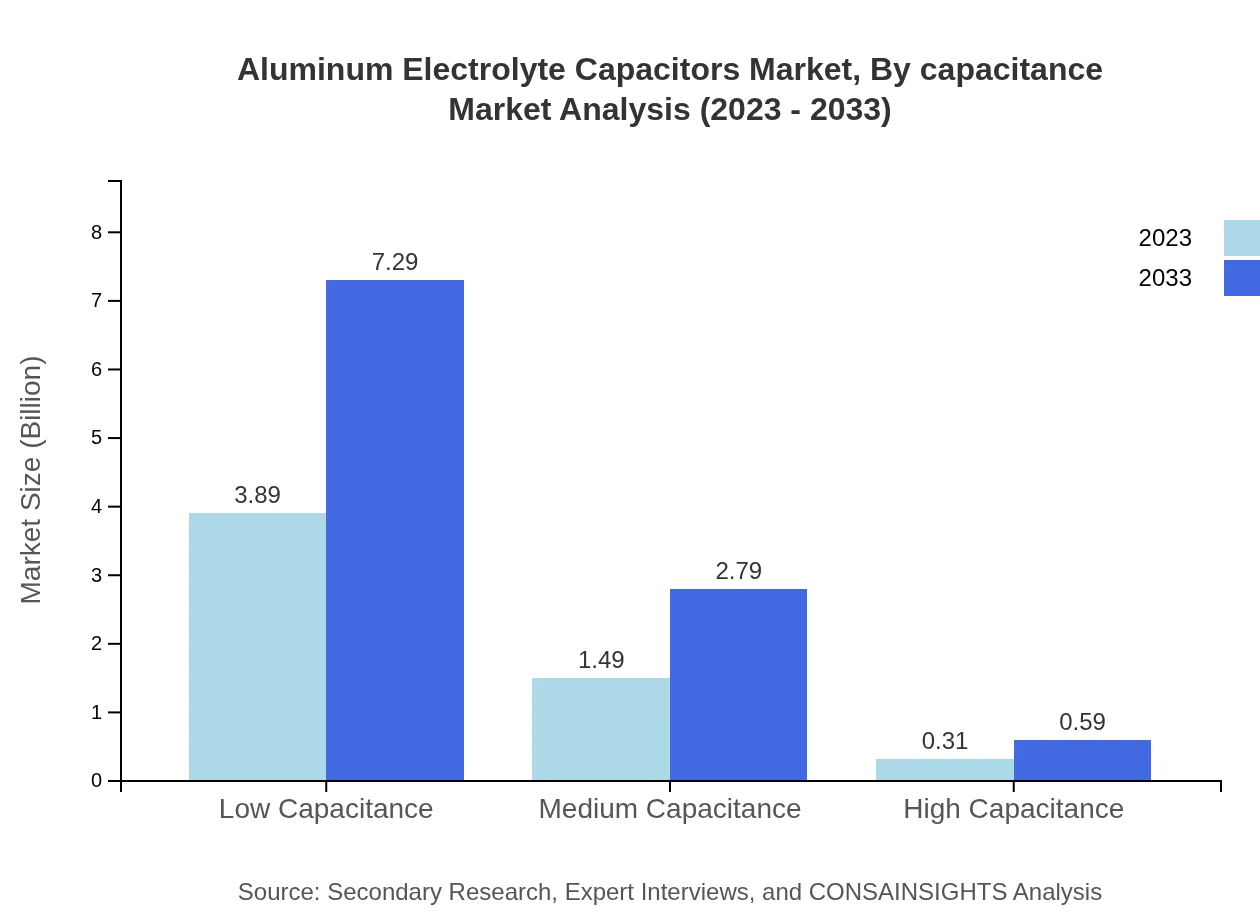

Aluminum Electrolyte Capacitors Market Analysis By Capacitance

The Aluminum Electrolyte Capacitors market is segmented by capacitance into low (68.33% market share), medium (26.16% market share), and high capacitance (5.51% market share). The low capacitance segment leads the market due to prevalent usage in portable consumer products and electronic devices, while growth in medium capacitance reflects increased automotive and industrial application.

