Artificial Intelligence In Manufacturing Market Report

Published Date: 31 January 2026 | Report Code: artificial-intelligence-in-manufacturing

Artificial Intelligence In Manufacturing Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Artificial Intelligence in Manufacturing market, including market trends, regional insights, segmentation data, and future forecasts from 2023 to 2033.

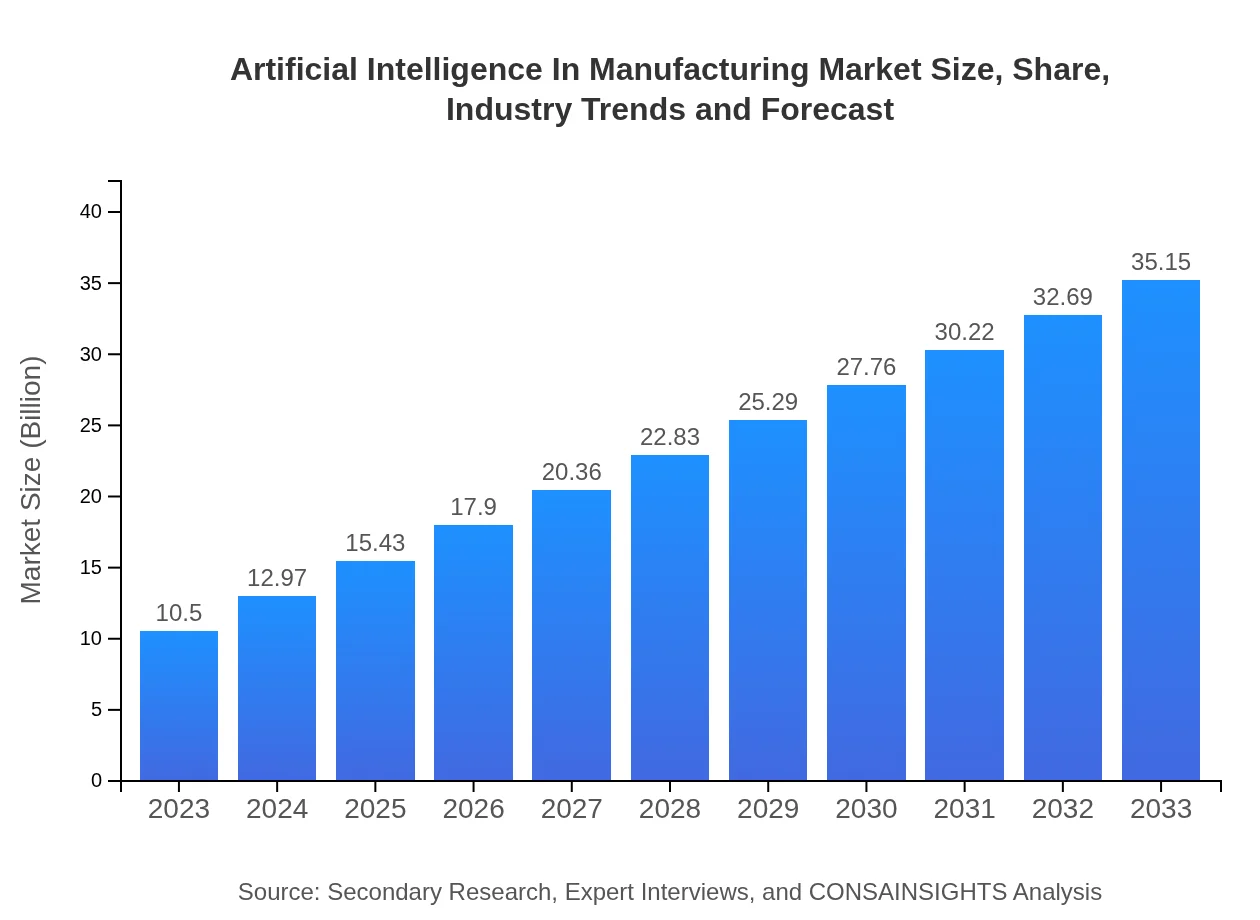

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 12.3% |

| 2033 Market Size | $35.15 Billion |

| Top Companies | Siemens AG, General Electric Company, IBM Corporation, Rockwell Automation, Honeywell International Inc. |

| Last Modified Date | 31 January 2026 |

Artificial Intelligence In Manufacturing Market Overview

Customize Artificial Intelligence In Manufacturing Market Report market research report

- ✔ Get in-depth analysis of Artificial Intelligence In Manufacturing market size, growth, and forecasts.

