Anti Slip Coatings Market Report

Published Date: 02 February 2026 | Report Code: anti-slip-coatings

Anti Slip Coatings Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Anti Slip Coatings market from 2023 to 2033, covering key insights on market size, trends, segments, and forecasts, along with regional analyses and competitive outlook.

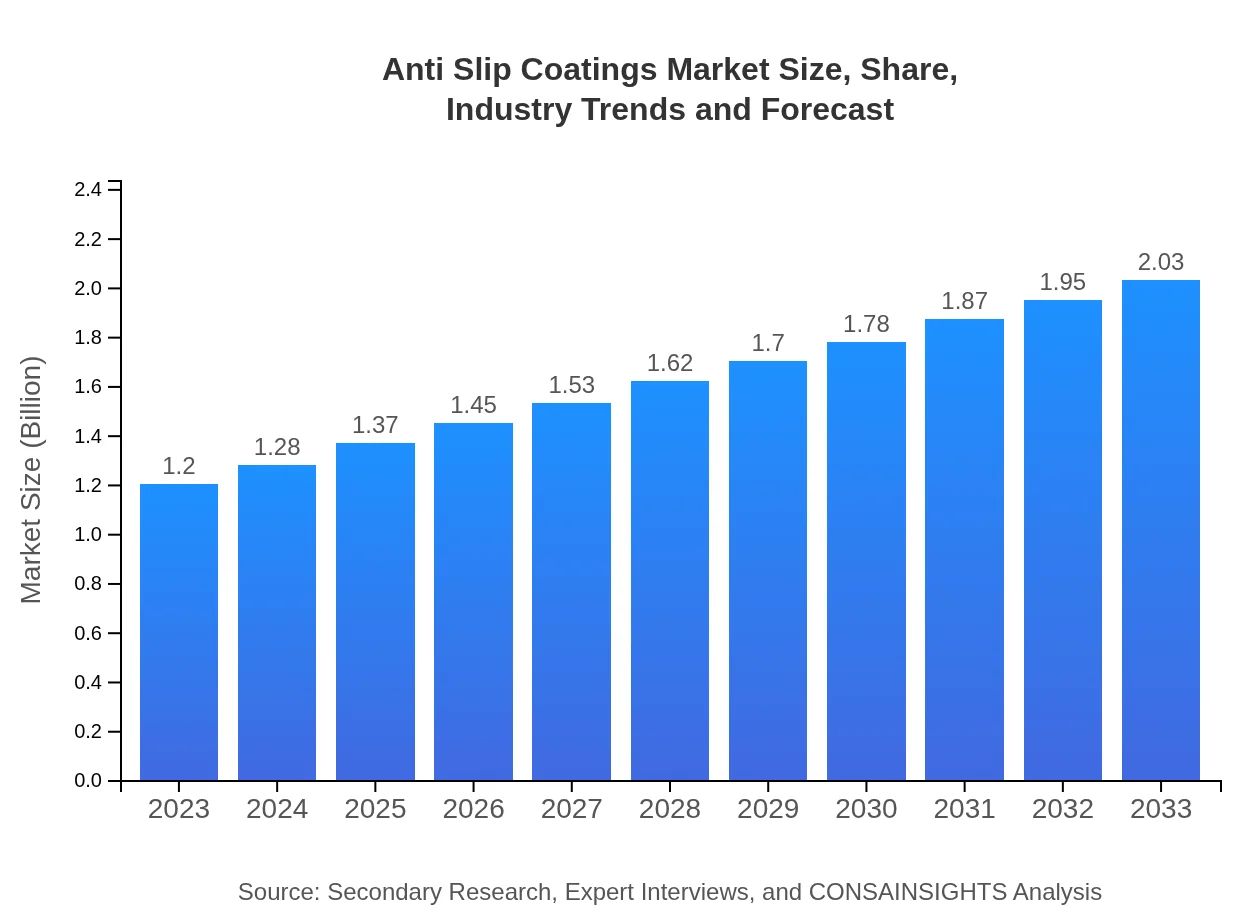

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 5.3% |

| 2033 Market Size | $2.03 Billion |

| Top Companies | Sherwin-Williams, PPG Industries, BASF, Rust-Oleum |

| Last Modified Date | 02 February 2026 |

Anti Slip Coatings Market Overview

Customize Anti Slip Coatings Market Report market research report

- ✔ Get in-depth analysis of Anti Slip Coatings market size, growth, and forecasts.

