Articulated Robots Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the global articulated robots market, including insights on market size, growth trends, and regional performance. It covers key segments and provides forecasts for the period from 2023 to 2033.

| Metric | Value |

|---|---|

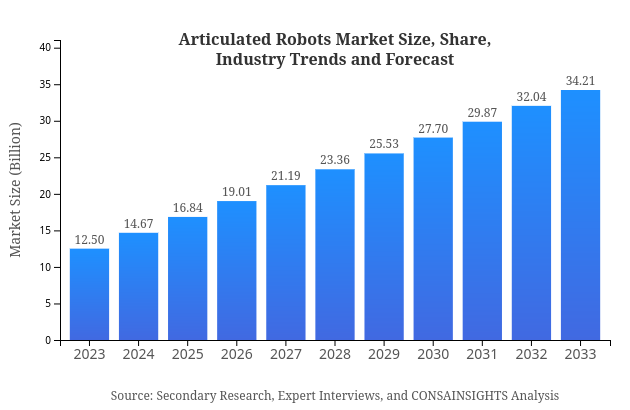

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 10.2% |

| 2033 Market Size | $34.21 Billion |

| Top Companies | ABB Robotics, KUKA AG, FANUC Corporation, Yaskawa Electric Corporation |

| Last Modified Date | 15 November 2024 |

Articulated Robots Market Overview

What is the Market Size & CAGR of Articulated Robots market in 2023?

Articulated Robots Industry Analysis

Articulated Robots Market Segmentation and Scope

Request a custom research report for industry.

Articulated Robots Market Analysis Report by Region

Europe Articulated Robots Market Report:

Europe’s market is anticipated to grow from $3.37 billion in 2023 to $9.22 billion in 2033. The region's strong emphasis on technological innovation and sustainability in manufacturing processes supports the increasing installation of articulated robots.Asia Pacific Articulated Robots Market Report:

In the Asia Pacific region, the articulated robots market is forecast to grow from $2.45 billion in 2023 to $6.70 billion in 2033, driven by increased industrialization and a shift towards automation in manufacturing sectors, particularly in countries like China and Japan.North America Articulated Robots Market Report:

North America remains the largest market, projected to expand from $4.69 billion in 2023 to $12.85 billion in 2033. The high adoption rate of automation technologies in manufacturing and the presence of major robotics companies contribute significantly to this growth.South America Articulated Robots Market Report:

The South American market is expected to grow from $0.60 billion in 2023 to $1.65 billion in 2033. Although slower than other regions, the demand for articulated robots is increasing in sectors such as food production and automotive manufacturing.Middle East & Africa Articulated Robots Market Report:

In the Middle East and Africa, the articulated robots market is expected to rise from $1.39 billion in 2023 to $3.80 billion in 2033. This growth will be fueled by an increase in infrastructural developments and the need for automation in various industries.Request a custom research report for industry.

Articulated Robots Market Analysis By Application

Global Articulated Robots Market, By Application Market Analysis (2024 - 2033)

The articulated robots market by application is segmented into welding, painting, assembly, and packaging. Welding dominates the application segment with a market share of around 50.14% in 2023, growing to 50.14% by 2033. Painting and assembly follow with significant shares in both years, reflecting their essential roles in manufacturing processes.

Articulated Robots Market Analysis By End User Industry

Global Articulated Robots Market, By End-User Industry Market Analysis (2024 - 2033)

Key end-user industries for articulated robots include manufacturing, healthcare, food and beverage, construction, and logistics. The manufacturing sector is the largest contributor with a 50.14% market share, followed by healthcare at 24.92%, highlighting the diverse applications of articulated robots across industries.

Articulated Robots Market Analysis By Configuration

Global Articulated Robots Market, By Configuration Market Analysis (2024 - 2033)

The configuration of articulated robots is crucial for their performance in various tasks. The market is largely dominated by 6-axis robots, which account for 67.89% of the market share in 2023, increasing to 67.89% by 2033, indicating their widespread usefulness in complex application areas.

Articulated Robots Market Analysis By Functionality

Global Articulated Robots Market, By Functionality Market Analysis (2024 - 2033)

Functionality in articulated robots is categorized into handling, welding, and assembly. Handling functionality holds the largest share due to its versatility in various operations, while welding robots are notable for their efficiency in precision tasks, maintaining a significant market presence.

Articulated Robots Market Analysis By Region

Global Articulated Robots Market, By Region Market Analysis (2024 - 2033)

The regional analysis indicates that North America leads in market size, followed by Europe and Asia-Pacific. Each region presents unique growth drivers, such as technological advancements in North America and rising industrial automation in Asia-Pacific.

Articulated Robots Market Trends and Future Forecast

Request a custom research report for industry.

Global Market Leaders and Top Companies in Articulated Robots Industry

ABB Robotics:

ABB is a global leader in industrial technology, providing advanced robotics solutions that enhance productivity and efficiency in manufacturing processes.KUKA AG:

KUKA AG specializes in robots and automation technology, offering a range of articulated robots designed for various industrial applications.FANUC Corporation:

FANUC is recognized for its innovation in manufacturing and automation technology, with a significant portfolio of articulated robots utilized in production lines worldwide.Yaskawa Electric Corporation:

Yaskawa is a key player in the robotics market, known for its smart and agile robotic solutions that cater to diverse industry needs.We're grateful to work with incredible clients.

Related Industries

FAQs

What is the market size of articulated robots?

The articulated robots market was valued at approximately $12.5 billion in 2023, with a projected CAGR of 10.2%. It is expected to witness significant growth, reaching substantial figures by 2033.

What are the key market players or companies in this articulated robots industry?

Key market players in the articulated robots industry include ABB, Fanuc Corporation, KUKA AG, Yaskawa Electric Corporation, and Mitsubishi Electric Corporation, which dominate the technological advancements and market share.

What are the primary factors driving the growth in the articulated robots industry?

Factors driving growth include increased automation in manufacturing, advancements in AI and robotics technologies, demand for efficiency and precision in production processes, and the rising need for safety in hazardous environments.

Which region is the fastest Growing in the articulated robots?

The Asia-Pacific region is the fastest-growing market for articulated robots, projected to grow from $2.45 billion in 2023 to $6.70 billion by 2033, benefiting from the rise of manufacturing hubs in countries like China and India.

Does ConsaInsights provide customized market report data for the articulated robots industry?

Yes, ConsaInsights provides customized market report data for the articulated robots industry, tailored to meet specific client needs and requirements, ensuring relevant insights and analysis.

What deliverables can I expect from this articulated robots market research project?

Deliverables include comprehensive market analysis reports, detailed insights on market trends, competitor landscape evaluation, forecasts, and strategic recommendations tailored for the articulated robots industry.

What are the market trends of articulated robots?

Current market trends in articulated robots include increasing adoption in automation, a shift towards collaborative robots, integration of AI technologies, and rising demand in sectors such as automotive, healthcare, and logistics.