Aluminum Nickel Catalysts Market Report

Published Date: 02 February 2026 | Report Code: aluminum-nickel-catalysts

Aluminum Nickel Catalysts Market Size, Share, Industry Trends and Forecast to 2033

This report provides in-depth insights into the Aluminum Nickel Catalysts market, covering key trends, forecasts, and analysis from 2023 to 2033. It explores market dynamics, segmentation, regional performance, technology advancements, and profiles of industry leaders.

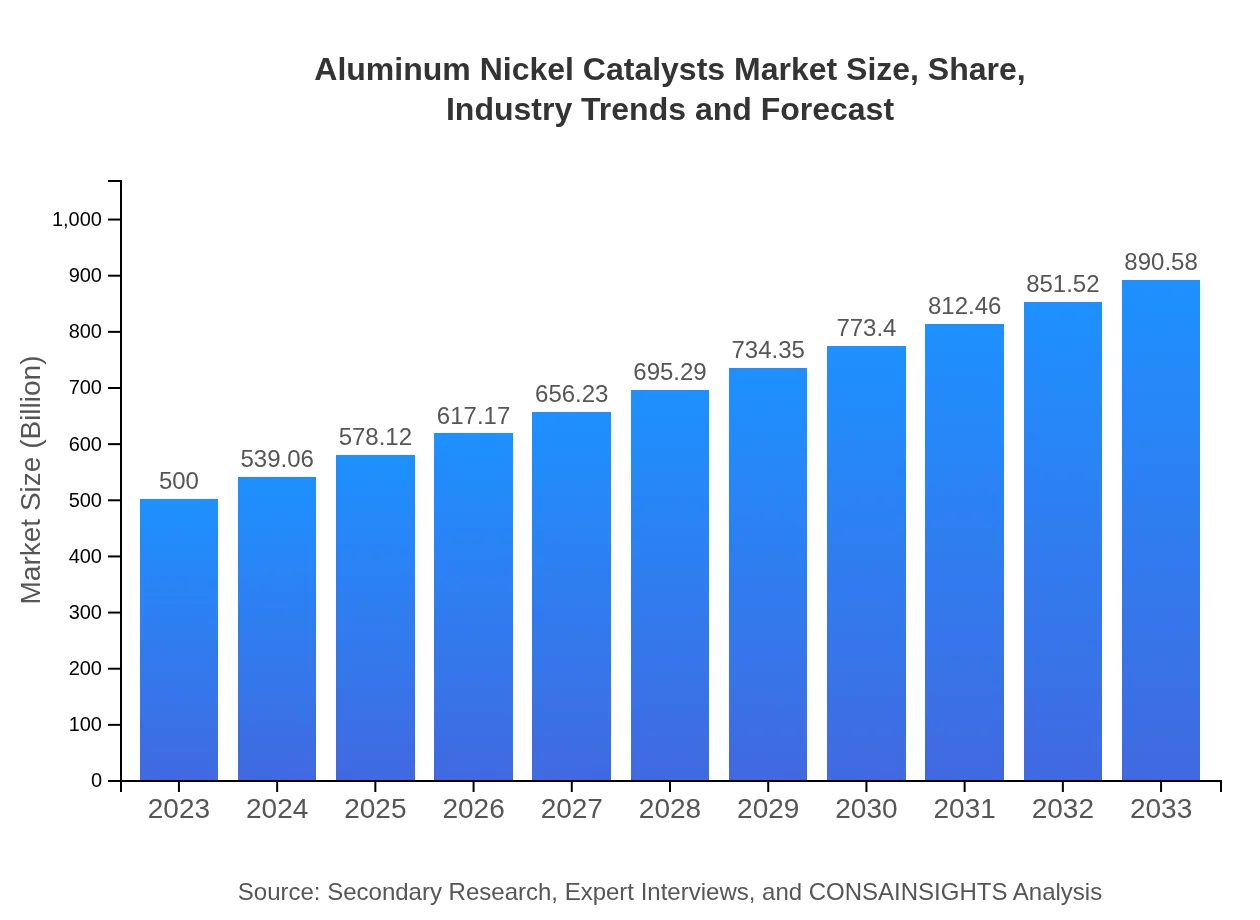

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $500.00 Million |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $890.58 Million |

| Top Companies | BASF SE, Johnson Matthey, Haldor Topsoe |

| Last Modified Date | 02 February 2026 |

Aluminum Nickel Catalysts Market Overview

Customize Aluminum Nickel Catalysts Market Report market research report

- ✔ Get in-depth analysis of Aluminum Nickel Catalysts market size, growth, and forecasts.

