Automated-3d Printing Market Report

Published Date: 22 January 2026 | Report Code: automated-3d-printing

Automated-3d Printing Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Automated-3D Printing market from 2023 to 2033, highlighting market dynamics, size, growth rates, regional insights, and future forecasts to provide valuable insights for stakeholders in this innovative industry.

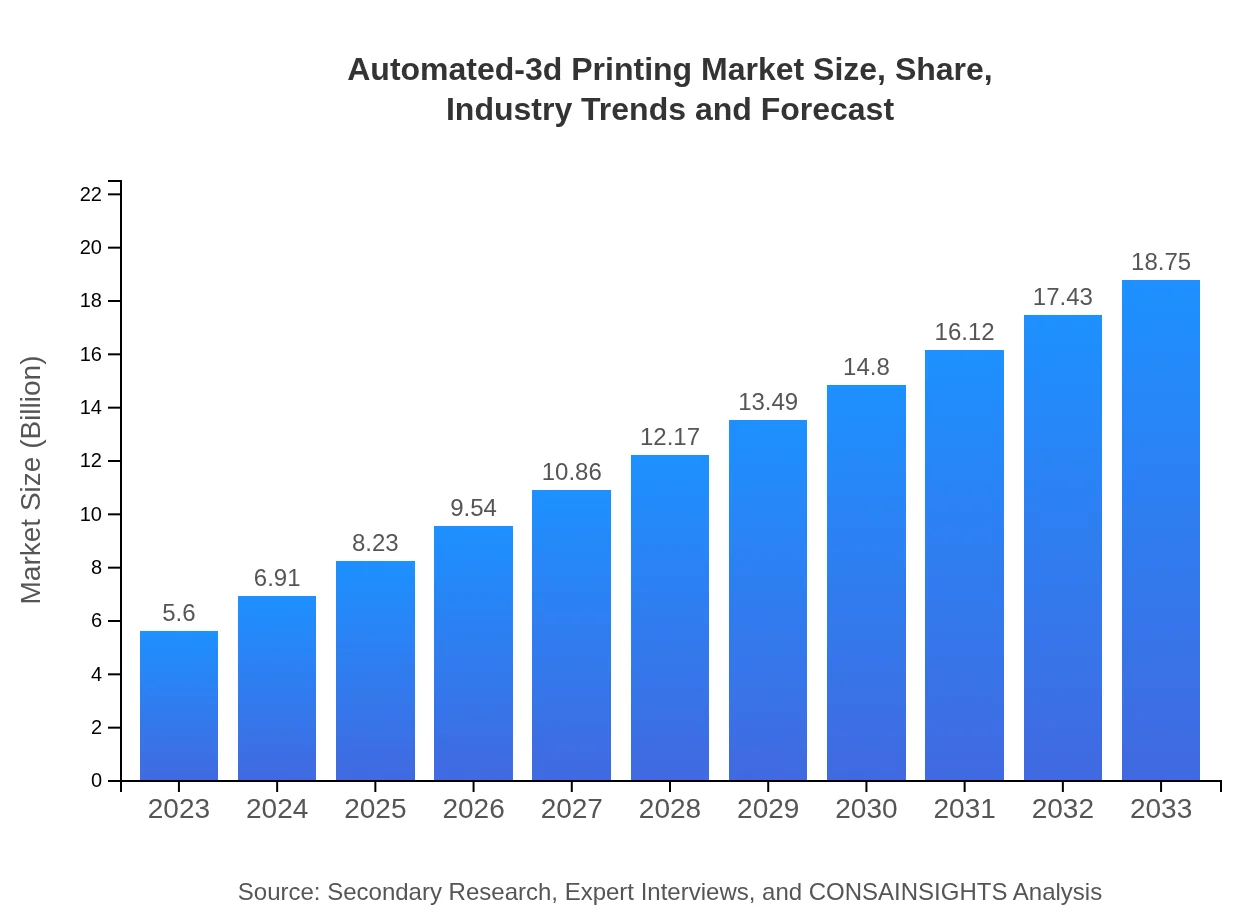

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 12.3% |

| 2033 Market Size | $18.75 Billion |

| Top Companies | Stratasys Ltd., 3D Systems Corporation, HP Inc., EOS GmbH, Materialise NV |

| Last Modified Date | 22 January 2026 |

Automated-3D Printing Market Overview

Customize Automated-3d Printing Market Report market research report

- ✔ Get in-depth analysis of Automated-3d Printing market size, growth, and forecasts.

