Antiblock Additive Market Report

Published Date: 02 February 2026 | Report Code: antiblock-additive

Antiblock Additive Market Size, Share, Industry Trends and Forecast to 2033

This market report presents a comprehensive analysis of the Antiblock Additive industry, covering market trends, projections from 2023 to 2033, and insights into regional markets. It also assesses key players and future opportunities in the sector.

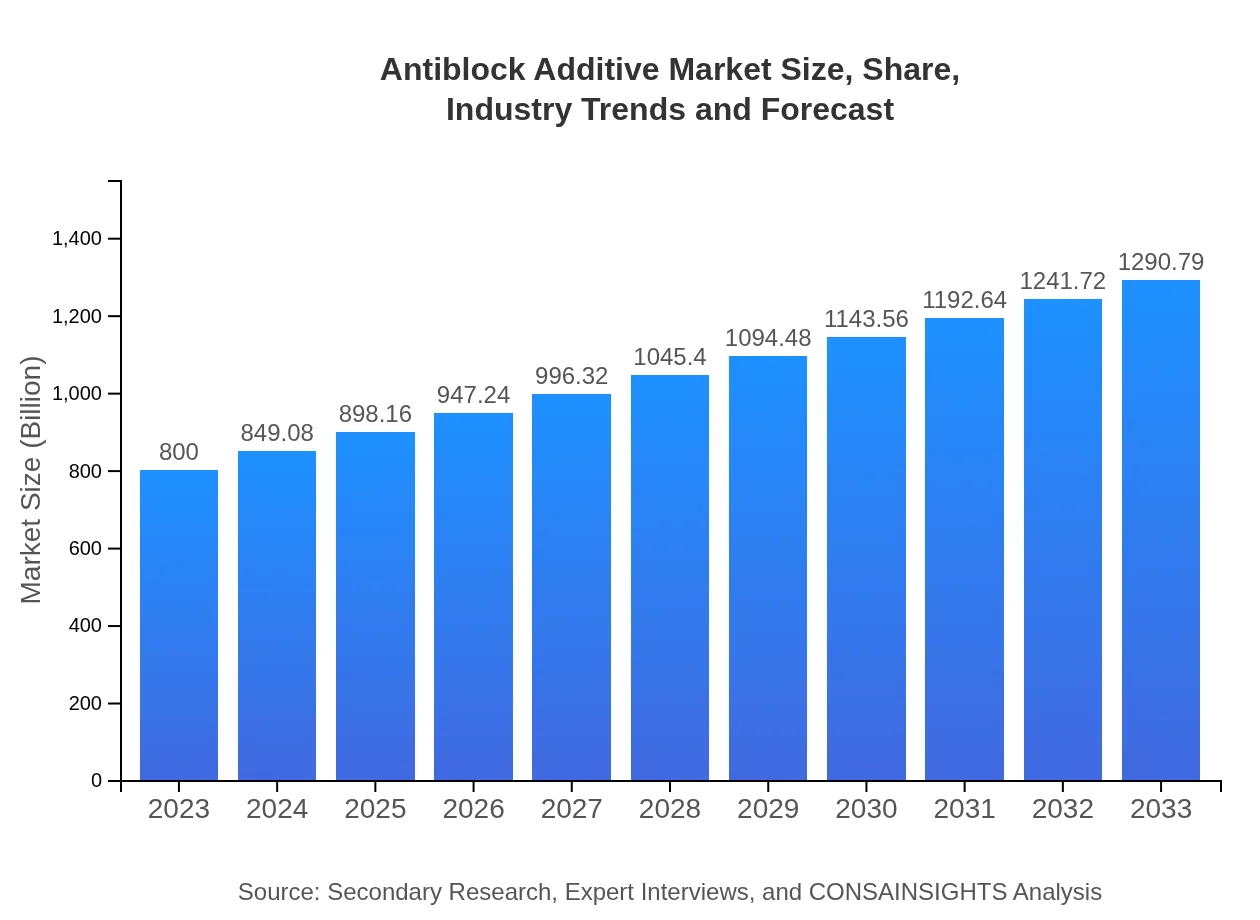

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $800.00 Million |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $1290.79 Million |

| Top Companies | Evonik Industries AG, BASF SE, Clariant AG, Honeywell International Inc. |

| Last Modified Date | 02 February 2026 |

Antiblock Additive Market Overview

Customize Antiblock Additive Market Report market research report

- ✔ Get in-depth analysis of Antiblock Additive market size, growth, and forecasts.

