Automatic Palletizer And Depalletizer Market Report

Published Date: 22 January 2026 | Report Code: automatic-palletizer-and-depalletizer

Automatic Palletizer And Depalletizer Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report analyzes the Automatic Palletizer and Depalletizer market, focusing on market dynamics, trends, and forecasts from 2023 to 2033. It includes insights into market size, segmentation, regional analysis, and industry leaders, providing a holistic view of the market landscape.

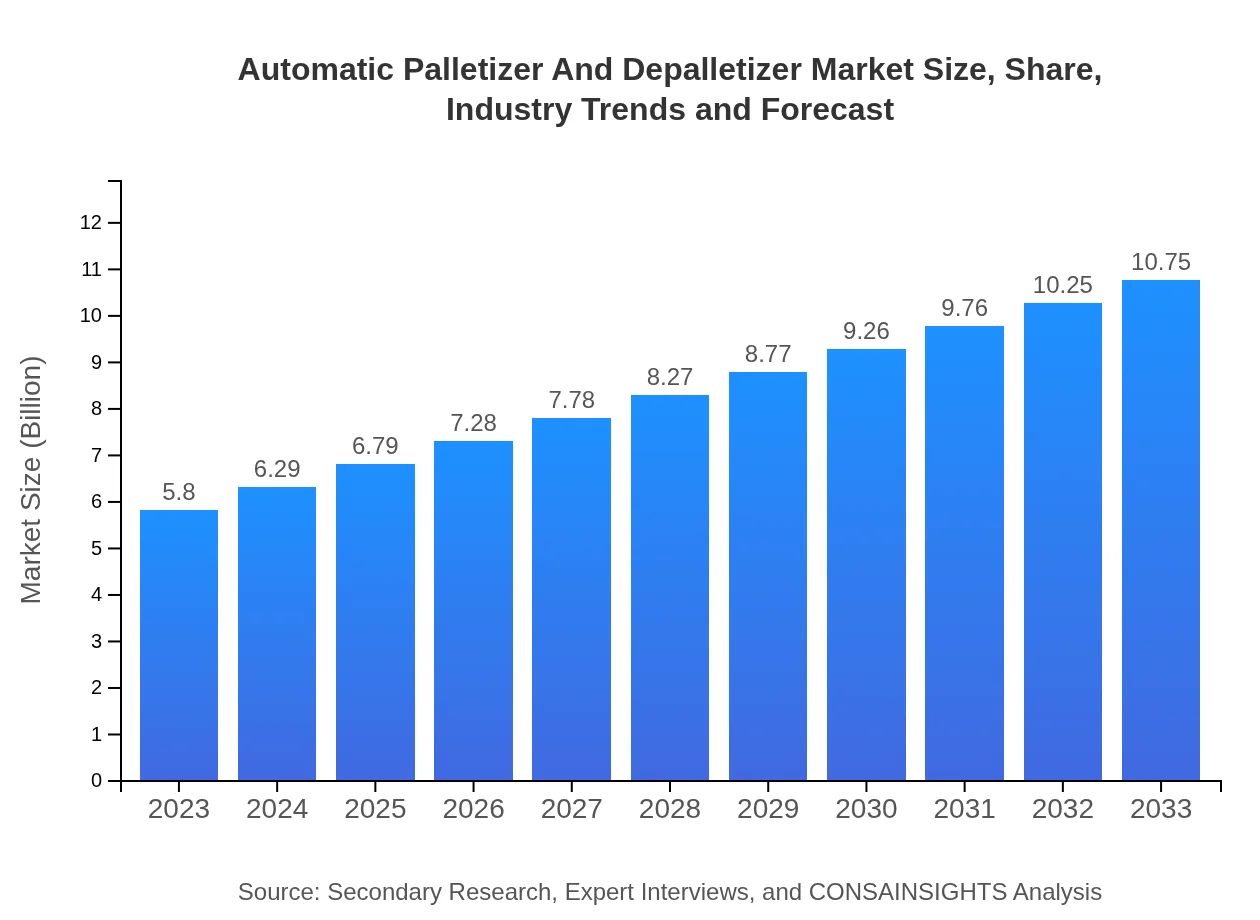

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $10.75 Billion |

| Top Companies | KUKA AG, FANUC Corporation, ABB Ltd., Mitsubishi Electric |

| Last Modified Date | 22 January 2026 |

Automatic Palletizer And Depalletizer Market Overview

Customize Automatic Palletizer And Depalletizer Market Report market research report

- ✔ Get in-depth analysis of Automatic Palletizer And Depalletizer market size, growth, and forecasts.

