Automatic Labeling Machine Market Report

Published Date: 22 January 2026 | Report Code: automatic-labeling-machine

Automatic Labeling Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Automatic Labeling Machine market, exploring key insights, trends, and projections from 2023 to 2033, including market size, growth rates, and industry dynamics.

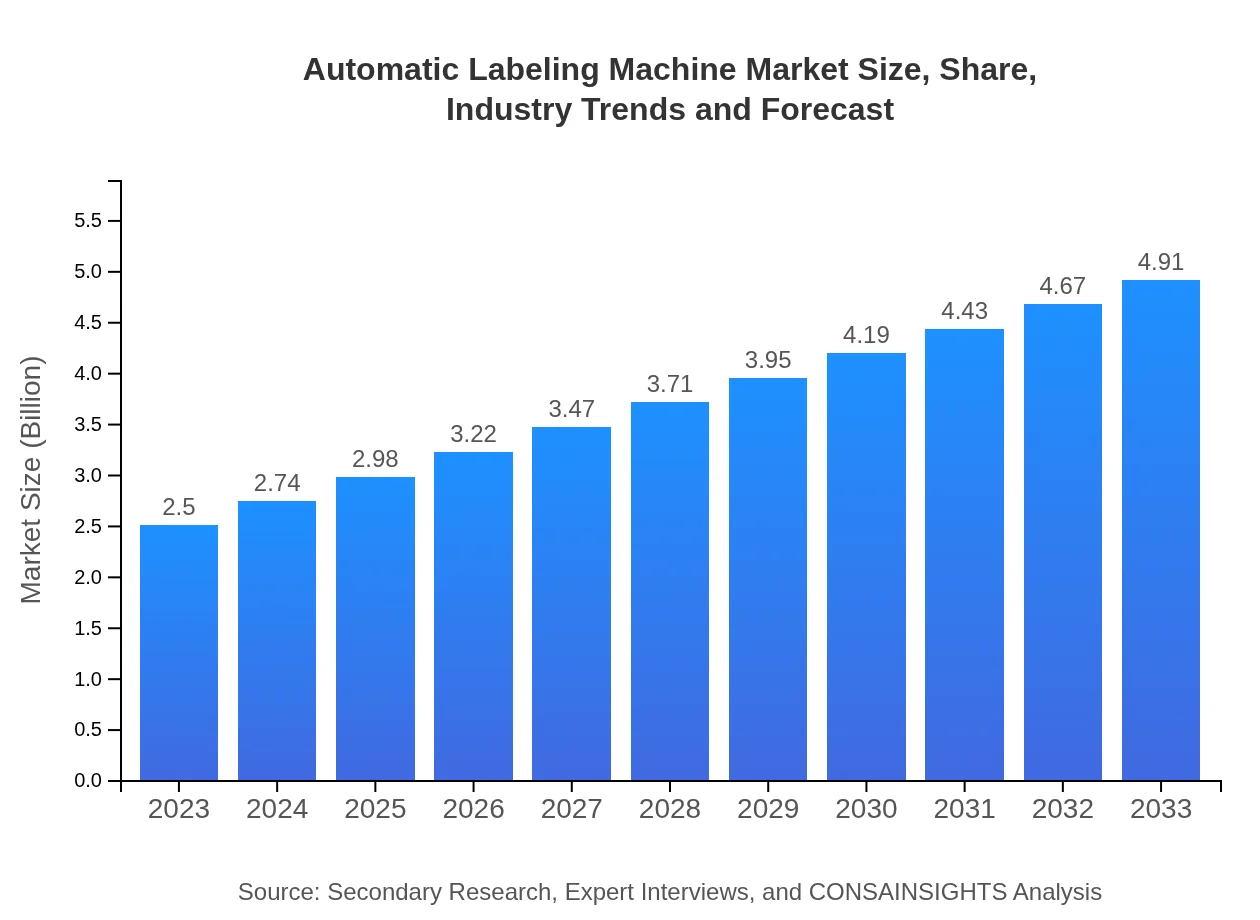

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | Accraply, Label Aire, HERMA, Codian Robotics, SATO Holdings Corporation |

| Last Modified Date | 22 January 2026 |

Automatic Labeling Machine Market Overview

Customize Automatic Labeling Machine Market Report market research report

- ✔ Get in-depth analysis of Automatic Labeling Machine market size, growth, and forecasts.

