Automatic Bending Machine Market Report

Published Date: 22 January 2026 | Report Code: automatic-bending-machine

Automatic Bending Machine Market Size, Share, Industry Trends and Forecast to 2033

This report presents a comprehensive analysis of the Automatic Bending Machine market, focusing on market trends, growth factors, and forecasts from 2023 to 2033. It provides valuable insights into market size, segmentation, and regional dynamics.

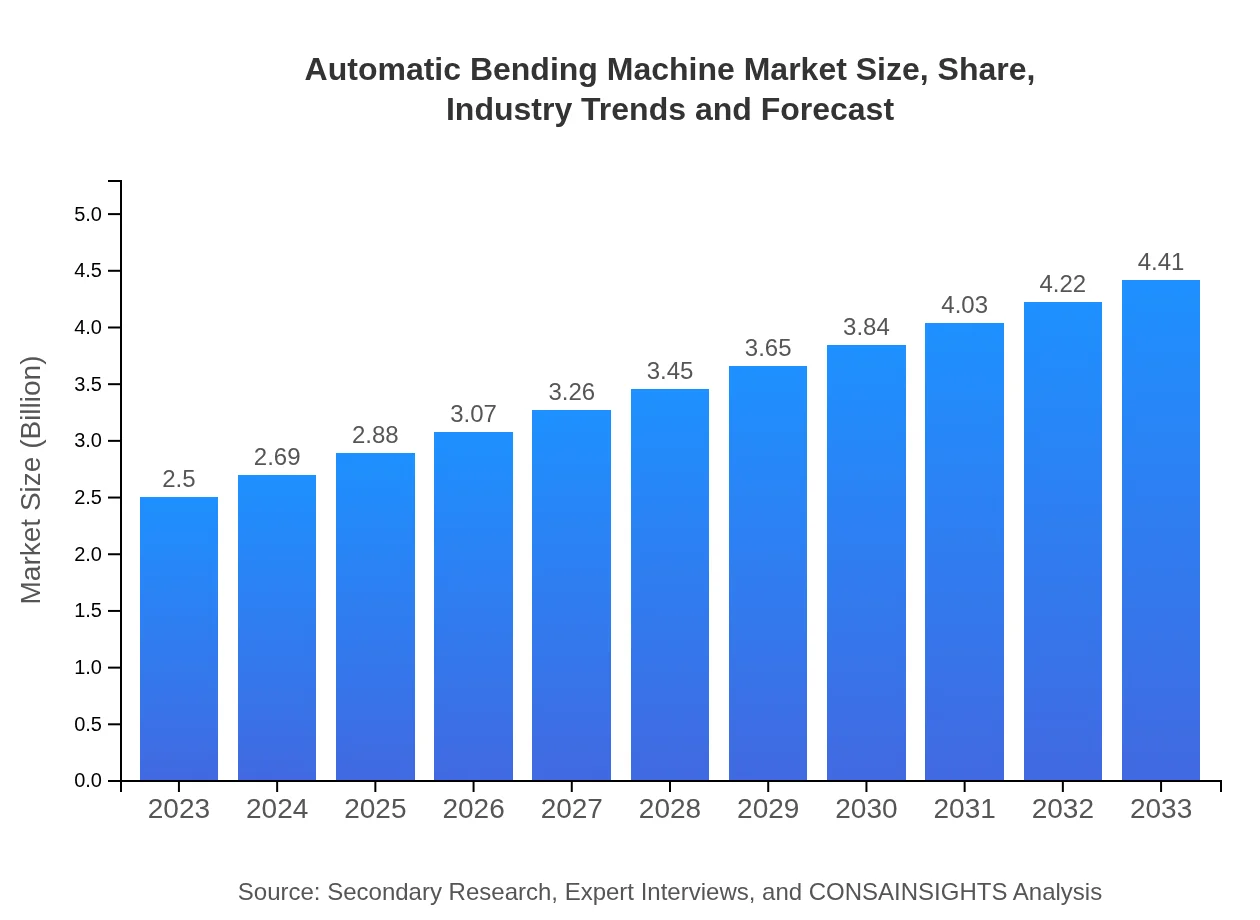

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.7% |

| 2033 Market Size | $4.41 Billion |

| Top Companies | Amada Company, Ltd, TRUMPF, Bystronic, Baileigh Industrial, Inc. |

| Last Modified Date | 22 January 2026 |

Automatic Bending Machine Market Overview

Customize Automatic Bending Machine Market Report market research report

- ✔ Get in-depth analysis of Automatic Bending Machine market size, growth, and forecasts.

