Aluminum Oxide Market Report

Published Date: 02 February 2026 | Report Code: aluminum-oxide

Aluminum Oxide Market Size, Share, Industry Trends and Forecast to 2033

This report offers comprehensive insights into the Aluminum Oxide market for the forecast period 2023-2033, including market size, trends, and growth drivers across various regions and segments.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

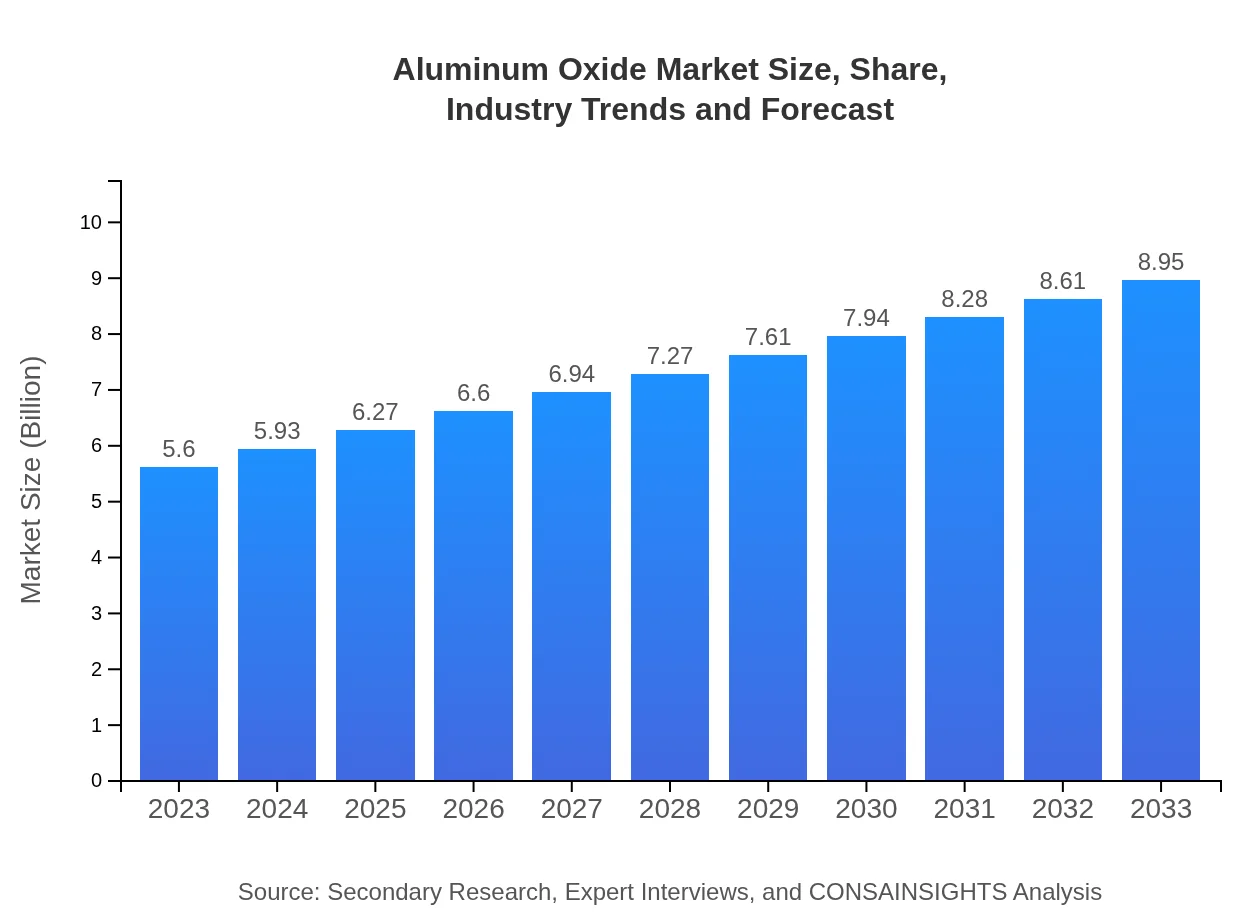

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $8.95 Billion |

| Top Companies | Alcoa Corporation, Rio Tinto Group, Norsk Hydro ASA, Kaiser Aluminum |

| Last Modified Date | 02 February 2026 |

Aluminum Oxide Market Overview

Customize Aluminum Oxide Market Report market research report

- ✔ Get in-depth analysis of Aluminum Oxide market size, growth, and forecasts.

