Amino Resin Market Report

Published Date: 02 February 2026 | Report Code: amino-resin

Amino Resin Market Size, Share, Industry Trends and Forecast to 2033

This report extensively covers the Amino Resin market from 2023 to 2033, providing critical insights on market trends, size, segmentation, regional analysis, and forecasts, serving as a valuable resource for stakeholders and decision-makers.

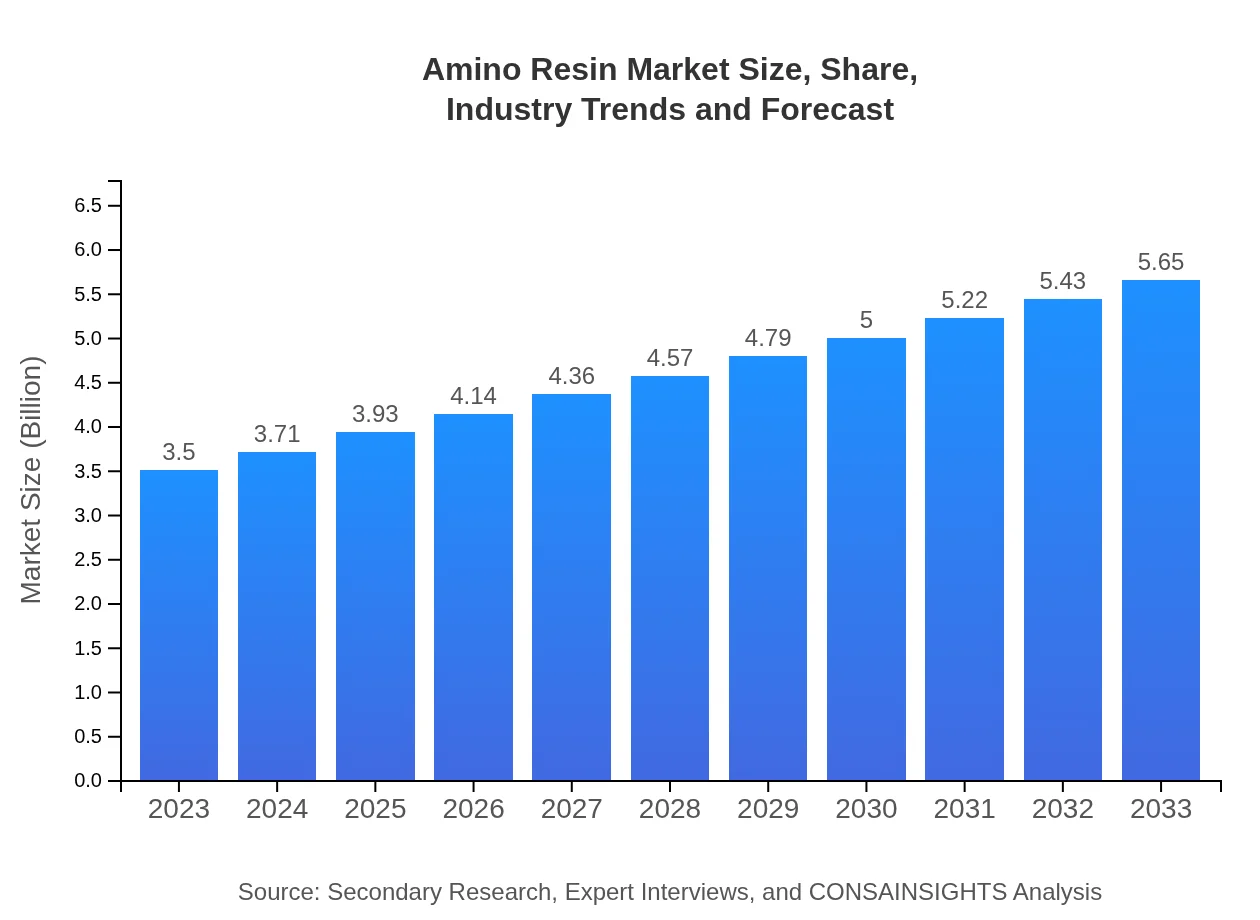

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $5.65 Billion |

| Top Companies | BASF, Hexion Inc., China National Chemical Corporation, Momentive Specialty Chemicals |

| Last Modified Date | 02 February 2026 |

Amino Resin Market Overview

Customize Amino Resin Market Report market research report

- ✔ Get in-depth analysis of Amino Resin market size, growth, and forecasts.