- ✔ Understand Automated-3d Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automated-3d Printing

What is the Market Size & CAGR of Automated-3D Printing market in 2023?

Automated-3D Printing Industry Analysis

Automated-3D Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automated-3D Printing Market Analysis Report by Region

Europe Automated-3d Printing Market Report:

Europe's Automated-3D Printing market is forecasted to grow from $1.97 billion in 2023 to $6.58 billion by 2033. The adoption of 3D printing in aerospace and automotive industries, along with stringent regulations promoting innovation, supports this growth.Asia Pacific Automated-3d Printing Market Report:

In the Asia Pacific region, the Automated-3D Printing market is projected to grow from $0.91 billion in 2023 to $3.05 billion by 2033. The region's growth is fueled by rapid industrialization, particularly in China and India, as well as increasing investments in technology start-ups focusing on 3D printing applications.North America Automated-3d Printing Market Report:

North America is one of the largest markets for Automated-3D Printing, with revenue expected to grow from $1.95 billion in 2023 to $6.52 billion by 2033. The presence of large manufacturing firms and technological advancements significantly contribute to this growth trajectory.South America Automated-3d Printing Market Report:

The South American market is anticipated to rise from $0.53 billion in 2023 to $1.76 billion by 2033. With increasing awareness of 3D printing benefits, industries such as automotive and healthcare are beginning to adopt these technologies, paving the way for future market expansion.Middle East & Africa Automated-3d Printing Market Report:

In the Middle East and Africa, the market is expected to increase from $0.25 billion in 2023 to $0.83 billion by 2033. The region is gradually recognizing the potential of Automated-3D Printing across various sectors, including manufacturing and education.Tell us your focus area and get a customized research report.