- ✔ Understand Antiblock Additive's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Antiblock Additive

What is the Market Size & CAGR of Antiblock Additive market in 2023?

Antiblock Additive Industry Analysis

Antiblock Additive Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Antiblock Additive Market Analysis Report by Region

Europe Antiblock Additive Market Report:

In Europe, the market is expected to reach around 337.03 million USD in 2033 from 208.88 million USD in 2023. The growth is propelled by increasing environmental regulations, promoting the use of biodegradable additives. The region's established industrial base supports robust R&D in developing innovative additive solutions.Asia Pacific Antiblock Additive Market Report:

The Asia Pacific region, valuing at approximately 156.00 million USD in 2023, is anticipated to grow to 251.71 million USD by 2033. This growth is attributed to the booming packaging industry in countries like China and India, fueled by increasing urbanization and consumer goods demand. Additionally, rising awareness of sustainable practices further boosts the need for innovative additive solutions.North America Antiblock Additive Market Report:

North America represents a significant market, with an expected growth from 262.96 million USD in 2023 to 424.28 million USD by 2033. The demand for Antiblock Additives is predominantly driven by the food and beverage sector, where effective packaging aids in production processes and product durability, coupled with stringent regulations on food safety.South America Antiblock Additive Market Report:

In South America, the Antiblock Additive market is projected to increase from 67.36 million USD in 2023 to 108.68 million USD by 2033. The growth is bolstered by evolving manufacturing processes and a shift towards enhanced product quality in the plastic industry, particularly in packaging and consumer goods.Middle East & Africa Antiblock Additive Market Report:

The Middle East and Africa market is projected to expand from 104.80 million USD in 2023 to 169.09 million USD by 2033. Rising industrial activities and growing consumer markets drive demand for effective packaging solutions, highlighting the potential for Antiblock Additives in localized applications.Tell us your focus area and get a customized research report.