- ✔ Understand Amino Resin's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Amino Resin

What is the Market Size & CAGR of Amino Resin market in 2033?

Amino Resin Industry Analysis

Amino Resin Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Amino Resin Market Analysis Report by Region

Europe Amino Resin Market Report:

The European Amino Resin market is anticipated to grow from $0.88 billion in 2023 to $1.42 billion by 2033. The stringent regulations related to formaldehyde emissions are leading to innovation in producing low-emission resins. The region's emphasis on sustainability also drives new developments in resin formulations.Asia Pacific Amino Resin Market Report:

In the Asia Pacific, the Amino Resin market was valued at $0.68 billion in 2023 and is expected to reach $1.09 billion by 2033. Rapid industrialization, urbanization, and growth in construction activities in countries like China and India are driving demand. Moreover, increasing automotive production and consumer electronics manufacturing further boost the market.North America Amino Resin Market Report:

The North American market, valued at $1.27 billion in 2023, is projected to reach $2.05 billion by 2033. The robust automotive sector, coupled with advancements in the construction industry, plays a significant role in market expansion. Additionally, there is a growing preference for eco-friendly adhesives and coatings.South America Amino Resin Market Report:

For South America, the market stood at $0.22 billion in 2023 with projections to reach $0.36 billion by 2033. The growing construction sector, combined with the demand for furniture, is expected to enhance the Amino Resin market. Countries like Brazil and Argentina are focusing on infrastructural development, which will amplify market growth.Middle East & Africa Amino Resin Market Report:

The Middle East and Africa are projected to see growth from $0.44 billion in 2023 to $0.72 billion by 2033. The increase in construction projects in countries like the UAE and South Africa, along with the rising manufacturing sector, will contribute to the demand for Amino Resins.Tell us your focus area and get a customized research report.