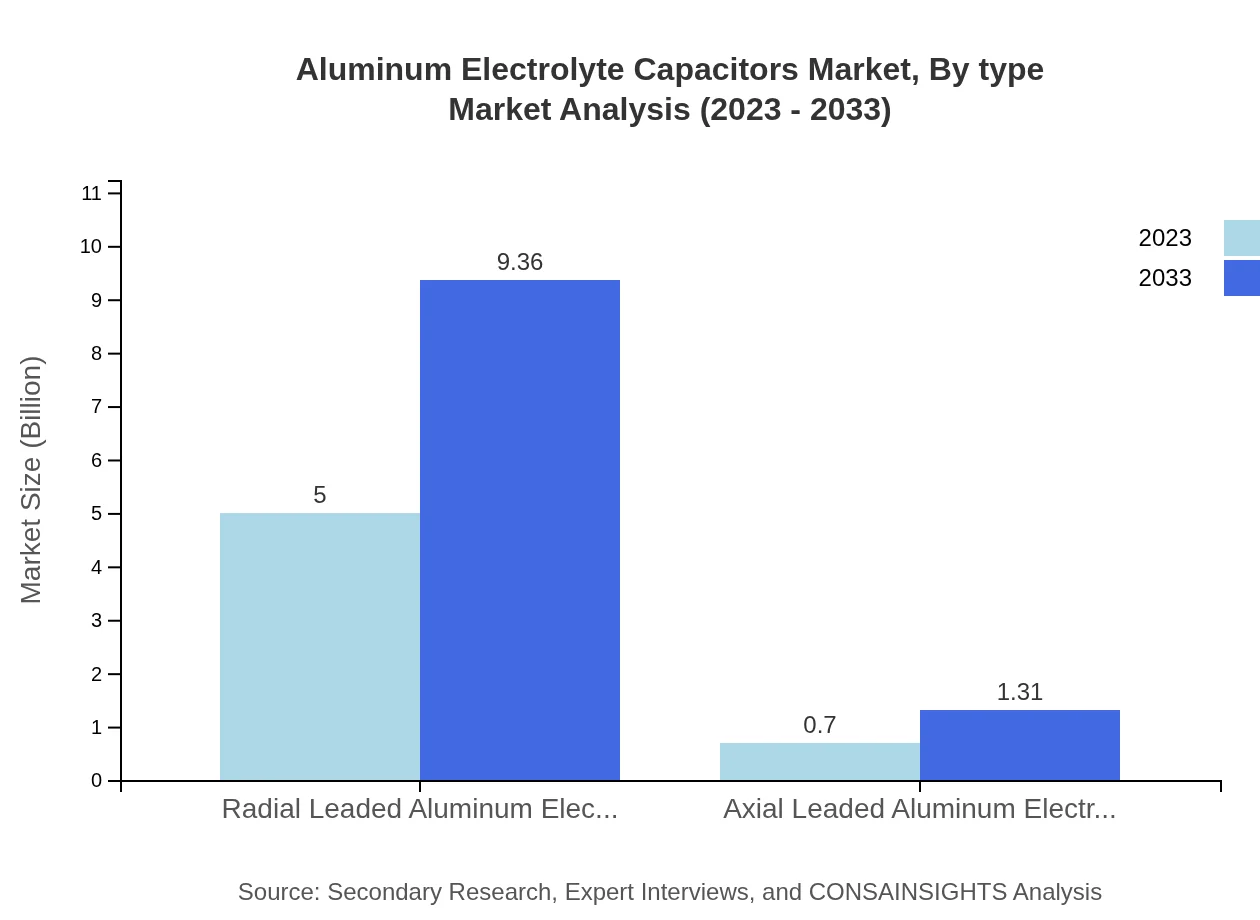

Aluminum Electrolyte Capacitors Market Analysis By Type

Radial Leaded Aluminum Electrolyte Capacitors account for a significant portion of the market (87.76% share) and are expected to grow from $5.00 billion in 2023 to $9.36 billion by 2033. Axial Leaded Capacitors, although a smaller segment (12.24% share), are also gaining traction in specific applications due to their compact size.

