Aramid Prepreg Market Report

Published Date: 02 February 2026 | Report Code: aramid-prepreg

Aramid Prepreg Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Aramid Prepreg market, offering comprehensive insights into its size, growth projections, and critical trends from 2023 to 2033. It includes market segmentation, regional analysis, and an overview of key industry players.

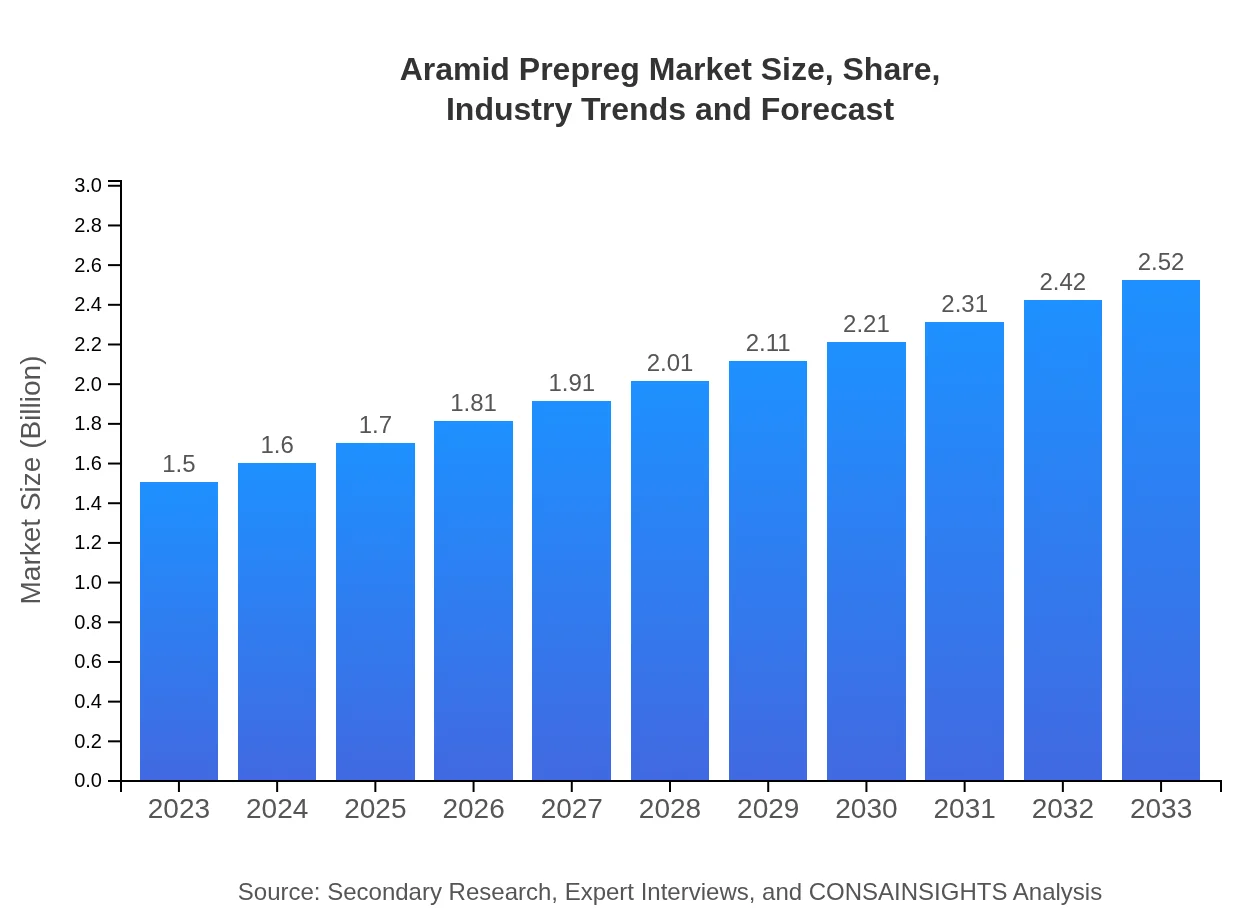

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $2.52 Billion |

| Top Companies | DuPont, Teijin Limited, Park Aerospace Corp., Toray Industries |

| Last Modified Date | 02 February 2026 |

Aramid Prepreg Market Overview

Customize Aramid Prepreg Market Report market research report

- ✔ Get in-depth analysis of Aramid Prepreg market size, growth, and forecasts.

