Aramid Fiber Reinforcement Materials Market Report

Published Date: 02 February 2026 | Report Code: aramid-fiber-reinforcement-materials

Aramid Fiber Reinforcement Materials Market Size, Share, Industry Trends and Forecast to 2033

This market report provides valuable insights into the Aramid Fiber Reinforcement Materials industry, including market size forecasts, segmentation, regional analysis, key players, and future trends from 2023 to 2033.

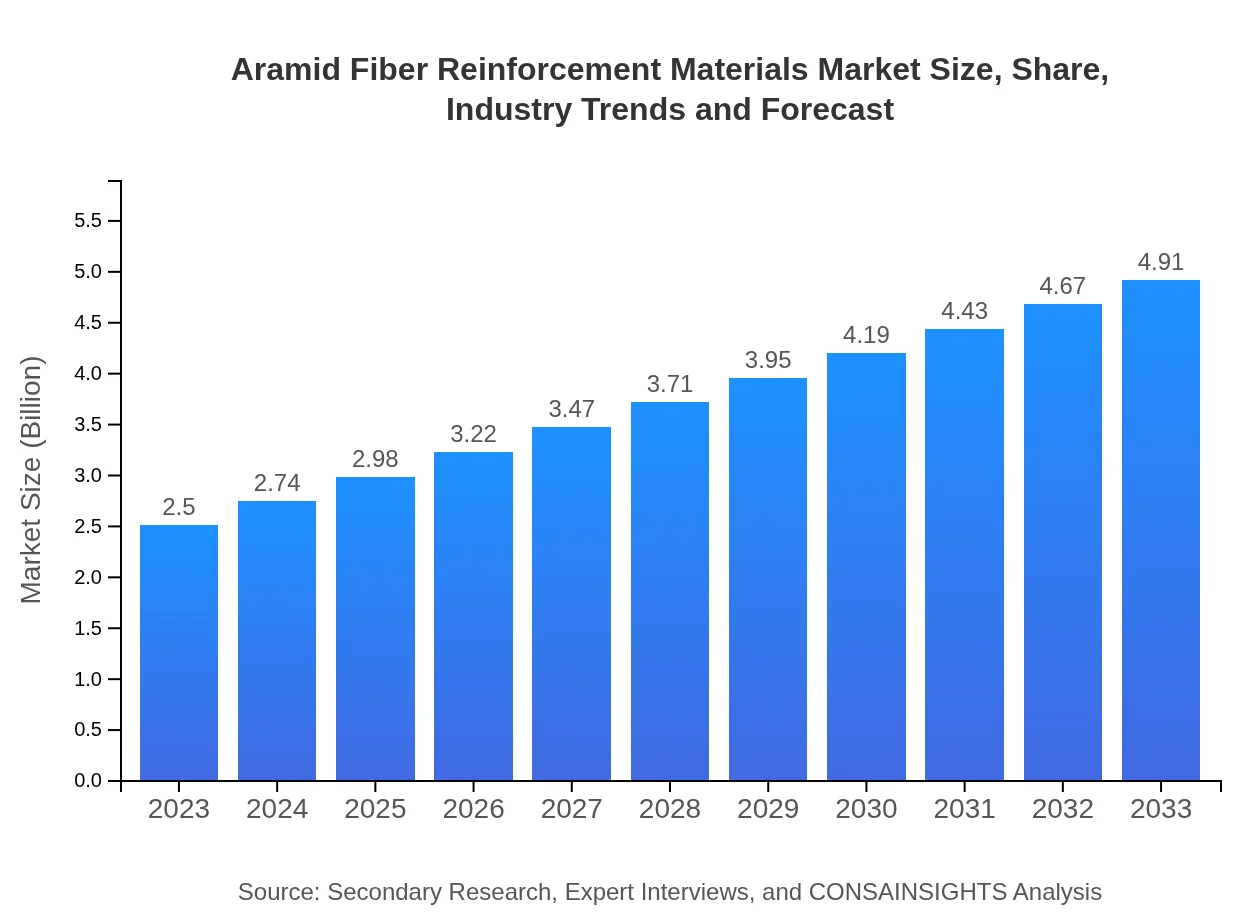

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | DuPont, Teijin Limited, Kermel, Hyosung |

| Last Modified Date | 02 February 2026 |

Aramid Fiber Reinforcement Materials Market Overview

Customize Aramid Fiber Reinforcement Materials Market Report market research report

- ✔ Get in-depth analysis of Aramid Fiber Reinforcement Materials market size, growth, and forecasts.

