Autoclaved Aerated Concrete Market Report

Published Date: 22 January 2026 | Report Code: autoclaved-aerated-concrete

Autoclaved Aerated Concrete Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report explores the Autoclaved Aerated Concrete (AAC) market from 2023 to 2033. It delivers insights into market size, growth forecasts, regional analysis, and emerging trends, providing stakeholders with valuable data for strategic planning.

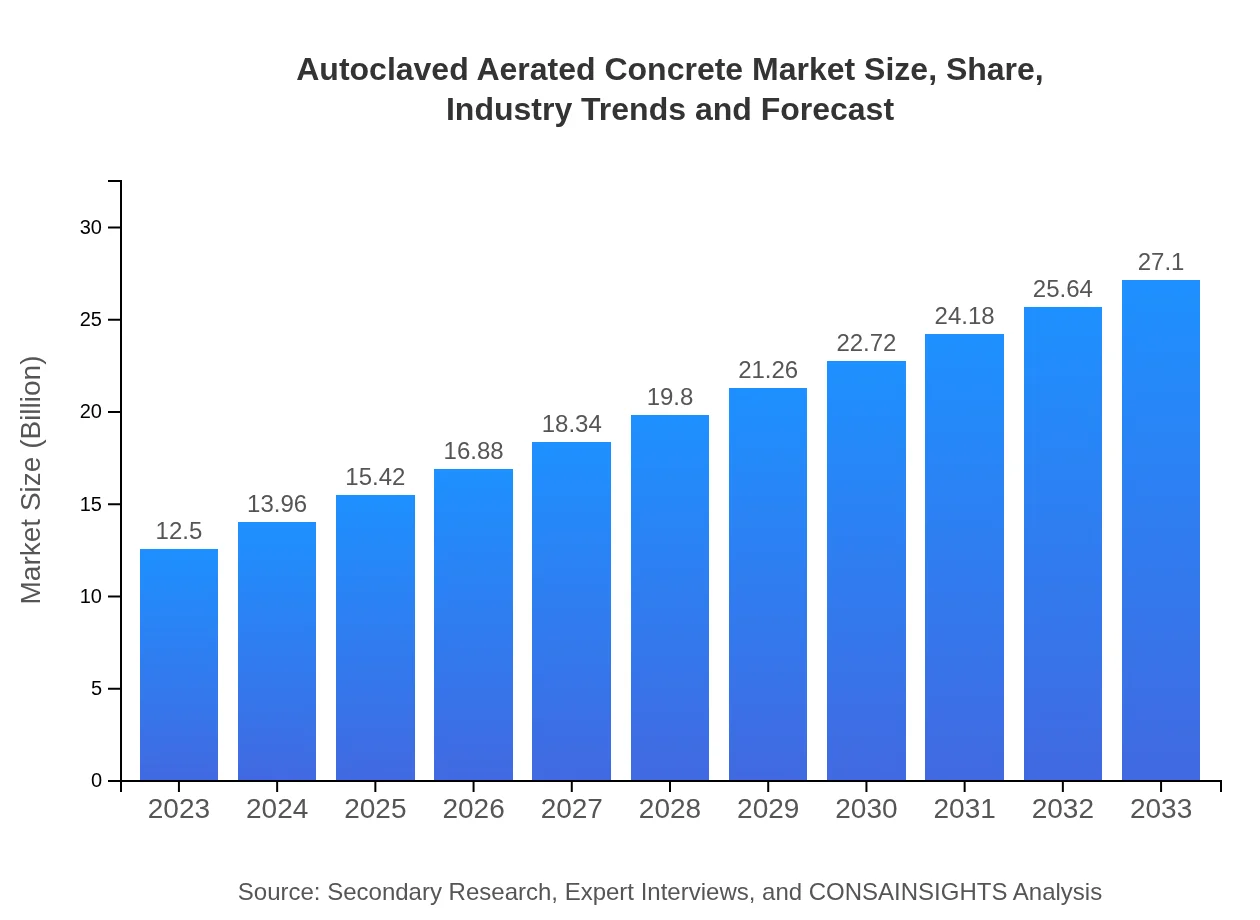

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $27.10 Billion |

| Top Companies | Xella International, H+H International A/S, Aercon AAC, Hebel |

| Last Modified Date | 22 January 2026 |

Autoclaved Aerated Concrete Market Overview

Customize Autoclaved Aerated Concrete Market Report market research report

- ✔ Get in-depth analysis of Autoclaved Aerated Concrete market size, growth, and forecasts.

