Aluminum Pigment Market Report

Published Date: 02 February 2026 | Report Code: aluminum-pigment

Aluminum Pigment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Aluminum Pigment market, highlighting market dynamics, size, segmentation, regional insights, and future trends from 2023 to 2033. It aims to equip stakeholders with actionable insights to make informed decisions in this evolving landscape.

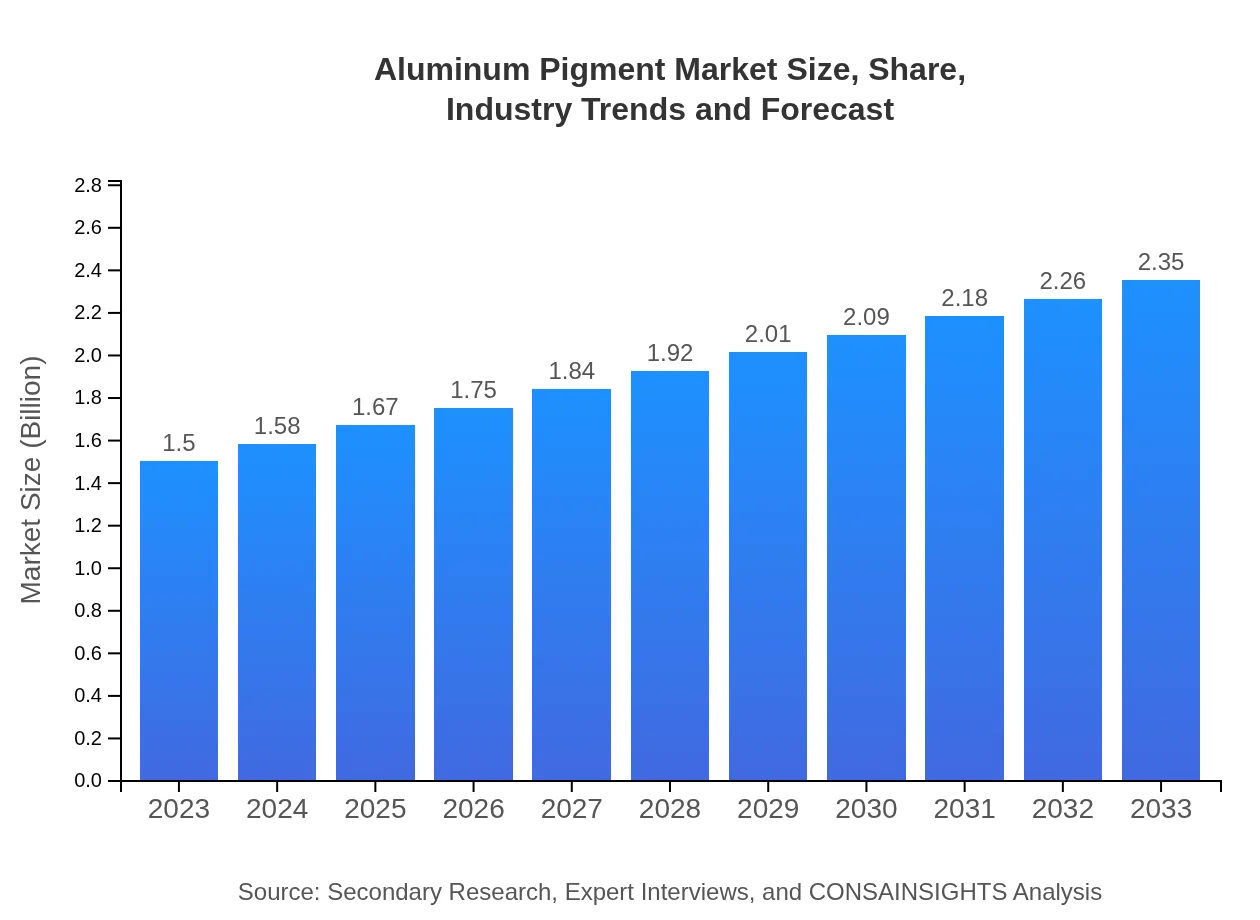

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $2.35 Billion |

| Top Companies | Silberline Manufacturing Co., Carl Schlenk AG, Metalprince, Kuncai |

| Last Modified Date | 02 February 2026 |

Aluminum Pigment Market Overview

Customize Aluminum Pigment Market Report market research report

- ✔ Get in-depth analysis of Aluminum Pigment market size, growth, and forecasts.