- ✔ Understand Automatic Palletizer And Depalletizer's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automatic Palletizer And Depalletizer

What is the Market Size & CAGR of Automatic Palletizer And Depalletizer market in 2033?

Automatic Palletizer And Depalletizer Industry Analysis

Automatic Palletizer And Depalletizer Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automatic Palletizer And Depalletizer Market Analysis Report by Region

Europe Automatic Palletizer And Depalletizer Market Report:

The European market is projected to grow from $1.47 billion in 2023 to $2.72 billion by 2033. The growth is driven by the push for higher efficiency in manufacturing processes and a growing focus on sustainability.Asia Pacific Automatic Palletizer And Depalletizer Market Report:

The Asia Pacific region is expected to experience significant growth, with the market size projected to increase from $1.11 billion in 2023 to $2.07 billion by 2033. Factors driving this growth include rapid industrialization, robust manufacturing sectors, and increasing adoption of automation in supply chains.North America Automatic Palletizer And Depalletizer Market Report:

North America leads the market with a size of $2.18 billion in 2023, expected to rise to $4.03 billion in 2033. The region's emphasis on advanced automation solutions and efficient supply chain management contributes significantly to this growth.South America Automatic Palletizer And Depalletizer Market Report:

In South America, the market is anticipated to grow from $0.47 billion in 2023 to $0.88 billion by 2033. The growth will be fueled by increasing investments in manufacturing and logistics enhancements.Middle East & Africa Automatic Palletizer And Depalletizer Market Report:

The market in the Middle East and Africa is expected to show growth from $0.57 billion in 2023 to $1.05 billion by 2033, driven by increasing manufacturing activities and adoption of advanced technologies.Tell us your focus area and get a customized research report.