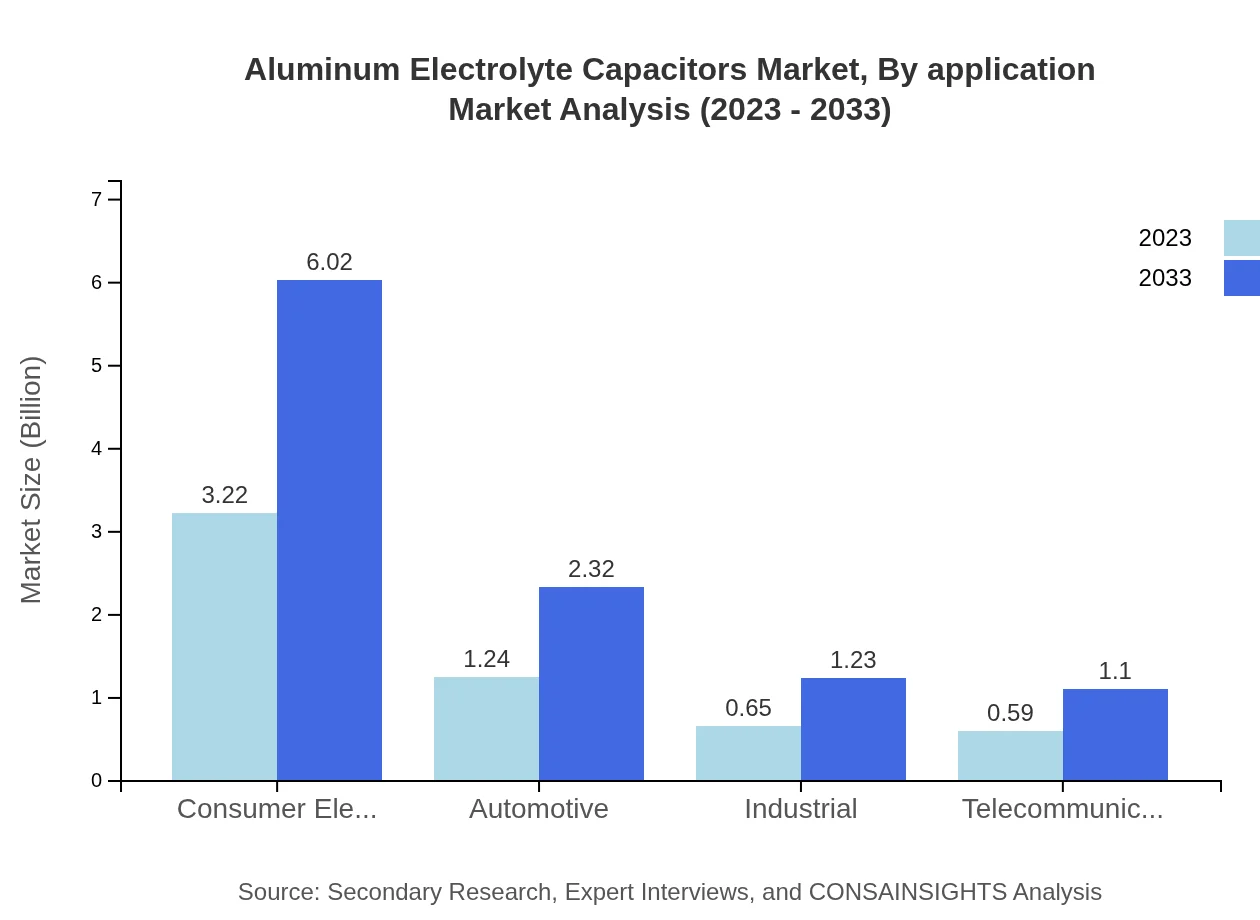

Aluminum Electrolyte Capacitors Market Analysis By Application

The market is primarily driven by the consumer electronics segment, which holds a 56.44% share, projected to grow from $3.22 billion in 2023 to $6.02 billion by 2033. The automotive application, at 21.72%, also shows strong growth potential due to shifts in electric vehicle manufacturing and smart automotive technologies.