- ✔ Understand Aluminum Oxide's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aluminum Oxide

What is the Market Size & CAGR of Aluminum Oxide market in 2023?

Aluminum Oxide Industry Analysis

Aluminum Oxide Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aluminum Oxide Market Analysis Report by Region

Europe Aluminum Oxide Market Report:

Europe's Aluminum Oxide market size is anticipated to expand from $1.87 billion in 2023 to $2.98 billion by 2033. This growth is attributed to the region's robust manufacturing base and stringent regulations driving the adoption of advanced materials and sustainable practices across industries.Asia Pacific Aluminum Oxide Market Report:

In the Asia Pacific region, the Aluminum Oxide market is projected to grow from $0.99 billion in 2023 to $1.58 billion by 2033, driven by rising industrial activities, especially in China and India. The region's expanding electronics and automotive sectors are primary contributors to this growth, supported by increasing investments in infrastructure projects.North America Aluminum Oxide Market Report:

In North America, the market is projected to grow from $1.98 billion in 2023 to $3.17 billion by 2033. The United States remains a key market due to significant demand in the aerospace and automotive industries, coupled with continuous advancements in manufacturing technologies.South America Aluminum Oxide Market Report:

The South American Aluminum Oxide market size is expected to increase from $0.28 billion in 2023 to $0.45 billion by 2033. Key factors influencing this growth include growing demand from the automotive sector and rising construction activities, particularly in Brazil and Argentina.Middle East & Africa Aluminum Oxide Market Report:

The Middle East and Africa market is expected to witness growth from $0.48 billion in 2023 to $0.76 billion by 2033. The increase in construction and industrial activities in countries like UAE and South Africa are pivotal in driving the demand for Aluminum Oxide.Tell us your focus area and get a customized research report.