- ✔ Understand Anti Slip Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Anti Slip Coatings

What is the Market Size & CAGR of Anti Slip Coatings market in 2023?

Anti Slip Coatings Industry Analysis

Anti Slip Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Anti Slip Coatings Market Analysis Report by Region

Europe Anti Slip Coatings Market Report:

In Europe, the market is valued at $0.34 billion in 2023, projecting an increase to $0.58 billion by 2033. The stringent safety regulations in workplaces and public facilities, along with a growing trend of retrofitting existing structures, are amplifying market growth. Additionally, countries like Germany and the UK are spearheading such initiatives.Asia Pacific Anti Slip Coatings Market Report:

In Asia Pacific, the Anti Slip Coatings market is valued at approximately $0.23 billion in 2023 and is projected to grow to $0.38 billion by 2033. This growth is driven by rapid urbanization, infrastructural developments, and increasing awareness regarding safety standards in workplaces. Countries like China and India are significant contributors due to their booming construction industries.North America Anti Slip Coatings Market Report:

North America shows a robust market size of $0.45 billion in 2023, escalating to $0.77 billion by 2033. The growth is mainly attributable to stringent regulations regarding workplace safety and the increasing adoption of anti-slip coatings in both residential and commercial sectors. The U.S. is the leading market player in this region, driven by extensive construction activities.South America Anti Slip Coatings Market Report:

The South America region is expected to grow from $0.10 billion in 2023 to $0.17 billion by 2033. The growth is fueled by rising investments in infrastructure, coupled with a growing focus on safety in construction and industrial applications. Brazil and Argentina are leading markets in this segment.Middle East & Africa Anti Slip Coatings Market Report:

The Middle East and Africa region exhibits a market volume of $0.08 billion in 2023, forecasted to increase to $0.13 billion by 2033. The growing construction sector, primarily in the UAE and South Africa, coupled with increasing safety measures in industrial facilities, supports the growth in this region.Tell us your focus area and get a customized research report.