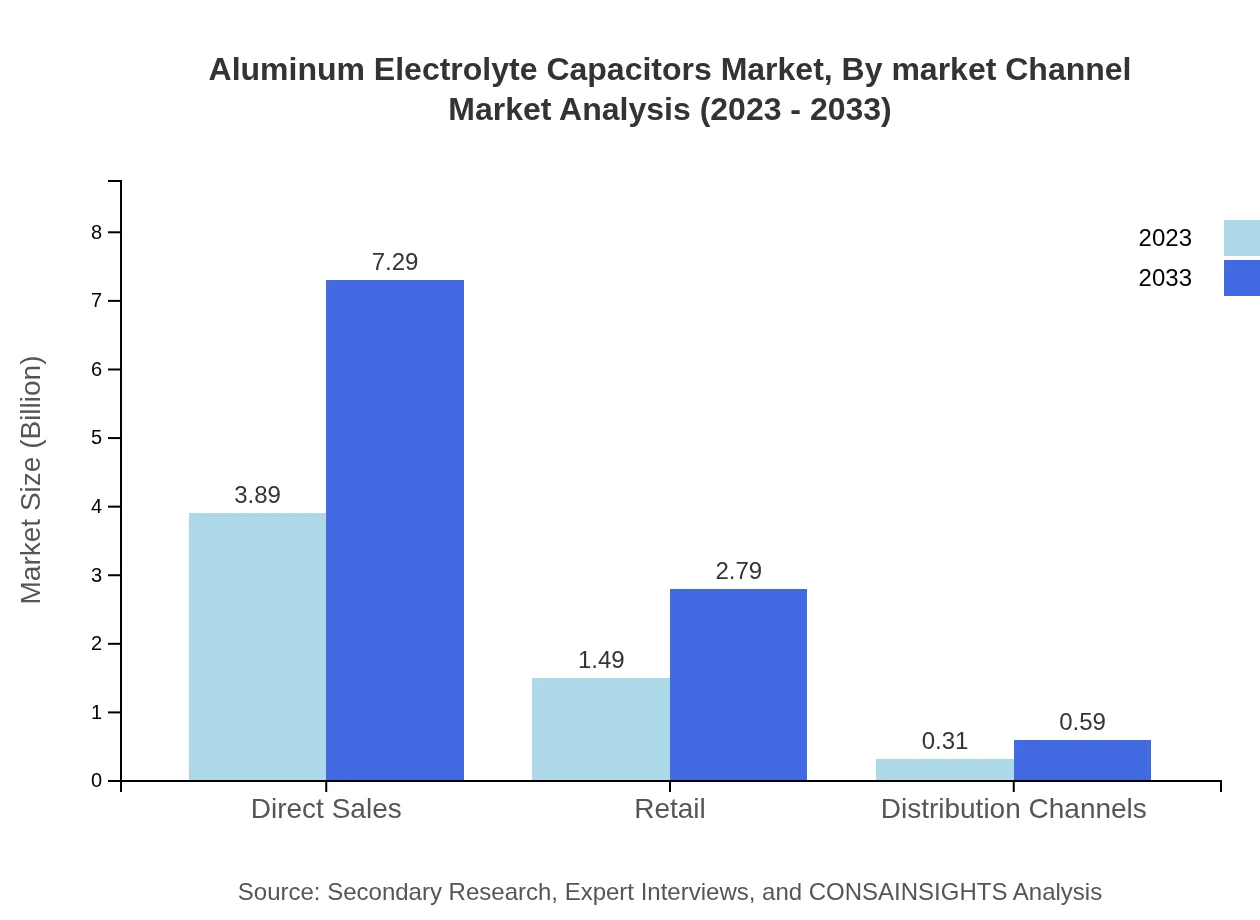

Aluminum Electrolyte Capacitors Market Analysis By Market Channel

Sales channels for Aluminum Electrolyte Capacitors include Direct Sales (68.33% market share) and Retail (26.16% market share). Direct sales are favored in bulk applications, while retail channels support consumer electronics purchases, facilitating accessibility and customer outreach.