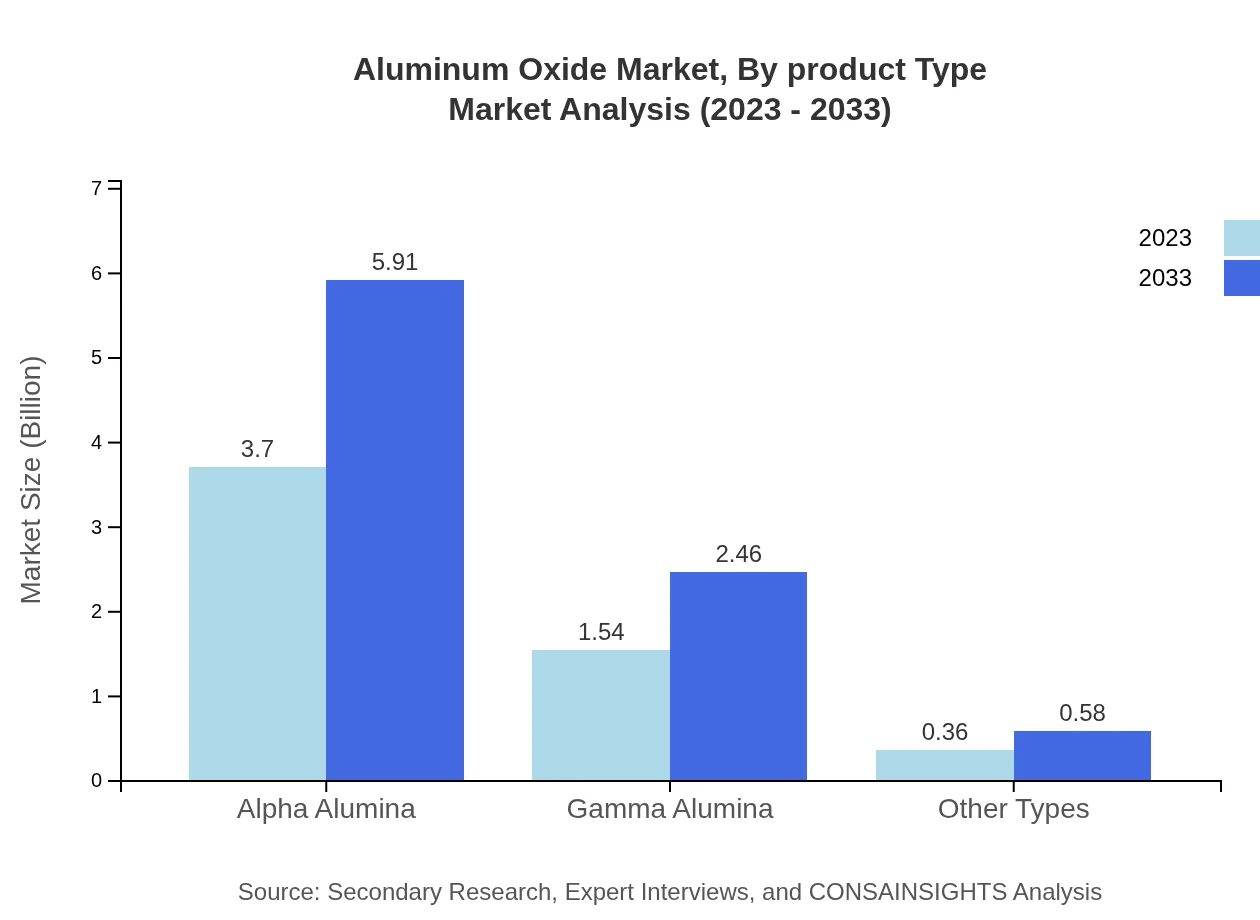

Aluminum Oxide Market Analysis By Product Type

The product type segmentation highlights that Alpha Alumina constitutes a substantial market share, valued at $3.70 billion in 2023, projected to increase to $5.91 billion in 2033. Gamma Alumina, while smaller, also exhibits growth potential, moving from $1.54 billion in 2023 to $2.46 billion by 2033, primarily driven by demand in catalysts and applications.