- ✔ Understand Aramid Fiber Reinforcement Materials's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aramid Fiber Reinforcement Materials

What is the Market Size & CAGR of Aramid Fiber Reinforcement Materials market in 2023?

Aramid Fiber Reinforcement Materials Industry Analysis

Aramid Fiber Reinforcement Materials Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aramid Fiber Reinforcement Materials Market Analysis Report by Region

Europe Aramid Fiber Reinforcement Materials Market Report:

Europe's market in aramid fiber reinforcement materials is projected to rise from $0.75 billion in 2023 to $1.47 billion by 2033. The government's push for sustainable materials and innovations in the automotive sector contribute significantly to this growth, with Germany, France, and the UK being major contributors.Asia Pacific Aramid Fiber Reinforcement Materials Market Report:

The Asia Pacific region, valued at $0.48 billion in 2023, is expected to grow to $0.94 billion by 2033, driven by rapid industrialization and increasing investment in the automotive and aerospace sectors. Countries like China, Japan, and India are leading this growth through substantial infrastructure projects and demand for lightweight materials in various applications.North America Aramid Fiber Reinforcement Materials Market Report:

North America is a strong market for aramid fiber reinforcement materials, beginning at $0.84 billion in 2023 and expected to grow to $1.65 billion by 2033. The presence of key manufacturers and the high demand for advanced materials in automotive and aerospace applications drive this growth, alongside stringent safety and environmental regulations.South America Aramid Fiber Reinforcement Materials Market Report:

The South American market, with a size of $0.13 billion in 2023, is projected to double to $0.26 billion by 2033. This growth is primarily attributed to increasing investments in infrastructure and defense industries, especially in Brazil and Argentina, enhancing the demand for aramid fiber reinforcement materials.Middle East & Africa Aramid Fiber Reinforcement Materials Market Report:

Valued at $0.31 billion in 2023, the Middle East and Africa market is set to increase to $0.60 billion by 2033. Growing investments in defense infrastructure and automotive manufacturing, particularly in countries like UAE and South Africa, are key drivers of growth in this region.Tell us your focus area and get a customized research report.