- ✔ Understand Automatic Bending Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automatic Bending Machine

What is the Market Size & CAGR of Automatic Bending Machine market in 2023-2033?

Automatic Bending Machine Industry Analysis

Automatic Bending Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automatic Bending Machine Market Analysis Report by Region

Europe Automatic Bending Machine Market Report:

Europe's market is projected to grow from $0.72 billion in 2023 to $1.27 billion by 2033. The region's focus on high-quality standards and advanced manufacturing solutions fosters a conducive environment for the growth of automatic bending machines. Countries like Germany and France are at the forefront of this evolution.Asia Pacific Automatic Bending Machine Market Report:

The Asia Pacific region holds substantial market potential, with a market size of $0.48 billion in 2023 projected to grow to $0.84 billion by 2033. The increasing manufacturing activities in countries like China and Japan, coupled with the rise of SMEs majorly drive this growth. Additionally, the adoption of automation in industries is witnessing an upward trend.North America Automatic Bending Machine Market Report:

North America, with a market of $0.91 billion in 2023 set to reach $1.61 billion by 2033, demonstrates strong growth attributed to advancements in manufacturing technologies, especially in the automotive and aerospace sectors where bending machines are extensively utilized. The emphasis on automation and efficiency in manufacturing processes supports this trend.South America Automatic Bending Machine Market Report:

In South America, the market is valued at approximately $0.20 billion in 2023, expected to increase to $0.35 billion by 2033. Economic growth and infrastructure development initiatives in countries such as Brazil and Argentina are contributing to the demand for automatic bending machines.Middle East & Africa Automatic Bending Machine Market Report:

The Middle East and Africa market is relatively smaller, valued at $0.19 billion in 2023 and expected to grow to $0.33 billion by 2033. Increased investment in infrastructure and manufacturing capabilities in countries such as the UAE and South Africa will drive this growth.Tell us your focus area and get a customized research report.