- ✔ Understand Aluminum Pigment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aluminum Pigment

What is the Market Size & CAGR of Aluminum Pigment market in 2023?

Aluminum Pigment Industry Analysis

Aluminum Pigment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aluminum Pigment Market Analysis Report by Region

Europe Aluminum Pigment Market Report:

Europe's market is anticipated to grow from $0.41 billion in 2023 to $0.64 billion in 2033. The region is focusing on sustainability and eco-friendly product developments, driving innovations in aluminum pigment formulations to meet stringent environmental regulations.Asia Pacific Aluminum Pigment Market Report:

In the Asia Pacific region, the Aluminum Pigment market is projected to grow from $0.32 billion in 2023 to $0.50 billion in 2033. This growth is driven by rapid industrialization, urbanization, and increasing demand from the automotive and construction sectors. Countries like China and India present significant opportunities due to their growing manufacturing capabilities and investment in infrastructure.North America Aluminum Pigment Market Report:

North America is projected to witness substantial growth, with market size expected to rise from $0.51 billion in 2023 to $0.79 billion in 2033. Factors such as the expansion of the automotive industry and increased consumer preference for high-performance coatings contribute to this rise.South America Aluminum Pigment Market Report:

The South American Aluminum Pigment market is expected to increase from $0.06 billion in 2023 to $0.10 billion by 2033. The growth is supported by the rising demand for decorative coatings and a rebound in construction activities, particularly in Brazil and Argentina.Middle East & Africa Aluminum Pigment Market Report:

In the Middle East and Africa, the market is expected to increase from $0.20 billion in 2023 to $0.31 billion by 2033. The growth is fueled by burgeoning construction activities and a growing interest in high-quality cosmetics in urban areas.Tell us your focus area and get a customized research report.