- ✔ Understand Aramid Prepreg's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Aramid Prepreg

What is the Market Size & CAGR of Aramid Prepreg market in 2023?

Aramid Prepreg Industry Analysis

Aramid Prepreg Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Aramid Prepreg Market Analysis Report by Region

Europe Aramid Prepreg Market Report:

The European Aramid Prepreg market is forecasted to grow from $0.50 billion in 2023 to $0.84 billion by 2033. The region's strong emphasis on quality and advancements in aeronautics, along with regulatory support for lightweight materials, significantly propels market expansion.Asia Pacific Aramid Prepreg Market Report:

In the Asia Pacific region, the market for Aramid Prepreg is anticipated to grow from $0.29 billion in 2023 to $0.48 billion by 2033. Key factors driving this growth include increasing aerospace manufacturing activities in countries like China and India, alongside rising demand in the automotive sector for lightweight materials.North America Aramid Prepreg Market Report:

North America, particularly the U.S., is a leading market for Aramid Prepreg, expected to increase from $0.49 billion in 2023 to $0.82 billion by 2033. Growth is driven by high demand from the aerospace and defense industries, coupled with advancements in manufacturing technologies.South America Aramid Prepreg Market Report:

South America's Aramid Prepreg market is projected to rise from $0.04 billion in 2023 to $0.08 billion by 2033. The growth is attributed to gradual industrial development, particularly in aerospace and electronics, despite economic challenges impacting broad market adoption.Middle East & Africa Aramid Prepreg Market Report:

The Middle East and Africa market for Aramid Prepreg is projected to rise from $0.18 billion in 2023 to $0.30 billion by 2033. Increasing investments in defense and aerospace sectors are crucial drivers, although market growth may vary due to regional geopolitical factors.Tell us your focus area and get a customized research report.