- ✔ Understand Autoclaved Aerated Concrete's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Autoclaved Aerated Concrete

What is the Market Size & CAGR of Autoclaved Aerated Concrete market in 2033?

Autoclaved Aerated Concrete Industry Analysis

Autoclaved Aerated Concrete Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Autoclaved Aerated Concrete Market Analysis Report by Region

Europe Autoclaved Aerated Concrete Market Report:

Europe's AAC market is currently valued at $3.57 billion and is expected to nearly double to $7.73 billion by 2033. Strong regulatory policies favoring green building materials significantly contribute to this growth.Asia Pacific Autoclaved Aerated Concrete Market Report:

In 2023, the AAC market in Asia Pacific is valued at approximately $2.61 billion, projected to grow to $5.65 billion by 2033, driven by rapid urbanization and infrastructure development. Countries like China and India are leading players promoting AAC usage.North America Autoclaved Aerated Concrete Market Report:

The North American market reached $4.40 billion in 2023 while it is forecasted to grow to $9.54 billion by 2033. The emphasis on sustainable construction practices and energy-efficient materials are critical growth drivers.South America Autoclaved Aerated Concrete Market Report:

The South American market is valued at around $1.10 billion in 2023 and is expected to expand to $2.39 billion by 2033. Increasing adoption of eco-friendly materials and ongoing construction projects fuel this growth.Middle East & Africa Autoclaved Aerated Concrete Market Report:

The Middle East and Africa market, currently valued at $0.82 billion, is projected to grow to $1.78 billion by 2033. Infrastructure projects and the push for energy-efficient housing enhance AAC acceptance.Tell us your focus area and get a customized research report.