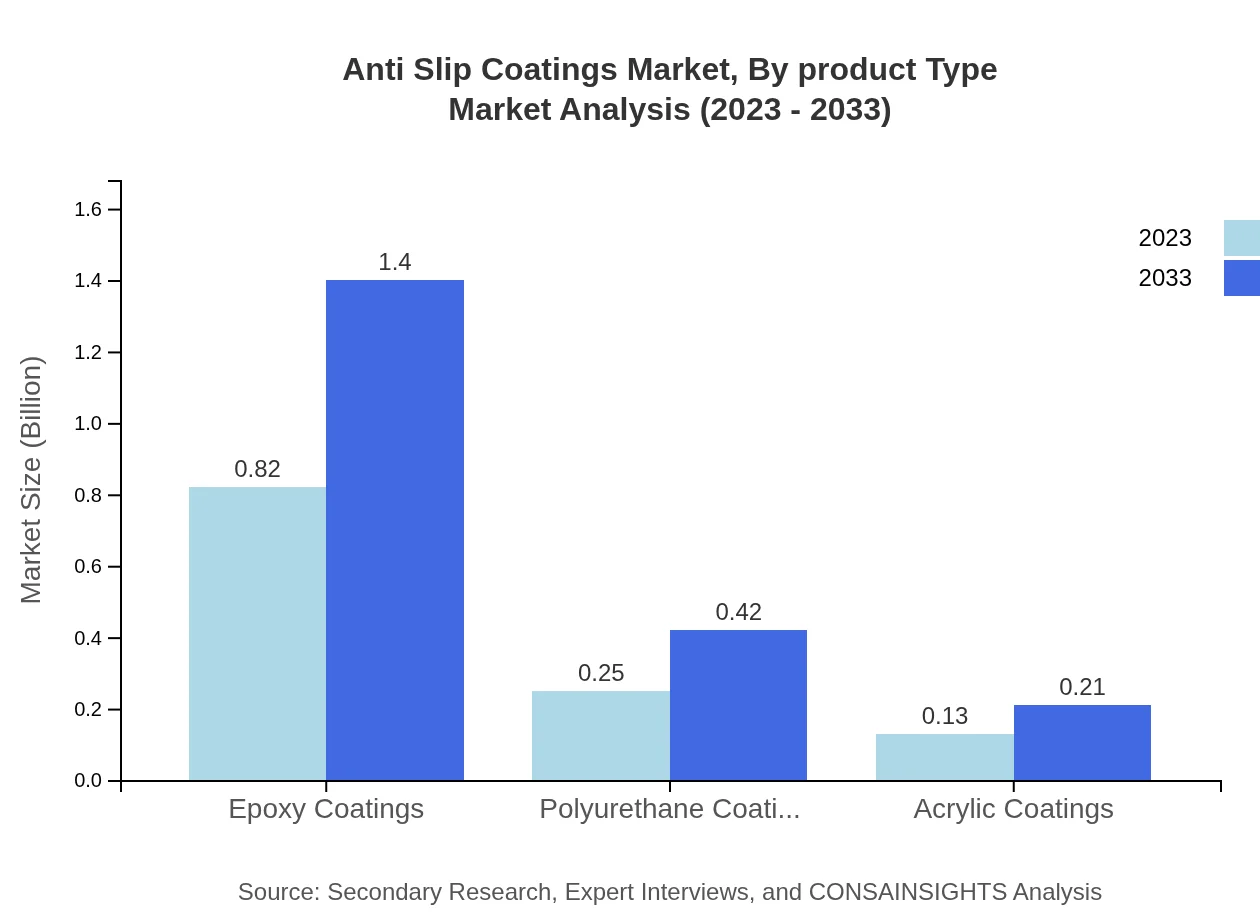

Anti Slip Coatings Market Analysis By Product Type

In 2023, epoxy coatings dominate the market with a size of $0.82 billion, projected to grow to $1.40 billion by 2033, maintaining a share of 68.72%. Polyurethane and acrylic coatings also see growth, reaching $0.25 and $0.13 billion respectively. The durability and versatility of epoxy coatings make them particularly favored in harsh conditions, while polyurethane offers flexibility, and acrylic provides quick-drying solutions.