- ✔ Understand Artificial Intelligence In Manufacturing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Artificial Intelligence In Manufacturing

What is the Market Size & CAGR of Artificial Intelligence In Manufacturing market in 2023?

Artificial Intelligence In Manufacturing Industry Analysis

Artificial Intelligence In Manufacturing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Artificial Intelligence In Manufacturing Market Analysis Report by Region

Europe Artificial Intelligence In Manufacturing Market Report:

Europe is anticipated to grow from $3.00 billion in 2023 to $10.05 billion by 2033. With a strong focus on digital transformation and Industry 4.0 initiatives, countries like Germany, the UK, and France are significantly investing in AI for manufacturing enhancements.Asia Pacific Artificial Intelligence In Manufacturing Market Report:

In the Asia Pacific region, the Artificial Intelligence in Manufacturing market is projected to grow from $2.01 billion in 2023 to $6.75 billion by 2033, reflecting a significant CAGR. Key countries driving this growth include China, Japan, and India, where industries are rapidly adopting AI for automation and efficiency improvements.North America Artificial Intelligence In Manufacturing Market Report:

North America dominated the market with a value of $3.46 billion in 2023, expanding to $11.59 billion by 2033. The United States and Canada are leading due to the presence of established firms investing in AI technologies and smart factories.South America Artificial Intelligence In Manufacturing Market Report:

The South American market is expected to experience growth from $0.81 billion in 2023 to $2.70 billion by 2033. Brazil and Argentina are the primary players, focusing on integrating AI solutions to enhance the manufacturing processes amid a growing industrial sector.Middle East & Africa Artificial Intelligence In Manufacturing Market Report:

The Middle East and Africa market is estimated to move from $1.22 billion in 2023 to $4.07 billion by 2033. Nations are increasingly recognizing the potential of AI in manufacturing to fuel economic growth, especially in the UAE and South Africa.Tell us your focus area and get a customized research report.