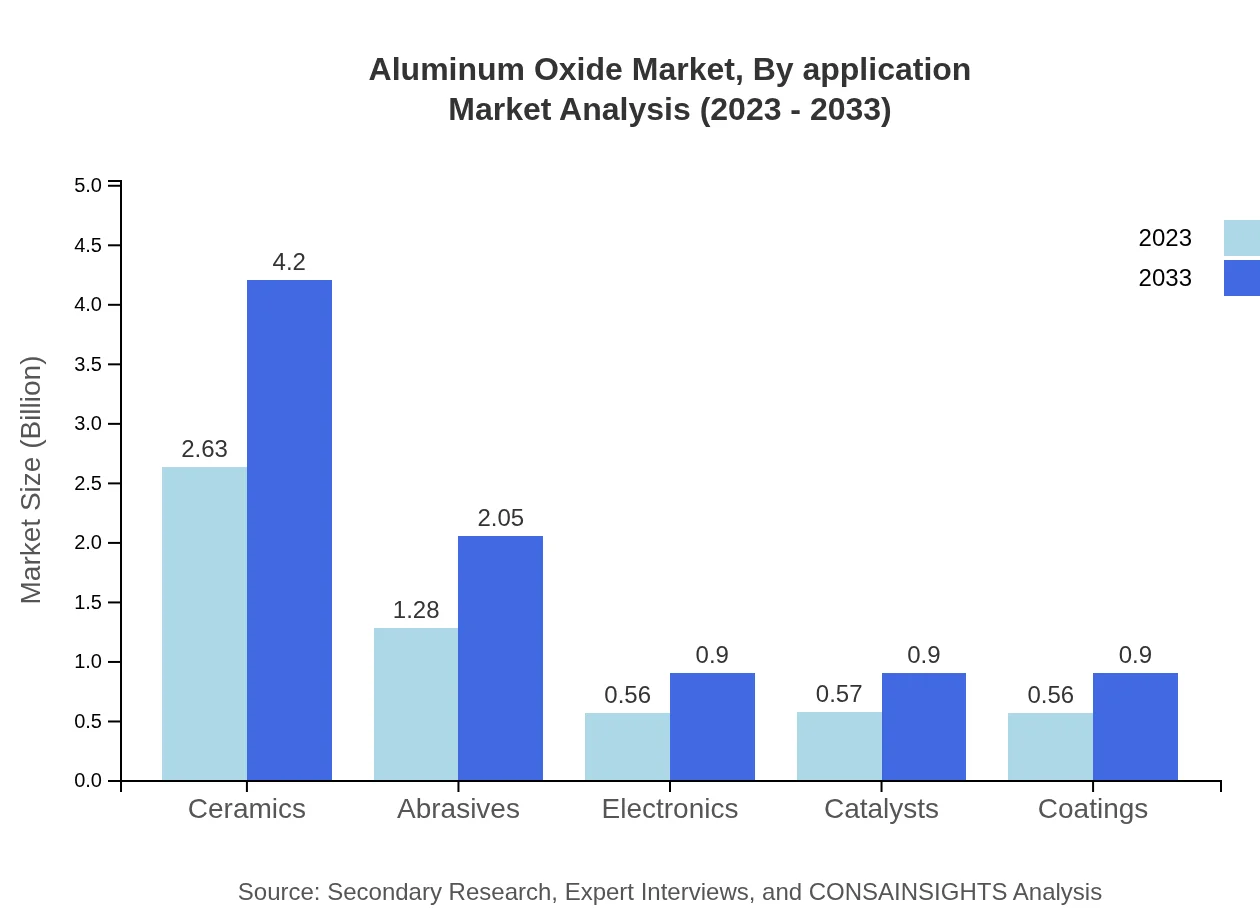

Aluminum Oxide Market Analysis By Application

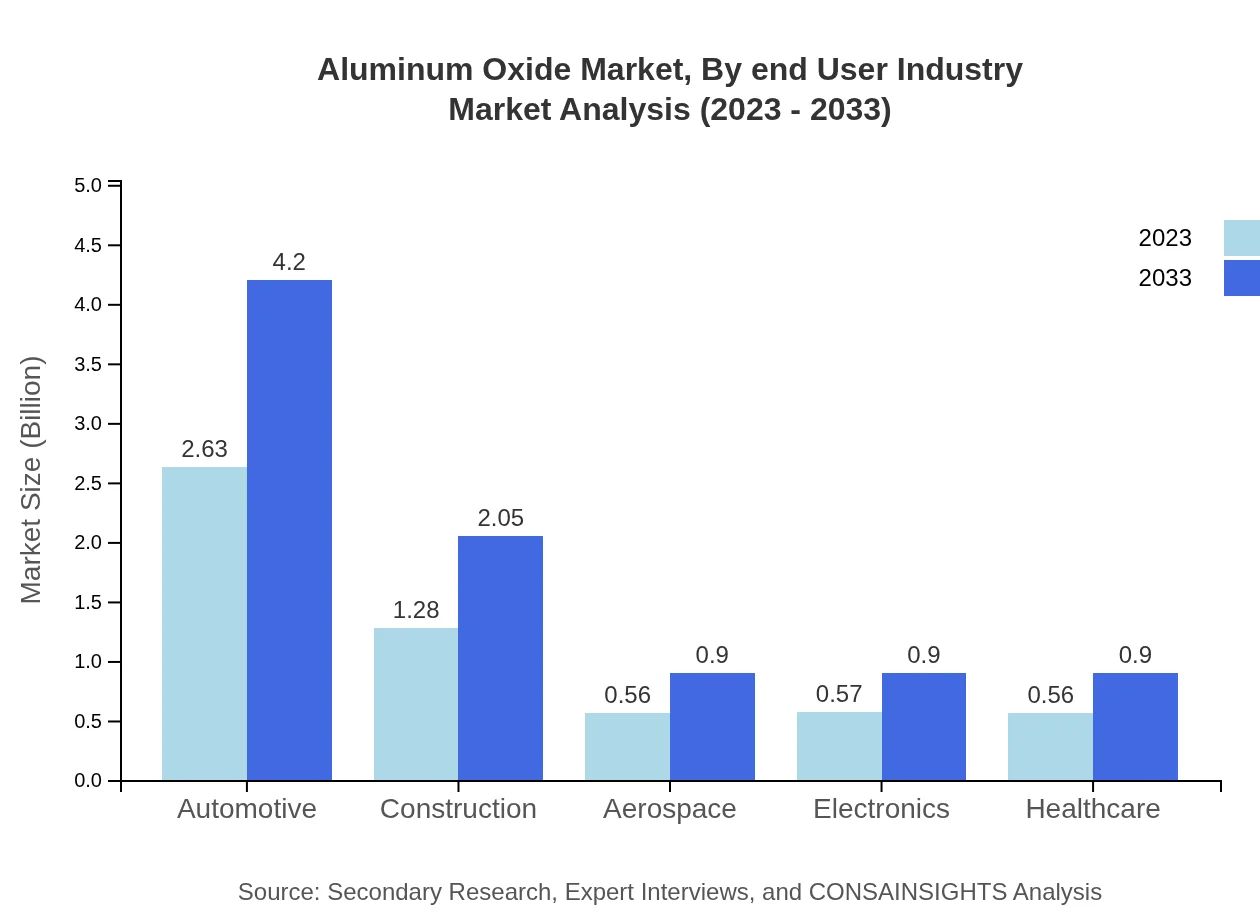

In terms of application, the construction sector leads with a market share of 46.89% in 2023, growing to 46.89% by 2033. Automotive applications are projected to rise from $2.63 billion in 2023 to $4.20 billion in 2033, showcasing the versatile uses of Aluminum Oxide in various industries.

