Anti Icing Coating Market Report

Published Date: 02 February 2026 | Report Code: anti-icing-coating

Anti Icing Coating Market Size, Share, Industry Trends and Forecast to 2033

This report covers insights into the Anti Icing Coating market, exploring its size, growth forecasts, industry dynamics, and segmentation from 2023 to 2033. Detailed analyses of regional markets, technological advancements, and key players are also included.

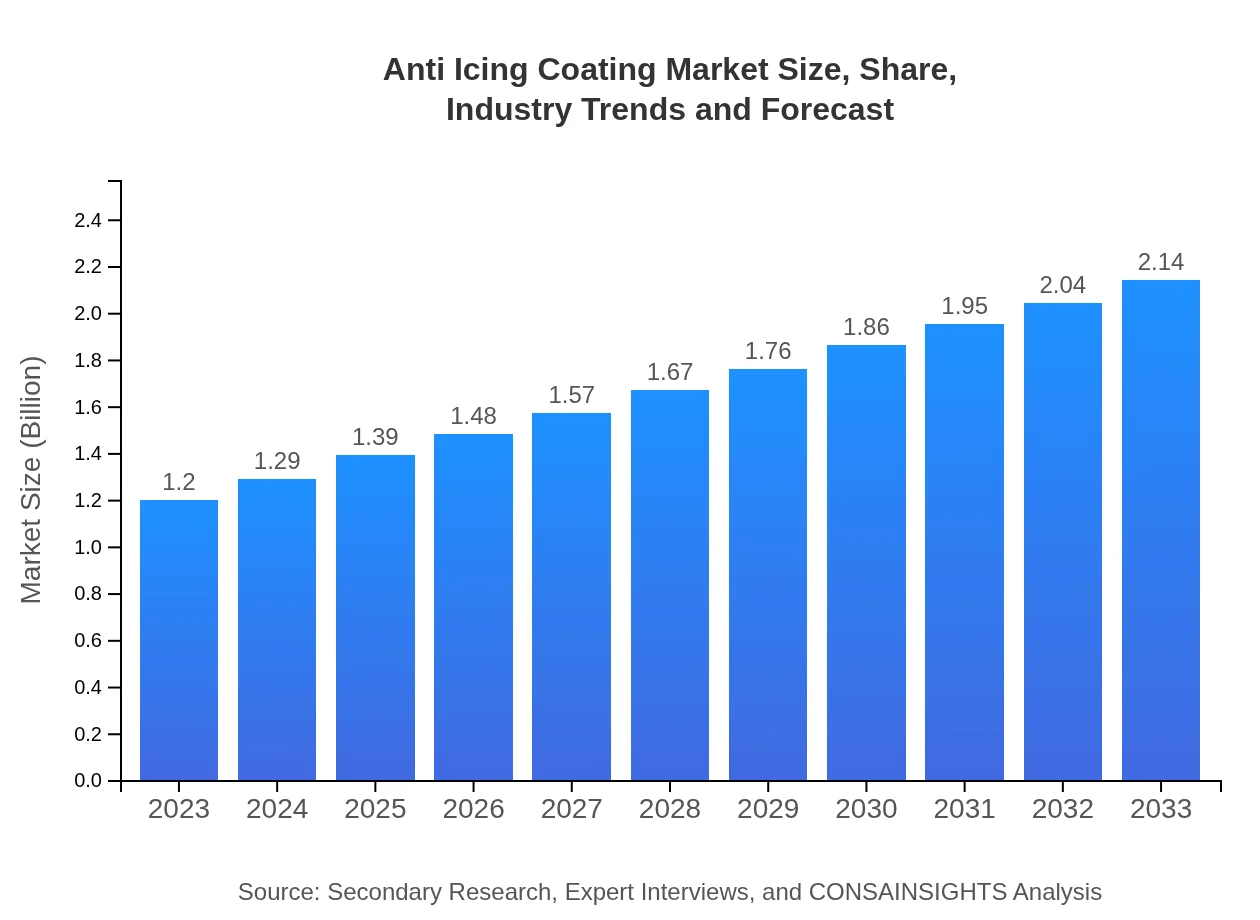

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $2.14 Billion |

| Top Companies | 3M Company, BASF SE, AkzoNobel N.V., DuPont, Nippon Paint Holdings Co., Ltd. |

| Last Modified Date | 02 February 2026 |

Anti Icing Coating Market Overview

Customize Anti Icing Coating Market Report market research report

- ✔ Get in-depth analysis of Anti Icing Coating market size, growth, and forecasts.

