Automatic Lubrication System Market Report

Published Date: 22 January 2026 | Report Code: automatic-lubrication-system

Automatic Lubrication System Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Automatic Lubrication System market, including current trends, forecasts from 2023 to 2033, market size, regional insights, and industry dynamics.

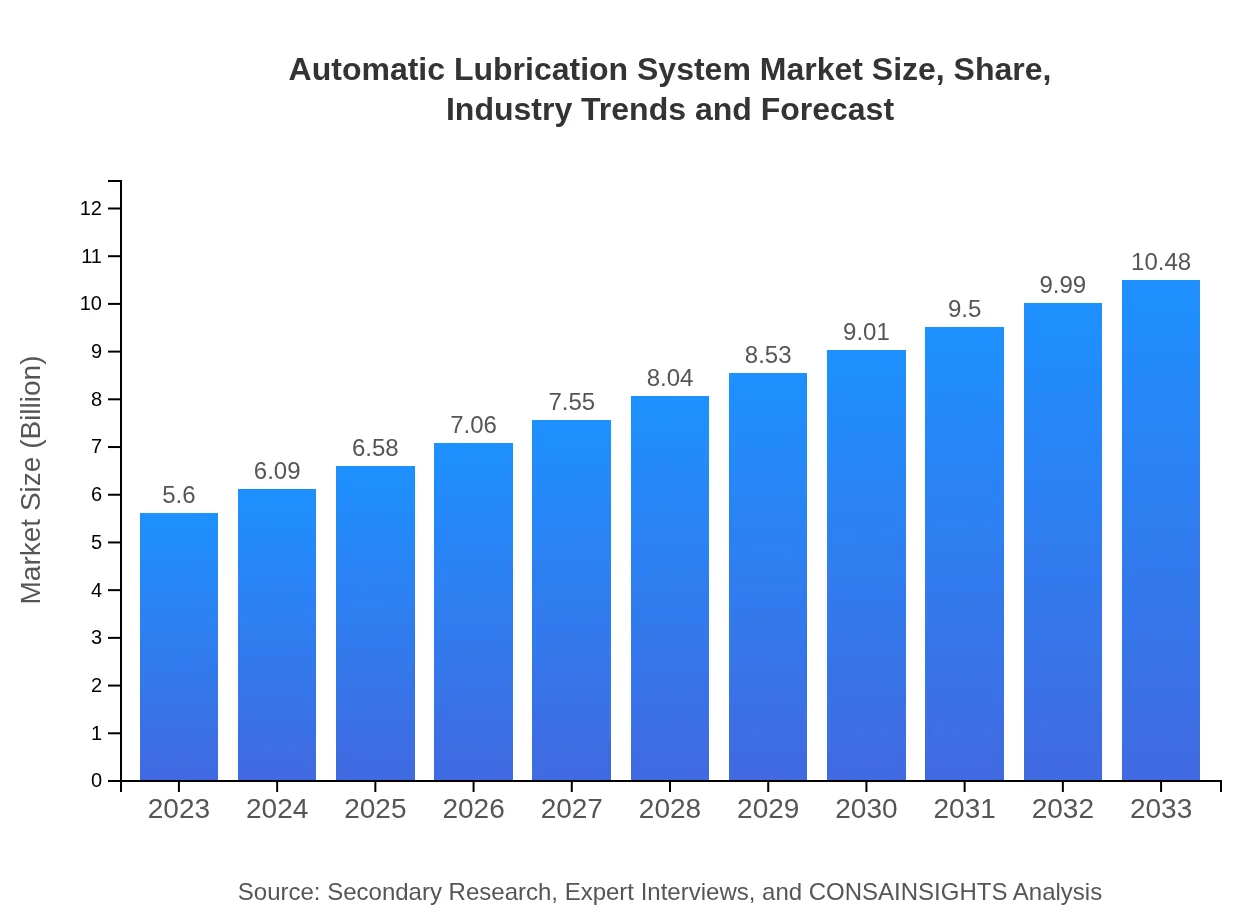

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $10.48 Billion |

| Top Companies | SKF Group, Graco Inc., Lincoln Industrial, Beka Lubrication |

| Last Modified Date | 22 January 2026 |

Automatic Lubrication System Market Overview

Customize Automatic Lubrication System Market Report market research report

- ✔ Get in-depth analysis of Automatic Lubrication System market size, growth, and forecasts.