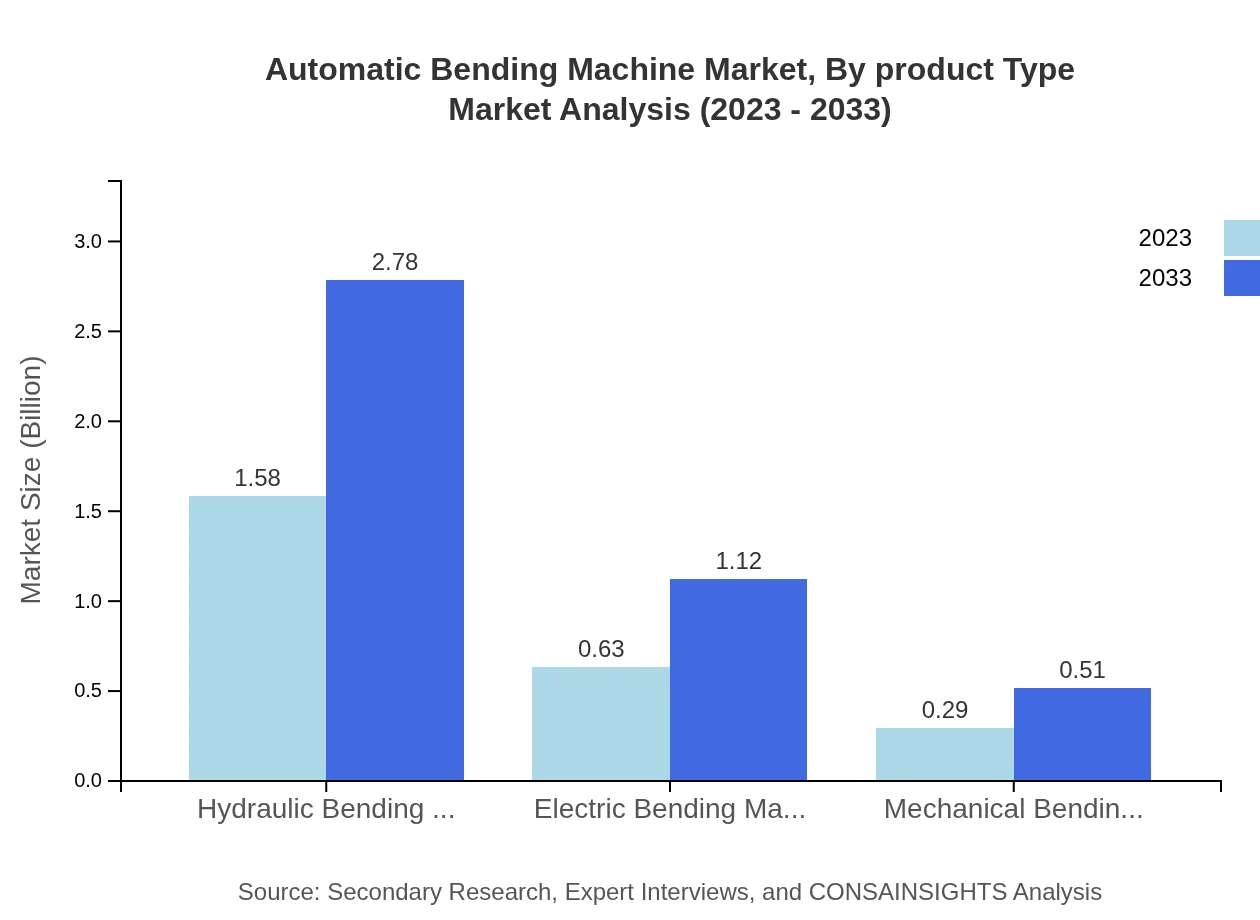

Automatic Bending Machine Market Analysis By Product Type

By product type, the market is segmented into hydraulic, electric, and mechanical bending machines. Hydraulic bending machines dominate the market with a value of $1.58 billion in 2023, set to increase to $2.78 billion by 2033. This type is favored for its superior performance in handling larger and thicker materials. Electric machines, valued at $0.63 billion in 2023, are expected to reach $1.12 billion by 2033, owing to their energy efficiency and lower operational costs. Mechanical machines, while smaller in market size at $0.29 billion, are also on the rise as they are preferred for specific applications due to their simplicity and effectiveness.