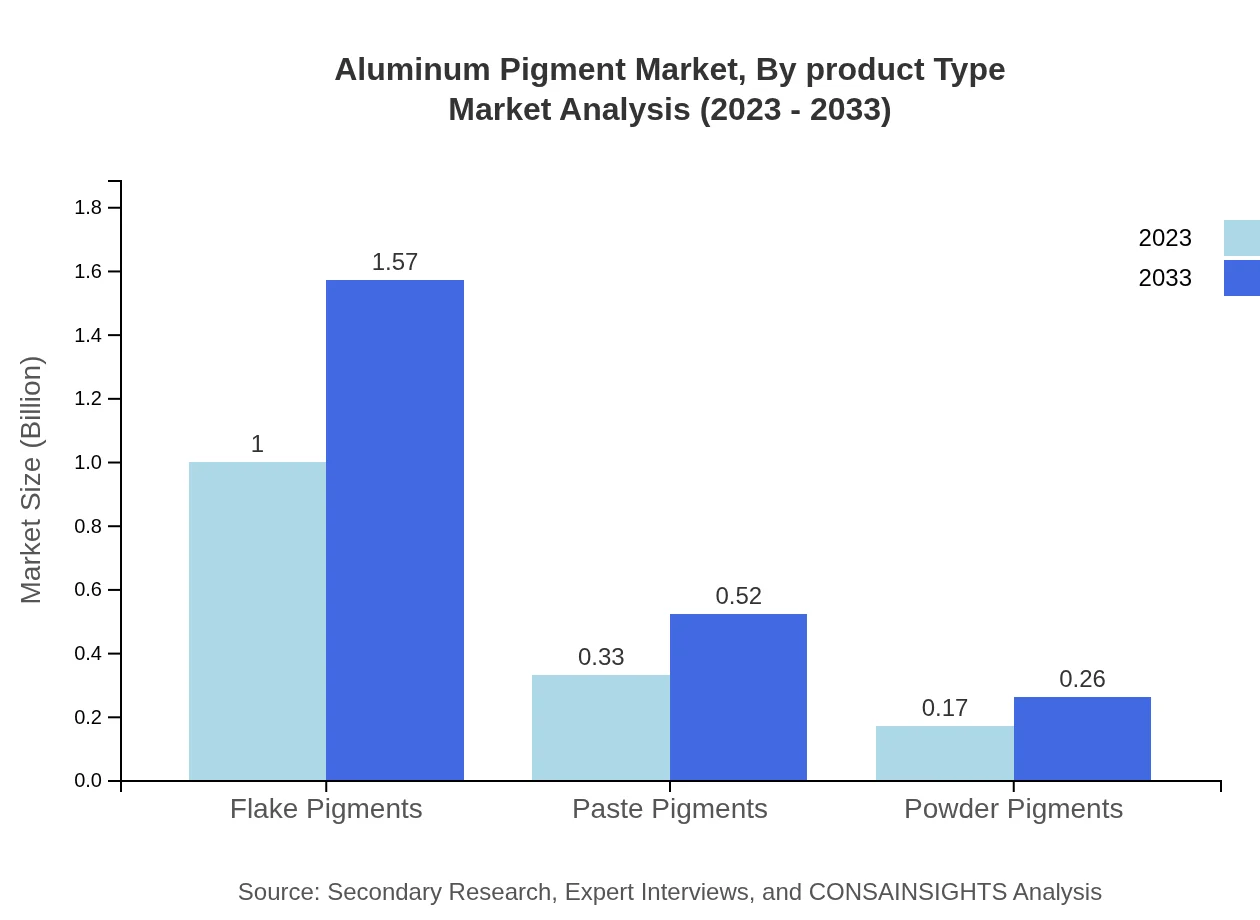

Aluminum Pigment Market Analysis By Product Type

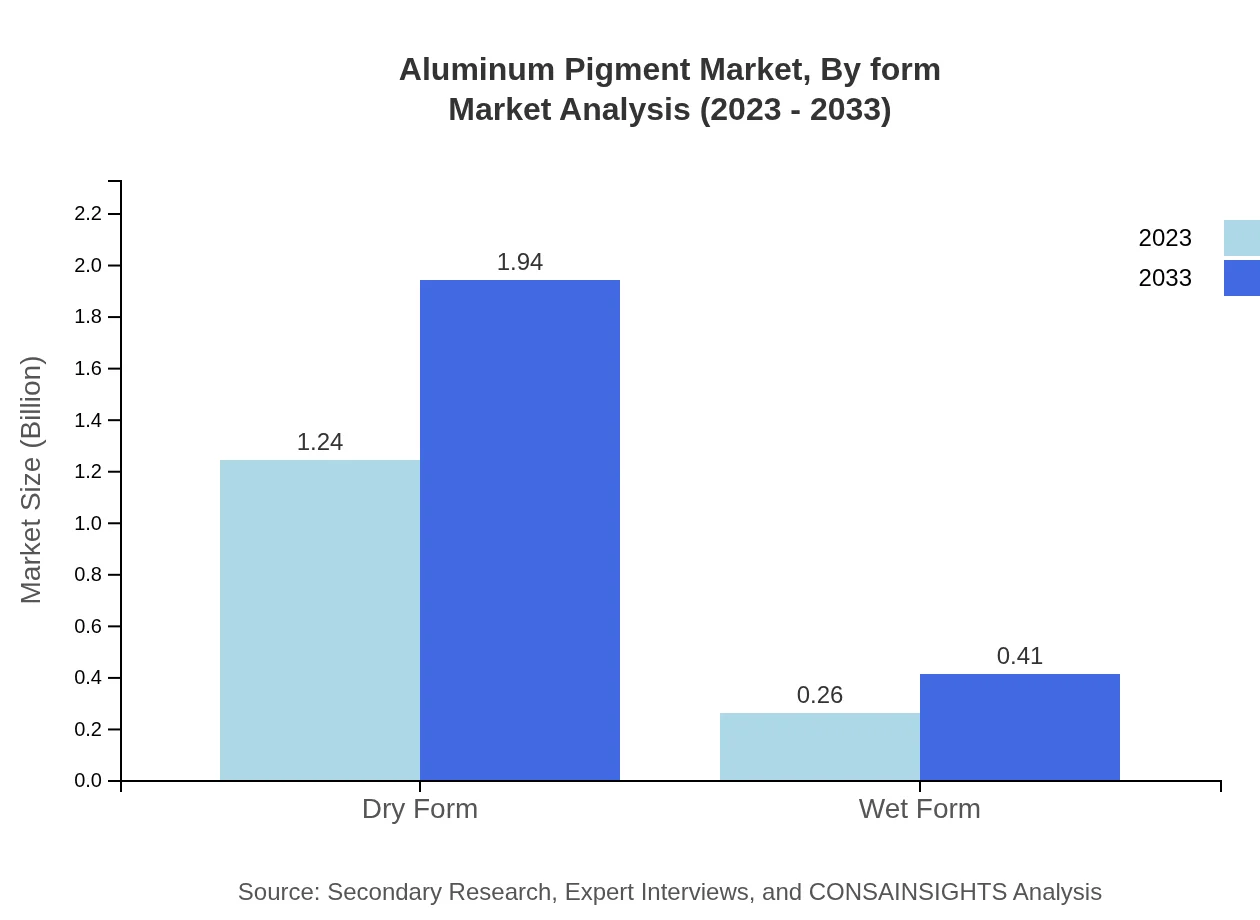

The Aluminum Pigment market is segmented by product type, with the dry form dominating the market, expected to grow from $1.24 billion in 2023 to $1.94 billion by 2033, maintaining a market share of 82.53%. In comparison, wet form pigments, while smaller, are anticipated to grow from $0.26 billion to $0.41 billion, holding a 17.47% share. The rise of flake pigments is also significant, expanding from $1.00 billion to $1.57 billion, reflecting their increasing adoption in various applications.