- ✔ Understand Anti Icing Coating's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Anti Icing Coating

What is the Market Size & CAGR of Anti Icing Coating market in 2023?

Anti Icing Coating Industry Analysis

Anti Icing Coating Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Anti Icing Coating Market Analysis Report by Region

Europe Anti Icing Coating Market Report:

Europe's market for Anti Icing Coating is anticipated to rise from $0.33 billion in 2023 to $0.59 billion by 2033. European countries are highly proactive in terms of regulations and innovation in anti-icing technologies across sectors. Environmental sustainability initiatives push for advanced solutions that comply with stringent regulations on ice management.Asia Pacific Anti Icing Coating Market Report:

The Asia Pacific region is anticipated to witness significant growth with a market value of $0.24 billion in 2023 and projected to reach $0.42 billion by 2033. The increase in road and rail infrastructure projects, combined with a booming aerospace industry, contributes to the rising demand for anti-icing solutions. Additionally, countries focusing on winter sports and tourism are likely to drive market expansion.North America Anti Icing Coating Market Report:

North America currently holds a significant market share with an estimated value of $0.45 billion in 2023, projected to grow to $0.80 billion by 2033. The region leads due to high adoption rates of innovative technologies in the aerospace and construction industries. The prevalence of harsh winter climates necessitates robust anti-icing solutions for infrastructure and transport.South America Anti Icing Coating Market Report:

In South America, the market is relatively smaller, valued at $0.04 billion in 2023, expected to grow to $0.07 billion by 2033. Growth factors include the enhancement of infrastructure in cold climate regions and increasing awareness of anti-icing technologies, though it remains a developing market compared to others. Government investments in infrastructure and energy sectors will aid this growth.Middle East & Africa Anti Icing Coating Market Report:

The Middle East and Africa market, although modest with an initial value of $0.15 billion in 2023, is expected to grow to $0.27 billion by 2033. The region's unique weather conditions necessitate specific applications, particularly in energy and infrastructure. Investment in renewable energy projects offers potential growth avenues for anti-icing solutions in wind turbines and solar panels.Tell us your focus area and get a customized research report.