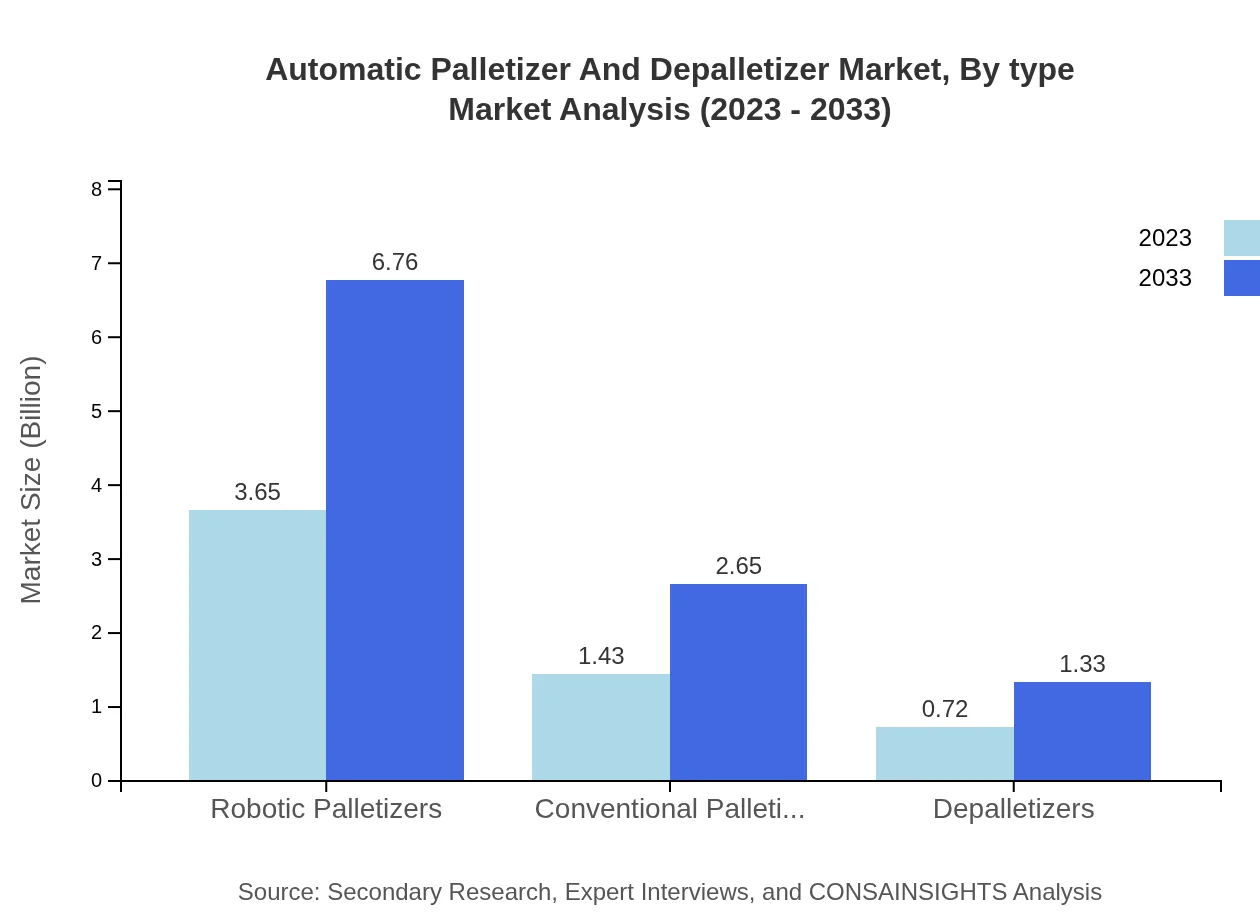

Automatic Palletizer And Depalletizer Market Analysis By Type

Robotic palletizers dominate the market, projected to grow from $3.65 billion in 2023 to $6.76 billion in 2033, capturing approximately 62.91% share. Conventional palletizers will see growth from $1.43 billion to $2.65 billion, maintaining a 24.69% market share. Depalletizers, while smaller, are expected to grow from $0.72 billion (12.4% share) to $1.33 billion by 2033.