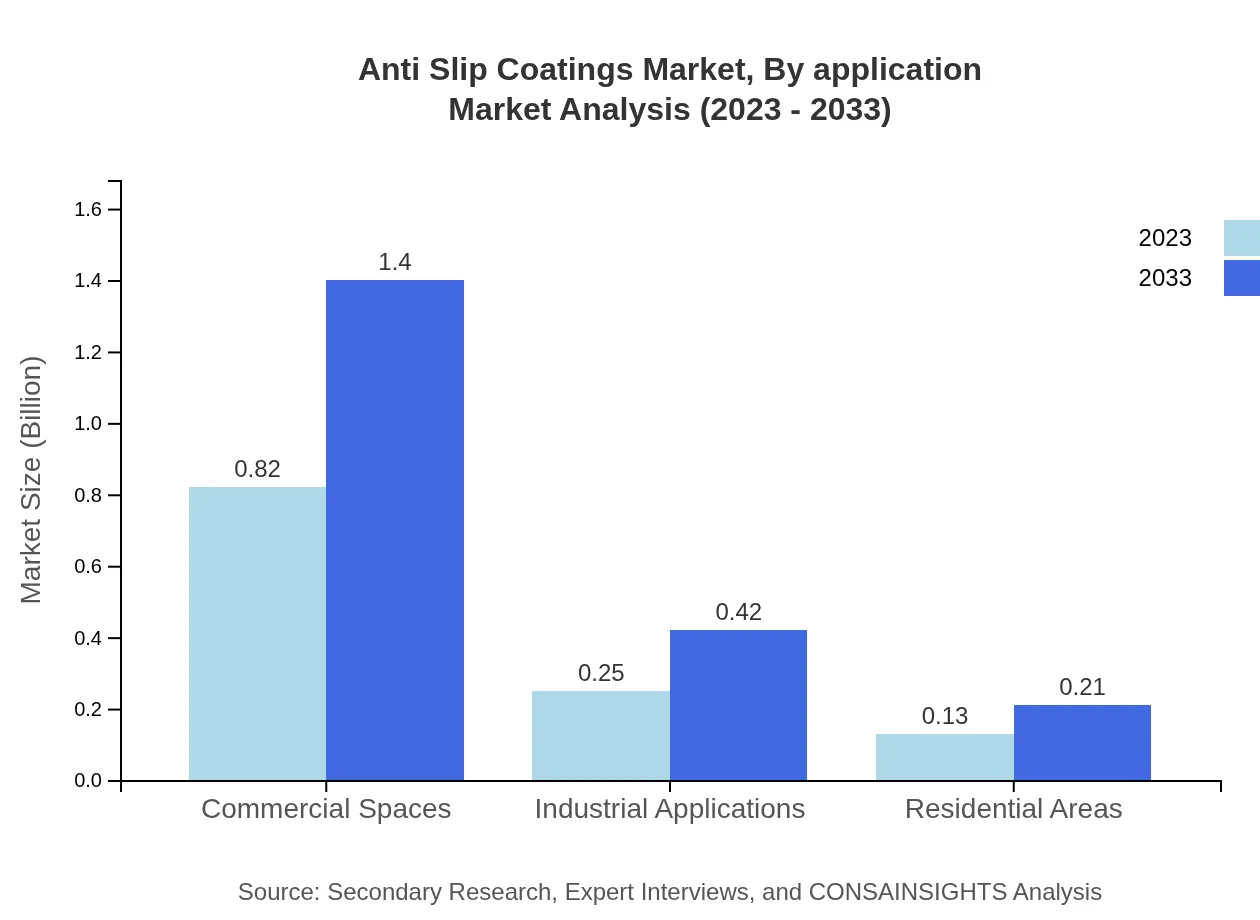

Anti Slip Coatings Market Analysis By Application

The construction industry represents the largest application segment, with a market size of $0.82 billion in 2023, forecasted to reach $1.40 billion by 2033. This segment maintains a steady share of 68.72%, reflecting the critical need for safety in building projects. The transportation segment, growing from $0.25 billion to $0.42 billion, responds to the increasing safety standards in vehicles and public transport.