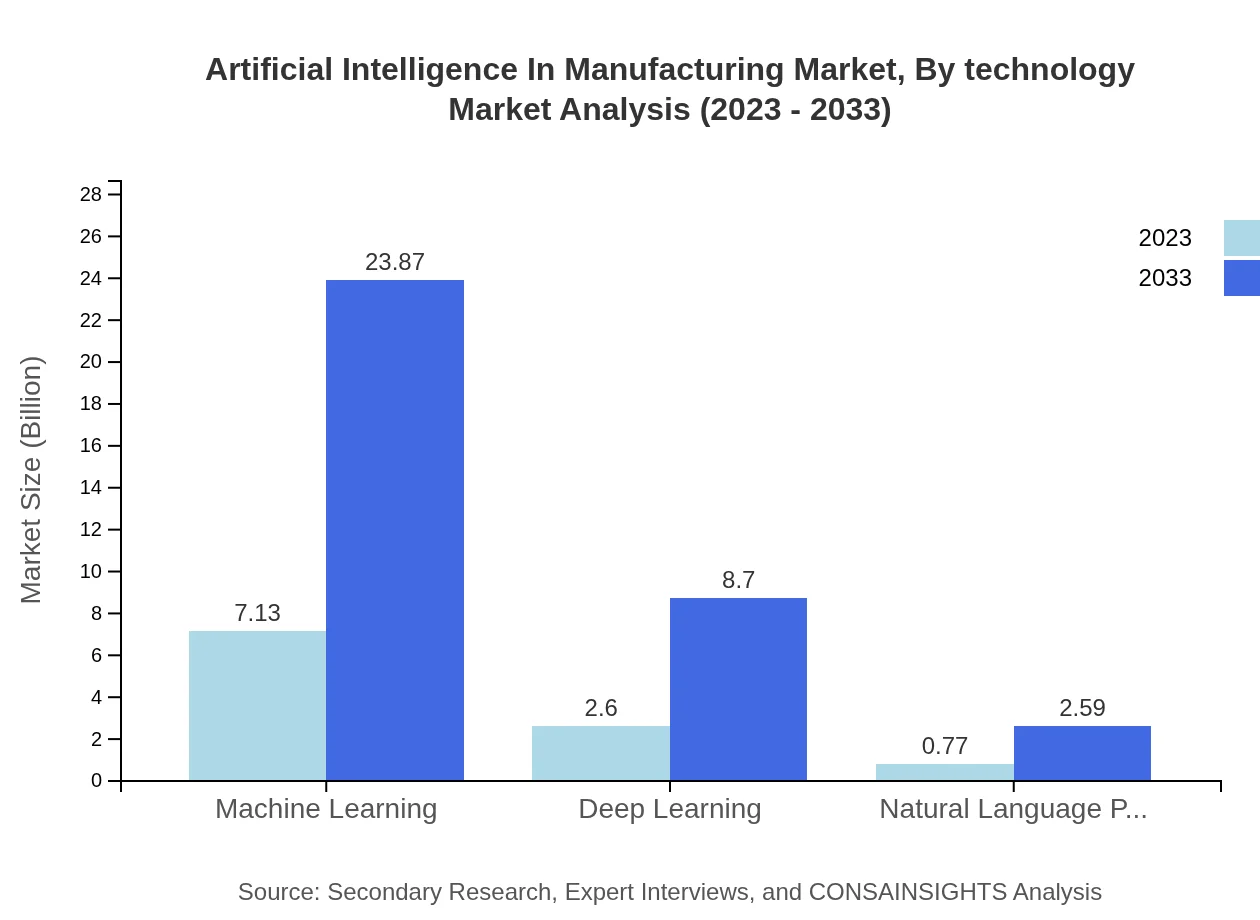

Artificial Intelligence In Manufacturing Market Analysis By Technology

The AI in Manufacturing market is heavily influenced by various technologies, particularly Machine Learning, Deep Learning, and Natural Language Processing. In 2023, Machine Learning holds the largest share, valued at approximately $7.13 billion, expected to grow significantly by 2033. Deep Learning and Natural Language Processing sectors are also expanding, critical for applications such as predictive maintenance and quality control.