- ✔ Understand Automatic Labeling Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automatic Labeling Machine

What is the Market Size & CAGR of Automatic Labeling Machine market in 2023?

Automatic Labeling Machine Industry Analysis

Automatic Labeling Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automatic Labeling Machine Market Analysis Report by Region

Europe Automatic Labeling Machine Market Report:

The European market, valued at $0.74 billion in 2023, is projected to reach $1.46 billion by 2033. Strong regulations governing product labeling in food and pharmaceuticals drive demand in this region. Moreover, the presence of established manufacturers and ongoing innovation further fuel market growth.Asia Pacific Automatic Labeling Machine Market Report:

The Asia Pacific region holds a significant market share, with a market size of $0.43 billion in 2023 projected to grow to $0.85 billion by 2033. Rapid industrialization, coupled with a growing consumer base, is driving demand for automatic labeling solutions. The increased focus on packaging quality and compliance with international standards has led manufacturers to invest in advanced labeling technologies.North America Automatic Labeling Machine Market Report:

North America represents a significant market, with a size of $0.96 billion in 2023 growing to $1.90 billion by 2033. The region's mature industrial sector and high standards of production efficiency are driving investments in labeling automation. Additionally, favorable regulatory frameworks and a strong focus on technological advancements make it a key player in the market.South America Automatic Labeling Machine Market Report:

In South America, the market is smaller but shows potential for growth, expected to increase from $0.17 billion in 2023 to $0.33 billion by 2033. Factors such as urbanization, rising consumer demand, and an increase in the manufacturing sector are contributing to the adoption of advanced labeling technologies. However, challenges such as economic fluctuations impact market stability.Middle East & Africa Automatic Labeling Machine Market Report:

The Middle East and Africa region's market for automatic labeling machines is gradually expanding, with a market size of $0.19 billion in 2023 expected to grow to $0.37 billion by 2033. Increasing consumer demand for packaged products and growing investments in the manufacturing sector are pivotal in driving market advancements in this area.Tell us your focus area and get a customized research report.