- ✔ Understand Aluminum Nickel Catalysts's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aluminum Nickel Catalysts

What is the Market Size & CAGR of Aluminum Nickel Catalysts market in 2023?

Aluminum Nickel Catalysts Industry Analysis

Aluminum Nickel Catalysts Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aluminum Nickel Catalysts Market Analysis Report by Region

Europe Aluminum Nickel Catalysts Market Report:

The European market for Aluminum Nickel Catalysts is anticipated to evolve from $125.85 million in 2023 to $224.16 million in 2033. The heightened focus on environmental sustainability and reductions in greenhouse gas emissions enhance demand in this region, particularly in advanced manufacturing sectors.Asia Pacific Aluminum Nickel Catalysts Market Report:

The Asia Pacific region is projected to witness significant growth due to rising industrialization, particularly in countries like China and India. The market size in 2023 is approximately $107.70 million and is expected to grow to $191.83 million by 2033. Increased demand for sustainable chemical processes significantly fuels this growth.North America Aluminum Nickel Catalysts Market Report:

North America remains a key market, with the size reaching $167.35 million in 2023 and expected to grow to $298.08 million by 2033. Major advancements in automotive and pharmaceutical applications contribute to this growth, alongside strict regulations promoting catalytic processes.South America Aluminum Nickel Catalysts Market Report:

In South America, the Aluminum Nickel Catalysts market is expected to grow from $31.35 million in 2023 to $55.84 million by 2033. The agriculture and petrochemical sectors are the primary drivers, supported by advancing agricultural technologies and an increase in petrochemical production.Middle East & Africa Aluminum Nickel Catalysts Market Report:

The Middle East and Africa market is likely to grow, with a forecasted increase from $67.75 million in 2023 to $120.67 million by 2033. The growth is primarily driven by improved oil and gas extraction technologies, requiring more efficient catalytic processes.Tell us your focus area and get a customized research report.