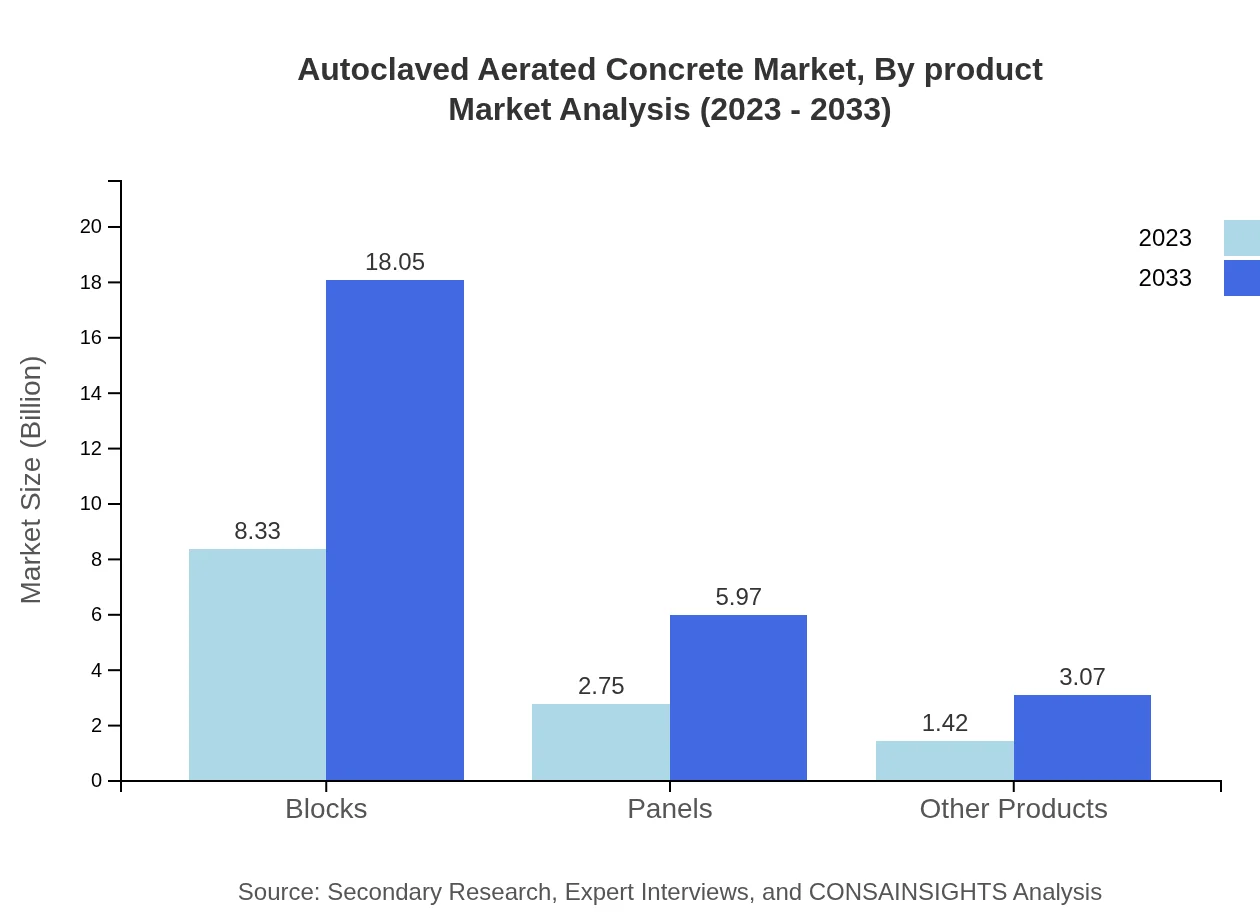

Autoclaved Aerated Concrete Market Analysis By Product

The AAC market, segmented by product type, is dominated by blocks, which are expected to grow from $8.33 billion in 2023 to $18.05 billion by 2033, maintaining a market share of 66.62%. Panels are anticipated to expand from $2.75 billion in 2023 to $5.97 billion by 2033, representing a 22.04% share. Other products will see growth from $1.42 billion to $3.07 billion, retaining an 11.34% share.