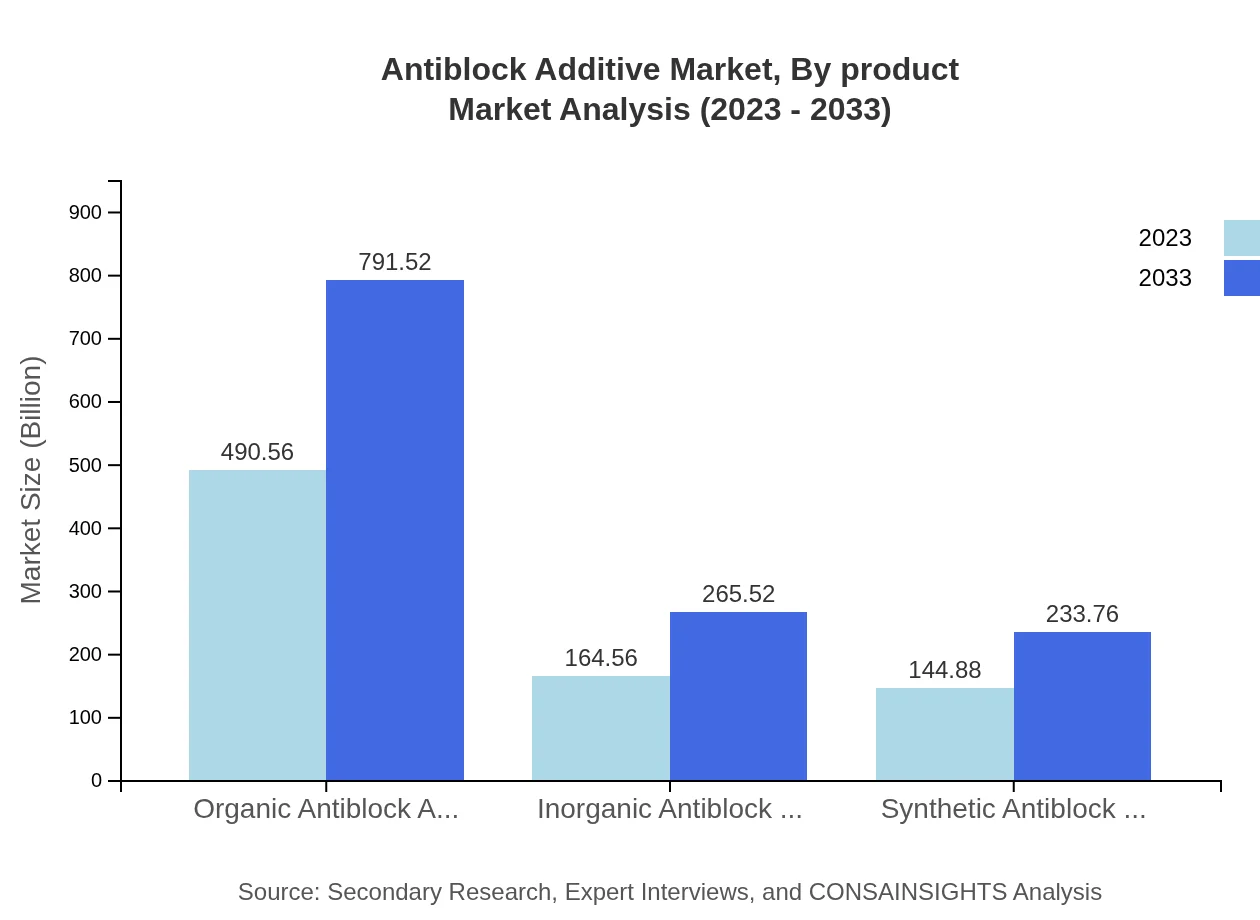

Antiblock Additive Market Analysis By Product

The segmentation based on product types includes organic, inorganic, and synthetic additives. In 2023, organic Antiblock Additives held a significant market share of 61.32%, expected to increase to 61.32% by 2033. Organic additives showcase superior performance in reducing adhesion for various films, proving essential for the packaging industry. In contrast, inorganic and synthetic segments are forecasted to grow steadily, with inorganic amounts at 20.57% and synthetic standing at 18.11% in market shares, both maintaining their relevance through diverse applications.