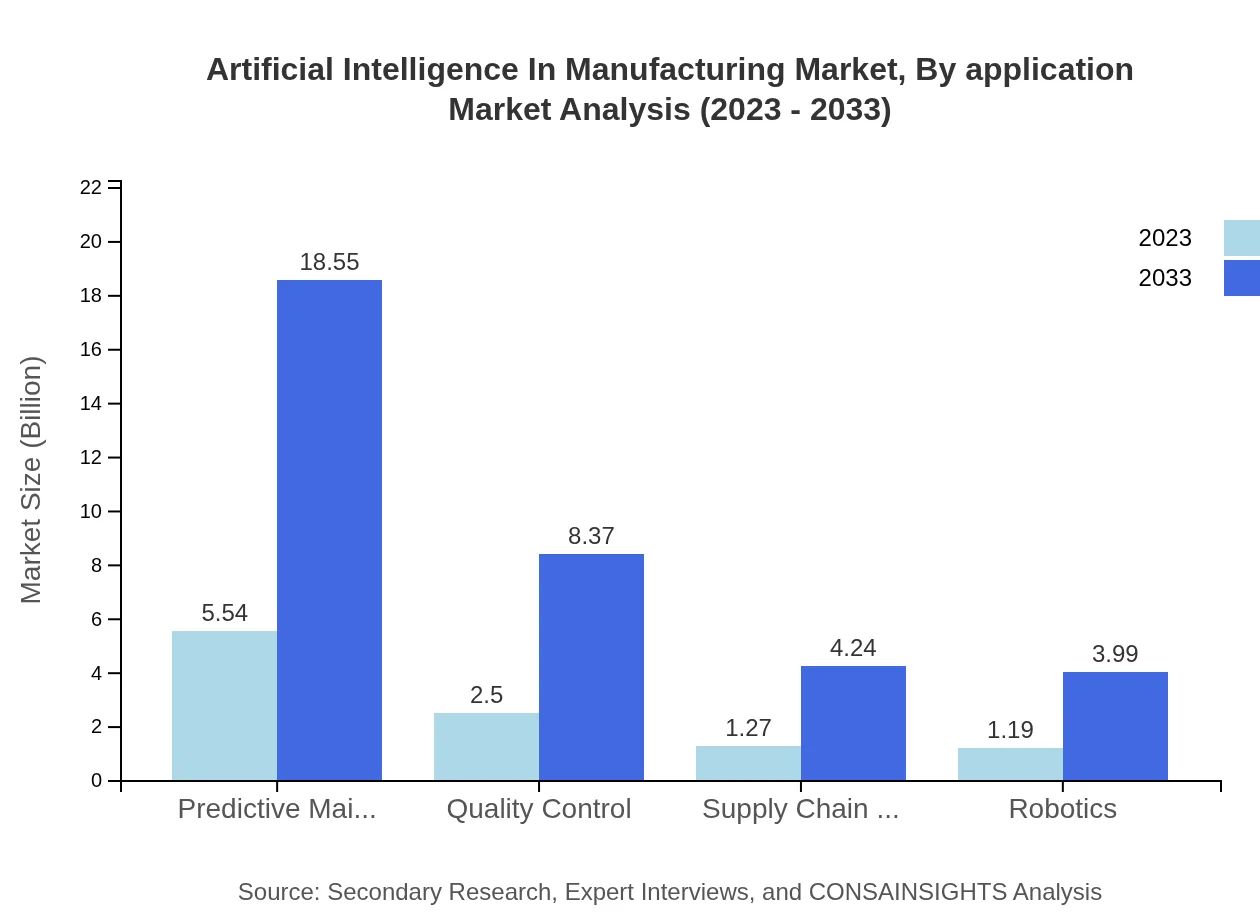

Artificial Intelligence In Manufacturing Market Analysis By Application

Applications such as Predictive Maintenance and Quality Control are driving the AI in Manufacturing market. Predictive Maintenance is expected to maintain dominance with a market size of $5.54 billion in 2023 and projected to reach $18.55 billion by 2033. Similarly, Quality Control remains crucial in ensuring product standards, contributing significantly to the market's growth.