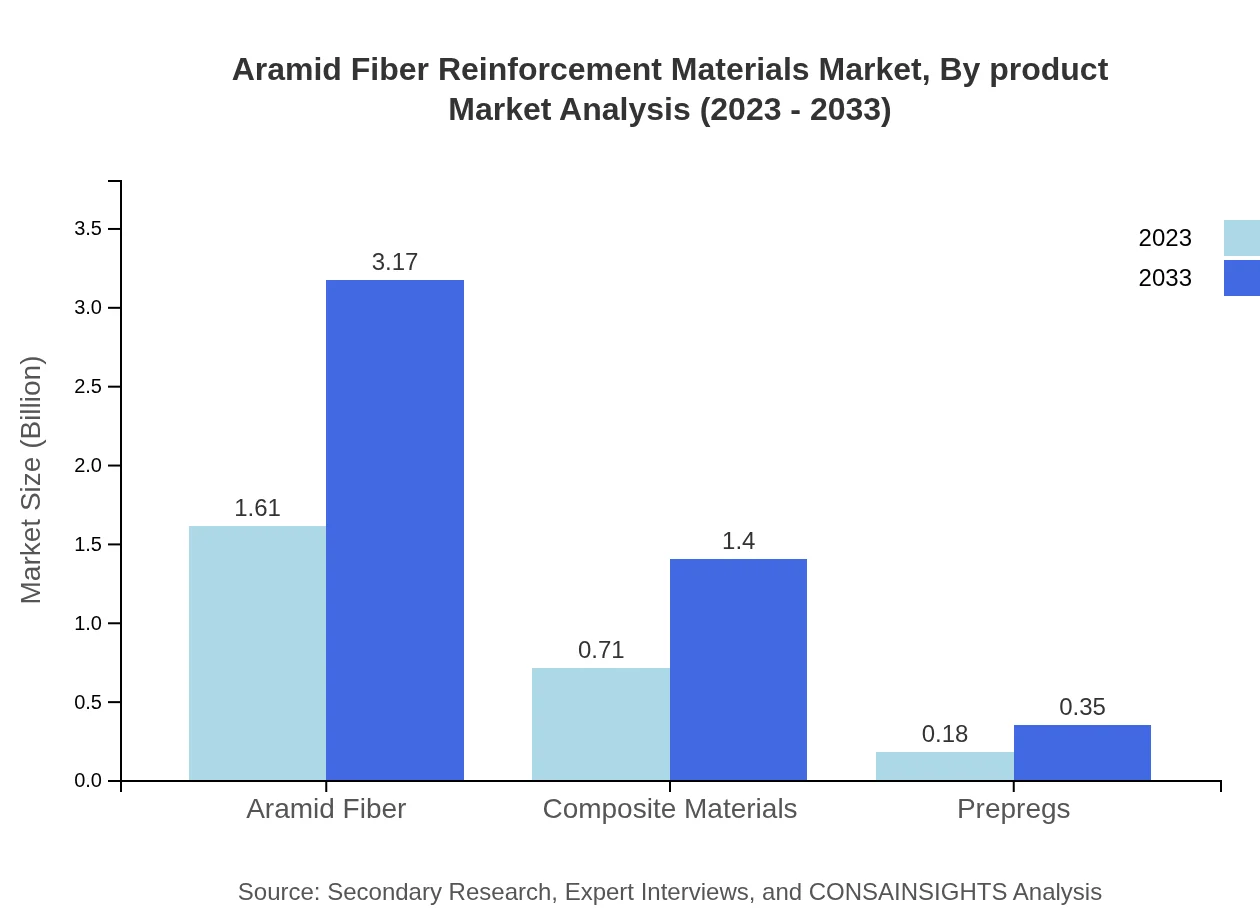

Aramid Fiber Reinforcement Materials Market Analysis By Product

In the product segment, Aramid Fiber is projected to dominate the market, growing from $1.61 billion in 2023 to $3.17 billion by 2033, driven by its versatility across multiple applications. Composite Materials follow, expected to grow from $0.71 billion to $1.40 billion, while Prepregs will see growth from $0.18 billion to $0.35 billion.