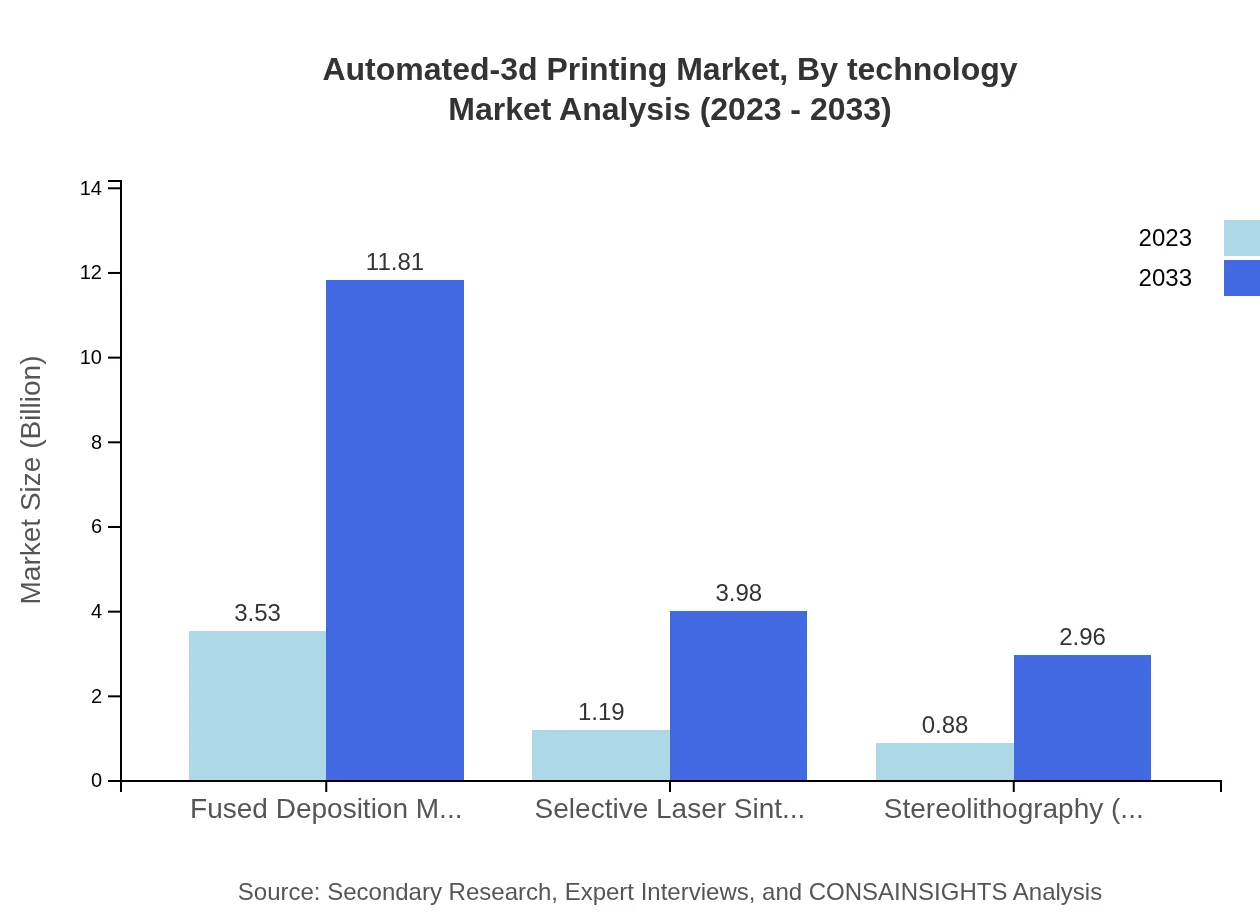

Automated-3d Printing Market Analysis By Technology

The technology segment is vast, with key methods like Fused Deposition Modeling (FDM) dominating the market due to its accessibility and cost-effectiveness, comprising 62.98% market share in 2023. Selective Laser Sintering (SLS) and Stereolithography (SLA) also hold significant shares, at 21.23% and 15.79% respectively.