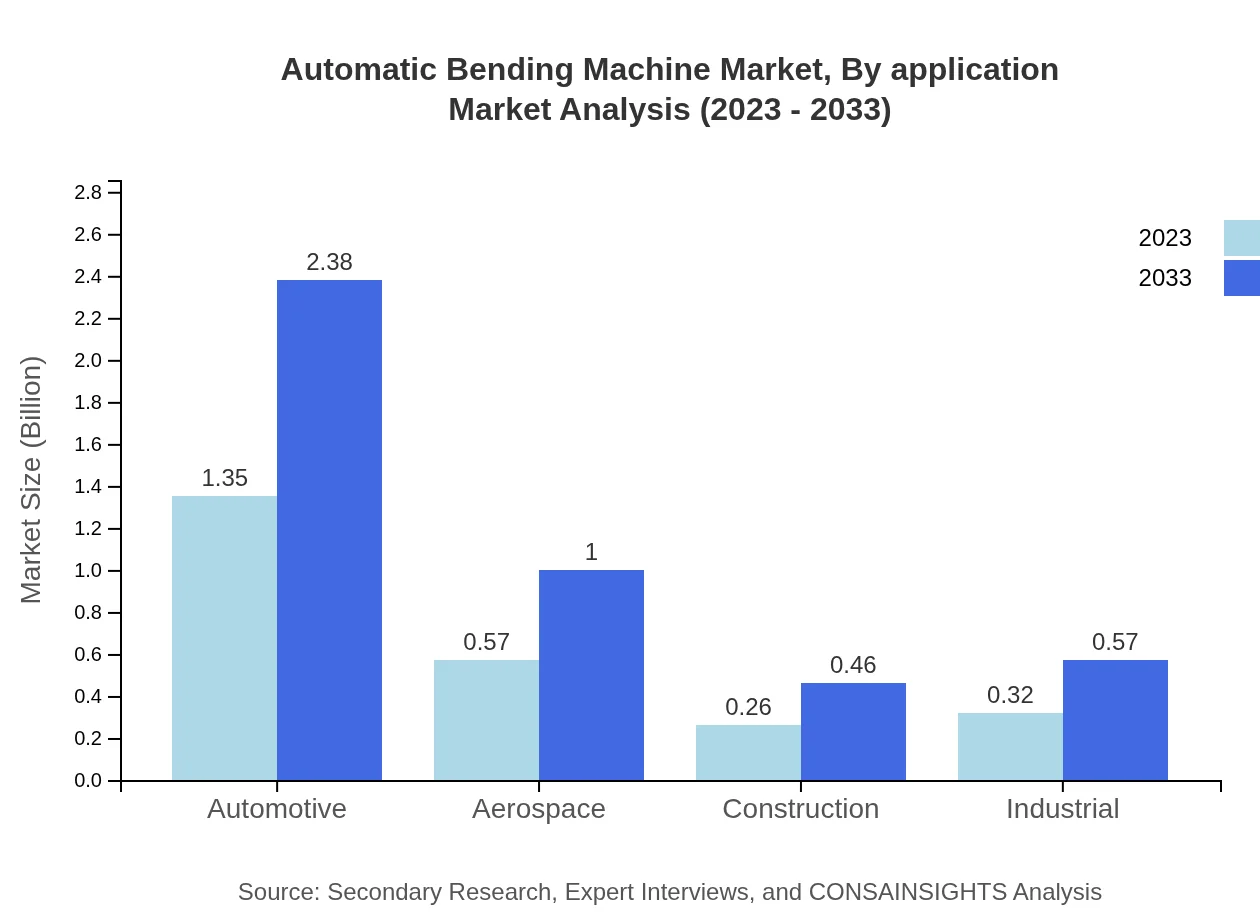

Automatic Bending Machine Market Analysis By Application

The market is segmented based on applications, including automotive, aerospace, construction, and industrial sectors. The automotive sector leads with a substantial market size of $1.35 billion in 2023, projected to grow to $2.38 billion by 2033. Their demand for precision and efficiency makes automatic bending machines essential. The aerospace industry, with a market size of $0.57 billion, is also expanding, expected to hit $1.00 billion by 2033, driven by a surge in air travel and related infrastructure improvements. The construction sector, although smaller at $0.26 billion, shows promise for growth as infrastructure projects increase globally.