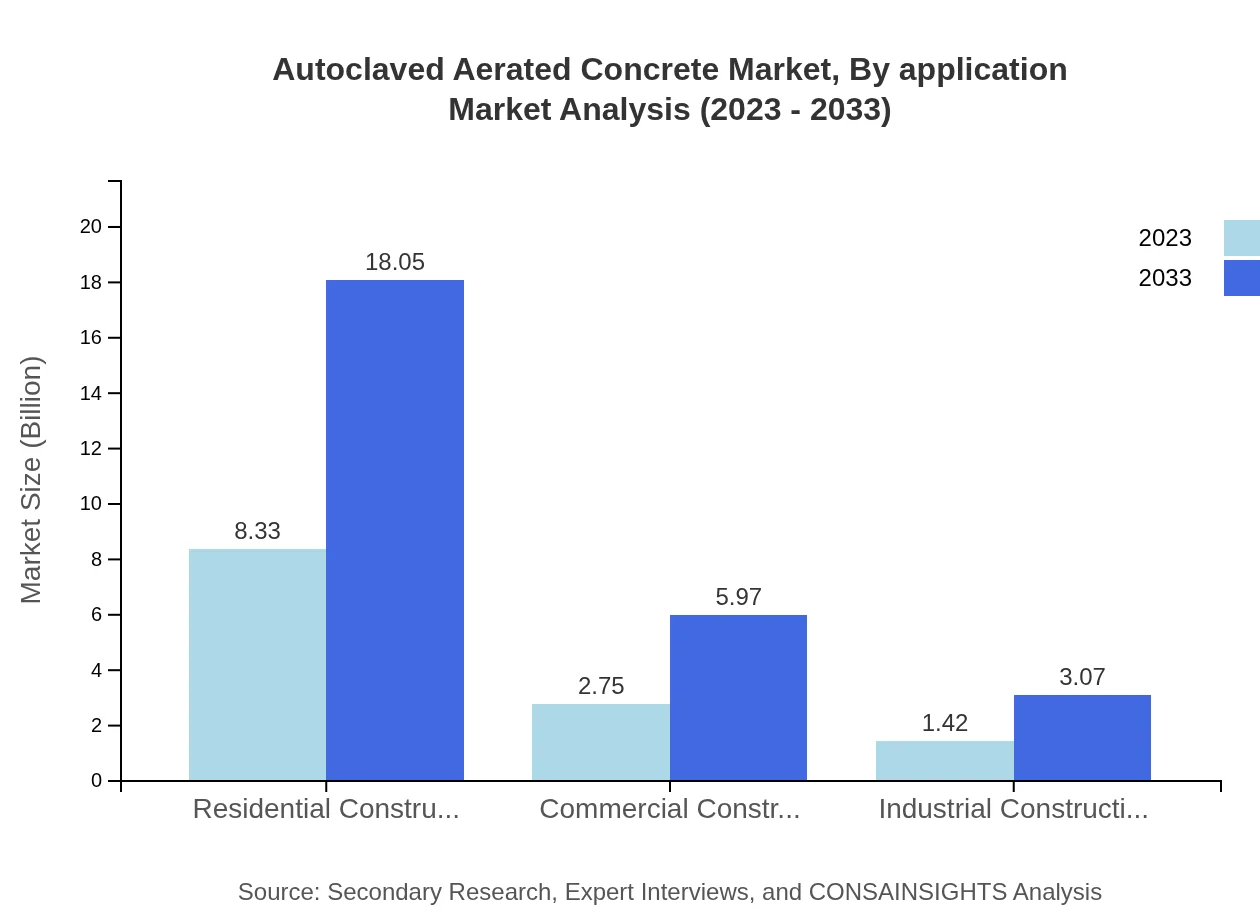

Autoclaved Aerated Concrete Market Analysis By Application

In terms of application, the AAC market for residential construction is projected to grow from $8.33 billion in 2023 to $18.05 billion by 2033, accounting for 66.62% of the market. Commercial construction is expected to increase from $2.75 billion to $5.97 billion, holding a 22.04% share, while industrial construction is anticipated to grow from $1.42 billion to $3.07 billion, representing 11.34% of the market.