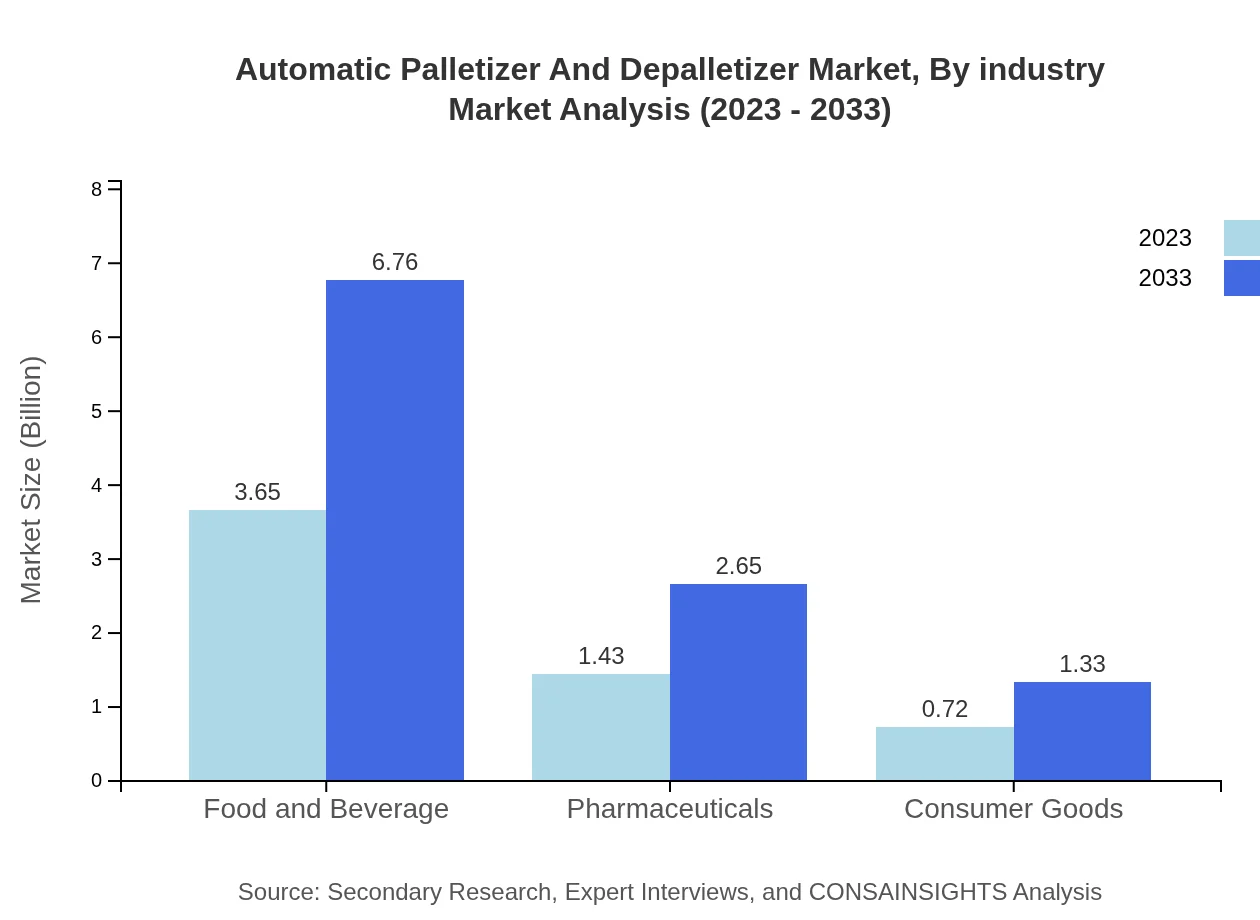

Automatic Palletizer And Depalletizer Market Analysis By Industry

The food and beverage industry is the largest sector, growing from $3.65 billion (62.91% share) in 2023 to $6.76 billion by 2033. Pharmaceuticals hold a significant portion with growth from $1.43 billion (24.69% share) to $2.65 billion. Consumer goods will rise from $0.72 billion (12.4% share) to $1.33 billion in the same timeframe.

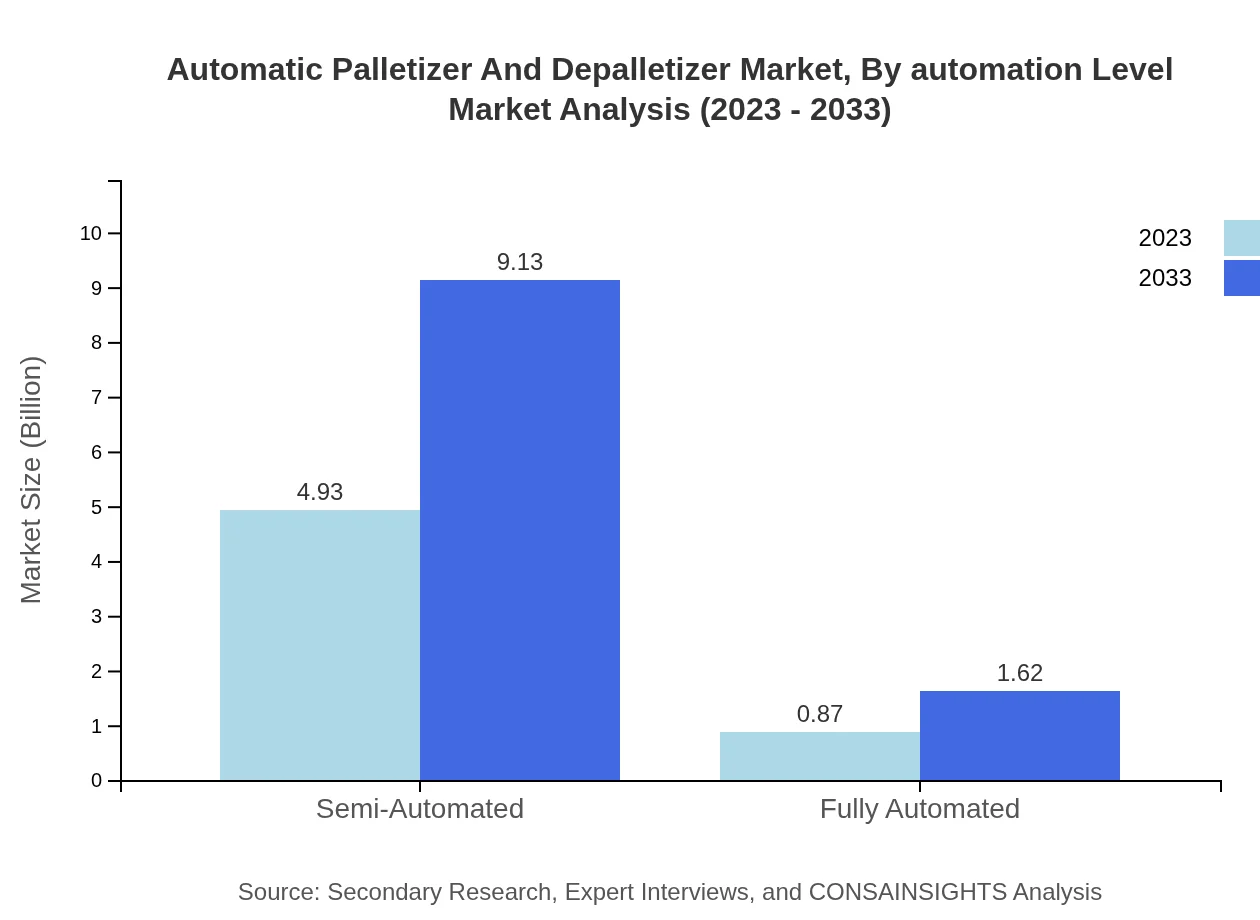

Automatic Palletizer And Depalletizer Market Analysis By Automation Level

The semi-automated systems dominate with a market size of $4.93 billion in 2023, expected to grow to $9.13 billion by 2033, maintaining an 84.96% market share. Fully automated systems are projected to increase from $0.87 billion to $1.62 billion, capturing a 15.04% share.