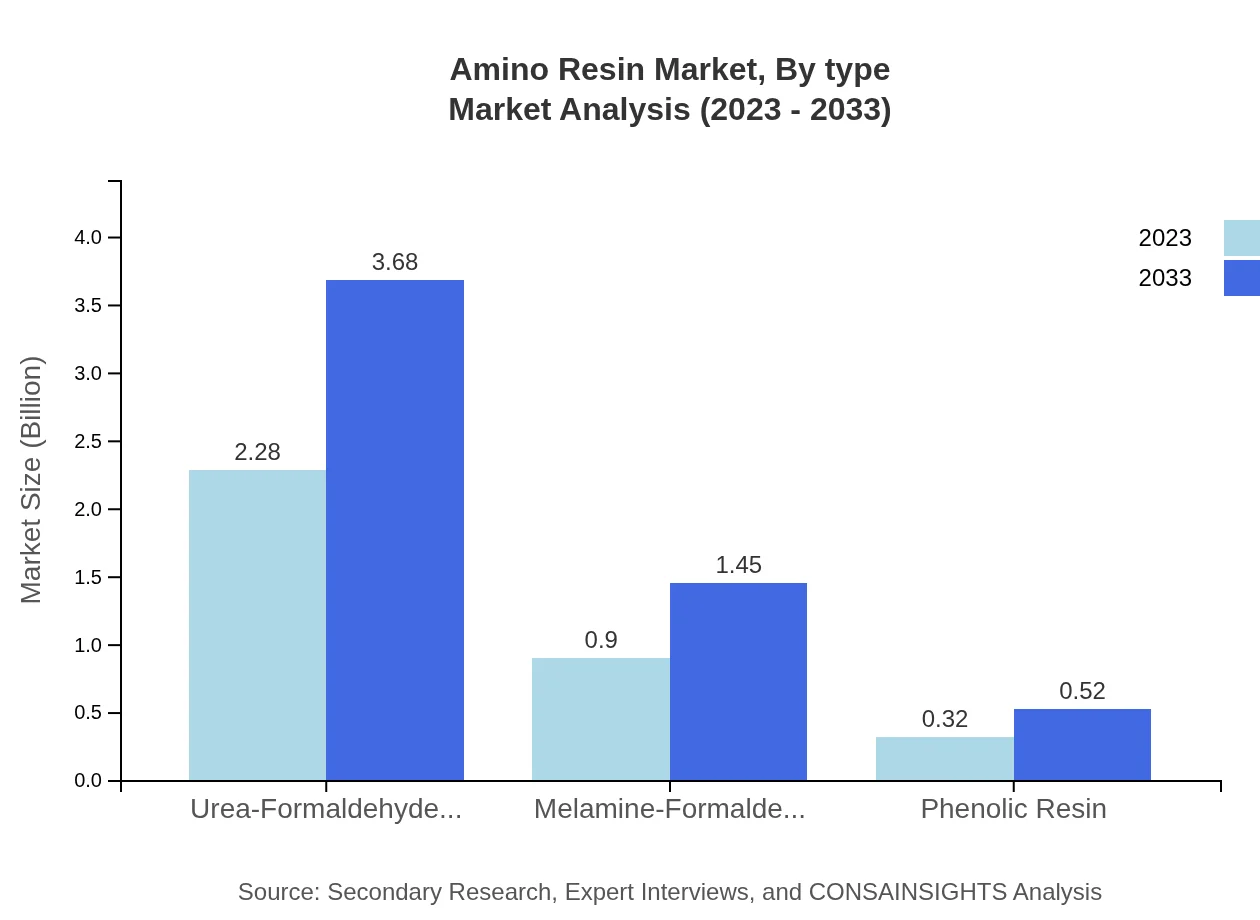

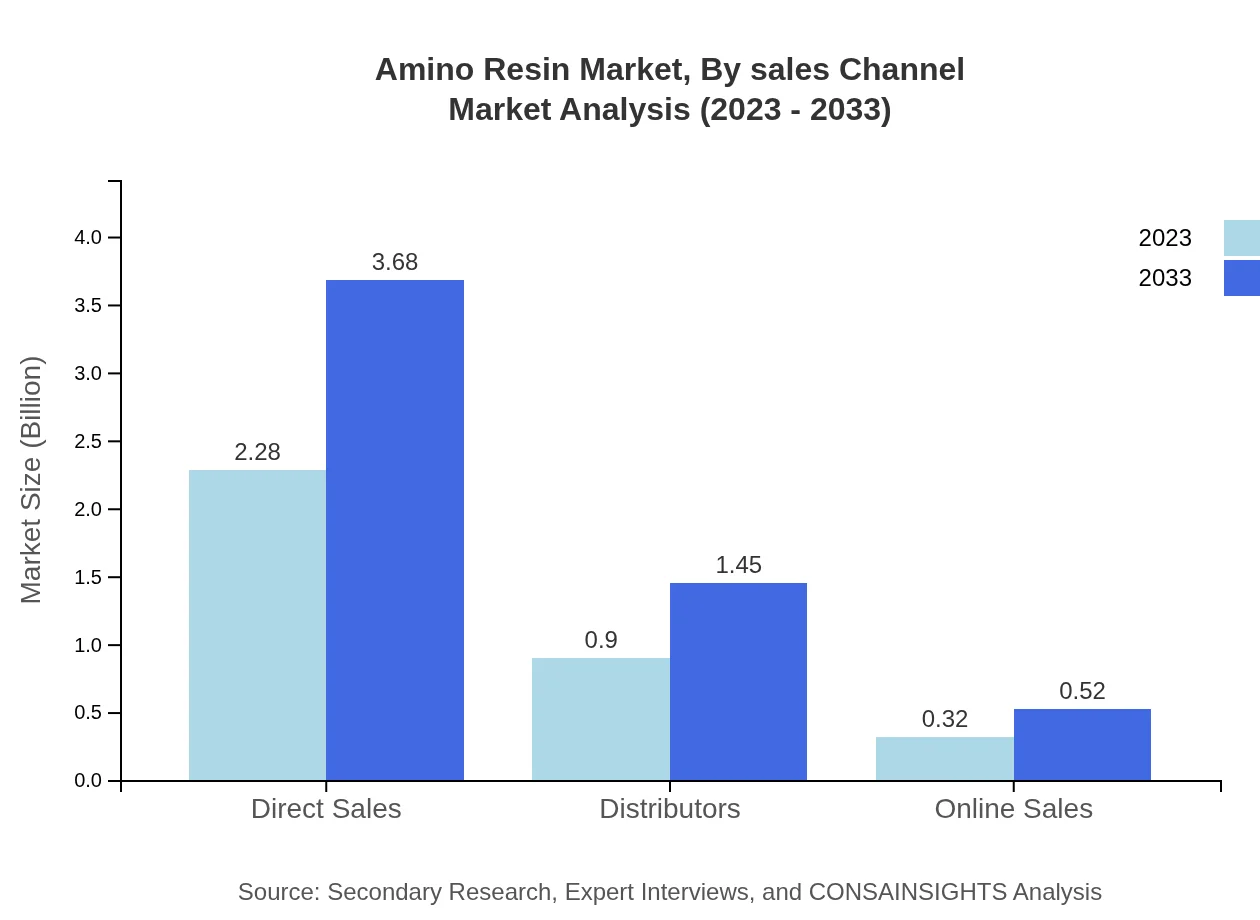

Amino Resin Market Analysis By Type

Urea-Formaldehyde Resin dominates the Amino Resin market, accounting for $2.28 billion in 2023 and projected to grow to $3.68 billion by 2033. Melamine-Formaldehyde follows, with a market size of $0.90 billion in 2023, expected to reach $1.45 billion by 2033. Phenolic Resin holds a smaller but significant share, reaching $0.32 billion in 2023 and forecasting growth to $0.52 billion by 2033.