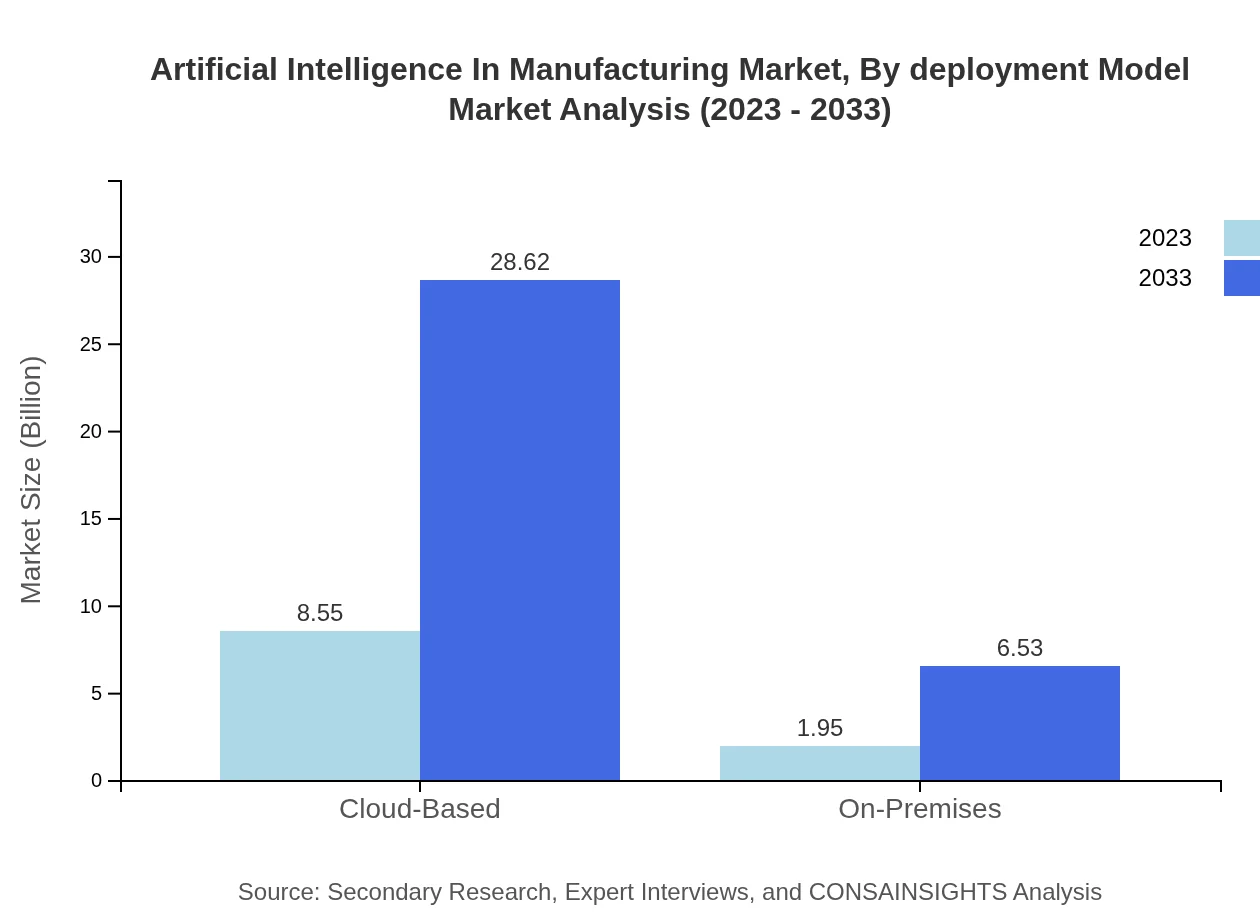

Artificial Intelligence In Manufacturing Market Analysis By Deployment Model

The AI in Manufacturing market can be segmented by deployment models: Cloud-Based and On-Premises solutions. Cloud-Based solutions dominate with a market size of $8.55 billion in 2023 and expected to rise to $28.62 billion by 2033. Conversely, On-Premises solutions, valued at $1.95 billion in 2023, are progressively finding niches within companies requiring strict data governance.