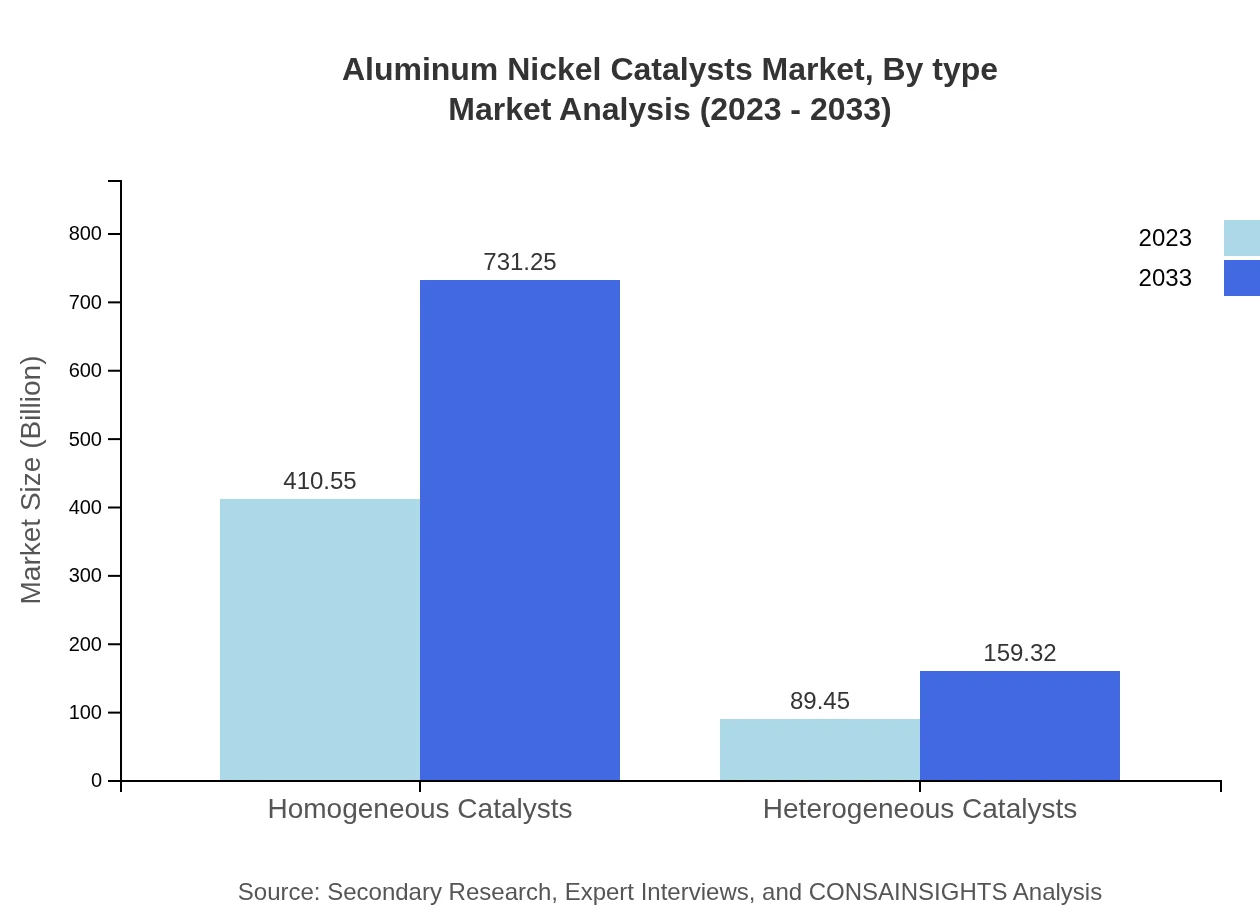

Aluminum Nickel Catalysts Market Analysis By Type

The market is divided into two primary categories: homogeneous and heterogeneous catalysts. In 2023, homogeneous catalysts dominate the market with a size of $410.55 million (82.11% share), while heterogeneous catalysts account for $89.45 million (17.89% share). By 2033, homogeneous catalysts are expected to grow to $731.25 million, maintaining their significant market share.