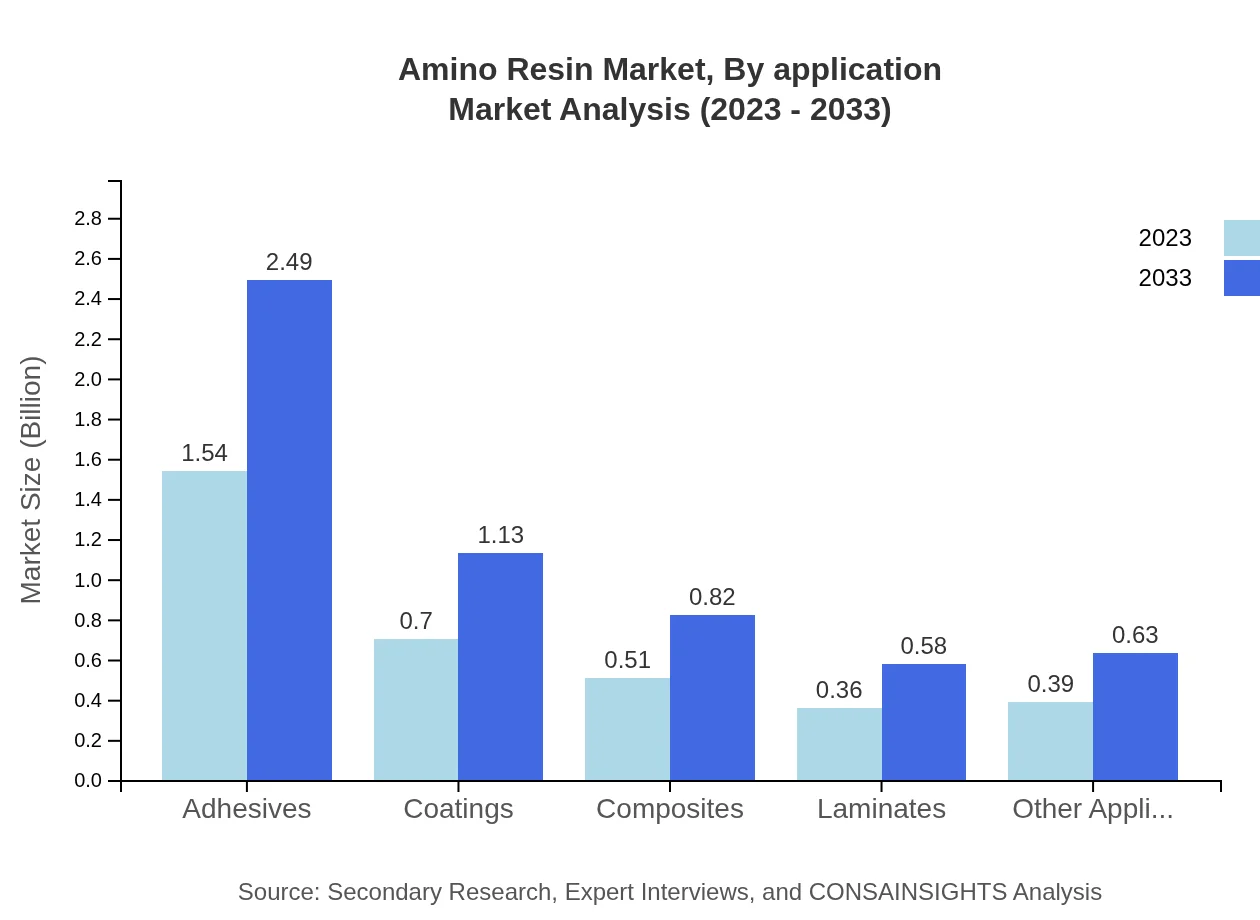

Amino Resin Market Analysis By Application

Key applications for Amino Resins include Construction, Automotive, Adhesives, and Coatings. The Construction sector leads the way with a market size of $1.54 billion in 2023, projected to rise to $2.49 billion by 2033. The Automotive sector is also important, projected to grow from $0.70 billion in 2023 to $1.13 billion in 2033, driven by innovations in lightweight materials.