- ✔ Understand Automatic Lubrication System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automatic Lubrication System

What is the Market Size & CAGR of Automatic Lubrication System market in 2023?

Automatic Lubrication System Industry Analysis

Automatic Lubrication System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automatic Lubrication System Market Analysis Report by Region

Europe Automatic Lubrication System Market Report:

Europe's market is predicted to grow from $1.80 billion in 2023 to approximately $3.36 billion in 2033, led by strict regulations regarding equipment maintenance and consistent investment in automation technologies across multiple industries.Asia Pacific Automatic Lubrication System Market Report:

The Asia Pacific region is forecasted to grow from $0.99 billion in 2023 to $1.85 billion in 2033, reflecting increasing investments in manufacturing and industrial sectors. Countries like China and India are at the forefront, pushing adoption through government initiatives aimed at boosting manufacturing output and efficiency.North America Automatic Lubrication System Market Report:

North America presents a significant market opportunity, growing from $2.01 billion in 2023 to $3.77 billion in 2033. The adoption of advanced technologies and strong regulatory incentives for automation and sustainability drives market growth in the region.South America Automatic Lubrication System Market Report:

In South America, the market is expected to increase from $0.36 billion in 2023 to $0.67 billion by 2033. This growth is fostered by a rising mining sector and a growing emphasis on reducing operational costs in industrial applications.Middle East & Africa Automatic Lubrication System Market Report:

The Middle East and Africa market is projected to increase from $0.44 billion in 2023 to $0.83 billion in 2033, as industries increasingly focus on improving equipment uptime and efficiency in oil extraction and processing sectors.Tell us your focus area and get a customized research report.