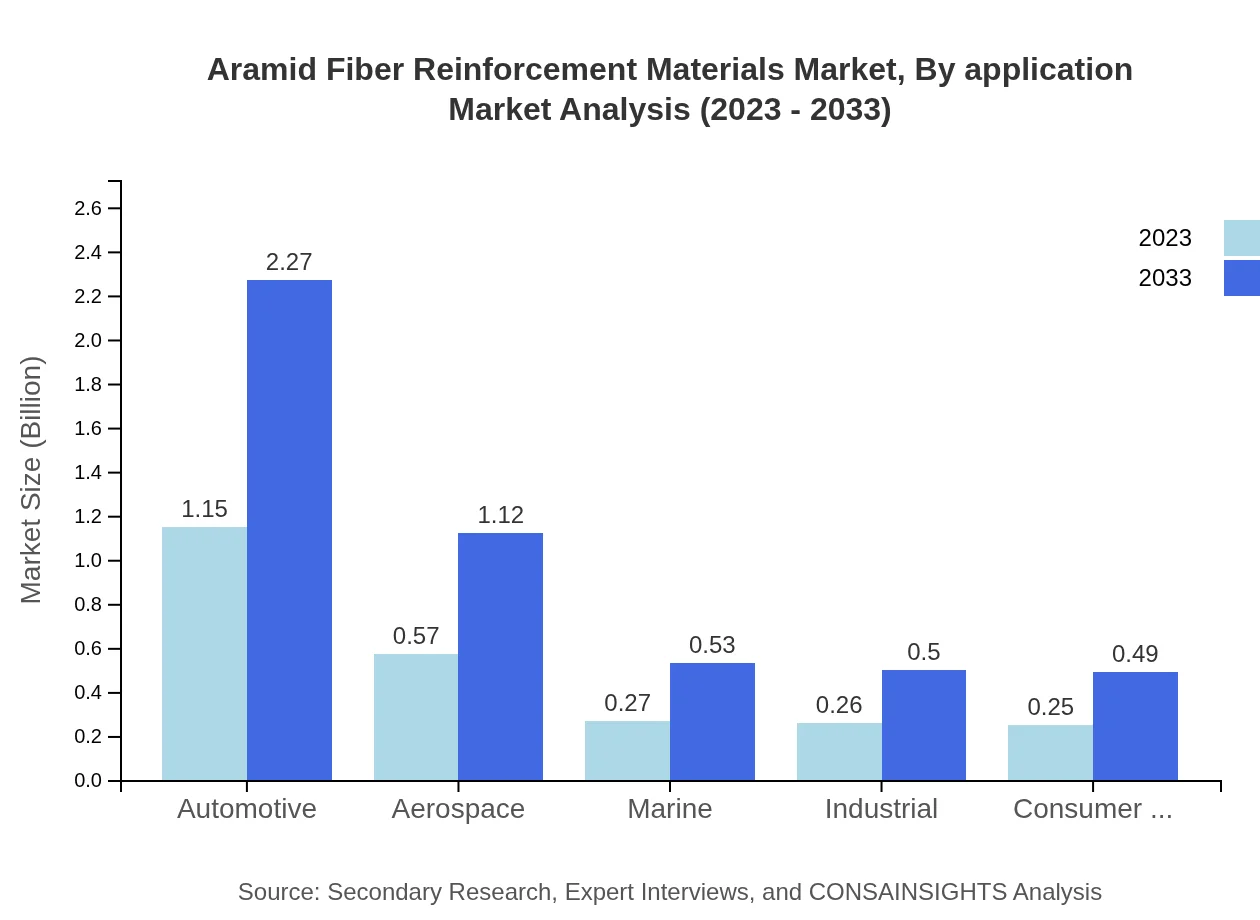

Aramid Fiber Reinforcement Materials Market Analysis By Application

In terms of application, the Defense sector stands out, beginning at $1.15 billion and projected to reach $2.27 billion by 2033. The Automotive segment is another significant contributor, replicating a similar growth trajectory. Other sectors, including Aerospace and Electronics, also exhibit considerable growth potential.