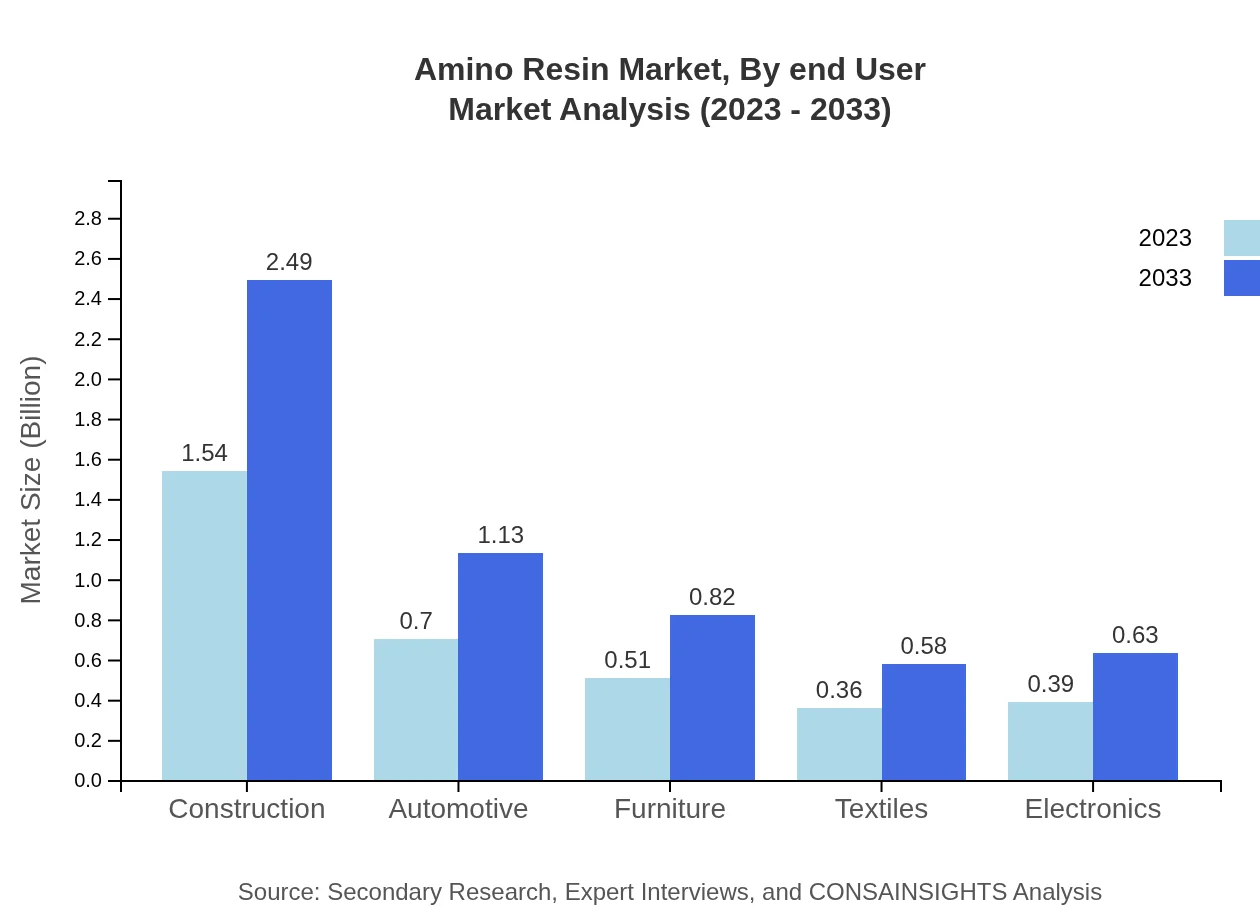

Amino Resin Market Analysis By End User

The end-user segments spread across numerous industries such as furniture, textiles, and electronics. The Furniture sector is significant, with a market size reaching $0.51 billion in 2023 and expected to grow to $0.82 billion by 2033. Additionally, the Textiles and Electronics sectors are contributing growing demands in the market.