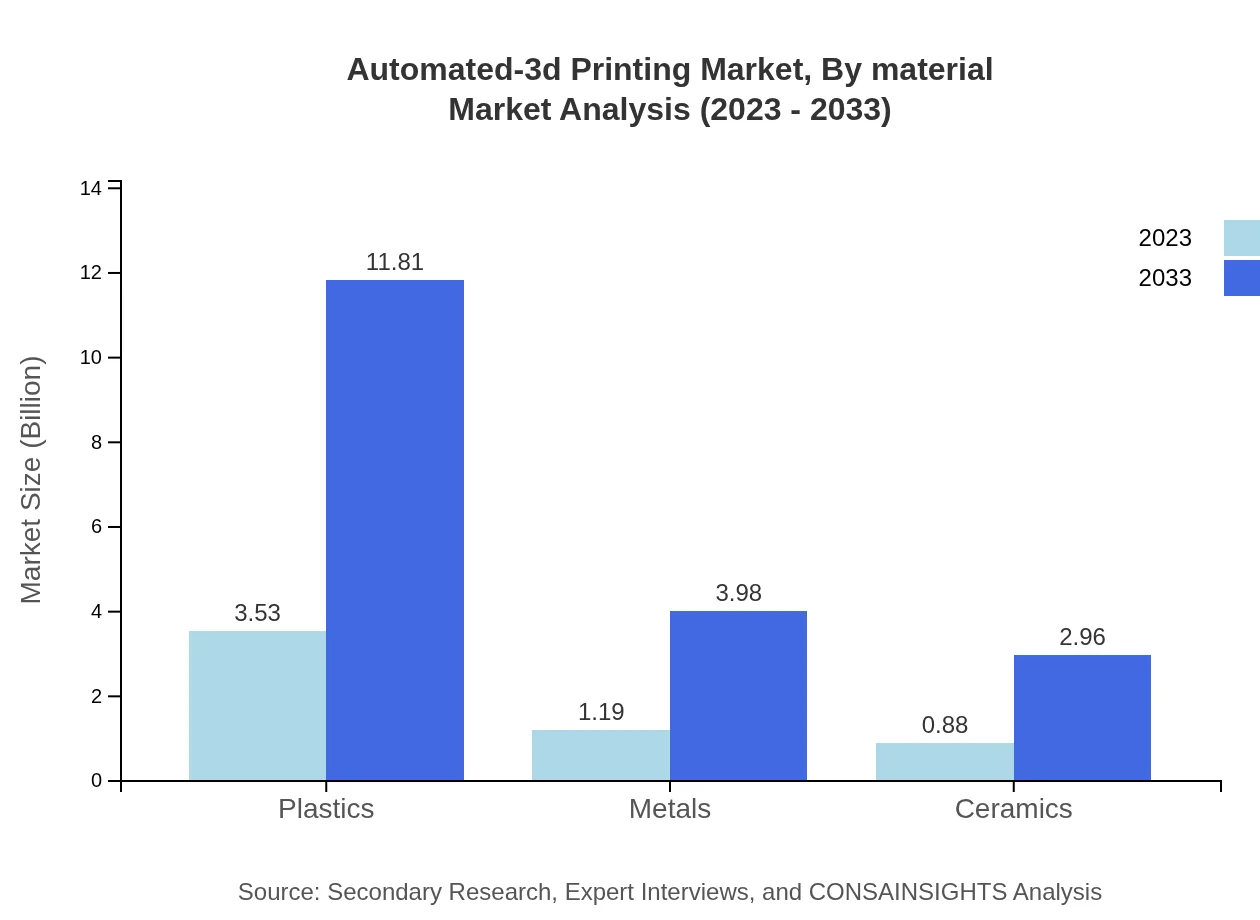

Automated-3d Printing Market Analysis By Material

Plastics lead the segment, capturing 62.98% of the market share in 2023, followed by metals and ceramics, which constitute 21.23% and 15.79% respectively. This indicates a robust demand for plastic-based products across various applications.