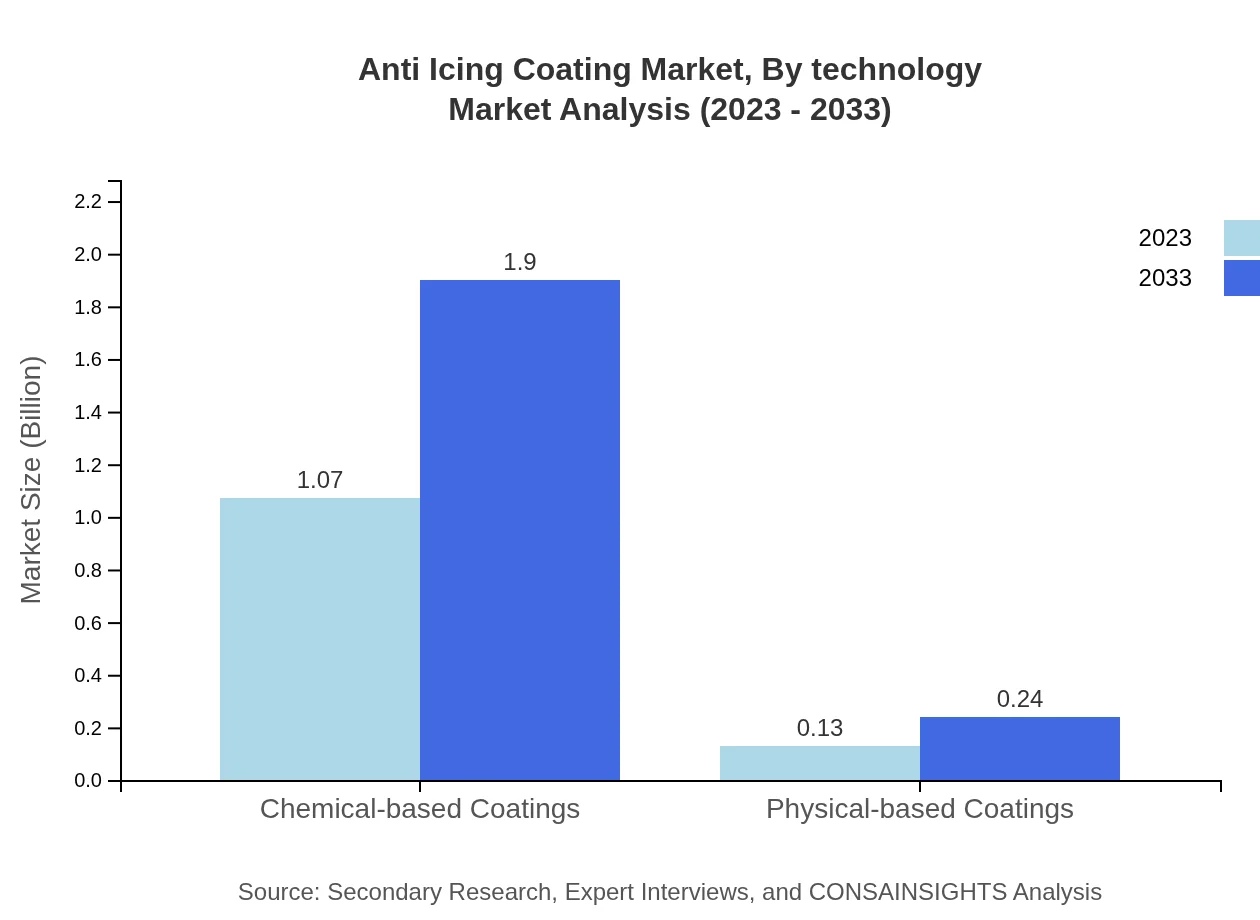

Anti Icing Coating Market Analysis By Technology

The market is primarily segmented into chemical-based coatings and physical-based coatings. In 2023, chemical-based coatings dominate the market with a share of 88.89%, valued at $1.07 billion, and expected to grow to $1.90 billion by 2033. Physical-based coatings maintain a smaller segment at 11.11%, valued at $0.13 billion in 2023 and projected at $0.24 billion by 2033. Chemical-based coatings are preferred for their effectiveness and durability.