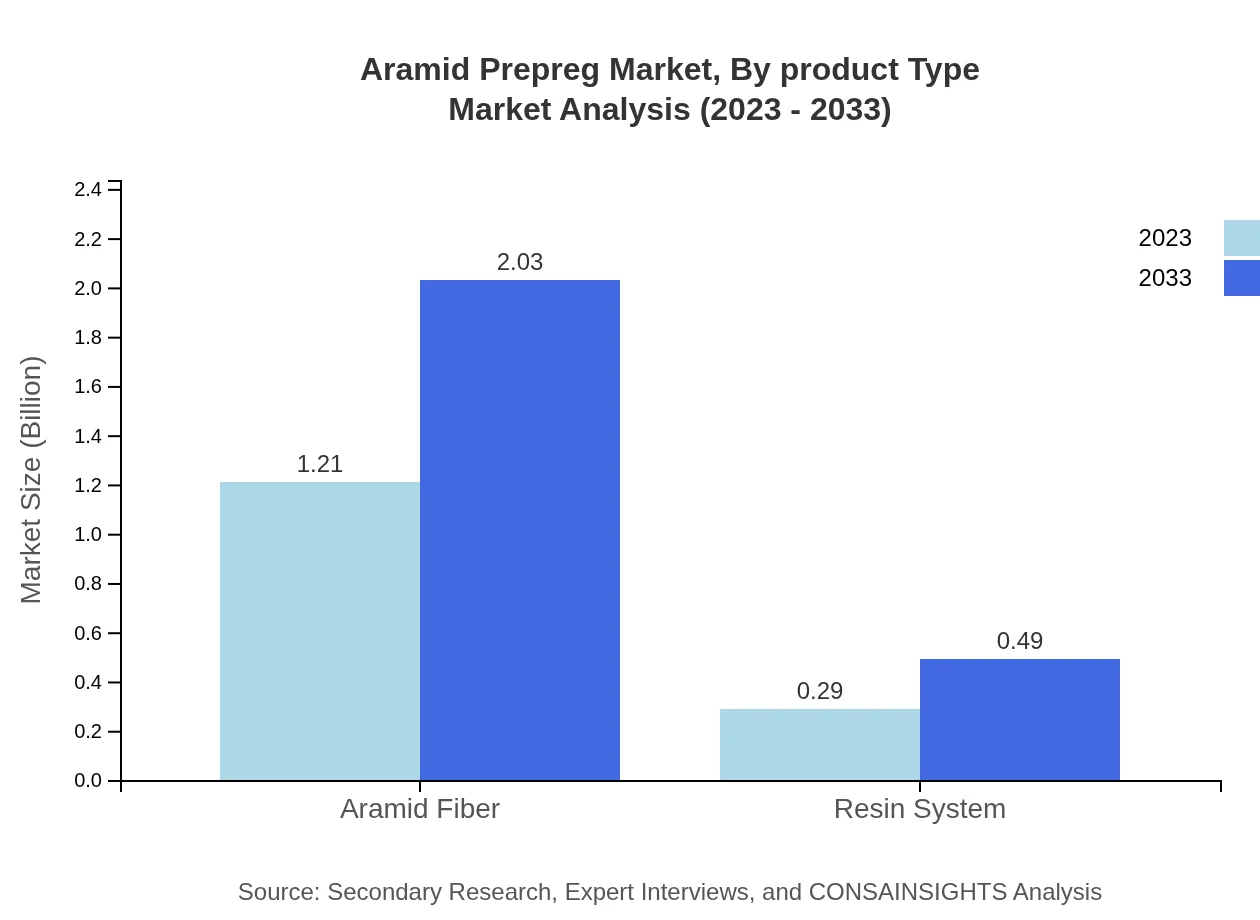

Aramid Prepreg Market Analysis By Product Type

The Aramid-Prepreg market is primarily dominated by the Aramid Fiber segment, which represents approximately 80.52% of the overall market share as of 2023. This segment is projected to grow significantly along with advancements in resin systems, which accounted for 19.48% of the market, highlighting the importance of resin compatibility in enhanced performance.