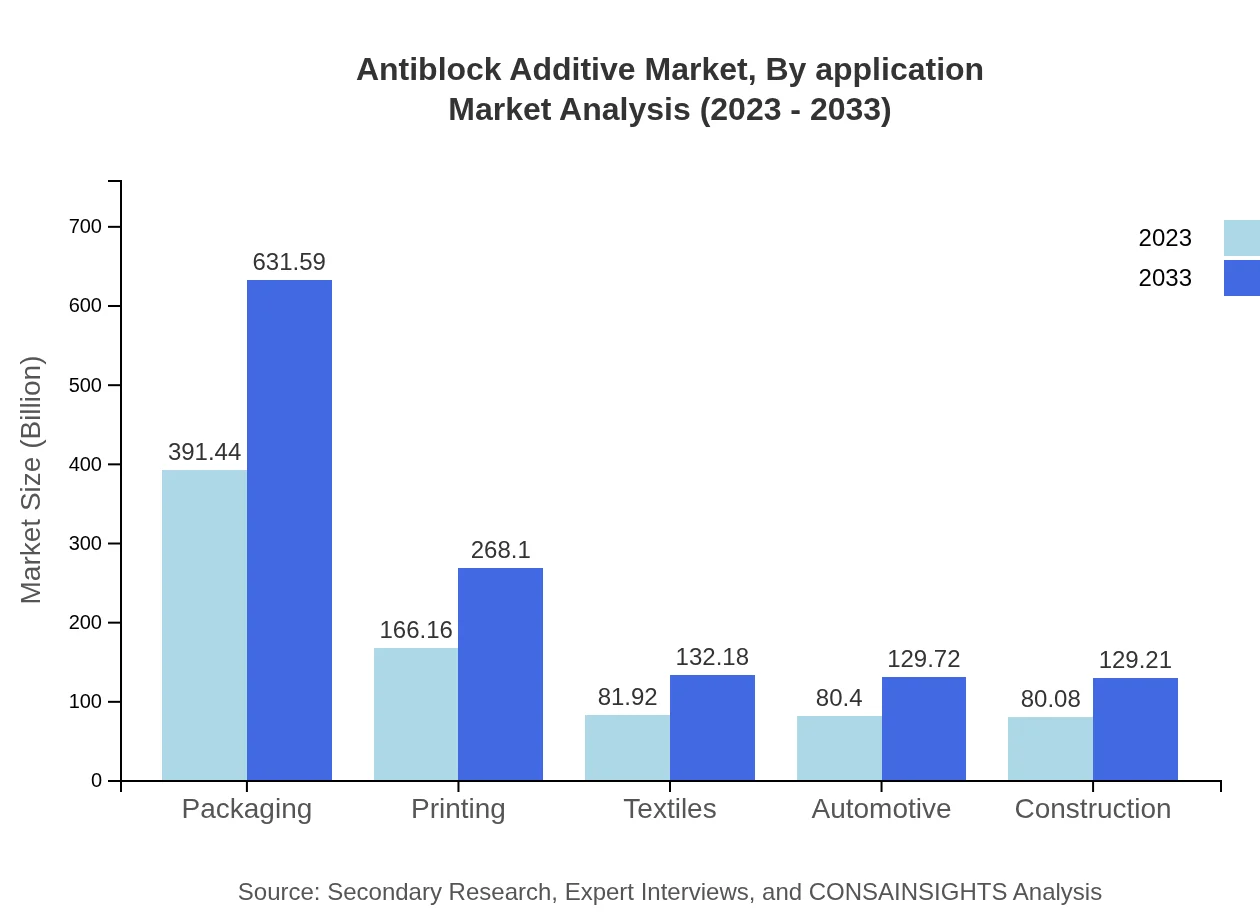

Antiblock Additive Market Analysis By Application

The application of Antiblock Additives reveals significant insights into their end-use industries, including packaging, printing, textiles, and food and beverage. Notably, the packaging sector commands 48.93% of the market share in 2023, projected to rise to 48.93% by 2033. This segment is particularly critical due to increasing product varieties and consumer demand for sustainable packaging configurations. Other segments like textiles and automotive are also thriving, with respective shares of 10.24% and 10.05%.