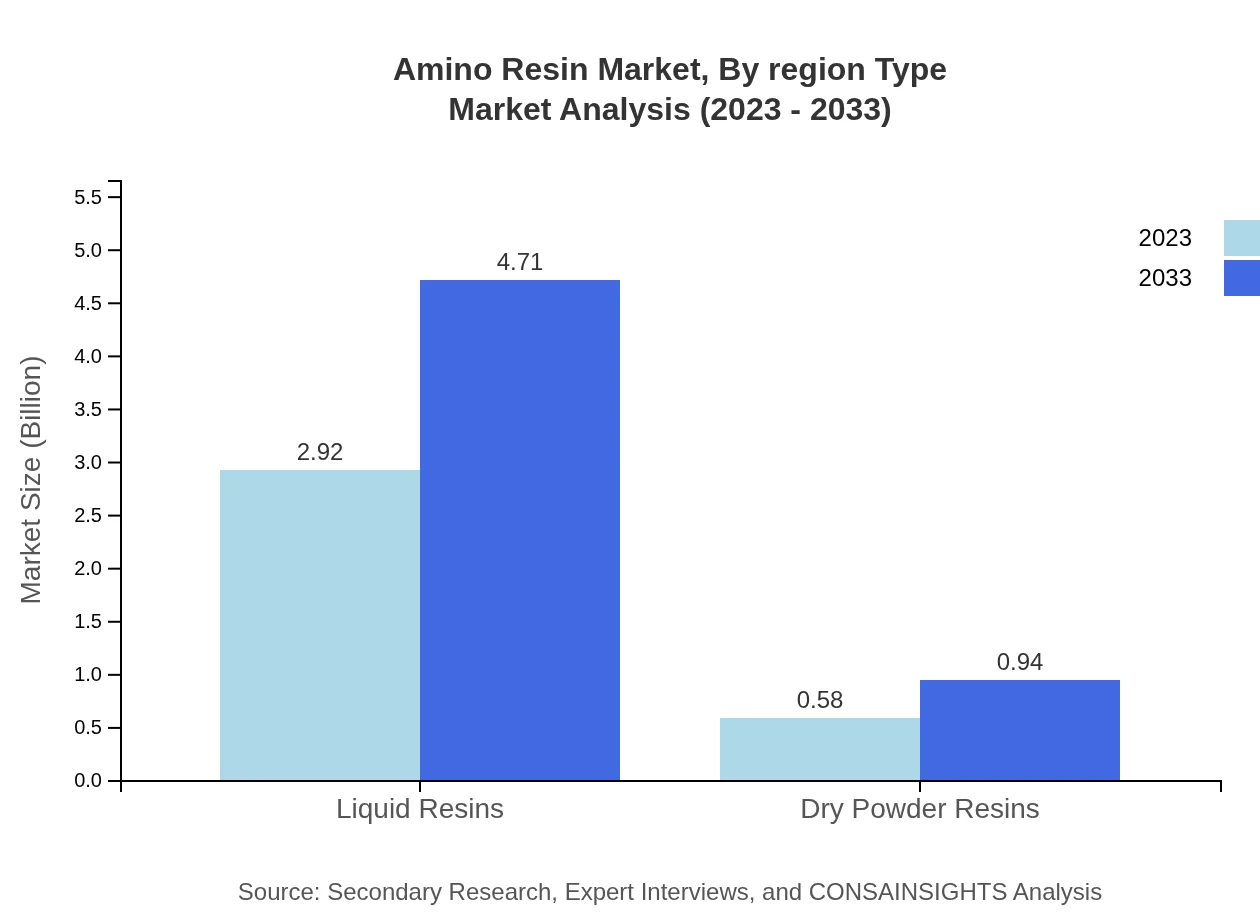

Amino Resin Market Analysis By Region Type

Liquid Resins account for the largest market share at $2.92 billion in 2023, expected to reach $4.71 billion by 2033. Dry Powder Resins, although smaller in size, show potential for growth, from $0.58 billion in 2023 to $0.94 billion by 2033, indicating a trend towards versatile application forms.

Amino Resin Market Analysis By Sales Channel

The market is segmented by sales channel into Direct Sales, Distributors, and Online Sales. Direct Sales lead the market with a size of $2.28 billion in 2023, increasing to $3.68 billion by 2033. The rise of e-commerce is also notable, with Online Sales projected to grow from $0.32 billion to $0.52 billion over the forecast period.

Amino Resin Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Amino Resin Industry

BASF:

BASF is a global leader in chemical production, providing a wide range of Amino Resins for various applications, focusing on innovations and sustainability.Hexion Inc.:

Hexion is a major player in the resin market, known for its high-performing Amino Resins and commitment to sustainable manufacturing practices.China National Chemical Corporation:

This prominent company heavily invests in technology and capacity expansion to meet rising market demands across the globe.Momentive Specialty Chemicals:

Momentive specializes in silane and resin technologies, catering to diverse industrial applications with a focus on performance and innovation.We're grateful to work with incredible clients.

FAQs

What is the market size of amino Resin?

The amino-resin market is projected to reach a size of $3.5 billion by 2033, growing at a CAGR of 4.8%. The increasing demand from various industries is contributing to this growth.

What are the key market players or companies in the amino Resin industry?

Key players in the amino-resin market include BASF, Hexion, and Huntsman Corporation. These companies lead in production capacity and innovation, driving the industry forward.

What are the primary factors driving the growth in the amino Resin industry?

Growth drivers for the amino-resin industry include increased construction activities, rising automotive production, and expanding furniture markets, all requiring durable and cost-effective materials.

Which region is the fastest Growing in the amino Resin market?

The Asia Pacific region is the fastest-growing in the amino-resin market, expected to grow from $0.68 billion in 2023 to $1.09 billion by 2033, reflecting a strong demand increase.

Does ConsaInsights provide customized market report data for the amino Resin industry?

Yes, ConsaInsights offers customized market report data tailored to specific industry needs in the amino-resin sector, ensuring relevant insights for strategic decision-making.

What deliverables can I expect from this amino Resin market research project?

Deliverables include a comprehensive market report, detailed segment analysis, regional insights, and projections, providing a complete overview of the amino-resin industry landscape.

What are the market trends of amino Resin?

Current trends in the amino-resin market include eco-friendly formulations, enhanced performance characteristics, and innovative applications across various industries, reflecting shifting consumer preferences.