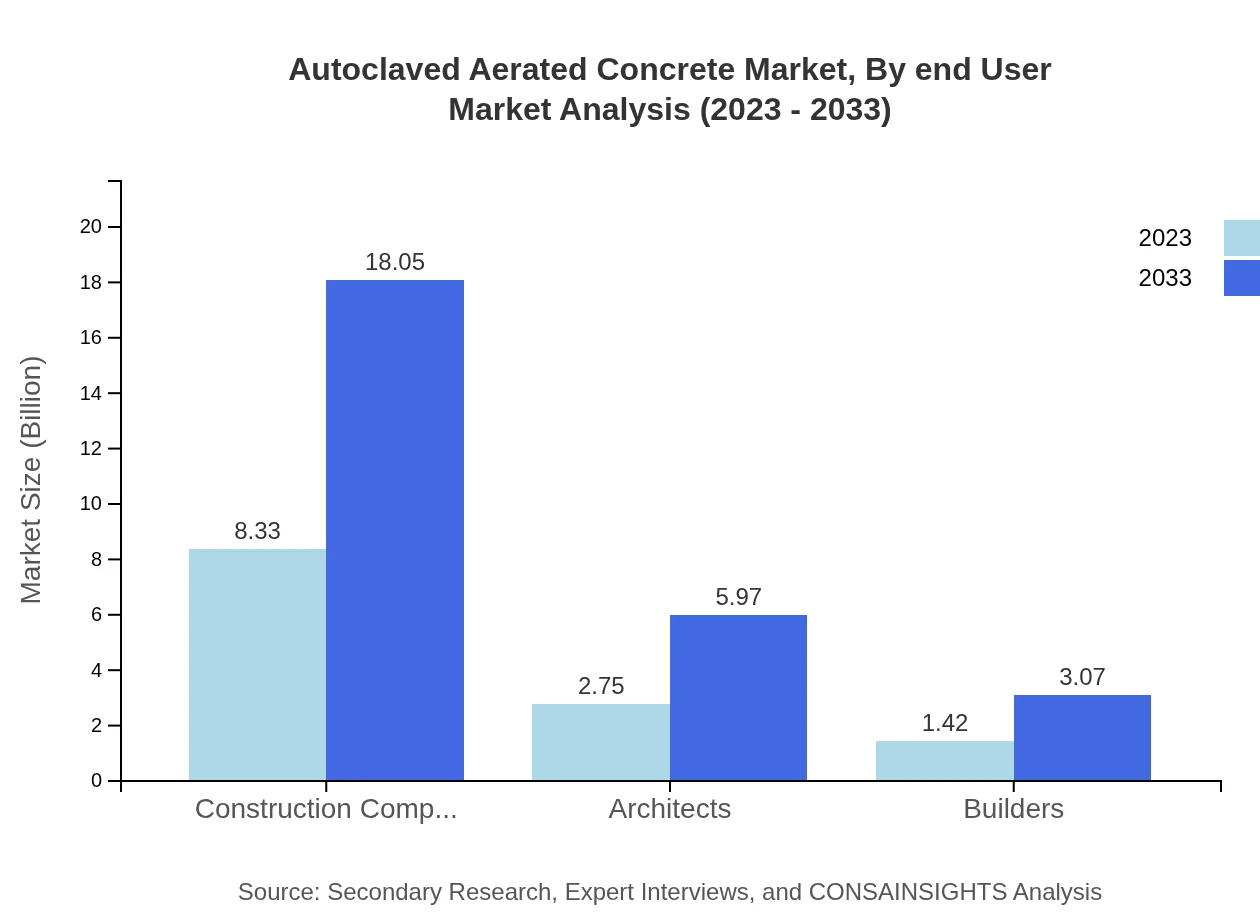

Autoclaved Aerated Concrete Market Analysis By End User

The market, viewed through the lens of end-users, reveals that construction companies dominate, growing from approximately $8.33 billion to $18.05 billion, maintaining 66.62% of the share. Architects will see their segment move from $2.75 billion to $5.97 billion (22.04% share), while builders will experience a rise from $1.42 billion to $3.07 billion, retaining an 11.34% stake.