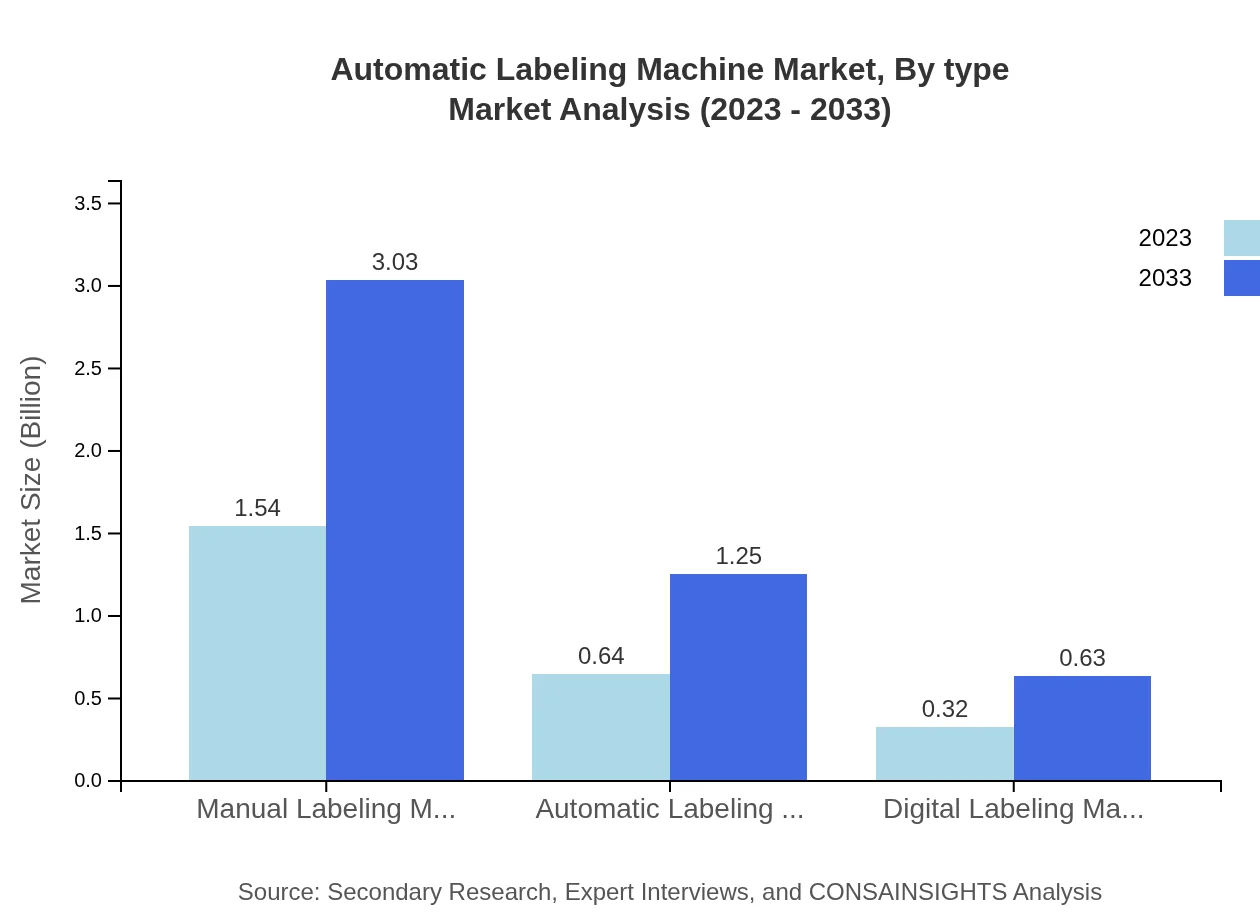

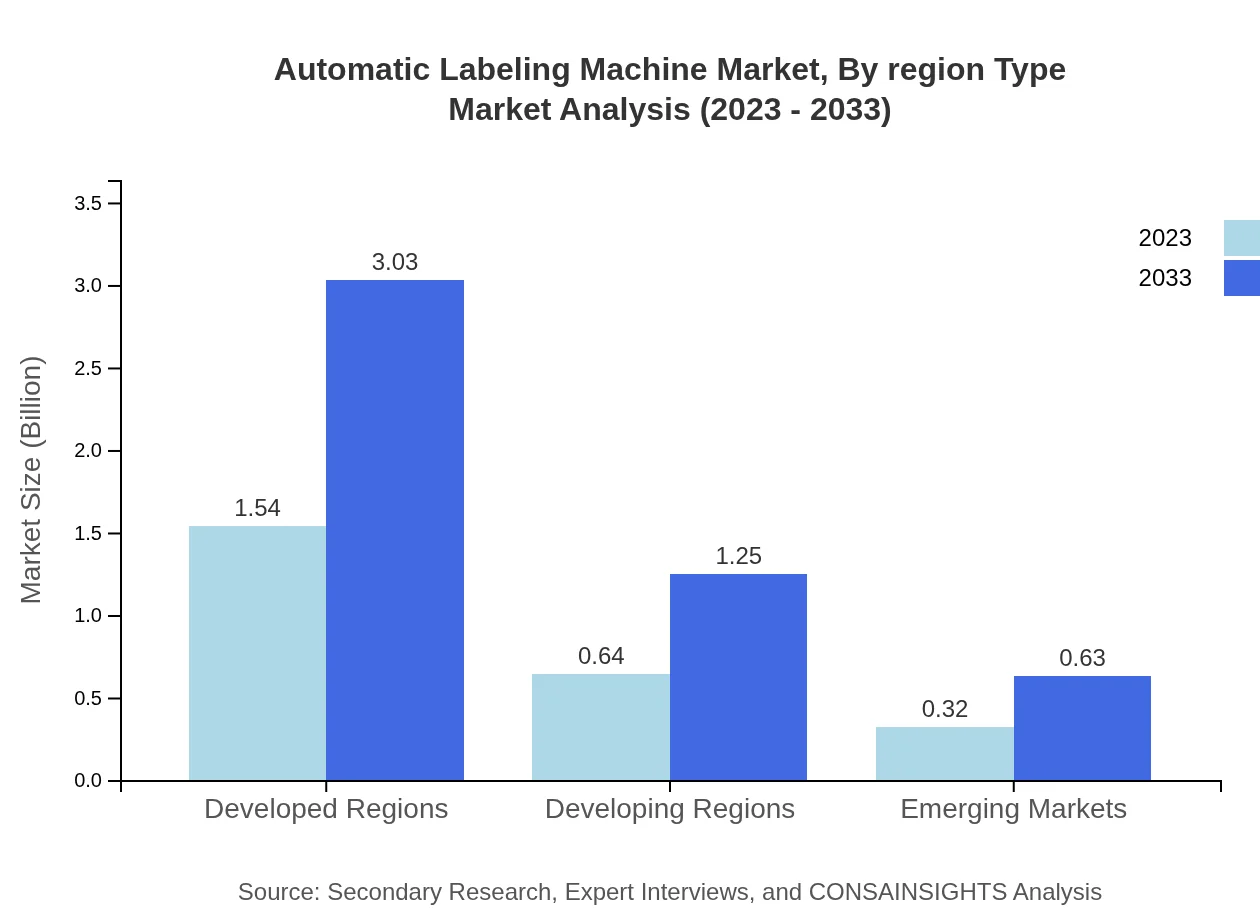

Automatic Labeling Machine Market Analysis By Type

The market is segmented into three main types: Manual Labeling Machines, Automatic Labeling Machines, and Digital Labeling Machines. In 2023, Manual Labeling Machines dominated the market with a size of $1.54 billion, representing 61.72% share, and expected to grow to $3.03 billion by 2033. Automatic Labeling Machines accounted for $0.64 billion (25.53% share) in 2023 and are projected to reach $1.25 billion by 2033. Digital Labeling Machines show a growing trend with a market size of $0.32 billion in 2023, anticipated to increase to $0.63 billion by 2033, reflecting the push for digital transformation in manufacturing.