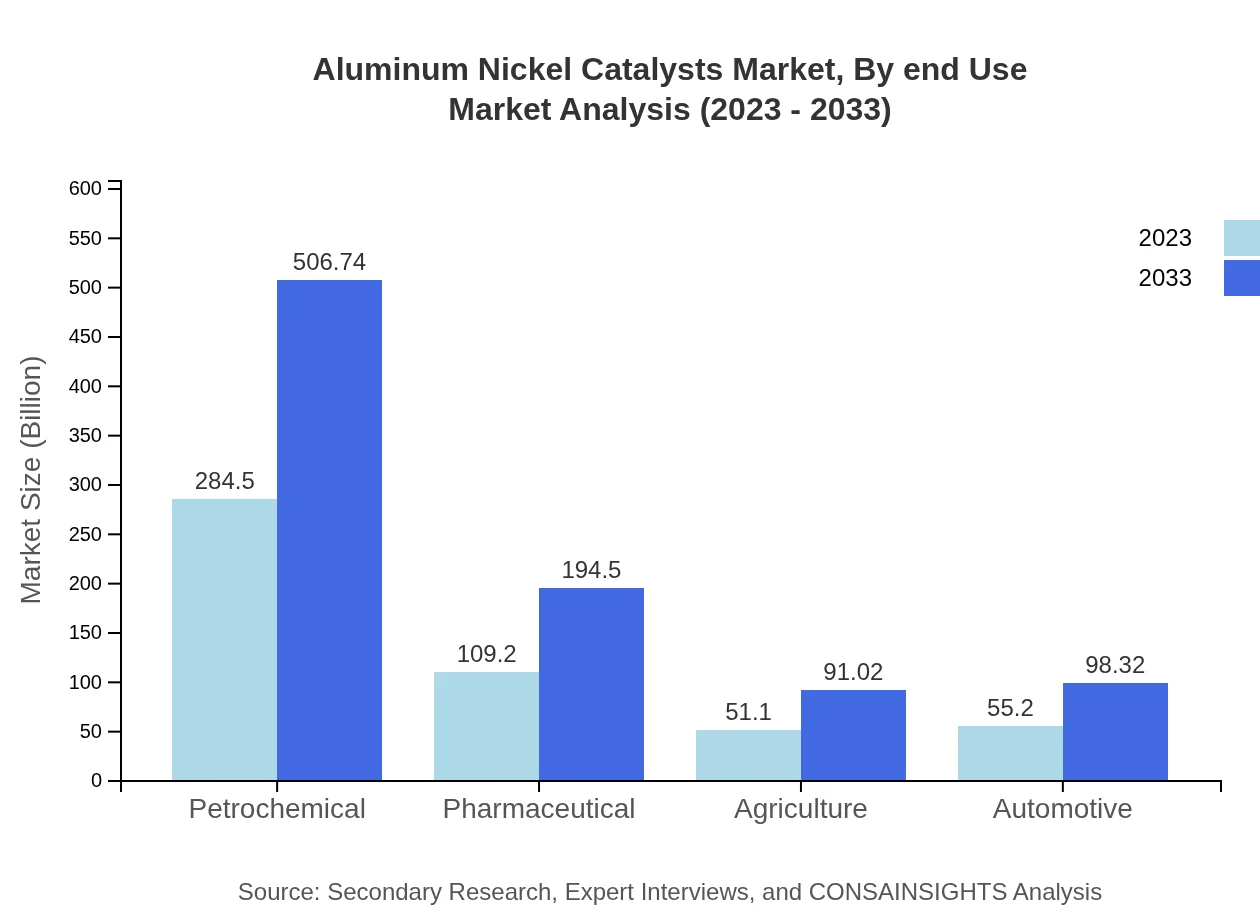

Aluminum Nickel Catalysts Market Analysis By End Use

The Aluminum Nickel Catalysts market in the petrochemical sector leads with a size of $284.50 million (56.90% share) in 2023 and is forecasted to reach $506.74 million by 2033. The pharmaceutical sector follows, with a market of $109.20 million (21.84% share) in 2023, expanding to $194.50 million by 2033. Other sectors include agriculture and automotive, indicating a diverse range of applications.