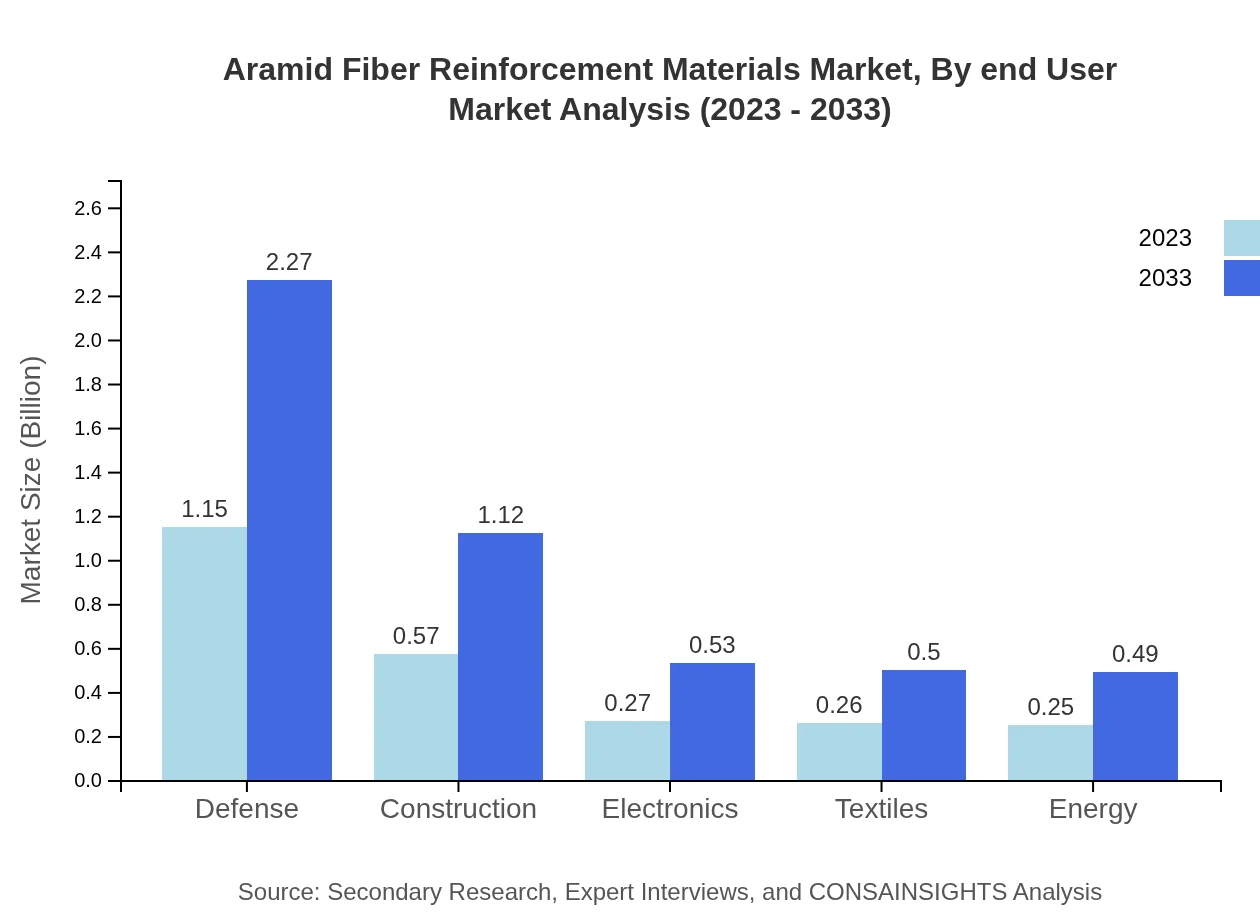

Aramid Fiber Reinforcement Materials Market Analysis By End User

The end-user segmentation highlights the Defense and Automotive industries as the largest consumers of aramid fiber reinforcement materials, accounting for over 46% of the market share, respectively. Aerospace, Construction, and Electronics also represent substantial market segments, each contributing significantly to revenue generation.