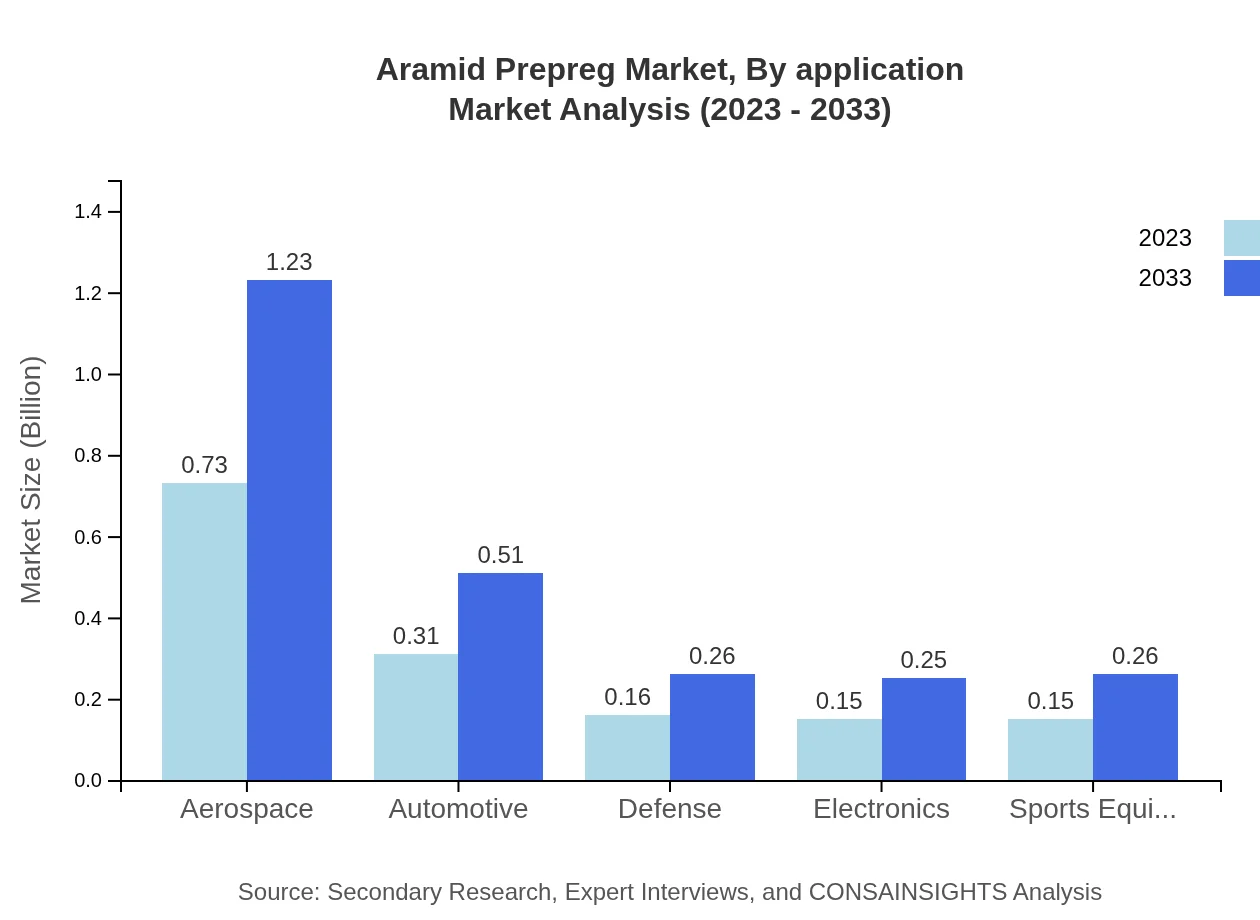

Aramid Prepreg Market Analysis By Application

Aerospace and defense applications constitute the largest segment within the Aramid Prepreg market, accounting for 56.42% of the market share in 2023, with a projected increase to 56.42% by 2033. The automotive industry follows closely, representing 20.81% of the market. Demand in electronics and sports gear manufacturing is also noteworthy, with respective shares of 12.7% and 10.07%.