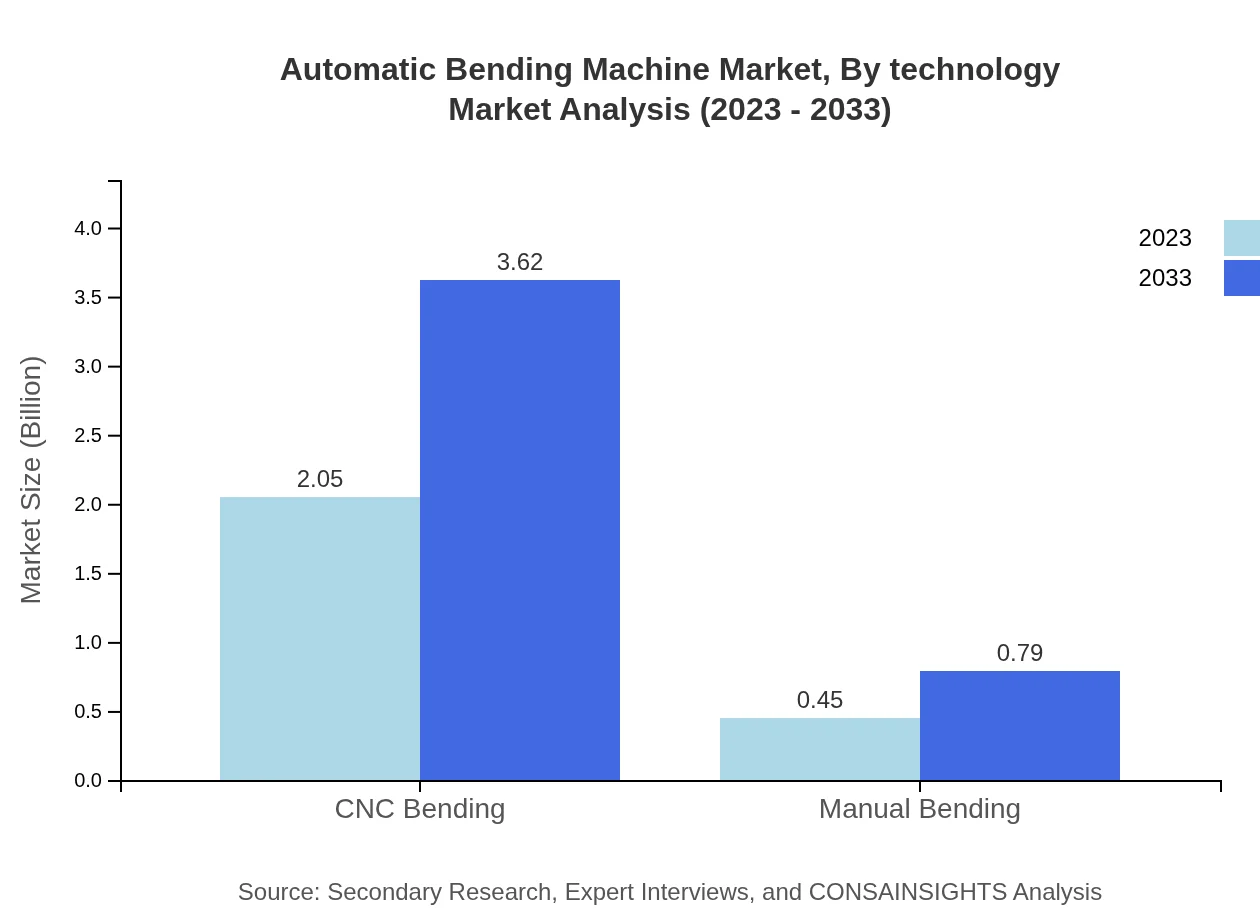

Automatic Bending Machine Market Analysis By Technology

Regarding technology, CNC bending is the most significant segment with a market size of $2.05 billion in 2023, maintaining an 82.1% market share. CNC technology has enhanced precision and efficiency significantly. Manual bending machines, while declining in preference, retain 17.9% of the market share, valued at $0.45 billion in 2023, growing slowly to $0.79 billion by 2033.