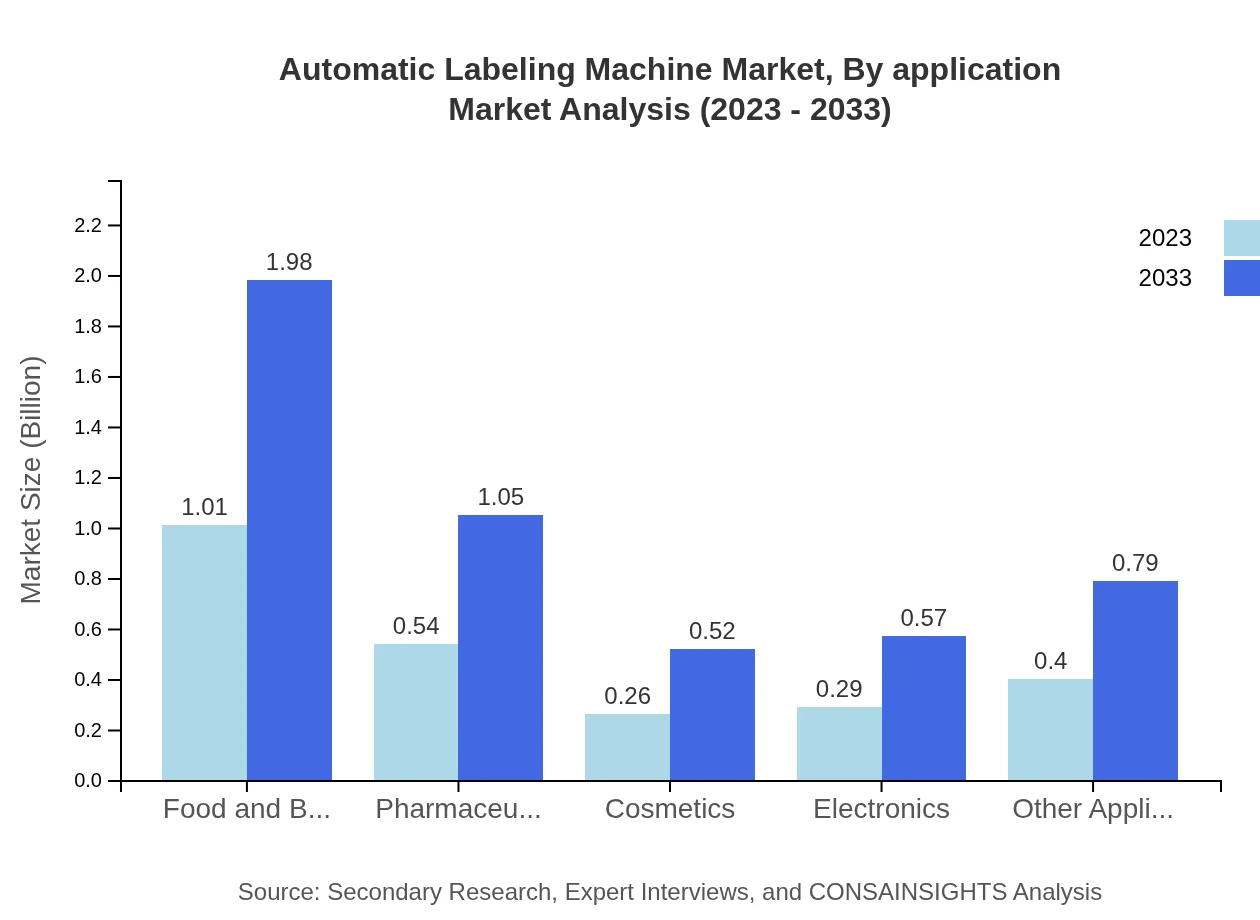

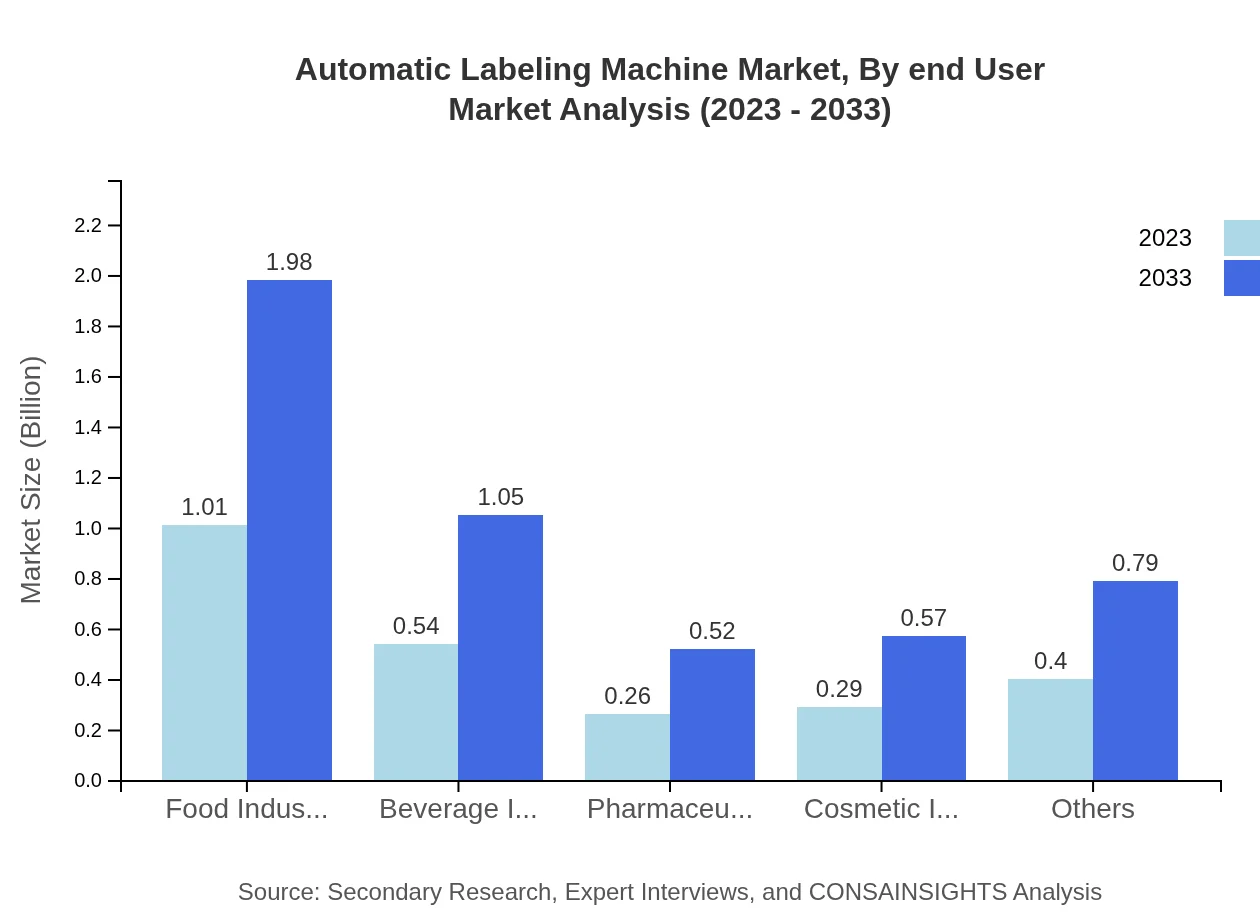

Automatic Labeling Machine Market Analysis By Application

The application segments show significant diversity, with the Food Industry being the largest segment at $1.01 billion in 2023 (40.33% share), growing to $1.98 billion by 2033. The Beverage Industry, worth $0.54 billion with a 21.45% share, is also expected to see substantial growth. The Pharmaceutical and Cosmetic Industries, each accounting for 10.49% and 11.63%, respectively, demonstrate the need for precise labeling to ensure compliance and brand integrity. Other applications contribute significantly to market dynamics as well.