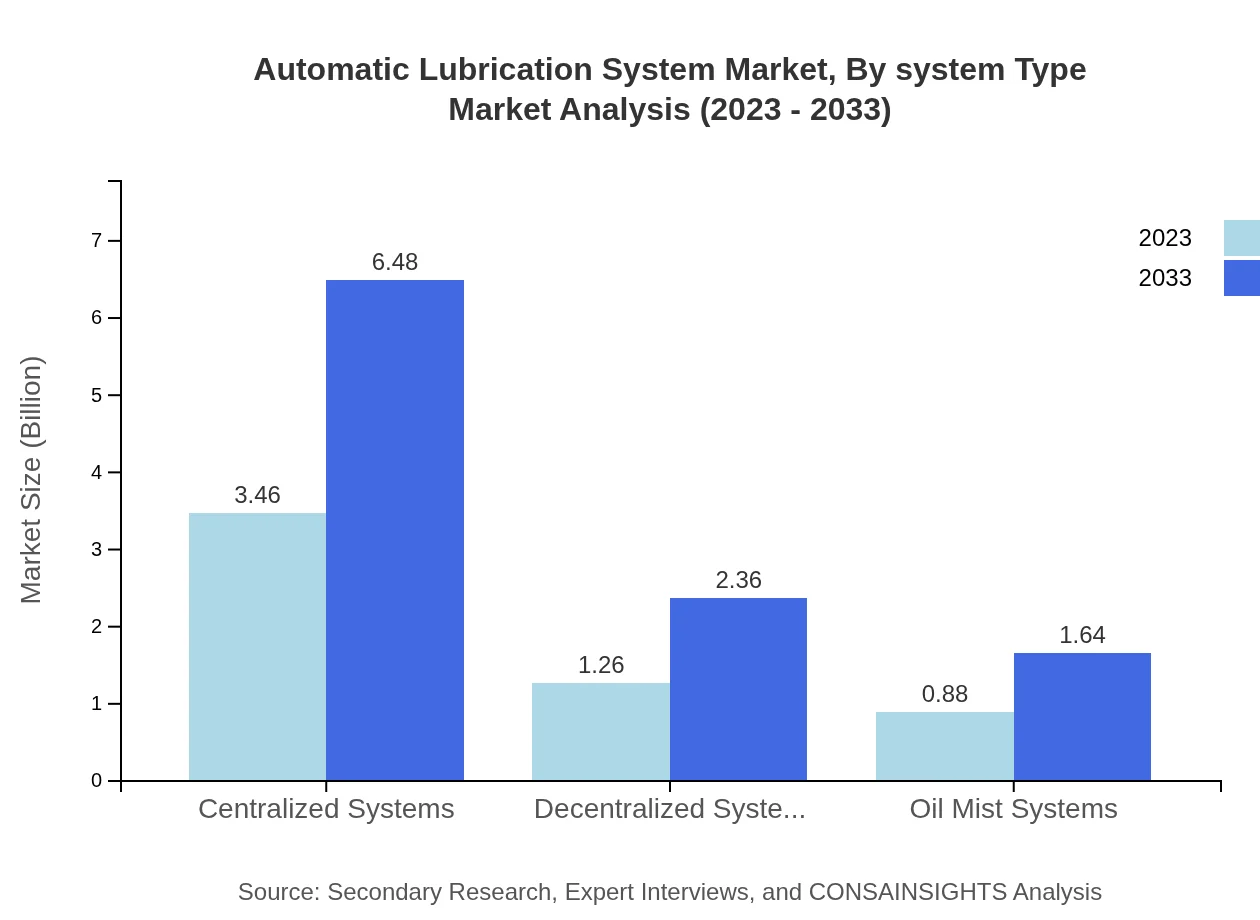

Automatic Lubrication System Market Analysis By System Type

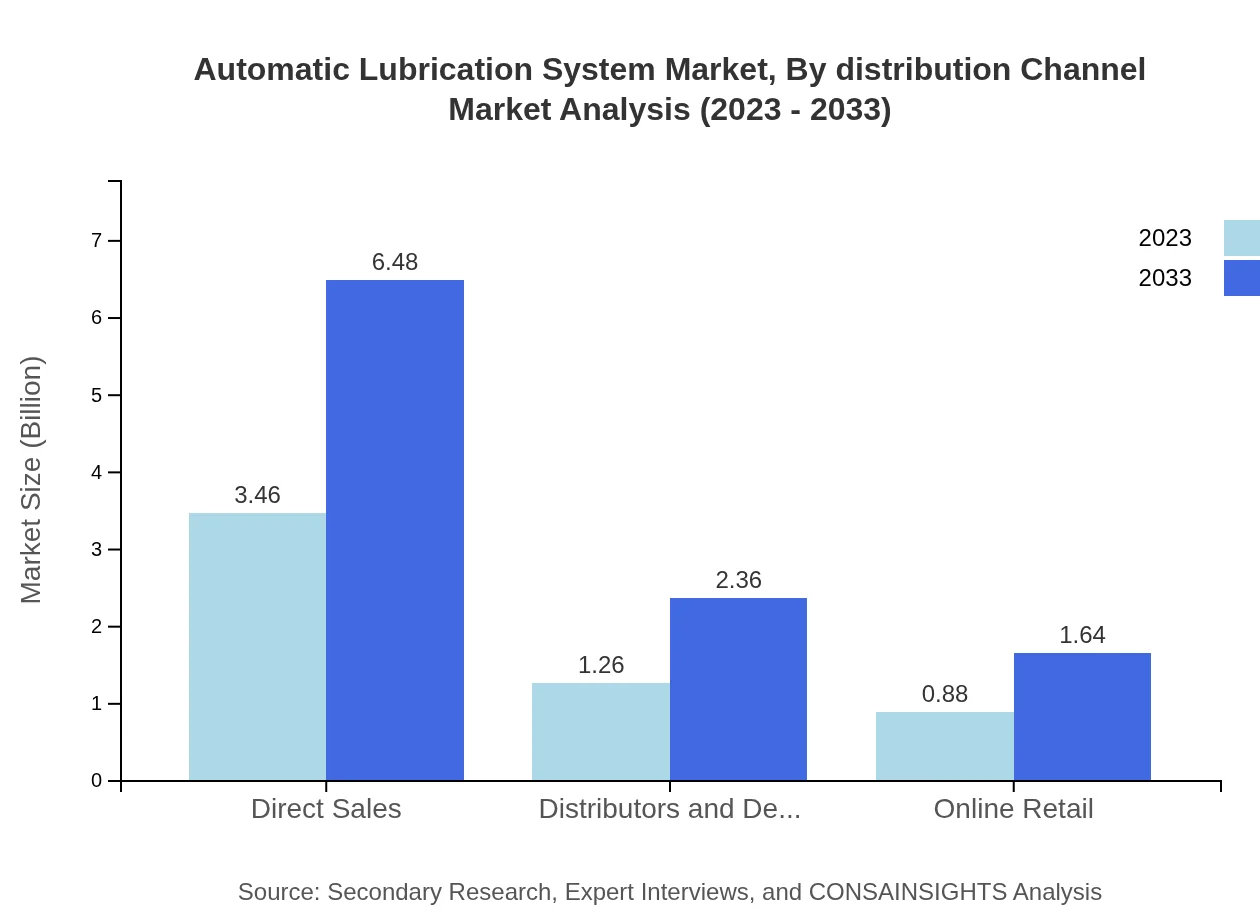

The market is categorized into centralized and decentralized systems. Centralized systems hold a dominant share, representing 61.84% in 2023 and growing from $3.46 billion in 2023 to $6.48 billion in 2033. Decentralized systems also show promising growth, increasing from $1.26 billion to $2.36 billion during the same period.