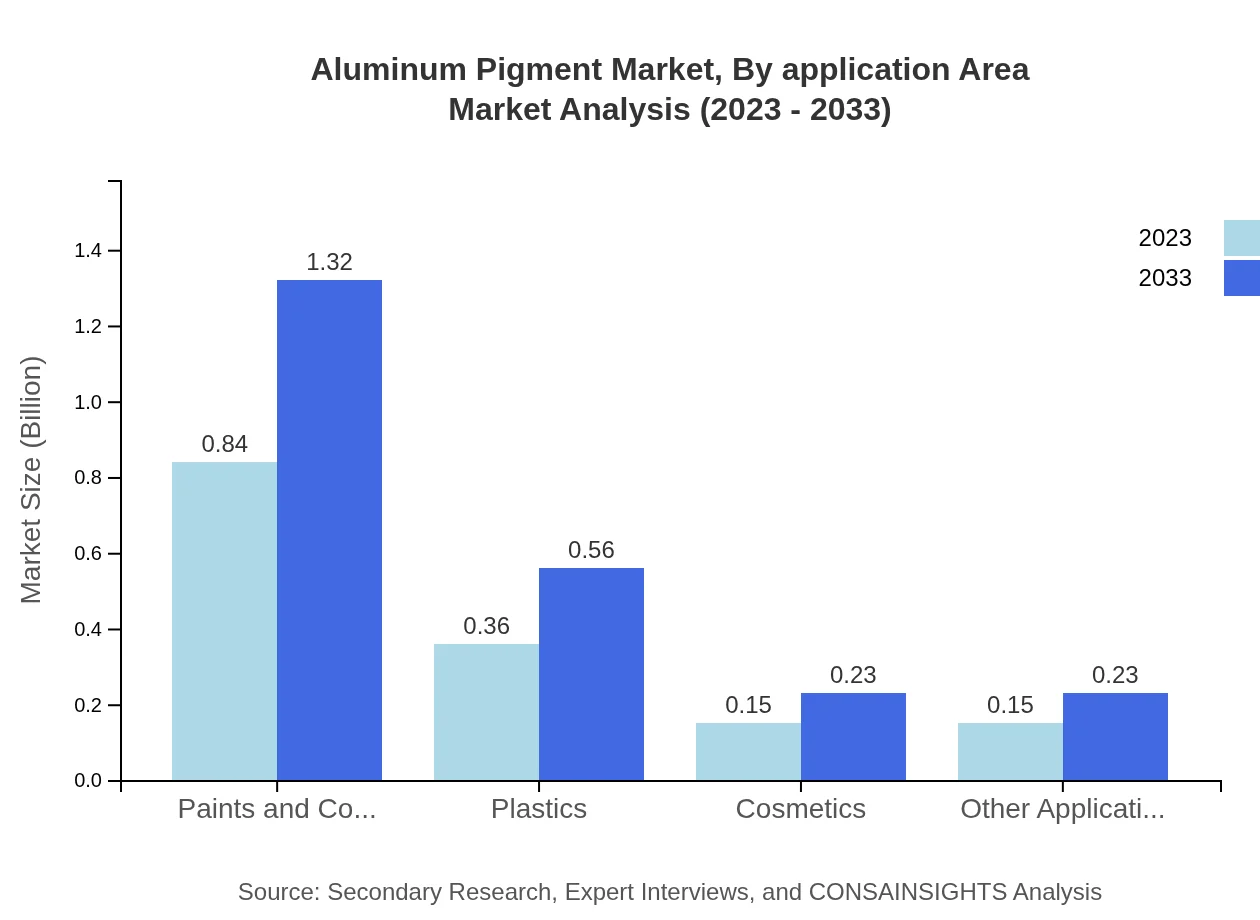

Aluminum Pigment Market Analysis By Application Area

In terms of application, paints and coatings lead with a market size expected to grow from $0.84 billion in 2023 to $1.32 billion by 2033, cementing a share of 56.08%. Automotive applications reflect similar growth trends, with a forecast from $0.84 billion to $1.32 billion. Plastics and cosmetics also represent vital markets, expecting growth from $0.36 billion to $0.56 billion and $0.15 billion to $0.23 billion, respectively, highlighting the versatility of aluminum pigments.