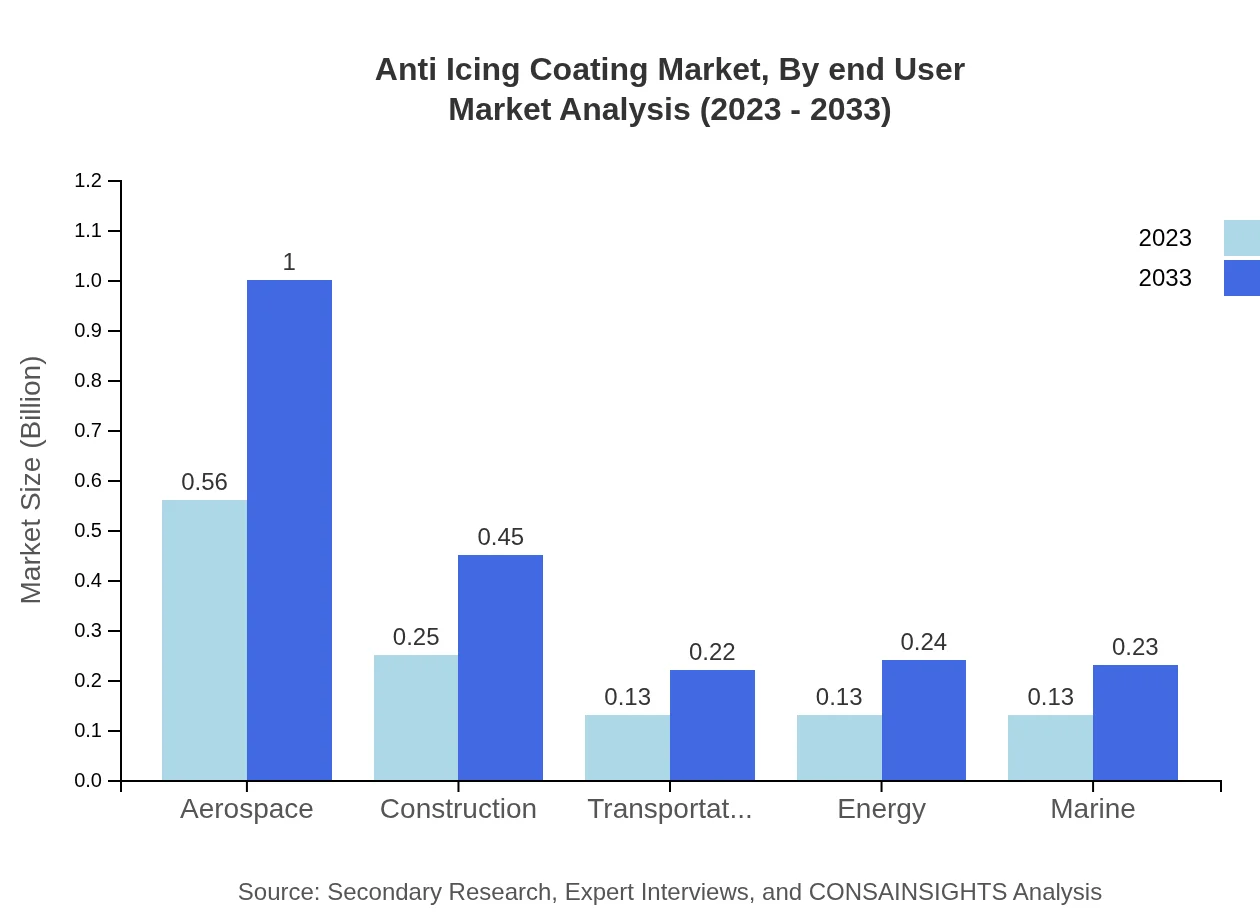

Anti Icing Coating Market Analysis By End User

By end-user, the aerospace sector leads with a market share of 57.79% valued at $0.69 billion in 2023 and projected to reach $1.24 billion by 2033. The construction sector follows with a 20.94% share, growing from $0.25 billion to $0.45 billion. Transportation and energy each contribute smaller shares of 10.5% and 11.19%, respectively. The focus on safety and performance in aerospace drives significant investment and innovation in anti-icing technologies.