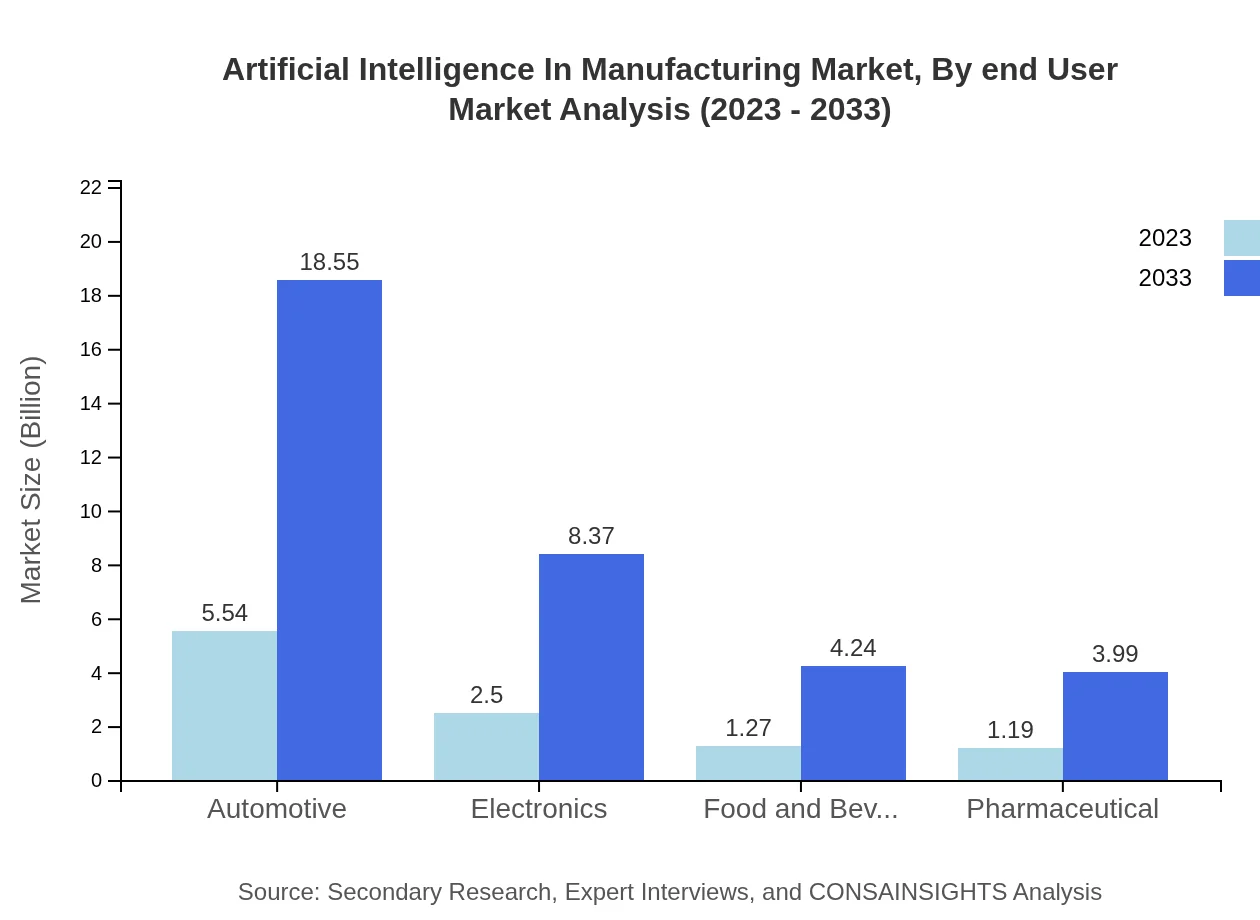

Artificial Intelligence In Manufacturing Market Analysis By End User

The automotive sector remains the largest end-user of AI in Manufacturing, with a 2023 market size of $5.54 billion, representing 52.76% of the market share. Other significant sectors include Electronics and Food and Beverages, focusing on integrating AI to enhance production efficiency and quality.