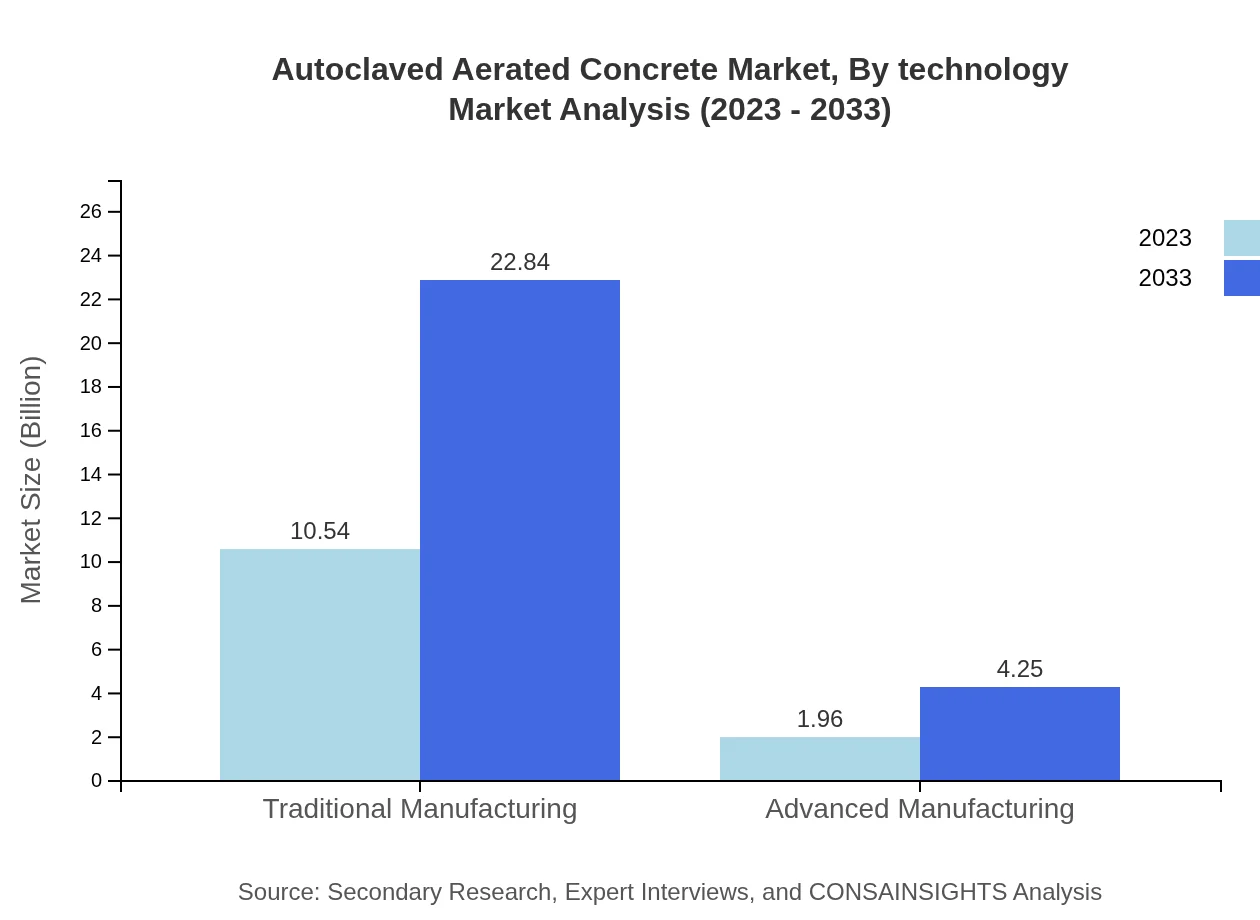

Autoclaved Aerated Concrete Market Analysis By Technology

The AAC technological landscape is bifurcated into traditional and advanced manufacturing technologies, where traditional methods command a significant share with a size of $10.54 billion in 2023, projected to reach $22.84 billion in 2033 (84.3% share). Advanced technologies, while smaller, will grow from $1.96 billion to $4.25 billion, maintaining a 15.7% share.