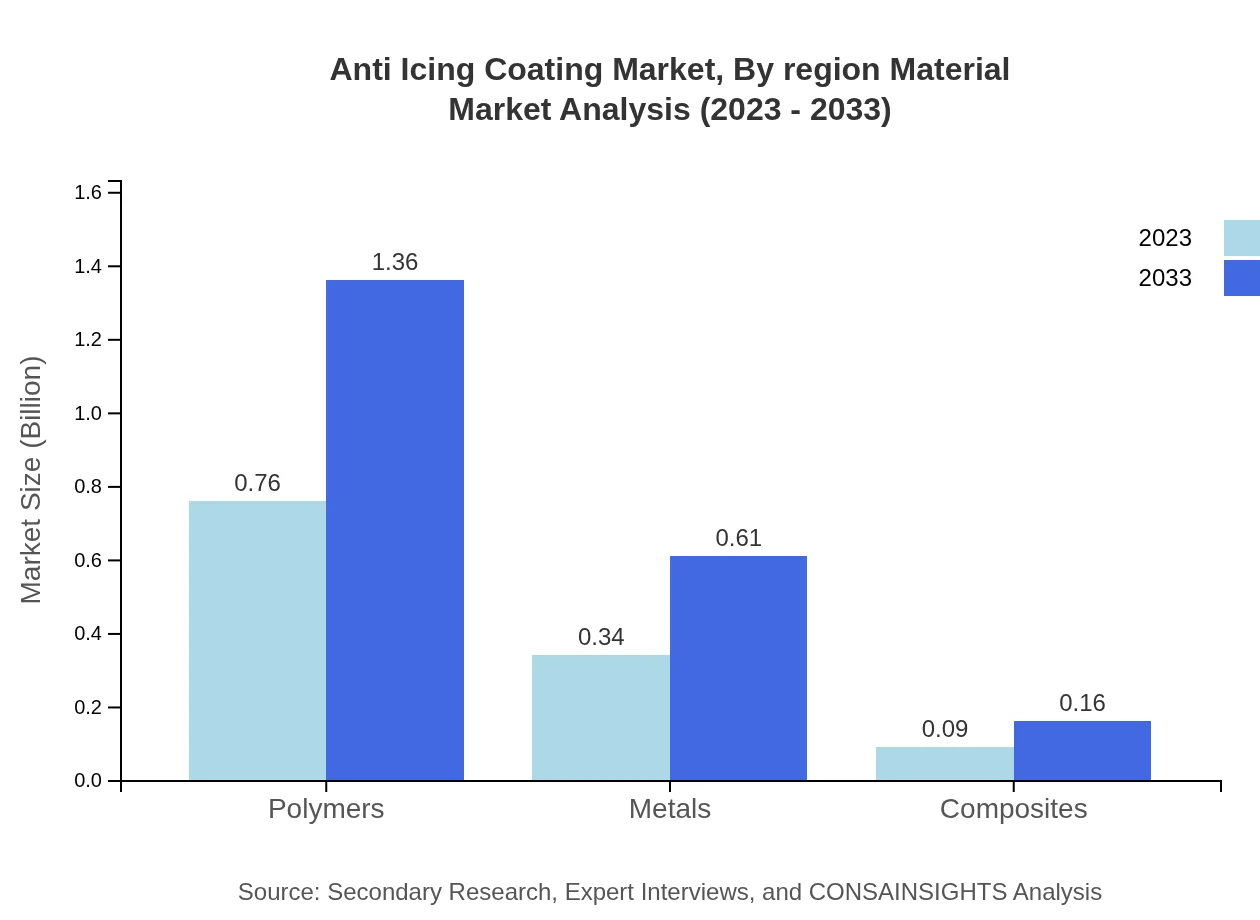

Anti Icing Coating Market Analysis By Region Material

The market also segments by materials, particularly focusing on Polymers and Metals. Polymers account for 63.6% of the market, valued at $0.76 billion in 2023, expected to reach $1.36 billion by 2033. Metals contribute 28.72% of the market, valued at $0.34 billion and growing to $0.61 billion as applications in heavy industry and infrastructure expand. The versatility and performance of polymer-based coatings are key drivers of their increasing market share.