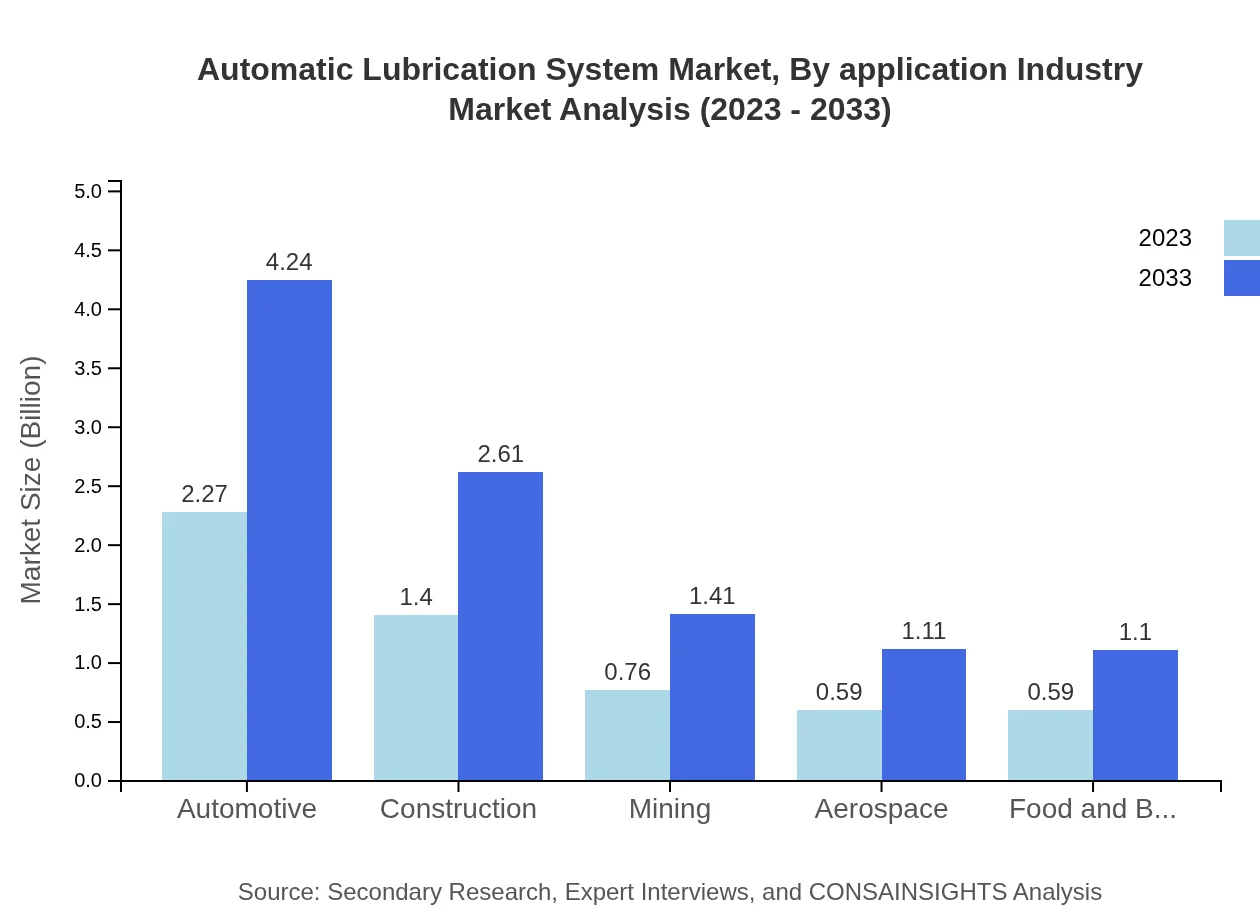

Automatic Lubrication System Market Analysis By Application Industry

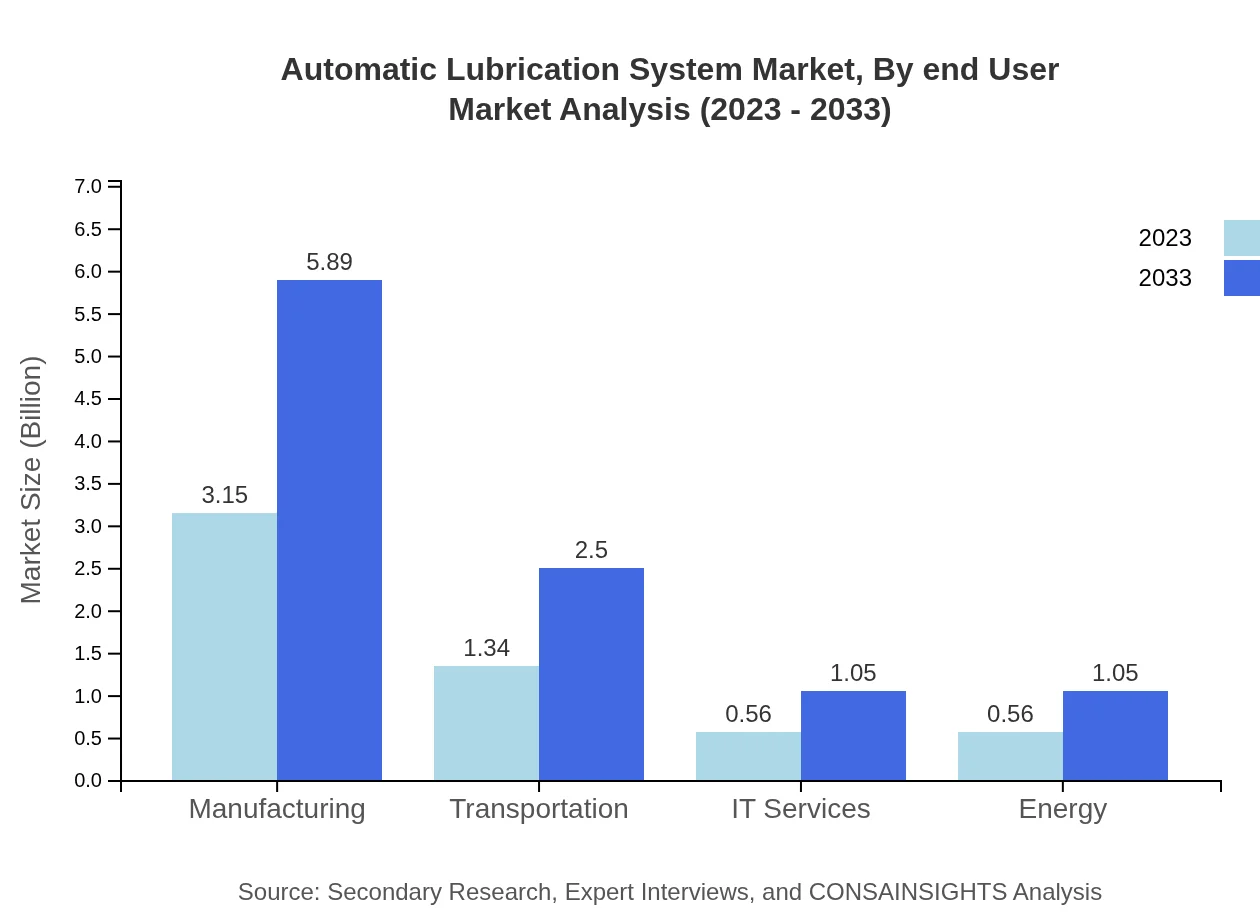

Key application industries include manufacturing, transportation, automotive, and construction. The manufacturing sector leads with a market size of $3.15 billion in 2023, expected to rise to $5.89 billion by 2033, showing strong growth potential. Transportation will also see significant growth, moving from $1.34 billion to $2.50 billion within the forecast period.