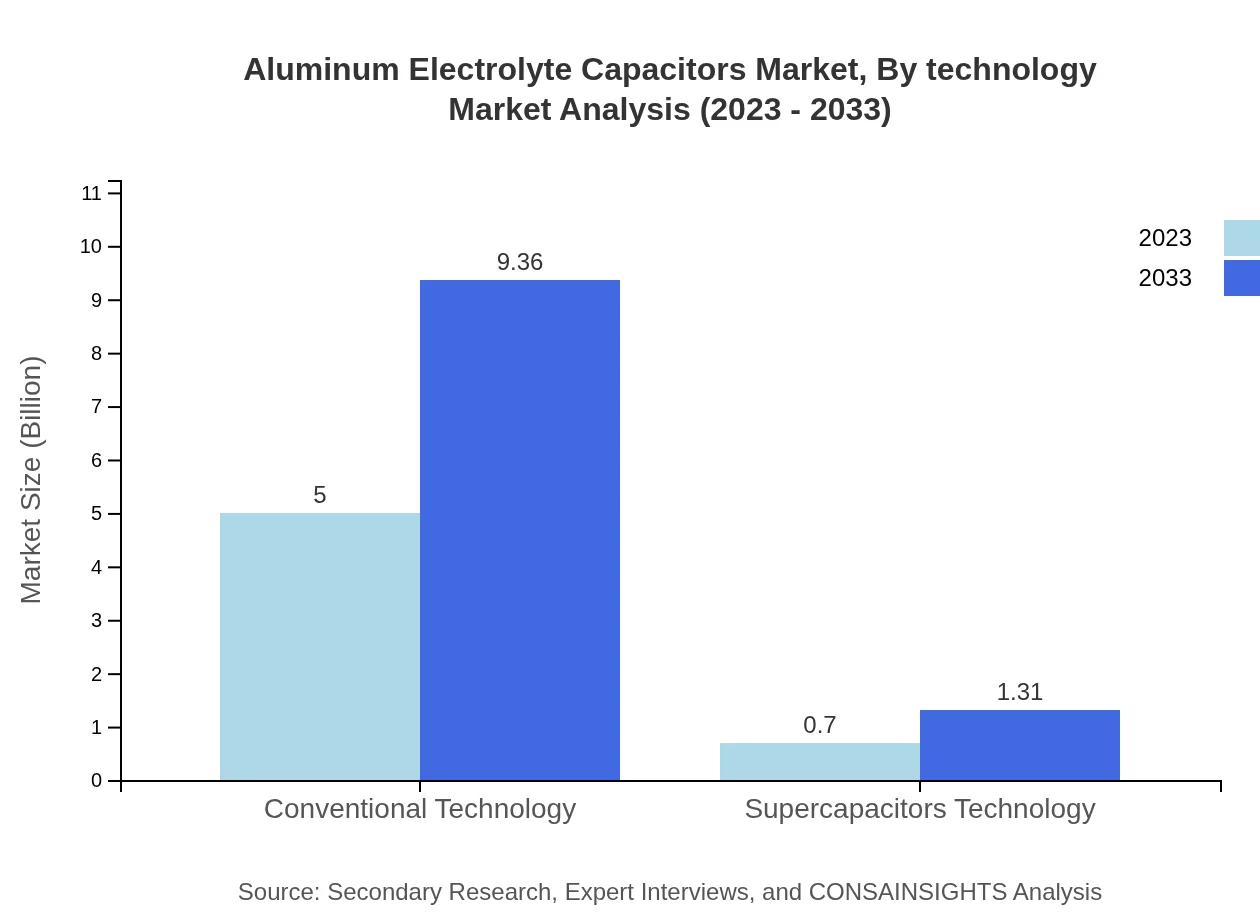

Aluminum Electrolyte Capacitors Market Analysis By Technology

The market is divided between Conventional Technology (87.76% share) and Supercapacitors Technology (12.24% share). Supercapacitors are gaining ground due to the demand for energy storage solutions in renewable energy systems, demonstrating potential for future growth.

Aluminum Electrolyte Capacitors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aluminum Electrolyte Capacitors Industry

Panasonic Corporation:

A leading manufacturer of electronic components, Panasonic offers a wide range of aluminum electrolytic capacitors known for their reliability and performance, powering multiple consumer electronic devices and industrial solutions.Nichicon Corporation:

Nichicon specializes in high-quality capacitors, providing innovative solutions for various applications, including automotive and telecommunications, with a strong global presence.Rubicon Technology:

Rubicon Technology is noted for its advanced technologies in aluminum capacitors that cater to high-performance applications across diverse sectors, including renewable energy.KEMET Corporation:

KEMET produces a diverse range of capacitor products with a strong emphasis on meeting sustainability standards, driving innovations in electrolytic capacitors.Vishay Intertechnology:

Vishay is a major player in the capacitor market, offering a broad spectrum of aluminum electrolytic capacitors for high-temperature applications across various industries.We're grateful to work with incredible clients.

FAQs

What is the market size of aluminum Electrolyte Capacitors?

The aluminum electrolyte capacitors market is projected to reach a size of approximately $5.7 billion by 2033, growing at a CAGR of 6.3%. This growth is driven by increasing demand in various sectors such as consumer electronics and automotive.