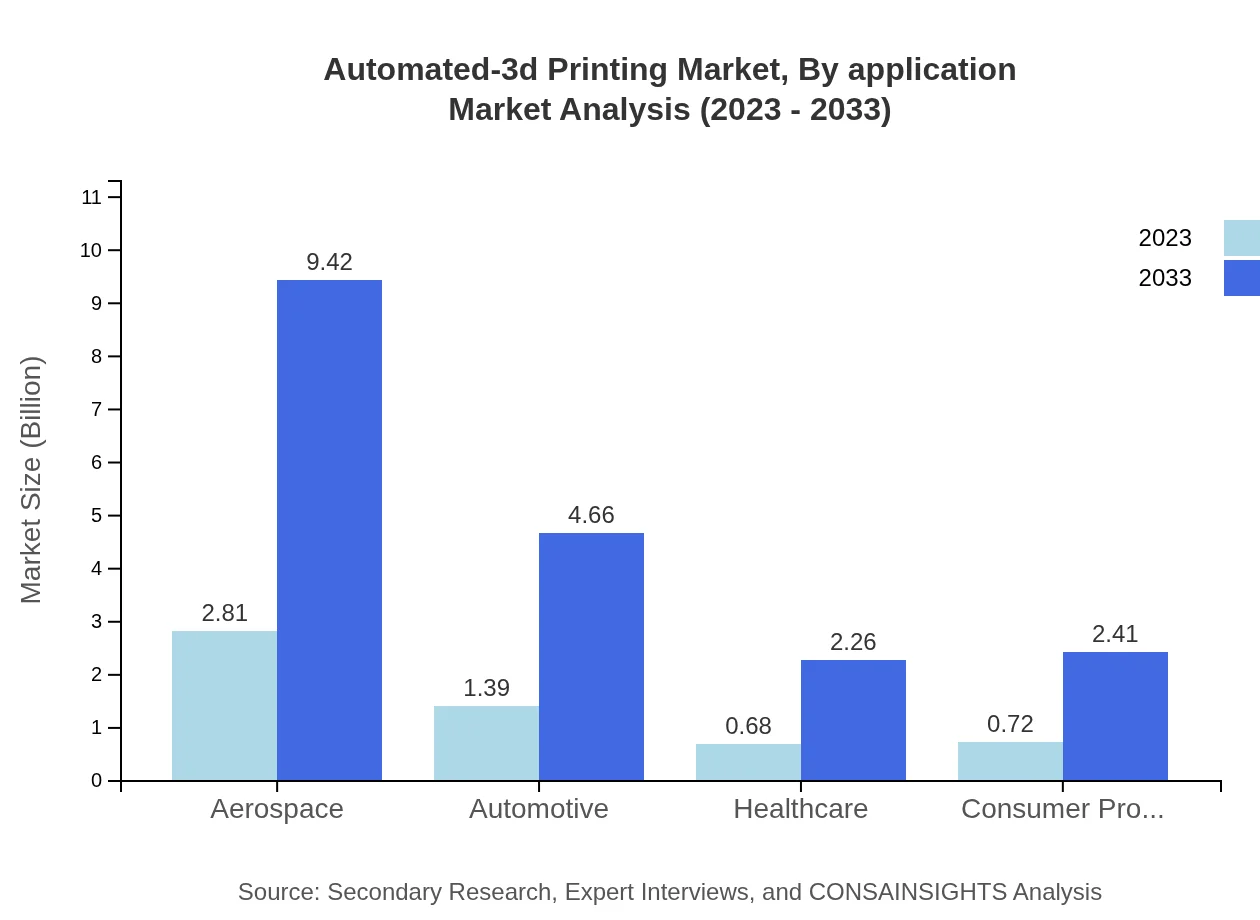

Automated-3d Printing Market Analysis By Application

Key applications include aerospace, automotive, healthcare, consumer products, industrial manufacturing, and education. The aerospace segment holds the largest share at 50.26% in 2023, benefiting from lightweight and complex structures that 3D printing facilitates.