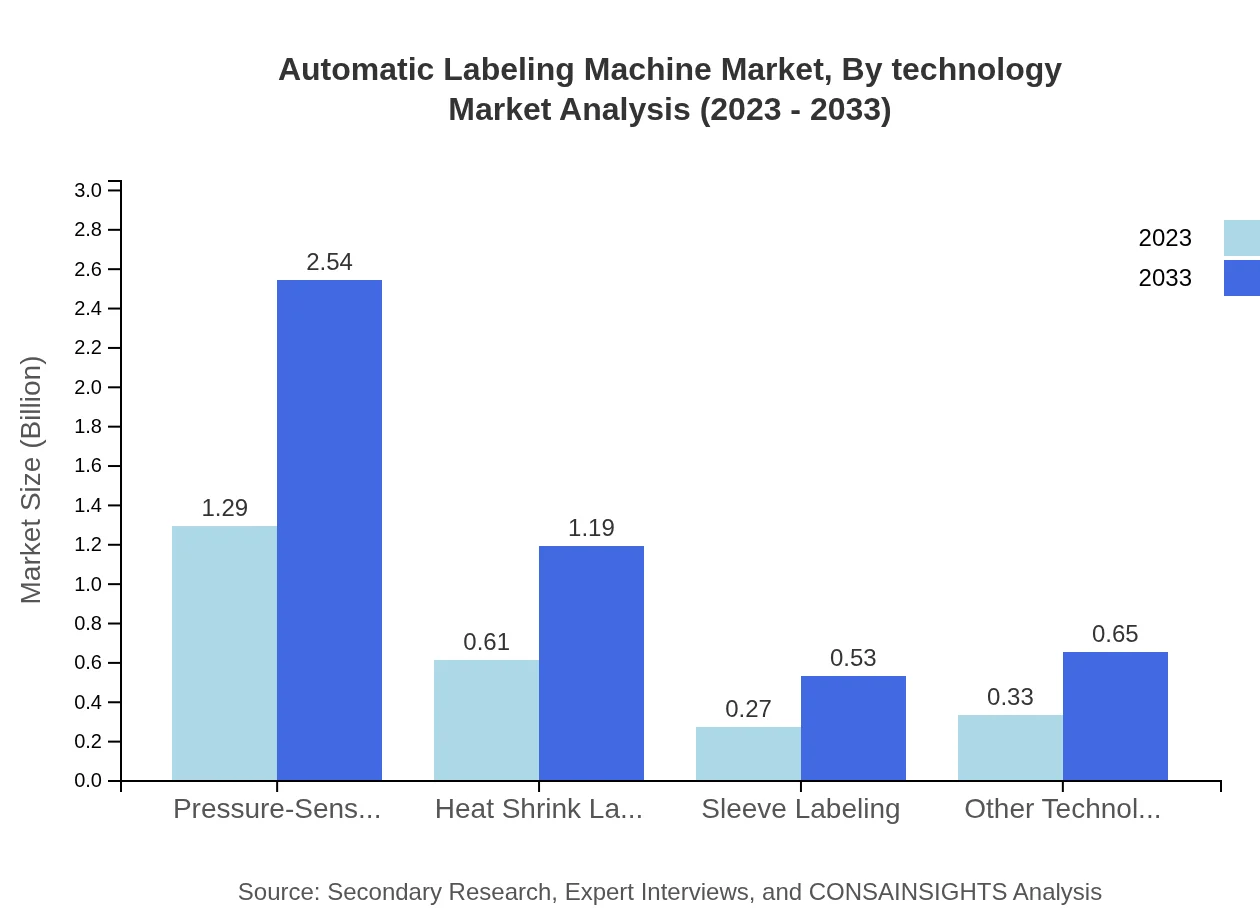

Automatic Labeling Machine Market Analysis By Technology

Innovation in technology plays a crucial role in shaping the Automatic Labeling Machine market. Pressure-sensitive labeling holds the largest share at 51.78% with a size of $1.29 billion in 2023 and is expected to increase to $2.54 billion by 2033. Heat shrink labeling follows with a notable share of 24.22%, expanding from $0.61 billion to $1.19 billion. Additional technologies, such as sleeve labeling and other technologies, contribute to market richness but are currently smaller segments.

Automatic Labeling Machine Market Analysis By End User

The end-user segment showcases a dominant position of the Food and Beverage industry, valued at $1.01 billion and sharing 40.33% in 2023. The Pharmaceutical industry holds a critical role with a share of 21.45%, reflecting the demand for stringent labeling standards. Other significant users include Cosmetics and Electronics, with contributions highlighting the diverse applicability of labeling solutions across sectors.

Automatic Labeling Machine Market Analysis By Region Type

The market's regional analysis reveals a dichotomy of developed regions and developing markets. Developed regions accounted for 61.72% share in 2023, enhancing the focus on automation and technology. In contrast, developing regions represent significant growth potential, with sizes expected to evolve from $0.64 billion to $1.25 billion by 2033, highlighting the need for modernization amidst increasing manufacturing demands.

Automatic Labeling Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automatic Labeling Machine Industry

Accraply:

Accraply is a leading manufacturer of labeling machines specializing in custom labeling solutions tailored to unique industry needs. Their innovative approach includes a strong focus on automation and technology integration.Label Aire:

Label Aire stands out for its extensive product range, offering automated labeling solutions that cater to various sectors, including food and beverage, healthcare, and consumer goods.HERMA:

HERMA is recognized for its advanced technological solutions and commitment to sustainability, providing efficient labeling systems for various applications.Codian Robotics:

Specializing in robotics and automations, Codian Robotics offers cutting-edge solutions in label application to enhance production efficiency and accuracy.SATO Holdings Corporation:

A major player in the labeling market, SATO engages in product innovation and maintains a focus on the digital transformation of the packaging industry.We're grateful to work with incredible clients.

FAQs

What is the market size of automatic Labeling Machine?

The automatic labeling machine market is valued at approximately $2.5 billion in 2023, with a projected growth at a CAGR of 6.8% leading to significant expansions by 2033.

What are the key market players or companies in this automatic Labeling Machine industry?

Key players in the automatic labeling machine market include significant manufacturers such as Accu-Label, ALTech, and Herma, who innovate and compete in a rapidly growing landscape.

What are the primary factors driving the growth in the automatic Labeling Machine industry?

The automatic labeling machine industry is driven by increasing automation in manufacturing, rising demand for packaged goods, and the need for compliance with labeling regulations, enhancing product traceability.

Which region is the fastest Growing in the automatic Labeling Machine?

The North America region is poised as the fastest-growing market for automatic labeling machines, expected to reach a valuation of approximately $1.90 billion by 2033, up from $0.96 billion in 2023.

Does ConsaInsights provide customized market report data for the automatic Labeling Machine industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the automatic labeling machine industry, ensuring comprehensive insights for clients.

What deliverables can I expect from this automatic Labeling Machine market research project?

Expected deliverables from the project include comprehensive market analysis, segmentation data, regional insights, competitive landscape, and actionable recommendations.

What are the market trends of automatic Labeling Machine?

Key market trends include an increased adoption of smart labeling solutions, rise in demand from food and beverage industries, and advancements in digital labeling technologies.