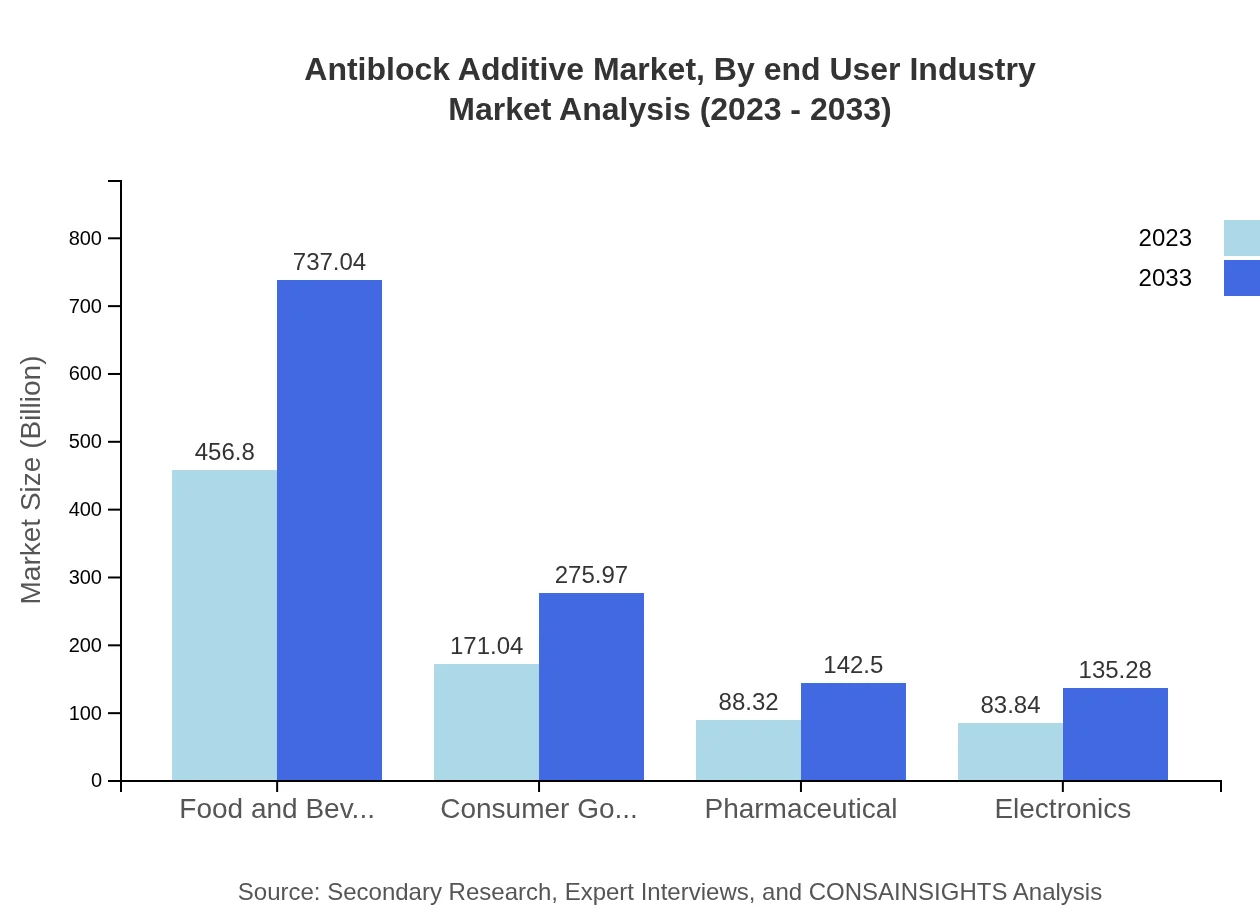

Antiblock Additive Market Analysis By End User Industry

End-user industries for Antiblock Additives include food and beverage, consumer goods, pharmaceuticals, and construction. The food and beverage sector holds the majority, with market sizes reaching 456.80 million USD in 2023 and projected at 737.04 million USD by 2033, asserting the critical role of additives in enhancing packaging performance and product safety. With a focus on consumer safety and regulatory compliance, this segment is likely to drive continuous growth results.