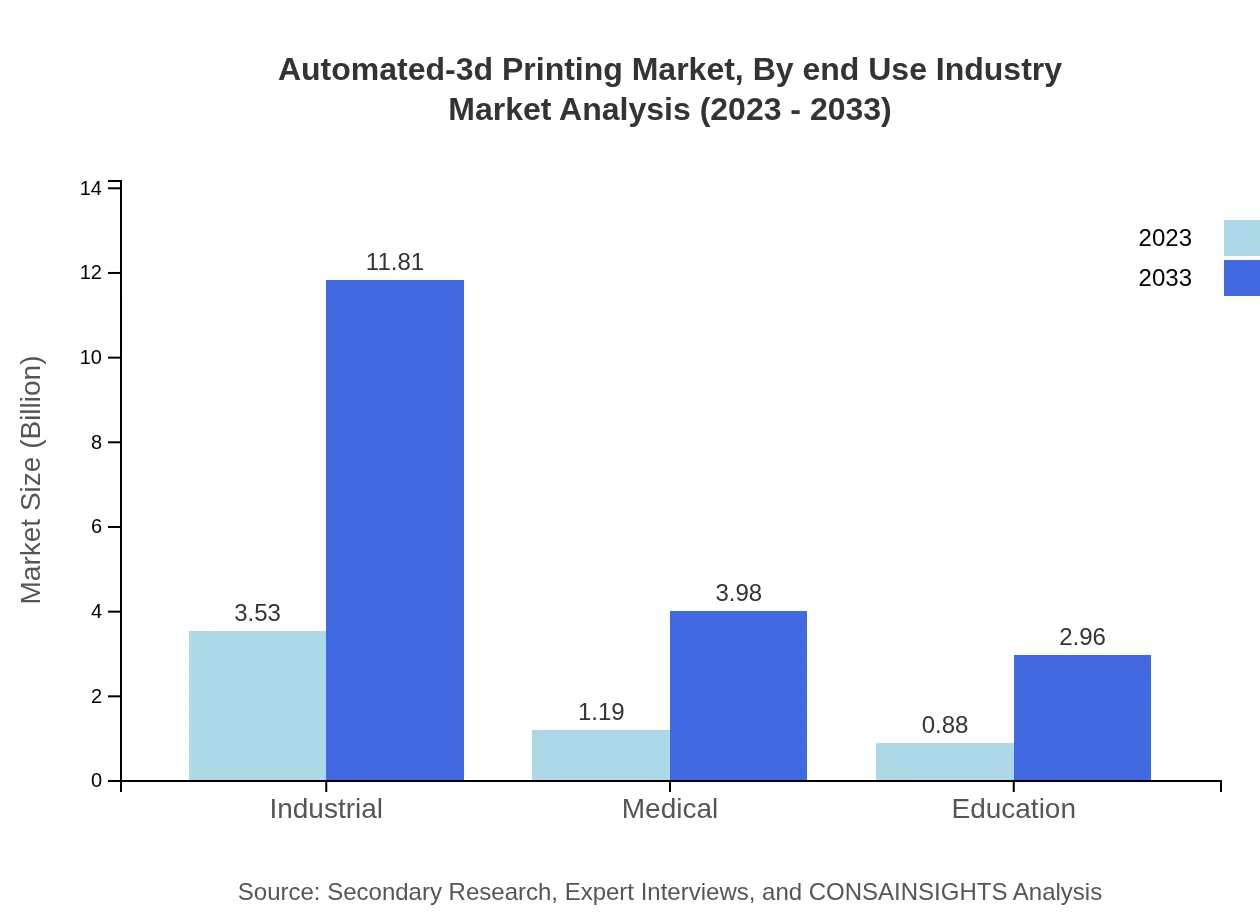

Automated-3d Printing Market Analysis By End Use Industry

The automotive and industrial sectors are substantial consumers of automated 3D printing technologies, with shares of 24.84% and 62.98% respectively. As industries seek to innovate and reduce time-to-market, the demand for 3D printing solutions is expected to rise.