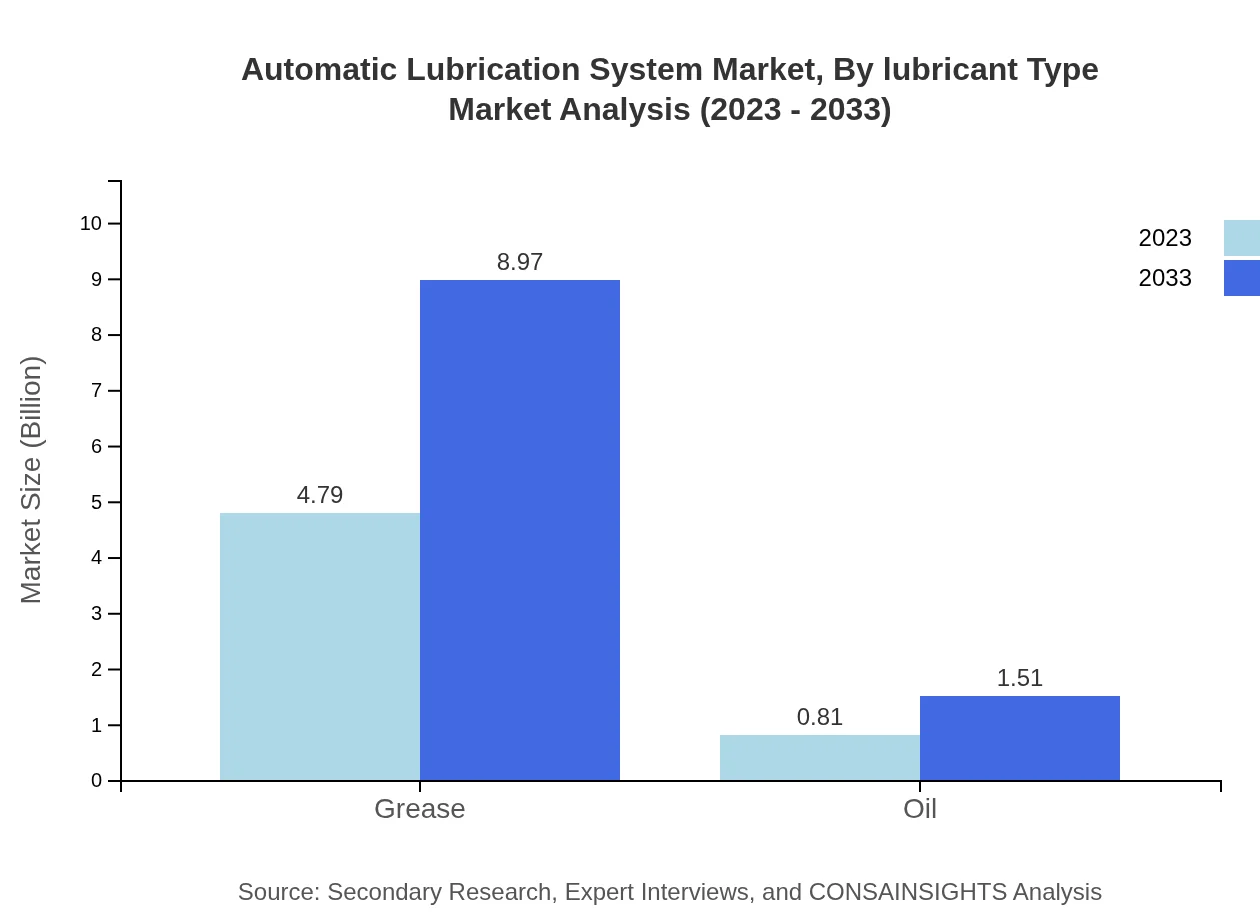

Automatic Lubrication System Market Analysis By Lubricant Type

The lubricant types analyzed include grease and oil, with grease dominating the market at 85.6%, forecasted to grow from $4.79 billion to $8.97 billion by 2033. Oil, although smaller, is expected to expand from $0.81 billion to $1.51 billion over the same time frame.

Automatic Lubrication System Market Analysis By End User

The end-user segments encompass automotive, construction, mining, and aerospace industries. Notably, the automotive sector represents a substantial market of $2.27 billion in 2023, anticipated to rise to $4.24 billion by 2033, underlining the critical need for effective lubrication in vehicle manufacturing.

Automatic Lubrication System Market Analysis By Distribution Channel

The distribution is carried out via direct sales, distributors, dealers, and online retail channels. Direct sales dominate with a 61.84% market share and are expected to reach $6.48 billion by 2033, showcasing the importance of personal customer relationships in the ALS market.

Automatic Lubrication System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automatic Lubrication System Industry

SKF Group:

A leader in lubrication solutions, ensuring optimal reliability and efficiency through innovative lubrication systems.Graco Inc.:

Specializes in fluid management solutions with a strong portfolio in automatic lubrication technology, enhancing service performance across various industries.Lincoln Industrial:

Known for its high-quality lubrication products and services, focusing on customer-driven solutions to improve operational efficiency.Beka Lubrication:

Delivers advanced automatic lubrication systems tailored for diverse industrial applications, renowned for their reliability and performance.We're grateful to work with incredible clients.

FAQs

What is the market size of automatic Lubrication System?

The global automatic lubrication system market is valued at approximately $5.6 billion in 2023 and is projected to reach significantly higher figures by 2033, growing at a CAGR of 6.3%. This growth trajectory indicates a strong increase in demand over the next decade.

What are the key market players or companies in this automatic Lubrication System industry?

Key players in the automatic lubrication system industry include established companies that specialize in providing innovative lubrication solutions. These firms typically focus on enhancing lubrication efficiency, reducing maintenance costs, and improving overall system reliability across various sectors.

What are the primary factors driving the growth in the automatic Lubrication System industry?

The growth of the automatic lubrication system market is driven by increasing industrial automation, rising demand for maintenance-free operations, and stringent regulations regarding equipment lubrication. Additionally, the need for enhanced operational efficiency and reduced downtime significantly contributes to market expansion.

Which region is the fastest Growing in the automatic Lubrication System?

Europe is the fastest-growing region in the automatic lubrication system market, with its market size expected to increase from $1.80 billion in 2023 to $3.36 billion by 2033. Other growing regions include North America and Asia Pacific, indicating a global demand surge.

Does ConsaInsights provide customized market report data for the automatic Lubrication System industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the automatic lubrication system industry. This service allows clients to get precise insights and analyses that align with their unique business requirements and market strategies.

What deliverables can I expect from this automatic Lubrication System market research project?

Clients can expect detailed market analysis reports, data visualizations, segment performance insights, competitive landscape assessments, and forecasts for growth and trends in the automatic lubrication system market, ensuring comprehensive information for strategic decision-making.

What are the market trends of automatic Lubrication System?

Current market trends in the automatic lubrication system sector include a shift towards smart automated systems, increased investment in industrial IoT technologies, and an emphasis on environmentally friendly lubrication solutions. Adoption of advanced materials and systems is also rising across various applications.