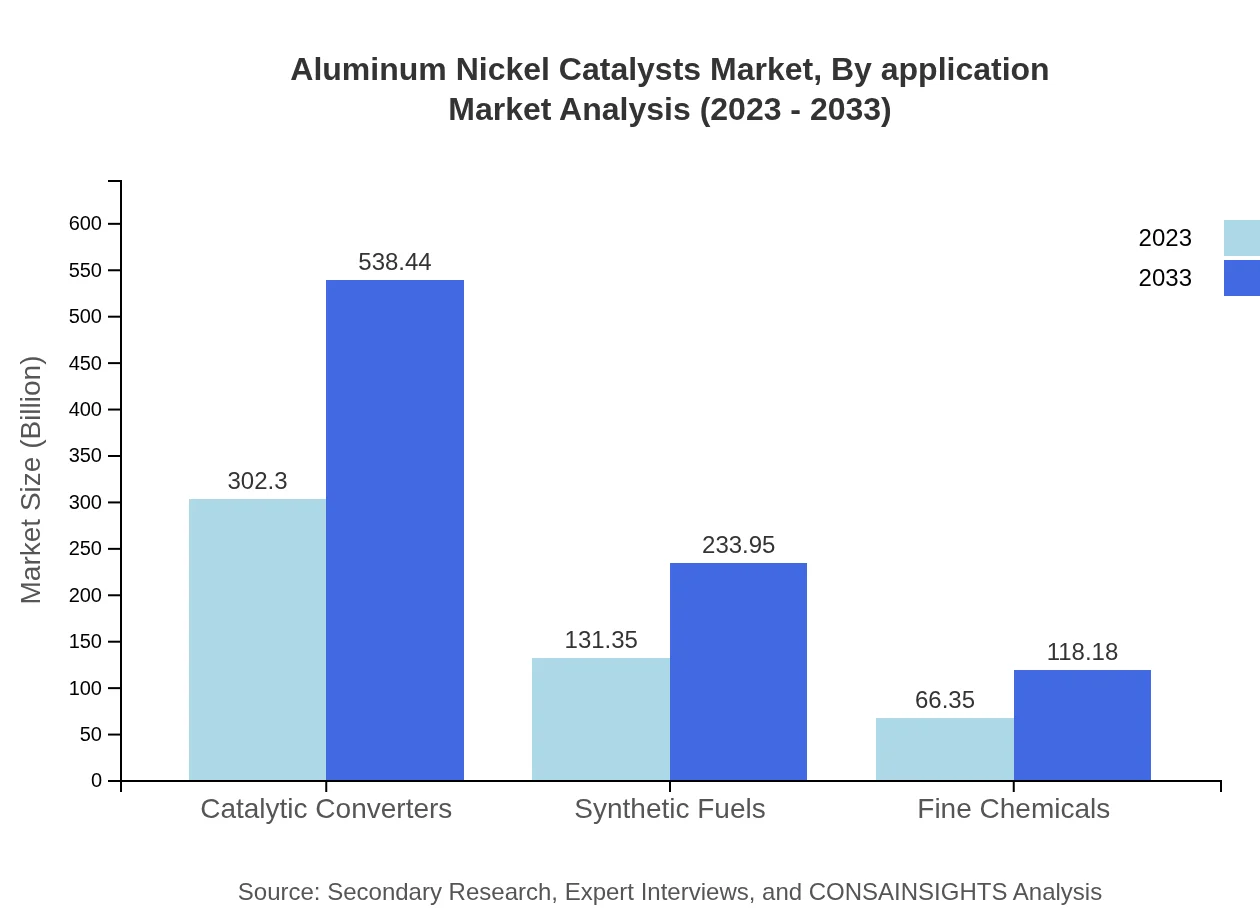

Aluminum Nickel Catalysts Market Analysis By Application

Applications including catalytic converters and synthetic fuels establish crucial market segments. In 2023, catalytic converters represent a market worth $302.30 million (60.46% share), growing to $538.44 million by 2033. Synthetic fuels, accounting for $131.35 million (26.27% share) in 2023, show strong growth potential to $233.95 million by 2033.