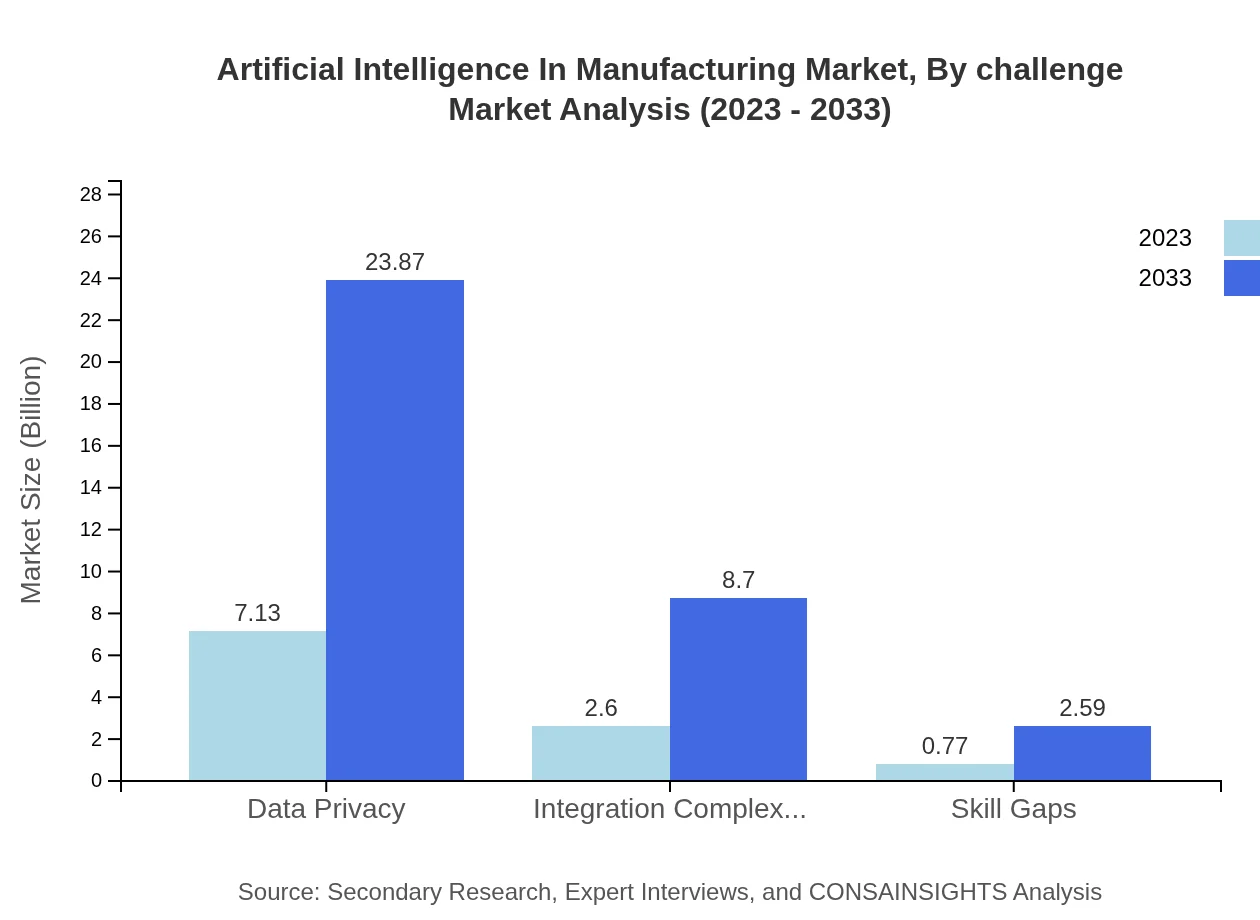

Artificial Intelligence In Manufacturing Market Analysis By Challenge

Challenges in the AI in Manufacturing market include Integration Complexities and Skill Gaps. Integration Complexities, with a market size of $2.60 billion in 2023, and Skill Gaps at $0.77 billion, pose significant hurdles often derailing AI adoption efforts.

Artificial Intelligence In Manufacturing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Artificial Intelligence In Manufacturing Industry

Siemens AG:

Leading provider of industrial automation and digitalization technology, heavily investing in AI to streamline manufacturing processes.General Electric Company:

Pioneering industrial AI solutions, particularly in predictive maintenance and operations efficiency across diverse manufacturing sectors.IBM Corporation:

Integrating AI and cognitive computing into manufacturing to enhance data analytics and improve operational outcomes.Rockwell Automation:

Focused on automation and information integration, delivering AI solutions that enhance productivity in manufacturing.Honeywell International Inc.:

Renowned for advanced AI technologies aimed at improving operational safety and efficiency in manufacturing environments.We're grateful to work with incredible clients.

FAQs

What is the market size of artificial Intelligence In Manufacturing?

The artificial intelligence in manufacturing market is projected to grow from $10.5 billion in 2023, with a robust CAGR of 12.3%, reaching an estimated size of $33.2 billion by 2033, driven by widespread AI adoption.

What are the key market players or companies in this artificial Intelligence In Manufacturing industry?

Key players include Siemens AG, IBM Corporation, General Electric, Rockwell Automation, and SAP. These companies lead in innovating AI solutions that enhance manufacturing efficiency and productivity, thereby capturing significant market share.

What are the primary factors driving the growth in the artificial intelligence in manufacturing industry?

Growth factors include increasing automation demands, advancements in AI technologies, need for operational efficiency, enhanced data analytics capabilities, and industry 4.0 initiatives focusing on smart manufacturing and predictive maintenance.

Which region is the fastest Growing in the artificial intelligence in manufacturing?

The North America region is the fastest-growing, expected to expand from $3.46 billion in 2023 to $11.59 billion by 2033. Europe and Asia-Pacific are also seeing substantial growth, driven by technological investments and manufacturing modernization.

Does ConsaInsights provide customized market report data for the artificial intelligence in manufacturing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the artificial intelligence in manufacturing industry, allowing businesses to gain insights relevant to their strategic goals and market positioning.

What deliverables can I expect from this artificial intelligence in manufacturing market research project?

Expect comprehensive reports that include market analysis, competitive landscape assessments, segment insights, regional market evaluations, and future growth forecasts tailored to meet your specific business requirements and strategic objectives.

What are the market trends of artificial intelligence in manufacturing?

Current trends include a shift towards predictive maintenance solutions, increased adoption of cloud-based AI technologies, and enhanced integration of machine learning and robotics in manufacturing processes, all aimed at optimizing production efficiency.