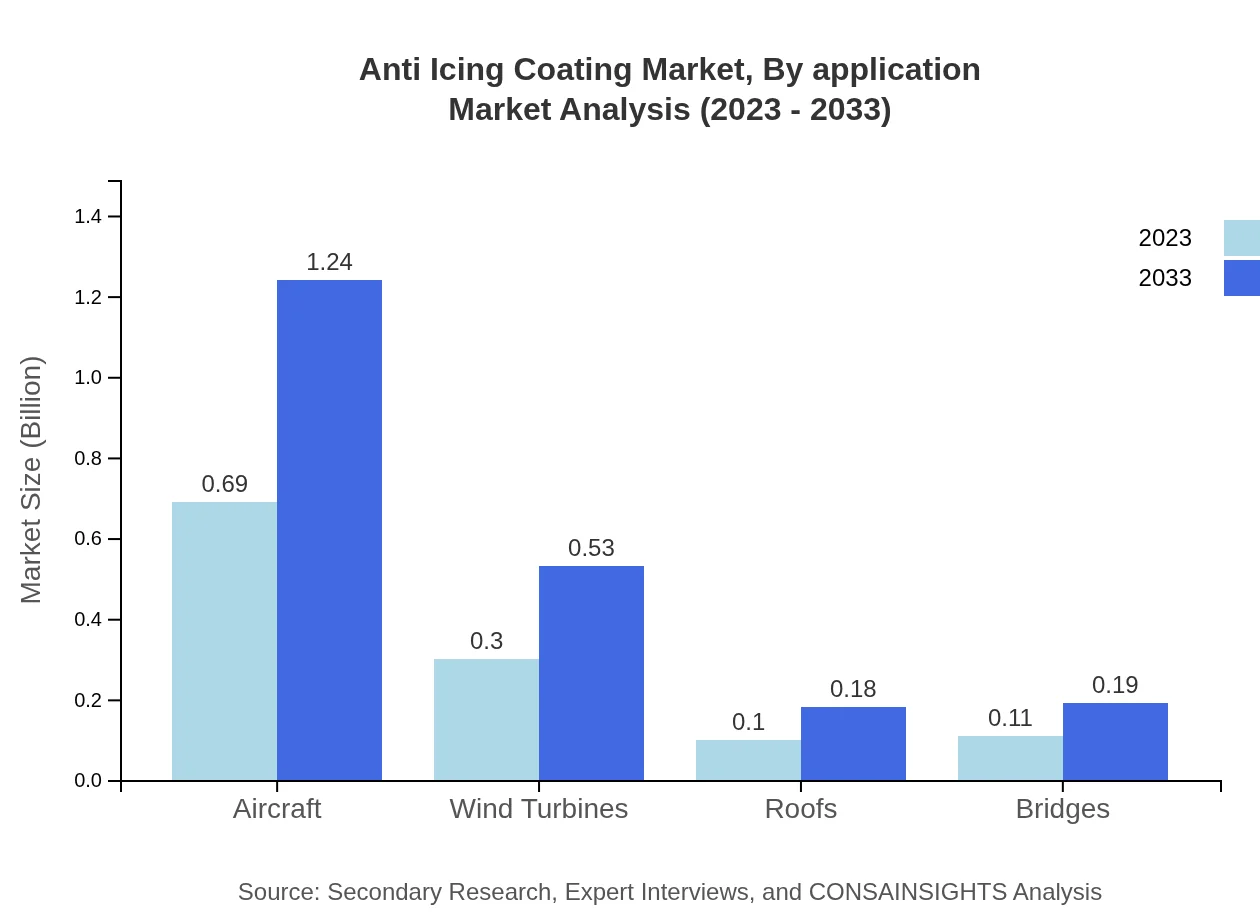

Anti Icing Coating Market Analysis By Application

Significant applications include Aerospace, Energy (Wind Turbines), and Construction. Aerospace stands out with a share of 46.8% valued at $0.56 billion in 2023, expanding to $1.00 billion by 2033. Energy applications are also important, particularly for wind turbines, projected to grow from $0.30 billion to $0.53 billion. Construction applications are gradually increasing, with significant investments in anti-icing solutions for new infrastructures.

Anti Icing Coating Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Anti Icing Coating Industry

3M Company:

A global leader in innovative anti-icing solutions, offering products that enhance safety and performance for various applications, including aerospace and infrastructure.BASF SE:

A major player in the coating industry, recognized for its high-performance anti-icing coatings tailored for construction and industrial applications.AkzoNobel N.V.:

A prominent coatings company that provides eco-friendly and effective anti-icing coatings, focusing on sustainability and innovation.DuPont:

Known for its advanced material science capabilities, DuPont offers anti-icing solutions across multiple sectors, including aerospace and energy.Nippon Paint Holdings Co., Ltd.:

A leading paint and coatings manufacturer in the Asia-Pacific region, providing various anti-icing coatings tailored for transportation and construction.We're grateful to work with incredible clients.

FAQs

What is the market size of anti Icing coating?

The global anti-icing coating market is projected to reach approximately $1.2 billion by 2033, growing at a CAGR of 5.8% from a market size of $1.2 billion in 2023. This growth reflects the increasing demand for effective anti-icing solutions across various industries.

What are the key market players or companies in the anti Icing coating industry?

Key players in the anti-icing coating market include manufacturers specializing in aerospace, construction, and energy sectors, with major companies focusing on innovative coating technologies, enhancing their product offerings to maintain competitiveness in this expanding market.

What are the primary factors driving the growth in the anti Icing coating industry?

The growth of the anti-icing coating industry is driven by increasing safety regulations, a rise in demand for durable coatings in aerospace and transportation, and technological advancements in coating formulations that improve efficiency and environmental resilience.

Which region is the fastest Growing in the anti Icing coating?

The fastest-growing region for anti-icing coatings from 2023 to 2033 is Europe, where the market is expected to grow from $0.33 billion to $0.59 billion. This growth is driven by stringent regulations in construction and transportation sectors.

Does ConsaInsights provide customized market report data for the anti Icing coating industry?

Yes, ConsaInsights offers customized market research reports for the anti-icing coating industry, enabling clients to gain insights tailored to specific market segments or geographical regions, ensuring comprehensive understanding of opportunities and trends.

What deliverables can I expect from this anti Icing coating market research project?

Expect deliverables such as comprehensive market analysis reports, detailed segment data, regional insights, competitive landscape reviews, and trends that provide actionable insights catering specifically to your strategic needs.

What are the market trends of anti Icing coating?

Current market trends in anti-icing coatings include a growing preference for environmentally friendly products, increased adoption in the aerospace and energy sectors, and advancements in formulations that enhance performance and reduce costs across applications.