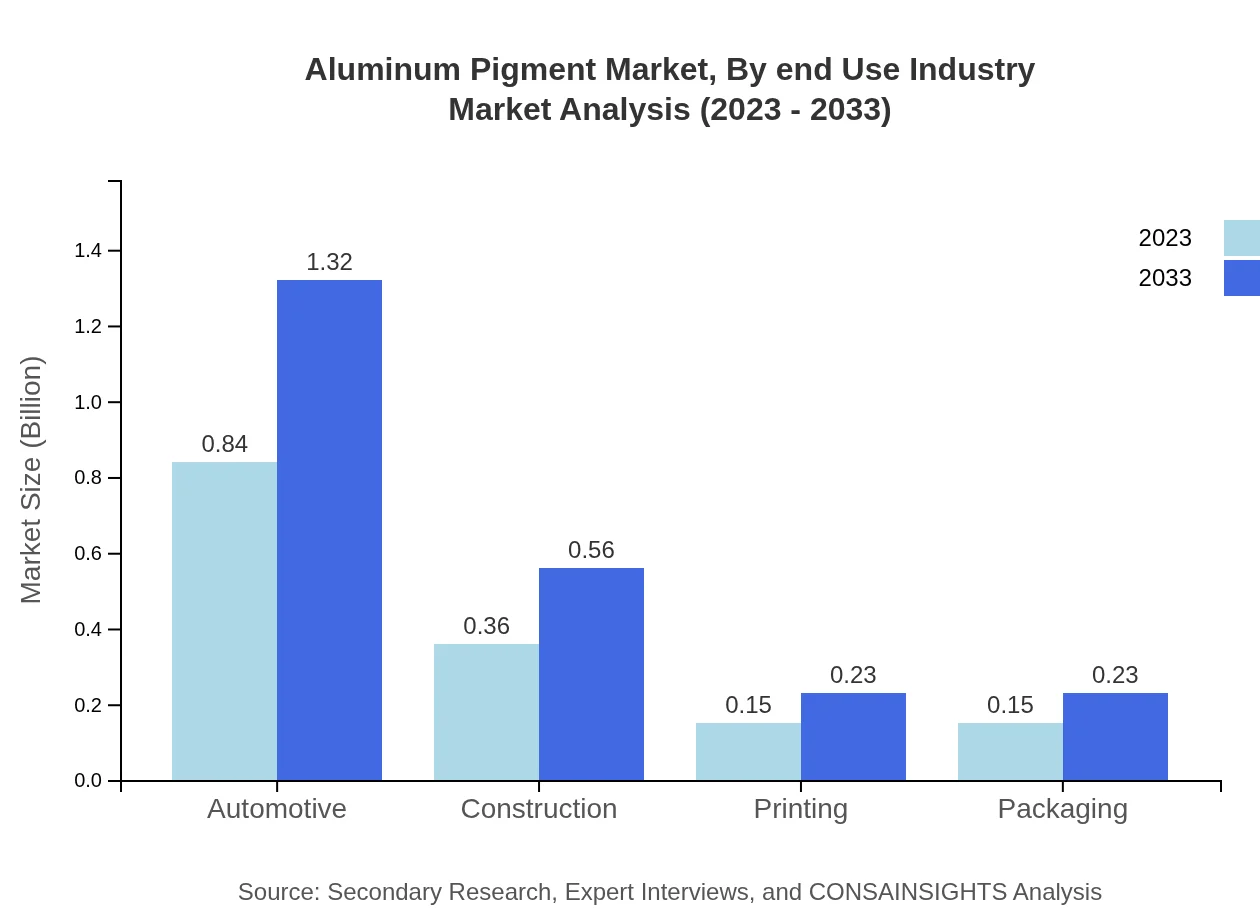

Aluminum Pigment Market Analysis By End Use Industry

The market segmentation by end-use industry shows that both automotive and construction industries are critical, each expecting to hold a share of 56.08% and 23.93%, respectively. The expansion in the construction sector and the automotive industry’s transition towards lightweight materials are driving growth in aluminum pigment usage. Other sectors like printing and packaging also represent niche markets with robust growth opportunities in the years ahead.

Aluminum Pigment Market Analysis By Form

The form of aluminum pigments is crucial in determining their application effectiveness. The dry form, accounting for 82.53% of the market share, remains the most utilized due to its versatile application in various products. On the other hand, paste and powder forms are expected to see gradual growth, reflecting shifts towards high-performance coatings and specialized applications in diverse industries.

Aluminum Pigment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aluminum Pigment Industry

Silberline Manufacturing Co.:

A leading manufacturer of aluminum pigments focused on innovation and sustainability, offering a wide range of products for various applications.Carl Schlenk AG:

Renowned for high-quality aluminum pigments, Carl Schlenk AG provides tailored solutions, focusing on meeting diverse customer requirements and regulatory standards.Metalprince:

Specializing in aluminum slurries and pigments for the coatings industry, Metalprince is recognized for its exceptional customer service and product development.Kuncai:

Kuncai is a key player in the Asian market, providing a broad spectrum of aluminum pigment products with a strong commitment to environmental sustainability.We're grateful to work with incredible clients.

FAQs

What is the market size of aluminum pigment?

As of 2023, the global aluminum pigment market is valued at approximately $1.5 billion, with a projected CAGR of 4.5% through to 2033. This growth is attributed to increasing applications in various industries.

What are the key market players or companies in the aluminum pigment industry?

Key players in the aluminum pigment market include established manufacturers renowned for innovation and product quality. These companies drive market dynamics through strategic partnerships, technological advancements, and expanding their portfolios to cater to evolving customer needs.

What are the primary factors driving the growth in the aluminum pigment industry?

The aluminum pigment market is driven by technological advancements, growing automotive and construction sectors, as well as increasing demand for high-quality coatings. Enhanced durability and aesthetic appeal of aluminum pigments further contribute to their rising popularity.

Which region is the fastest Growing in the aluminum pigment market?

The Asia Pacific region is the fastest-growing market for aluminum pigments, projected to rise from $0.32 billion in 2023 to $0.50 billion by 2033. Strong industrialization and infrastructure development fuel this significant growth in demand.

Does ConsaInsights provide customized market report data for the aluminum pigment industry?

Yes, ConsaInsights offers tailored market report data for the aluminum pigment industry. They customize reports to address specific client needs, focusing on unique market trends, consumer demands, and forecasted growth figures.

What deliverables can I expect from this aluminum pigment market research project?

Deliverables for the aluminum pigment market research project include comprehensive reports detailing market size, segmentation analysis, regional insights, and trend forecasts, providing strategic overviews tailored to industry stakeholders.

What are the market trends of aluminum pigment?

Current trends in the aluminum pigment market include a shift towards eco-friendly products, increased use in advanced packaging solutions, and a growing emphasis on decorative applications, driven by consumer preferences for sustainable and visually appealing products.