What are the key market players or companies in this aluminum Electrolyte Capacitors industry?

Key players in the aluminum electrolyte capacitors market include major manufacturers such as Nippon Chemi-Con, Rubycon, Vishay, and Panasonic. These companies lead in innovation and production capacity, catering to the growing industry demand.

What are the primary factors driving the growth in the aluminum Electrolyte Capacitors industry?

Growth factors include the increasing demand for electronic devices, advancements in automotive technologies, and the expansion of renewable energy sources. These trends create a significant need for reliable capacitor solutions across various applications.

Which region is the fastest Growing in the aluminum Electrolyte Capacitors?

The Asia Pacific region is the fastest-growing market, expected to grow from $1.08 billion in 2023 to $2.02 billion by 2033. This rapid growth is fueled by the rising electronics sector and automotive production in countries like China and India.

Does ConsaInsights provide customized market report data for the aluminum Electrolyte Capacitors industry?

Yes, ConsaInsights offers tailored market report data for the aluminum electrolyte capacitors industry, catering to specific needs and insights. Custom reports provide in-depth analysis on market segments, trends, and forecasts.

What deliverables can I expect from this aluminum Electrolyte Capacitors market research project?

Deliverables include comprehensive market analysis, regional breakdowns, competitive landscape reviews, and segmented data insights. Clients will receive actionable insights that help in strategic decision-making.

What are the market trends of aluminum Electrolyte Capacitors?

Current market trends show a shift towards low-capacitance solutions dominating the market share, with innovations in supercapacitors gaining traction. Additionally, consumer electronics and automotive applications continue to drive significant demand.