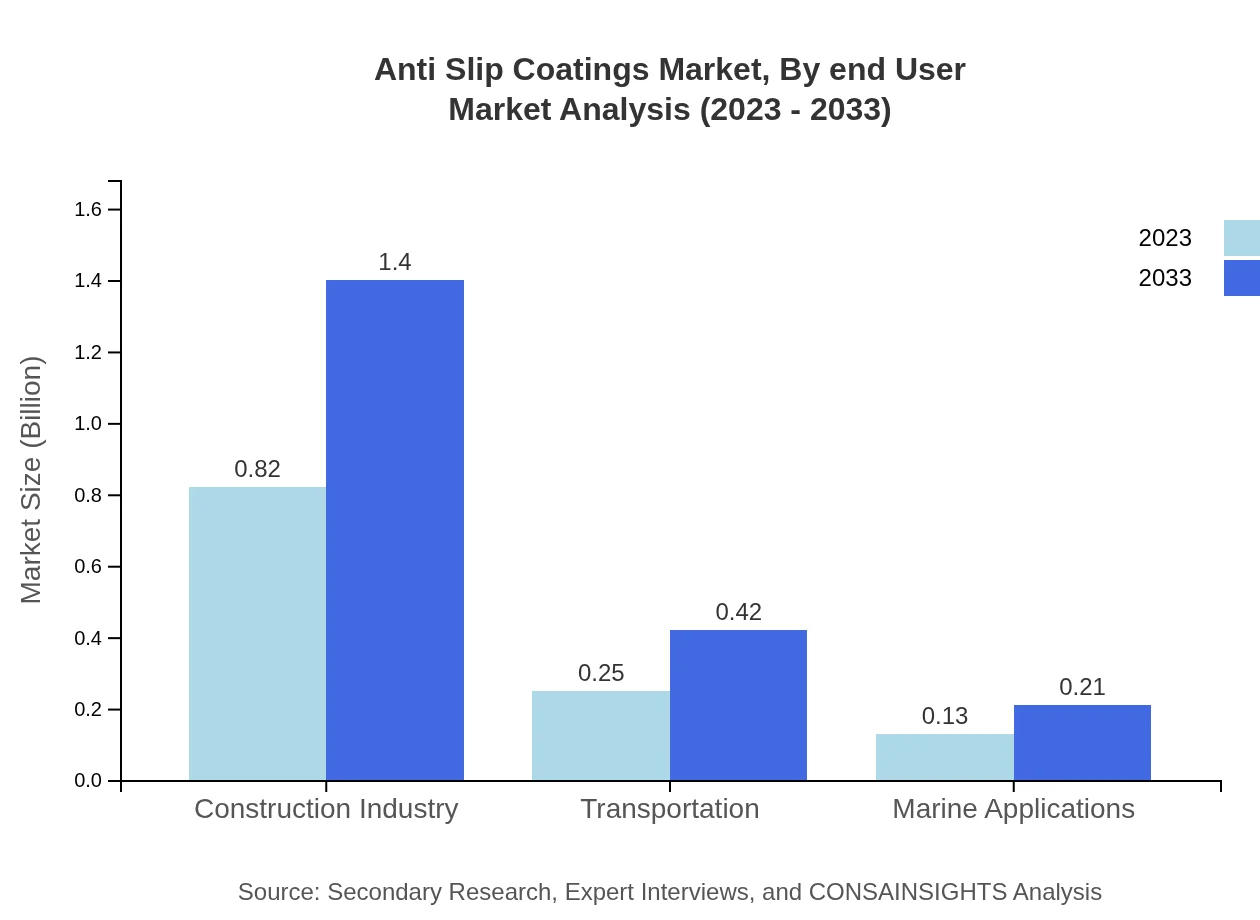

Anti Slip Coatings Market Analysis By End User

Key end-user segments include commercial spaces, industrial applications, and residential areas. Commercial spaces hold a market value of $0.82 billion in 2023, with industrial applications at $0.25 billion. These segments are integral due to their need for maintaining safe operational environments while adhering to regulatory requirements.