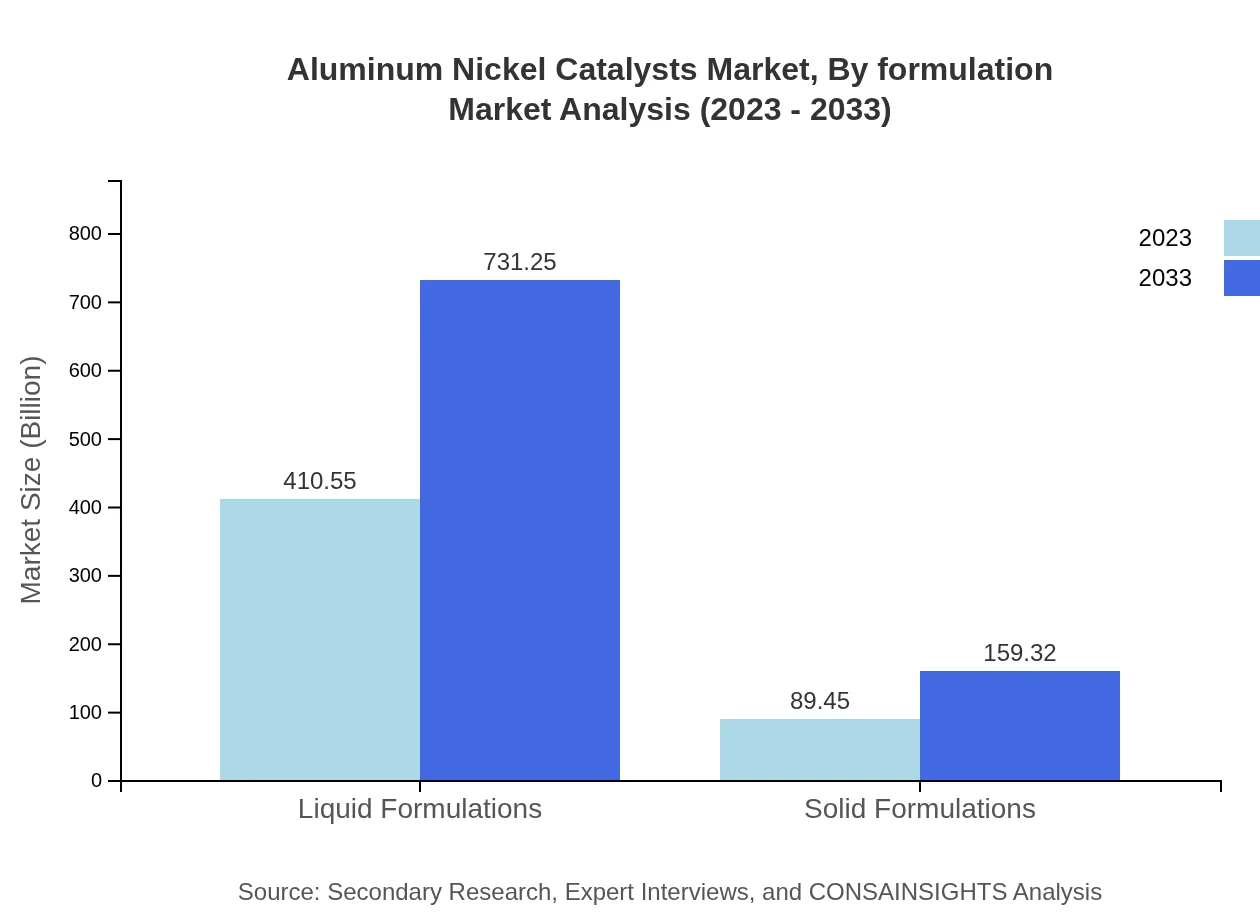

Aluminum Nickel Catalysts Market Analysis By Formulation

The market is segmented into liquid and solid formulations. Liquid formulations dominate with a size of $410.55 million (82.11% share) in 2023, growing to $731.25 million by 2033. Conversely, solid formulations represent a smaller segment with $89.45 million (17.89% share), increasing to $159.32 million by 2033, highlighting the preference for efficient application methodologies.