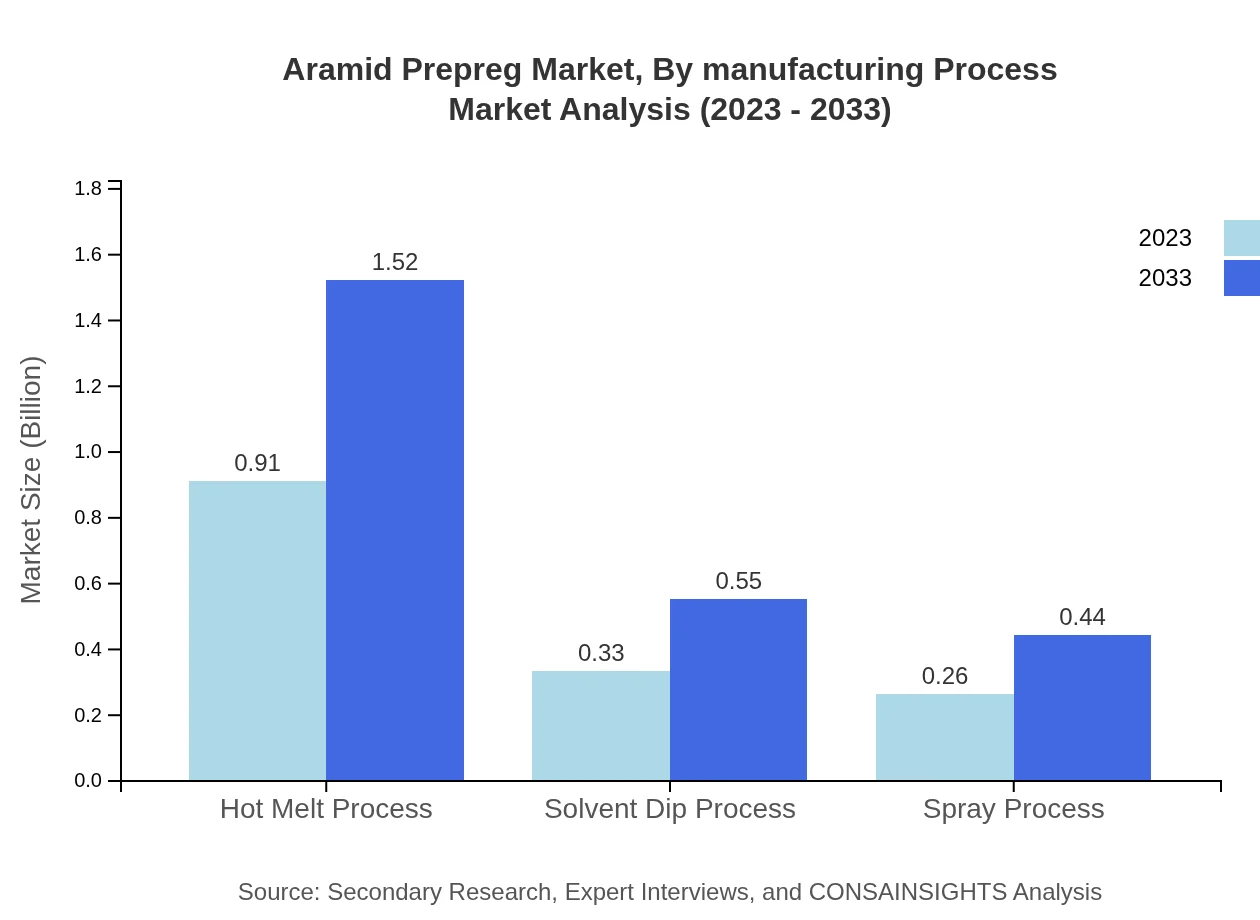

Aramid Prepreg Market Analysis By Manufacturing Process

The Hot Melt process leads the manufacturing segment, constituting 60.51% of the market in 2023 and expected to rise further as it allows for quicker processing times and better end-product quality. The Solvent Dip and Spray processes also contribute significantly, taking shares of 21.94% and 17.55%, respectively.