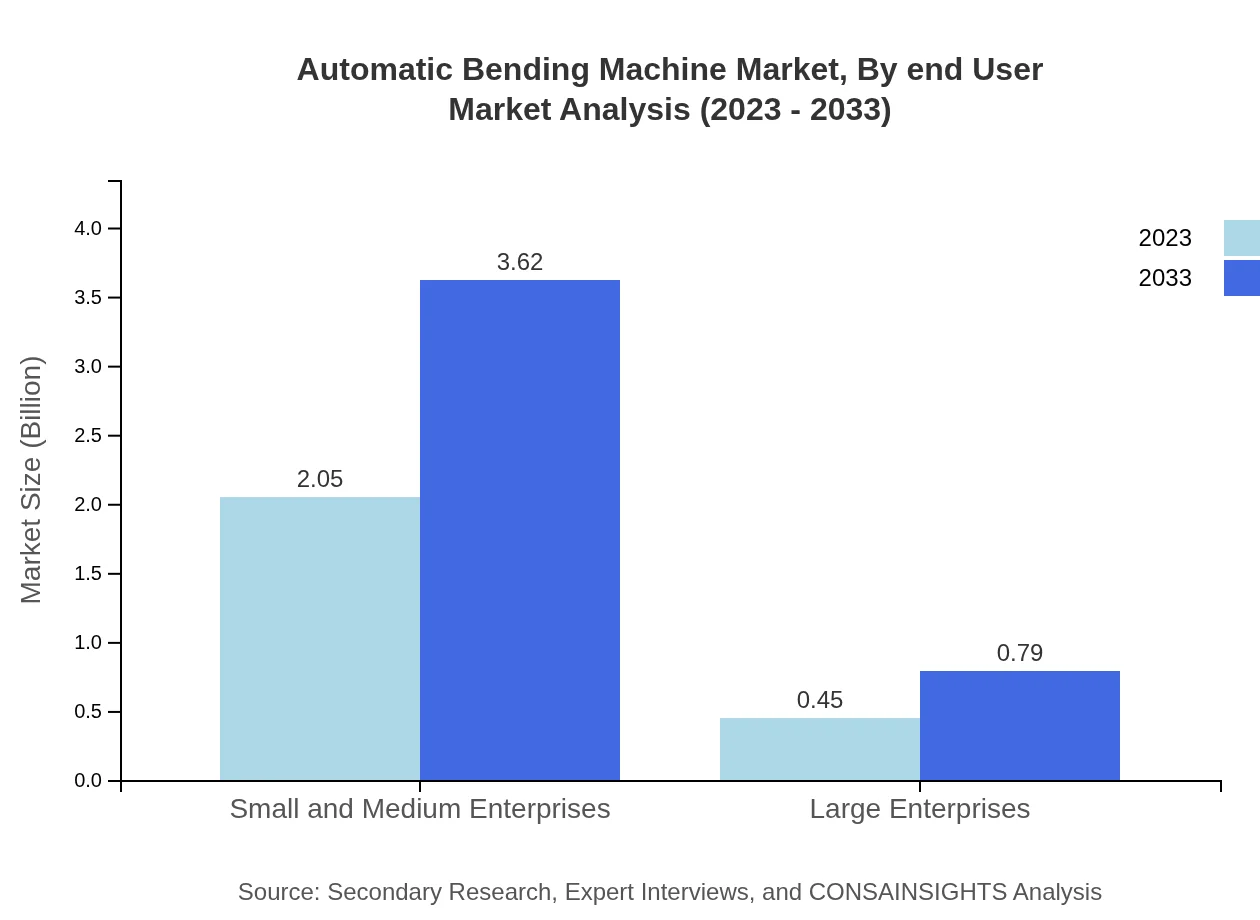

Automatic Bending Machine Market Analysis By End User

The end-user segmentation includes small and medium enterprises (SMEs) and large enterprises. SMEs dominate the market, with a value of $2.05 billion in 2023, expected to rise to $3.62 billion by 2033, constituting 82.1% of the overall market. Large enterprises are making significant contributions as well, with a market value of $0.45 billion in 2023, set to increase to $0.79 billion by 2033, representing 17.9% market share.

Automatic Bending Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automatic Bending Machine Industry

Amada Company, Ltd:

A leading manufacturer of precision sheet metal processing equipment, Amada has developed a range of advanced automatic bending machines to cater to various industrial needs.TRUMPF:

TRUMPF specializes in manufacturing bending machines that integrate advanced technology with user-friendly interfaces, fostering efficiency in production processes.Bystronic:

Bystronic is known for its innovative solutions in the automated bending sector, focusing on digitalization and automation for increased efficiency.Baileigh Industrial, Inc.:

Baileigh offers an extensive lineup of bending machines tailored for various applications with a focus on reliability and performance.We're grateful to work with incredible clients.

FAQs

What is the market size of automatic Bending Machine?

The automatic bending machine market is expected to reach $2.5 billion by 2033, growing at a CAGR of 5.7% from 2023. This growth reflects increasing demand for automation across various industries, enhancing production efficiency and precision.

What are the key market players or companies in the automatic Bending Machine industry?

Key players in the automatic bending machine industry include major manufacturing companies and technology innovators, focusing on developing advanced bending solutions. They strive to enhance product efficiency to cater to the expanding needs of their diverse customer base.

What are the primary factors driving the growth in the automatic Bending Machine industry?

Factors driving growth in this industry include rising demand for automation, increased production efficiency, improvements in technology, and evolving industry standards. Furthermore, investments in infrastructure and manufacturing capabilities significantly boost market growth.

Which region is the fastest Growing in the automatic Bending Machine?

The fastest-growing region for automatic bending machines is North America, forecasted to grow from $0.91 billion in 2023 to $1.61 billion by 2033. Europe and Asia Pacific are also showing significant growth trends, supported by robust manufacturing sectors.

Does ConsaInsights provide customized market report data for the automatic Bending Machine industry?

Yes, ConsaInsights offers customized market report data tailored to the automatic bending machine industry, allowing clients to obtain specific insights aligned with their unique business needs and strategic objectives.

What deliverables can I expect from this automatic Bending Machine market research project?

Deliverables include comprehensive market reports, segment analysis, competitive landscape assessments, and actionable insights. These reports will guide strategic planning and investment decisions in the automatic bending machine industry.

What are the market trends of automatic Bending Machine?

Current market trends include a shift towards CNC bending technologies, increasing integration of IoT for machine efficiency, and a growing focus on sustainability. The demand from automotive and aerospace sectors continues to drive innovations in machine design and functions.