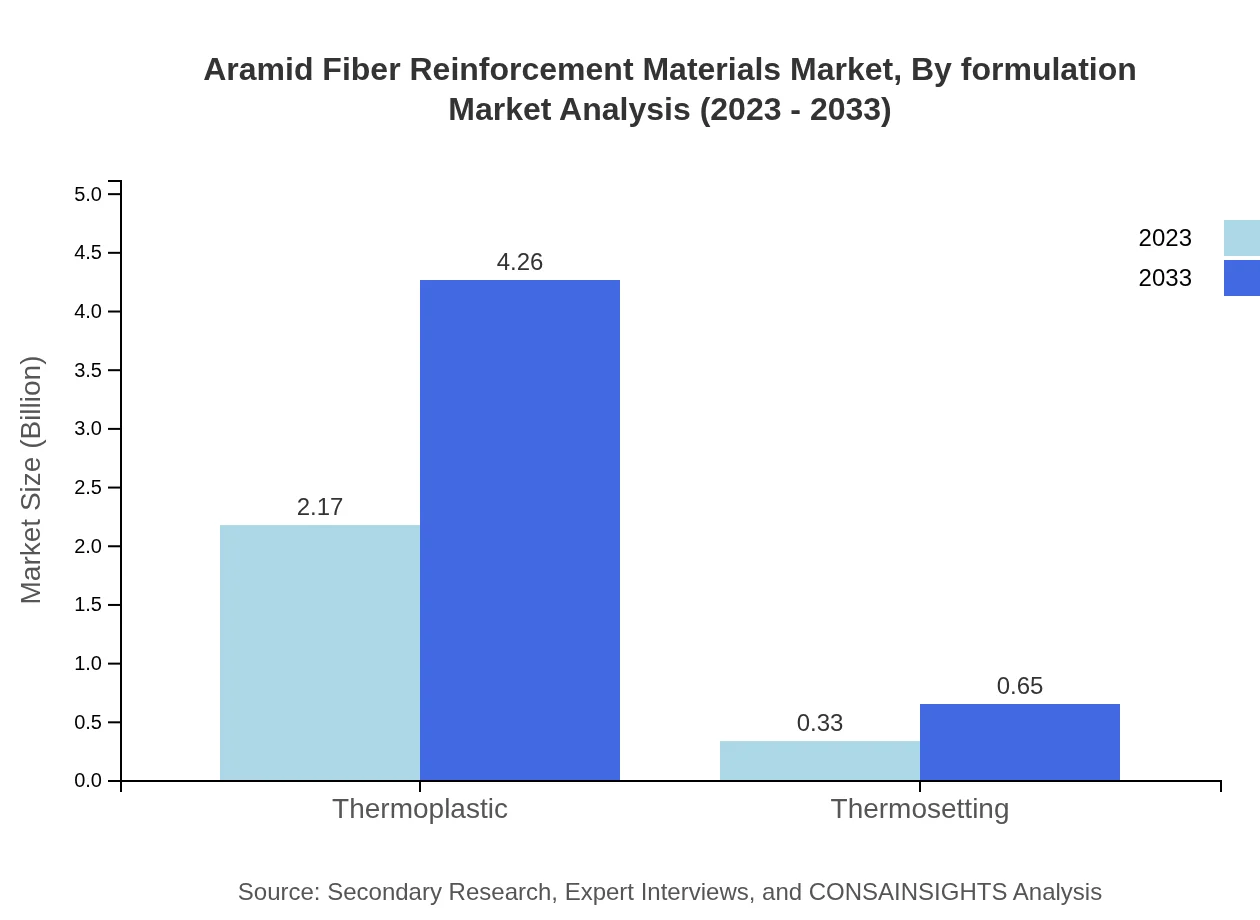

Aramid Fiber Reinforcement Materials Market Analysis By Formulation

The market is further categorized by formulation, highlighting Thermoplastic materials as a major segment due to their extensive applications in industrial, consumer, and automotive fields. Thermosetting materials, while holding a smaller share, still contribute to niche applications requiring high performance.