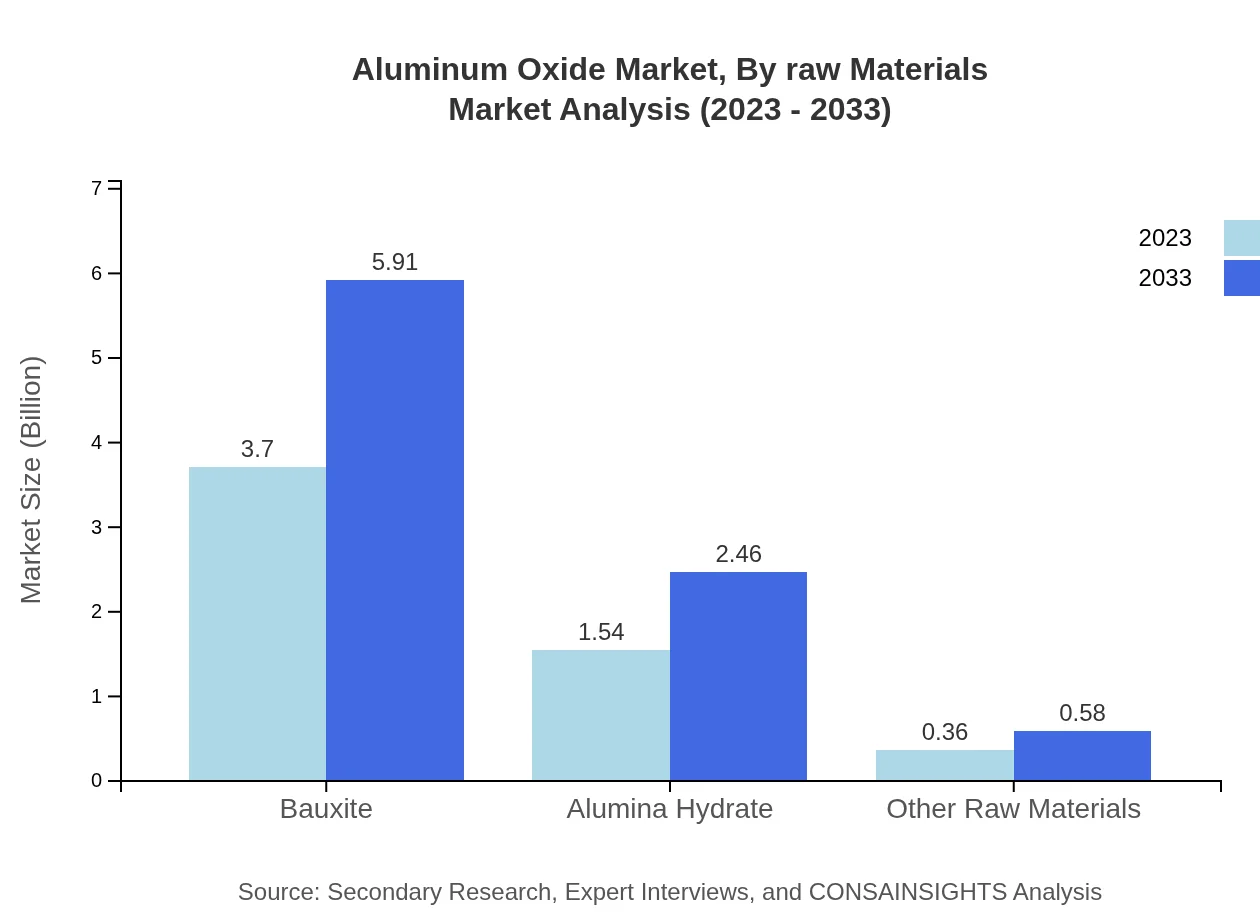

Aluminum Oxide Market Analysis By Raw Materials

The raw materials segment is dominated by Bauxite, accounting for 66.06% of the market share in 2023 and remaining stable until 2033. Alumina Hydrate also plays a crucial role, with its market projected to increase from $1.54 billion in 2023 to $2.46 billion by 2033.