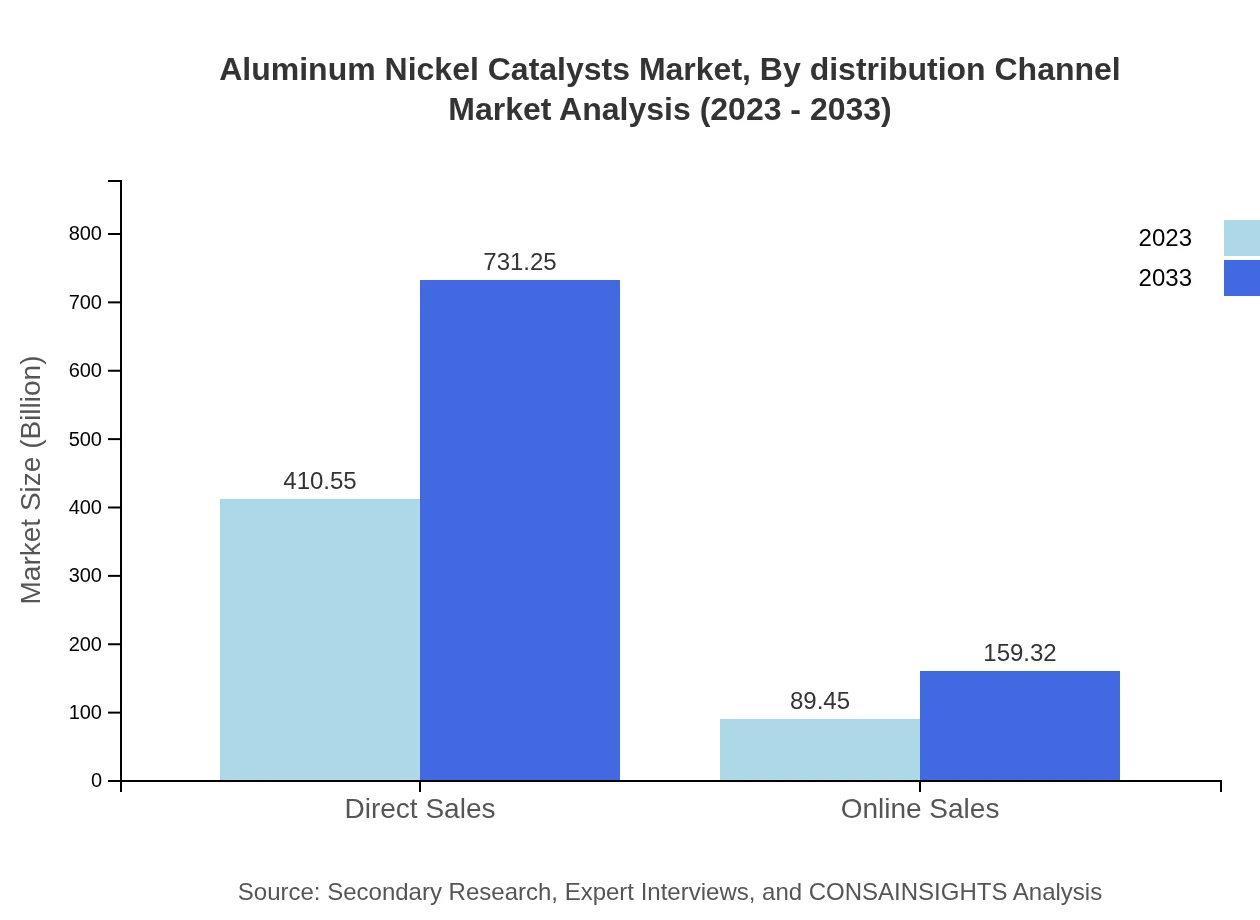

Aluminum Nickel Catalysts Market Analysis By Distribution Channel

Direct sales dominate the distribution channel with a considerable market size of $410.55 million (82.11% share) in 2023 and projected to reach $731.25 million by 2033. Online sales, while smaller in proportion (17.89% share), accounted for $89.45 million in 2023, highlighting the growing trend towards e-commerce in this sector.

Aluminum Nickel Catalysts Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aluminum Nickel Catalysts Industry

BASF SE:

BASF SE is a leading player in the chemical industry, offering a range of aluminum nickel catalysts used across various sectors, including automotive and pharmaceuticals, known for their innovative and high-performance products.Johnson Matthey:

Johnson Matthey is renowned for its sustainable technologies, producing advanced catalysts that significantly reduce emissions in industrial applications and contribute to cleaner chemical processes.Haldor Topsoe:

Haldor Topsoe specializes in catalysis, focusing on efficient and innovative solutions that drive sustainability and performance in catalytic processes, impacting industries worldwide.We're grateful to work with incredible clients.

FAQs

What is the market size of aluminum Nickel Catalysts?

The global aluminum-nickel-catalysts market is projected to reach a size of approximately $500 million by 2033, growing at a compound annual growth rate (CAGR) of 5.8% from 2023.

What are the key market players or companies in the aluminum Nickel Catalysts industry?

Key players in the aluminum-nickel-catalysts market include leading chemical manufacturers and technology firms that specialize in catalyst production, particularly in sectors like petrochemicals and pharmaceuticals.

What are the primary factors driving the growth in the aluminum Nickel Catalysts industry?

Growth is driven by advancements in catalytic technologies, increasing demand in the petrochemical and automotive sectors, and regulatory pressure for cleaner production processes to reduce environmental impact.

Which region is the fastest Growing in the aluminum Nickel Catalysts market?

The Asia-Pacific region is the fastest-growing market, expected to rise from $107.70 million in 2023 to $191.83 million by 2033, driven by industrialization and increasing investments in chemical manufacturing.

Does ConsaInsights provide customized market report data for the aluminum Nickel Catalysts industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the aluminum-nickel-catalysts industry, ensuring clients receive relevant and actionable insights.

What deliverables can I expect from this aluminum Nickel Catalysts market research project?

Deliverables typically include a comprehensive report with market analysis, trends, forecasts, competitive landscapes, and actionable insights tailored to stakeholders in the aluminum-nickel-catalysts sector.

What are the market trends of aluminum Nickel Catalysts?

Key trends include growing innovations in heterogeneous catalysts, increasing adoption in the automotive industry for emission control, and rising investments in greener chemical processes across various sectors.