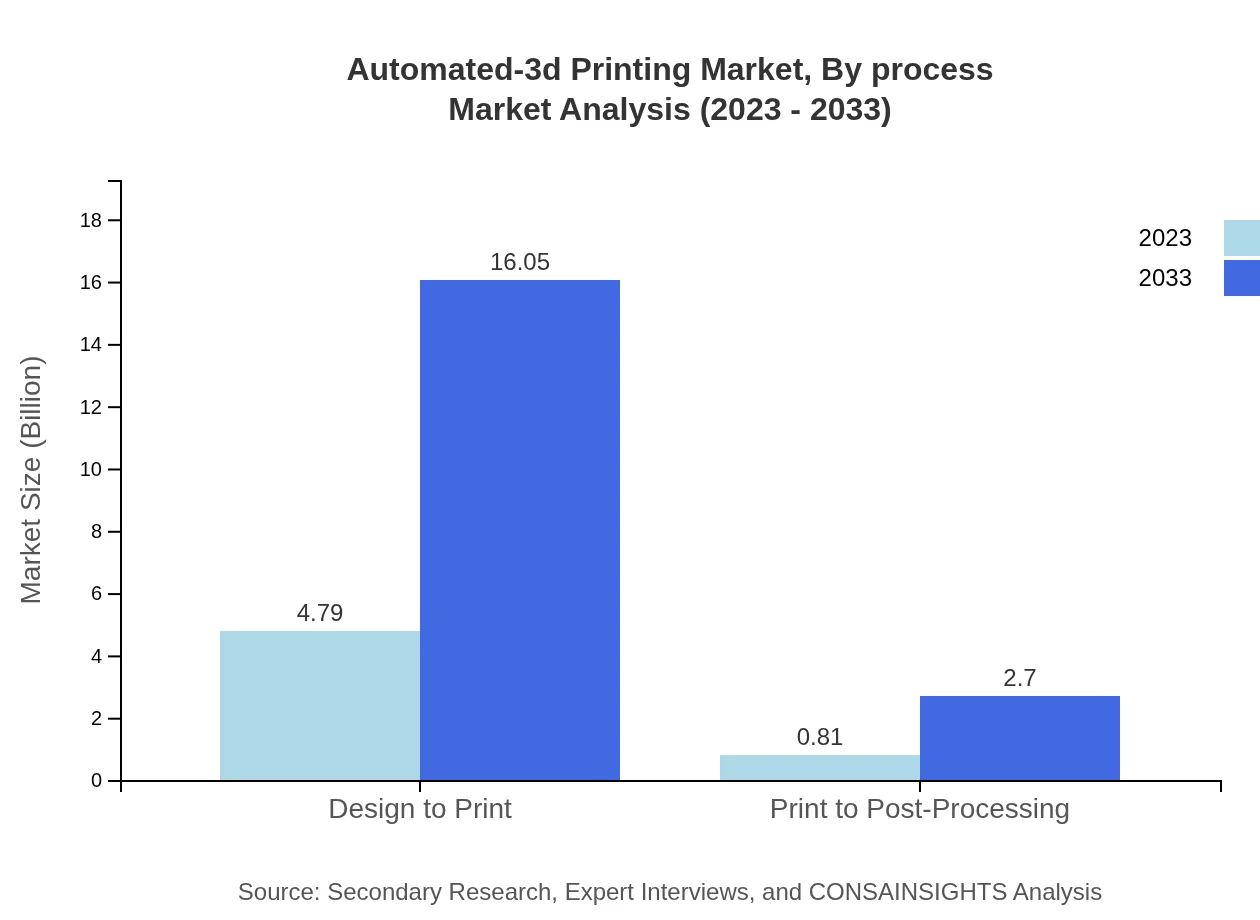

Automated-3d Printing Market Analysis By Process

Process analysis indicates that 'Design to Print' is the predominant stage, forecasted to account for significant growth due to its streamlining of workflows in 3D printing production.

Automated-3D Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automated-3D Printing Industry

Stratasys Ltd.:

Stratasys is a leader in 3D printing solutions, providing product development and customized manufacturing services that drive innovation in various sectors.3D Systems Corporation:

Renowned for its pioneering 3D printing technology, 3D Systems offers an extensive portfolio of 3D printing systems and engineering materials.HP Inc.:

HP is revolutionizing the 3D printing landscape with its Multi Jet Fusion technology, known for improving the speed and economics of part production.EOS GmbH:

EOS specializes in industrial 3D printing solutions, particularly metal and polymer laser sintering, enabling processes across multiple sectors.Materialise NV:

Materialise offers software solutions alongside 3D printing services, contributing significantly to the advancement of the industry through innovative applications.We're grateful to work with incredible clients.

FAQs

What is the market size of automated-3d Printing?

The automated 3D printing market has a current size of approximately $5.6 billion in 2023, and it is projected to grow at a compound annual growth rate (CAGR) of 12.3% through 2033.

What are the key market players or companies in the automated-3d Printing industry?

Key players in the automated 3D printing sector include industry leaders such as Stratasys, 3D Systems, and HP, as well as other prominent companies like Ultimaker and Materialise, all actively contributing to innovation and market expansion.

What are the primary factors driving the growth in the automated 3D printing industry?

The primary growth drivers for automated 3D printing include advancements in technology, increasing demand for customized products, rapid prototyping capabilities, and cost reductions in production processes, contributing to widespread adoption across various sectors.

Which region is the fastest Growing in the automated 3D printing market?

The European region is the fastest-growing market for automated 3D printing, projected to increase from $1.97 billion in 2023 to $6.58 billion by 2033, representing significant growth potential and increased market activities.

Does ConsaInsights provide customized market report data for the automated 3D printing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the automated 3D printing industry, enabling clients to access insights that are relevant to their unique business contexts and strategic goals.

What deliverables can I expect from this automated 3D printing market research project?

From the automated 3D printing market research project, clients can expect detailed reports including market size, growth projections, segment analysis, competitive landscape, and strategic recommendations based on comprehensive data analysis.

What are the market trends of automated 3D printing?

Current market trends in automated 3D printing include the rise of sustainable materials, increased adoption in sectors like aerospace and healthcare, and growing integration with artificial intelligence for improved efficiency and innovation.