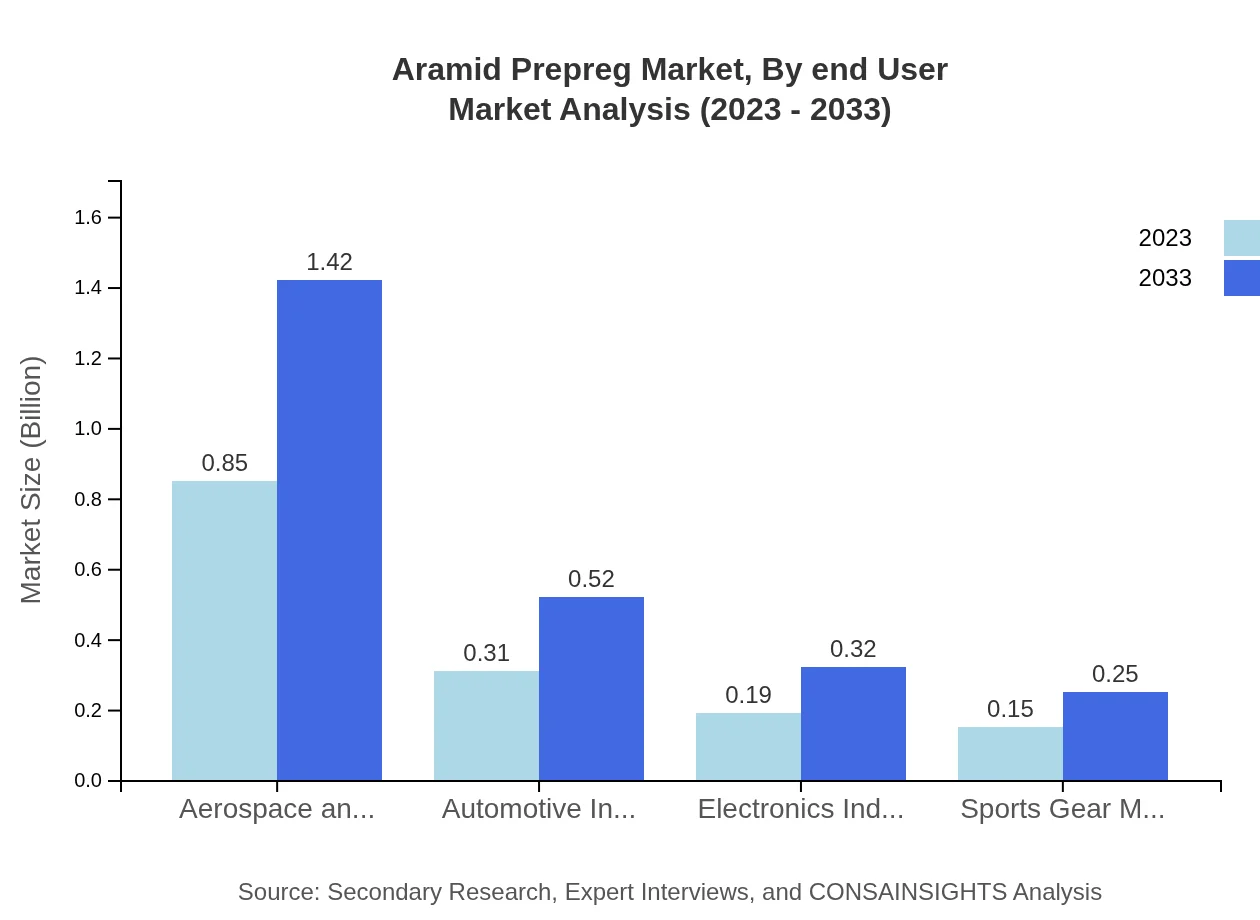

Aramid Prepreg Market Analysis By End User

Major end-user industries for Aramid Prepreg include aerospace & defense, automotive, electronics, and sports equipment manufacturing. Aerospace & defense captures 48.91% of the total market share in 2023, with consistent growth supported by the ongoing evolution of high-performance aircraft and military equipment.

Aramid Prepreg Market Analysis By Region Segment

Global Aramid-Prepreg Market, By Region Segment Market Analysis (2023 - 2033)

The regional analysis reveals North America as the dominant market, due to its mature aerospace sector, followed by Europe, where regulatory support and innovation accelerate growth. Asia Pacific is emerging rapidly, with technological advancements driving production and adoption.

Aramid Prepreg Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Aramid Prepreg Industry

DuPont:

A leading innovator in advanced materials, DuPont produces Kevlar, a well-known Aramid fiber used in various high-performance applications, including safety and military gear.Teijin Limited:

Teijin is recognized for its comprehensive range of Aramid fibers and related products, focusing on high-strength materials for automotive and industrial applications.Park Aerospace Corp.:

A prominent supplier of advanced composite materials, Park plays a crucial role in the aerospace sector, particularly with its Aramid Prepreg solutions designed for aerospace structures.Toray Industries:

Toray is a global leader in carbon fiber and advanced materials, offering enhancements in Aramid-based products for diverse applications, including electronics and automotive.We're grateful to work with incredible clients.

FAQs

What is the market size of aramid Prepreg?

The aramid prepreg market is projected to reach 1.5 billion USD by 2033, expanding at a CAGR of 5.2% from 2023. This growth highlights the rising demand for advanced composite materials across various industries.

What are the key market players or companies in this aramid Prepreg industry?

Key players in the aramid prepreg market include companies like Teijin Limited, DuPont, Hexcel Corporation, and Solvay. These companies are known for innovation and extensive product offerings in the aramid materials sector.

What are the primary factors driving the growth in the aramid Prepreg industry?

Growth in the aramid prepreg market is driven by increased demand in aerospace, automotive, and defense sectors. The material's superior properties such as lightweight, high strength, and resistance to heat make it essential in manufacturing processes.

Which region is the fastest Growing in the aramid Prepreg?

Asia Pacific is emerging as the fastest-growing region in the aramid prepreg market. The market is expected to grow from 0.29 billion USD in 2023 to 0.48 billion USD by 2033, indicating a strong compound annual growth rate.

Does ConsaInsights provide customized market report data for the aramid Prepreg industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the aramid prepreg industry, ensuring relevant insights and analysis that cater to individual business goals.

What deliverables can I expect from this aramid Prepreg market research project?

You can expect comprehensive reports, market forecasts, competitive analysis, and insights on market trends. Detailed deliverables will provide a clear understanding of growth opportunities in the aramid prepreg market.

What are the market trends of aramid Prepreg?

Current market trends include increasing adoption of aramid prepreg within aerospace and defense, with aerospace applications leading with a significant share of 56.42% in 2023, reflecting technological advancements and emphasis on performance.