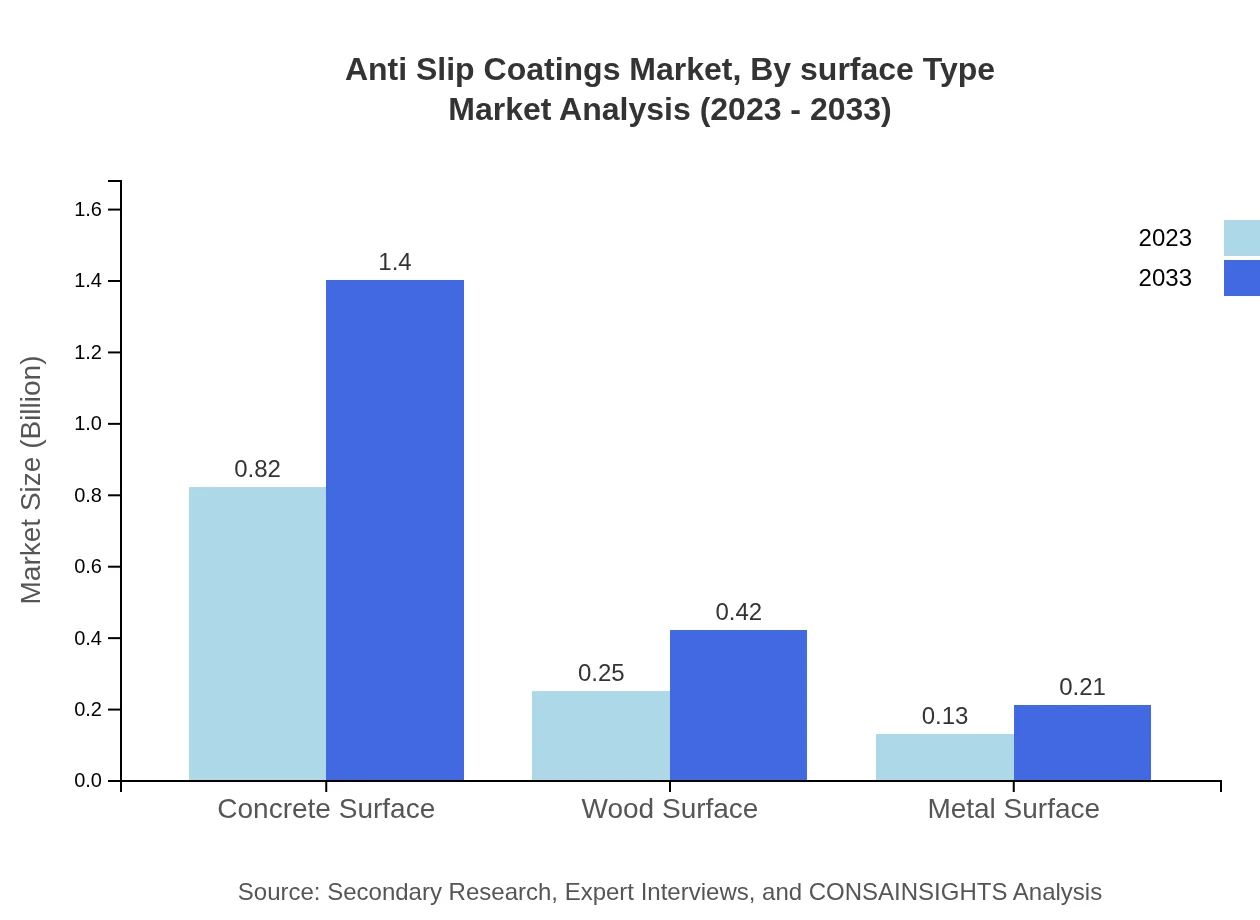

Anti Slip Coatings Market Analysis By Surface Type

The surface type segment is primarily composed of concrete, wood, and metal surfaces. Concrete surfaces account for the lion's share with $0.82 billion in 2023, due to their widespread use in construction and industrial applications. Wood surfaces and metal surfaces are also growing segments, driven by rising demands for outdoor safety and equipment maintenance.

Anti Slip Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Anti Slip Coatings Industry

Sherwin-Williams:

Sherwin-Williams is a global leader in coatings and paints, offering a comprehensive line of anti-slip coatings designed for various applications including industrial, commercial, and residential sectors.PPG Industries:

PPG Industries is known for its manufacturing of paints, coatings, and specialty materials. Their anti-slip coating lines cater to diverse industry needs, emphasizing safety and durability.BASF:

BASF is a leading chemical company that produces a wide range of materials, including advanced anti-slip coatings featuring eco-friendly formulations suited for different surfaces.Rust-Oleum:

Rust-Oleum specializes in protective paints and coatings, including a variety of anti-slip products utilized across multiple sectors for safety and protection.We're grateful to work with incredible clients.

FAQs

What is the market size of anti Slip Coatings?

The global anti-slip coatings market is valued at approximately $1.2 billion in 2023, with a projected growth rate of 5.3% CAGR by 2033. This growth reflects increasing demand across various sectors, driving innovation and expansion in product offerings.

What are the key market players or companies in this anti Slip Coatings industry?

Key players in the anti-slip coatings market include renowned companies specializing in protective coatings and surface treatments. While specific names are not detailed here, industry leaders often focus on innovation and developing products that meet safety standards across multiple applications.

What are the primary factors driving the growth in the anti Slip coatings industry?

The growth of the anti-slip coatings industry is primarily driven by increased safety regulations across industries, heightened awareness of slip and fall hazards, and the expansion of construction and transportation sectors necessitating safety-enhancing solutions.

Which region is the fastest Growing in the anti Slip coatings market?

The Asia-Pacific region is anticipated to emerge as the fastest-growing market for anti-slip coatings, with a rise from $0.23 billion in 2023 to $0.38 billion by 2033. This growth is fueled by rapid urbanization and infrastructure development.

Does ConsaInsights provide customized market report data for the anti Slip coatings industry?

Yes, ConsaInsights offers customized market report data tailored to client-specific needs in the anti-slip coatings industry. Clients can request detailed segment analyses, regional insights, and future market forecasts based on their requirements.

What deliverables can I expect from this anti Slip coatings market research project?

Deliverables from the anti-slip coatings market research project typically include comprehensive market analysis reports, segmented data, growth forecasts, competitive landscape evaluations, and strategic recommendations tailored to the client’s objectives.

What are the market trends of anti Slip coatings?

Current trends in the anti-slip coatings market include increased adoption of environmentally friendly formulations, innovations in texture and application technologies, and a push towards personalized solutions for specific industrial applications.