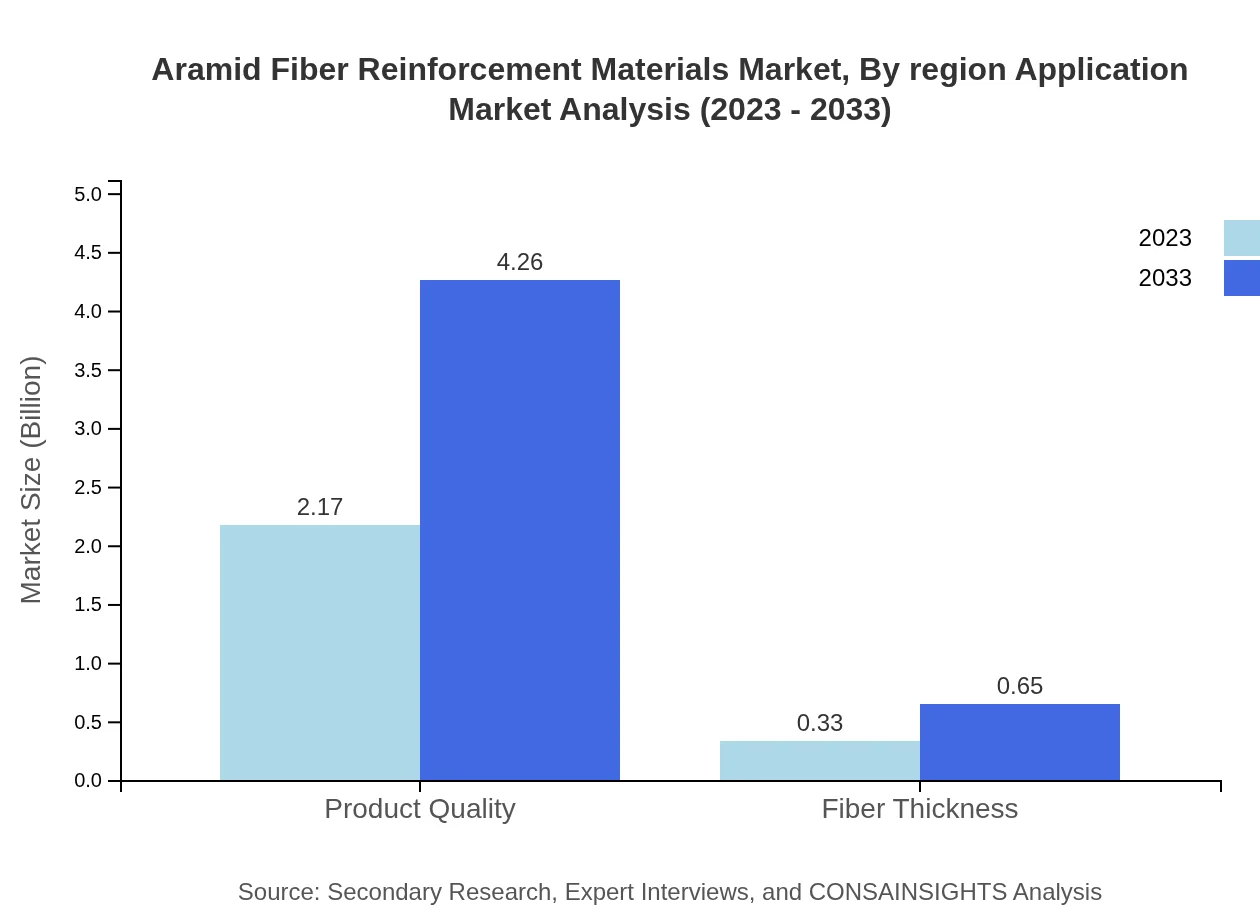

Aramid Fiber Reinforcement Materials Market Analysis By Region Application

The analysis emphasizes the importance of thermoplastic formulations, which account for 86.67% of the market share, as the preferred choice for manufacturers. The product applications across various regions reflect a balanced growth trend in the use of aramid-reinforced materials.

Aramid Fiber Reinforcement Materials Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aramid Fiber Reinforcement Materials Industry

DuPont:

A pioneer in aramid technology, DuPont integrates innovative materials into automotive, aerospace, and industrial markets, known for their flagship product, Kevlar.Teijin Limited:

Teijin is a leading manufacturer of aramid fibers, known for its advanced applications in aerospace and defense industries, offering high-performance solutions tailored to client needs.Kermel:

Kermel specializes in aramid fiber solutions focusing on safety applications, particularly in firefighting and protective clothing.Hyosung:

Hyosung is recognized for its commitment to innovation in fiber technology, providing high-performance aramid fibers suited for diverse applications across regional markets.We're grateful to work with incredible clients.

FAQs

What is the market size of aramid Fiber Reinforcement Materials?

The aramid fiber reinforcement materials market is projected to reach approximately $2.5 billion by 2033, growing at a CAGR of 6.8%. With increasing applications in various industries, this segment demonstrates significant expansion potential.

What are the key market players or companies in this aramid Fiber Reinforcement Materials industry?

Prominent companies in the aramid fiber reinforcement materials industry include DuPont, Teijin Limited, and Honeywell. These leaders are pivotal in driving innovations, enhancing material properties, and expanding their market presence.

What are the primary factors driving the growth in the aramid Fiber Reinforcement Materials industry?

Key factors driving growth include increasing demand for lightweight, durable materials in automotive and aerospace sectors, heightened safety regulations, and advancements in manufacturing processes that enhance product efficiency.

Which region is the fastest Growing in the aramid Fiber Reinforcement Materials?

The North American region is the fastest-growing market, expected to expand from $0.84 billion in 2023 to $1.65 billion in 2033, driven by robust automotive and aerospace industries, along with technological advancements.

Does ConsaInsights provide customized market report data for the aramid Fiber Reinforcement Materials industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the aramid fiber reinforcement materials industry, ensuring detailed insights that align with unique business goals and market strategies.

What deliverables can I expect from this aramid Fiber Reinforcement Materials market research project?

Deliverables include comprehensive market reports, detailed growth forecasts, segmentation analysis, competitive landscape insights, and actionable recommendations tailored for strategic decision-making.

What are the market trends of aramid Fiber Reinforcement Materials?

Market trends indicate a growing focus on sustainability, increased utilization of aramid fibers in defense and automotive applications, and ongoing research for advanced composites that enhance performance while reducing weight.