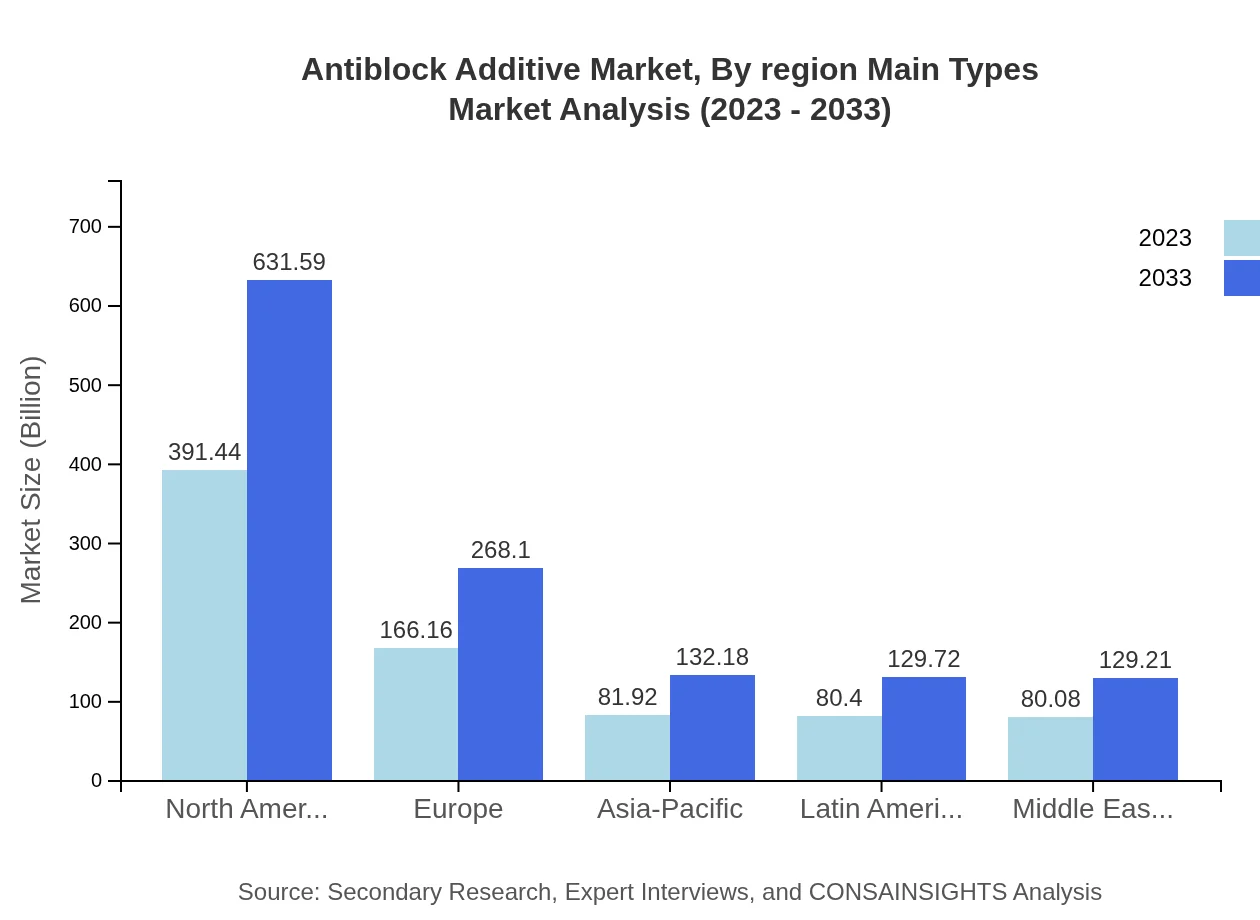

Antiblock Additive Market Analysis By Region Main Types

Regional analysis substantiates the varying performance of Antiblock Additives within different geographic locations. North America leads in market size, followed closely by Europe and the Asia Pacific, where diverse applications command prominent demand spans. Understanding regional nuances facilitates strategic positioning for manufacturers to cater to specific market dynamics and capitalize on emerging trends.

Antiblock Additive Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Antiblock Additive Industry

Evonik Industries AG:

A leader in specialty chemicals, Evonik is known for its innovative approach to additive manufacturing solutions, providing high-performance Antiblock Additives for diverse applications.BASF SE:

BASF is a global chemical company that offers a wide portfolio of Antiblock Additives, focusing on sustainability and performance enhancement in various industries.Clariant AG:

Clariant specializes in specialty chemicals, including Antiblock Additives, and is renowned for its commitment to sustainable practices and advanced product solutions.Honeywell International Inc.:

Honeywell provides a range of innovative materials and additives that cater to the Antiblock Additive market, emphasizing enhanced performance in industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of antiblock Additive?

The global antiblock additive market is valued at approximately $800 million in 2023, with a projected CAGR of 4.8% extending to 2033. This growth is driven by increasing demand for enhanced plastic packaging solutions across various industries.

What are the key market players or companies in the antiblock additive industry?

Key players in the antiblock additive industry include prominent companies such as Cabot Corporation, Dow Chemical Company, and BASF. These companies are recognized for their innovative products and extensive distribution networks, contributing significantly to market dynamics.

What are the primary factors driving the growth in the antiblock additive industry?

Factors driving growth in the antiblock additive industry include rising consumer demand for packaged goods, advancements in polymer technologies, and increasing applications across food, pharmaceuticals, and textiles, leading to greater usage of antiblocking solutions.

Which region is the fastest Growing in the antiblock additive market?

North America is identified as the fastest-growing region within the antiblock additive market, with its market size projected to increase from $262.96 million in 2023 to $424.28 million by 2033, reflecting robust demand in packaging applications.

Does ConsaInsights provide customized market report data for the antiblock additive industry?

Yes, ConsaInsights offers customized market report data for the antiblock additive industry tailored to specific client needs. This includes in-depth analysis, regional insights, and targeted market trends that cater to unique business interests.

What deliverables can I expect from this antiblock additive market research project?

Expect deliverables such as a comprehensive market report, detailed regional and segment analyses, growth forecasts, and insights into competitive landscapes, ensuring you receive actionable data necessary for strategic decision-making.

What are the market trends of antiblock additive?

Current trends in the antiblock additive market include a shift toward organic additives, increasing sustainability efforts, and the growing importance of advanced functional characteristics in consumer products, which emphasize performance enhancements.