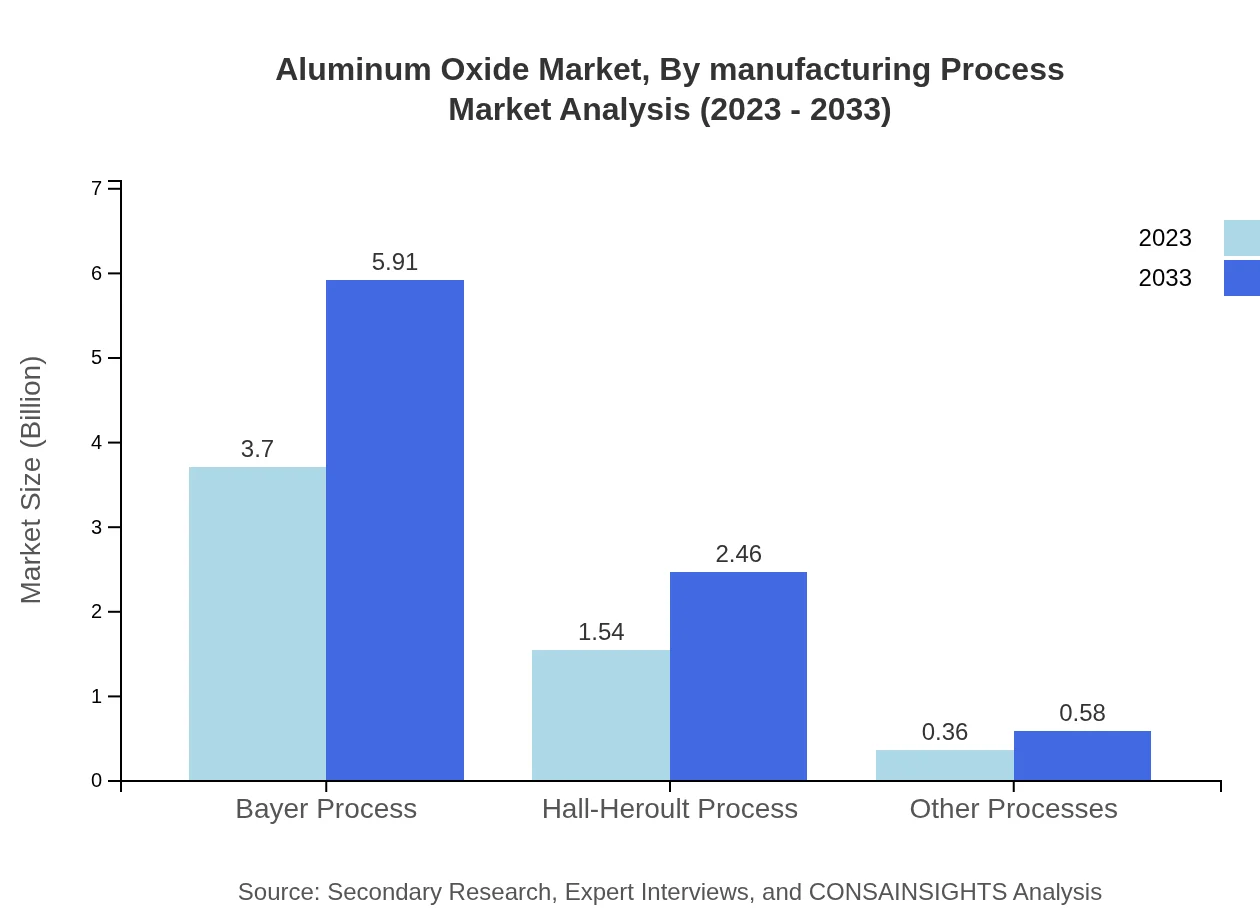

Aluminum Oxide Market Analysis By Manufacturing Process

The Bayer Process continues to dominate the market, representing 66.06% in 2023. The Hall-Heroult Process follows with a notable 27.48%. Together, these processes contribute significantly to the global Aluminum Oxide supply chain, responding to growing market demands.

Aluminum Oxide Market Analysis By End User Industry

Key end-user industries for Aluminum Oxide include automotive, aerospace, and healthcare. The automotive sector alone is set to grow from $2.63 billion in 2023 to $4.20 billion by 2033, indicating significant growth as global demand for lighter materials rises.

Aluminum Oxide Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aluminum Oxide Industry

Alcoa Corporation:

A leading innovator in the aluminum industry, Alcoa offers high-performance Aluminum Oxide products tailored for various applications, enhancing efficiency in aluminum production processes.Rio Tinto Group:

This global mining group is a significant player in the Aluminum Oxide market, ensuring sustainable production practices while contributing to the development of advanced aluminum solutions.Norsk Hydro ASA:

Norsk Hydro is a fully integrated aluminum company known for its sustainable operations and commitment to developing innovative materials for the Aluminum Oxide market.Kaiser Aluminum:

Kaiser Aluminum focuses on the production of high-quality aluminum products, emphasizing the importance of Aluminum Oxide in their manufacturing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of aluminum Oxide?

The aluminum oxide market was valued at approximately $5.6 billion in 2023, with an expected compound annual growth rate (CAGR) of 4.7% from 2023 to 2033.

What are the key market players or companies in the aluminum Oxide industry?

Key players in the aluminum oxide market include companies such as Alcoa Corporation, Rio Tinto Group, and Norsk Hydro, which significantly contribute to the production and supply chain of aluminum oxide products.

What are the primary factors driving the growth in the aluminum oxide industry?

Growth drivers in the aluminum oxide market include increasing demand from the automotive and construction industries, advancements in manufacturing technologies, and the rising need for high-purity aluminum oxide in electronics and coatings.

Which region is the fastest Growing in the aluminum oxide market?

North America is the fastest-growing region in the aluminum oxide market, expected to rise from $1.98 billion in 2023 to $3.17 billion by 2033, driven by expanding industrial applications and infrastructure investments.

Does ConsaInsights provide customized market report data for the aluminum oxide industry?

Yes, ConsaInsights offers customized market report data tailored to the aluminum oxide industry, delivering insights that align with specific business needs and market queries.

What deliverables can I expect from this aluminum oxide market research project?

Deliverables from the aluminum oxide market research project include detailed market analysis, regional growth forecasts, segmentation insights, competitive landscape assessments, and strategic recommendations for market entry.

What are the market trends of aluminum oxide?

Market trends in aluminum oxide include a shift towards sustainable production processes, increasing use in advanced manufacturing applications, and growing market interest in high-performance materials for varied industrial sectors.