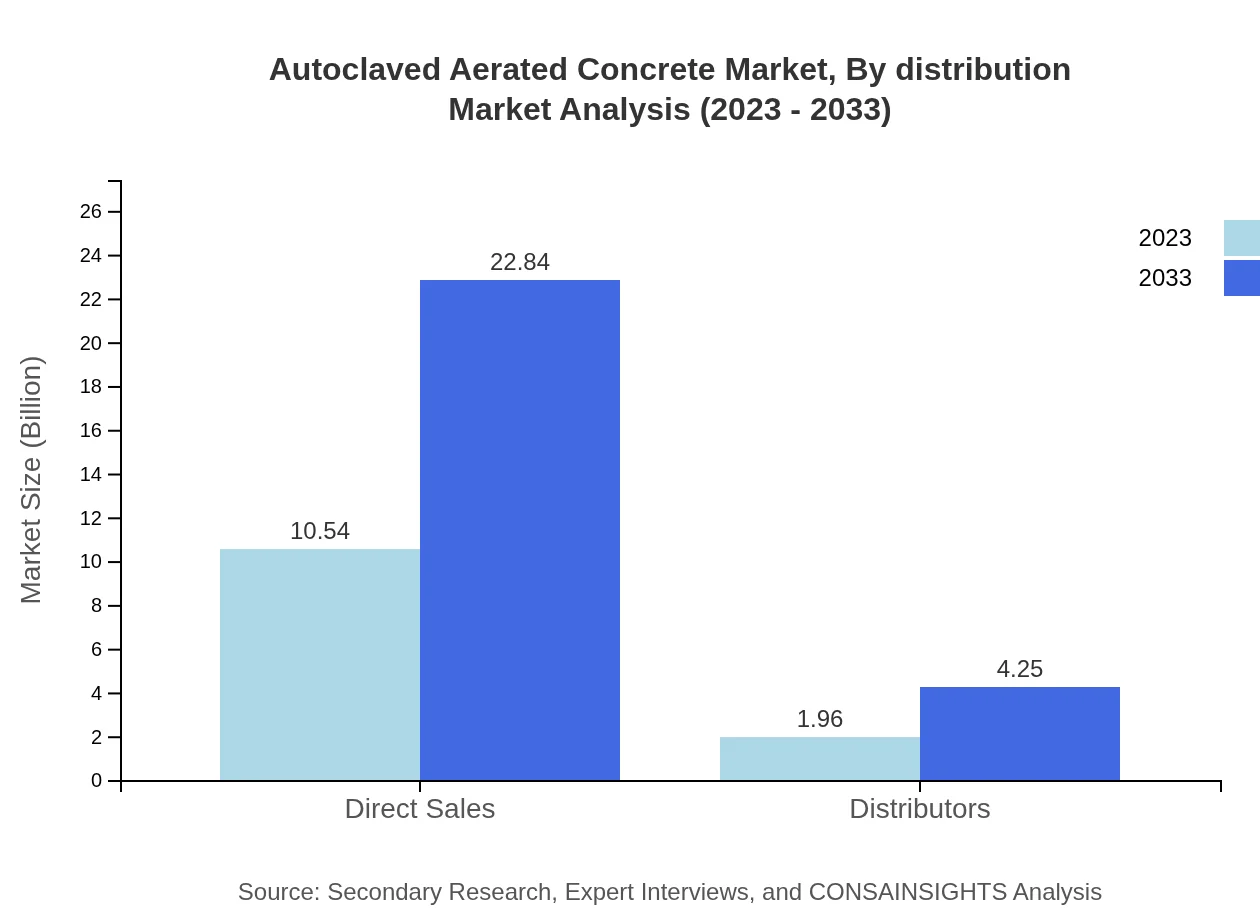

Autoclaved Aerated Concrete Market Analysis By Distribution

Distribution channels for AAC are markedly split between direct sales and distributors, with direct sales currently at $10.54 billion, moving to $22.84 billion (84.3% share), while the distribution segment is poised for growth from $1.96 billion to $4.25 billion, holding a 15.7% share.

Autoclaved Aerated Concrete Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Autoclaved Aerated Concrete Industry

Xella International:

Xella is one of the leading manufacturers of AAC and holds a strong market presence across Europe, known for its commitment to sustainability and high-quality AAC products.H+H International A/S:

H+H International is renowned for its innovative AAC solutions and has a robust distribution network across Europe and Asia, focusing on eco-friendly building materials.Aercon AAC:

Aercon AAC is a prominent player in the North American region, specializing in the production of AAC products tailored for commercial and residential applications.Hebel:

Hebel, a subsidiary of the CSR Limited group, is a leading manufacturer in Australia, recognized for its efficient manufacturing processes and high-performance AAC construction materials.We're grateful to work with incredible clients.

FAQs

What is the market size of autoclaved Aerated Concrete?

The global autoclaved aerated concrete (AAC) market is valued at approximately USD 12.5 billion in 2023 and is anticipated to grow at a CAGR of 7.8% over the next decade, projecting notable market expansion by 2033.

What are the key market players or companies in this autoclaved Aerated Concrete industry?

Key players in the AAC industry include strategic manufacturers and suppliers such as Xella International, AeroAggregates, and H+H International, which influence market dynamics through innovation and competitive strategies.

What are the primary factors driving the growth in the autoclaved Aerated Concrete industry?

Growing demand for eco-friendly building materials, urbanization, and increased construction activities globally drive the AAC market growth. Additionally, the benefits of AAC, such as lightweight and insulation properties, further enhance its popularity.

Which region is the fastest Growing in the autoclaved Aerated Concrete market?

The fastest-growing region in the AAC market is North America, which is expected to increase its market size from USD 4.40 billion in 2023 to USD 9.54 billion by 2033, highlighting significant growth prospects.

Does ConsaInsights provide customized market report data for the autoclaved Aerated Concrete industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the autoclaved-aerated concrete industry, providing insights and forecasts based on unique business parameters and market conditions.

What deliverables can I expect from this autoclaved Aerated Concrete market research project?

Deliverables from this market research project typically include comprehensive market analysis reports, segmented data insights, and growth forecasts, along with strategic recommendations tailored to industry-specific needs.

What are the market trends of autoclaved Aerated Concrete?

Trends in the AAC market include increased usage in residential and commercial sectors, innovation in manufacturing processes, and a focus on sustainability and energy efficiency in construction practices.