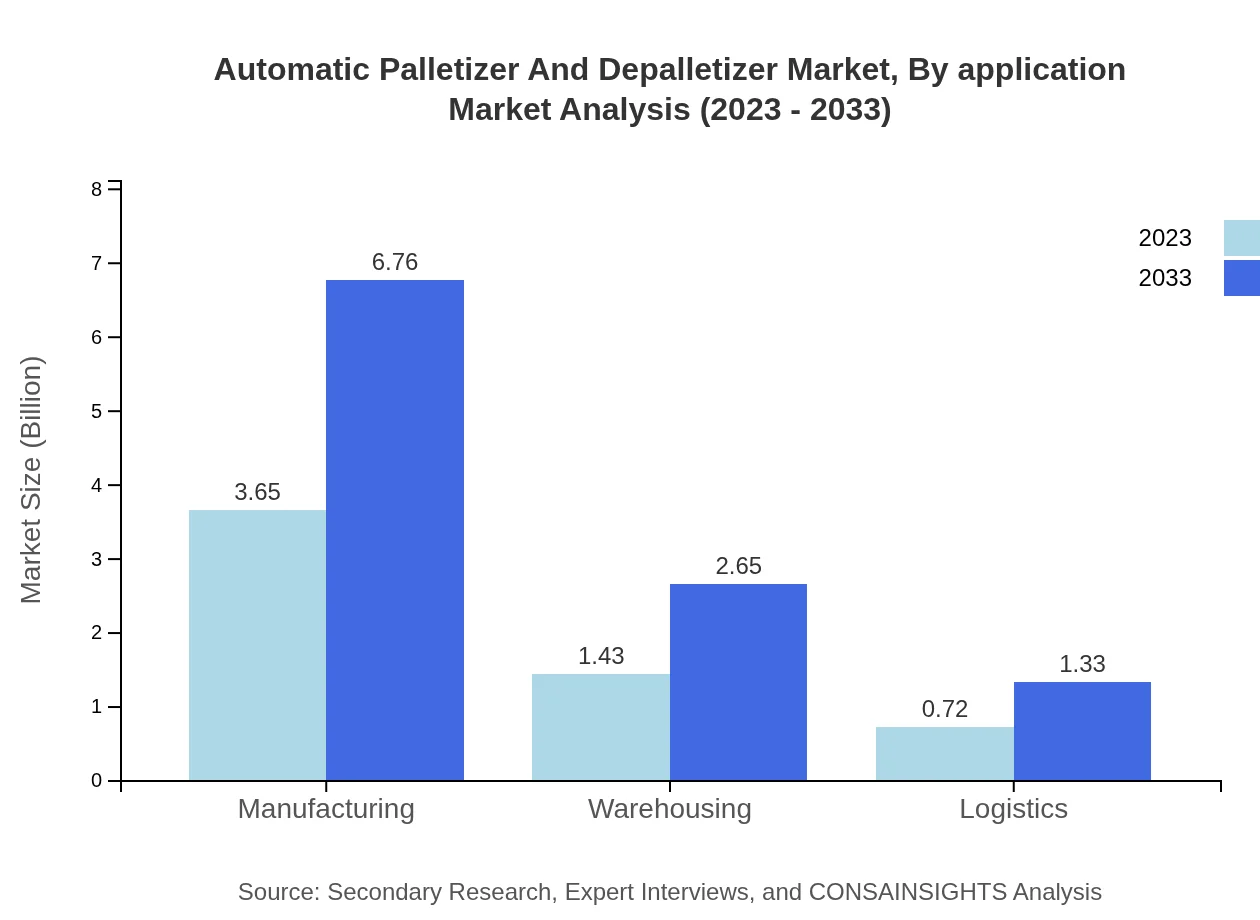

Automatic Palletizer And Depalletizer Market Analysis By Application

The manufacturing application holds the largest segment, growing from $3.65 billion (62.91% share) in 2023 to $6.76 billion in 2033. The warehousing segment will grow from $1.43 billion (24.69% share) to $2.65 billion, while the logistics application is expected to rise from $0.72 billion (12.4% share) to $1.33 billion.

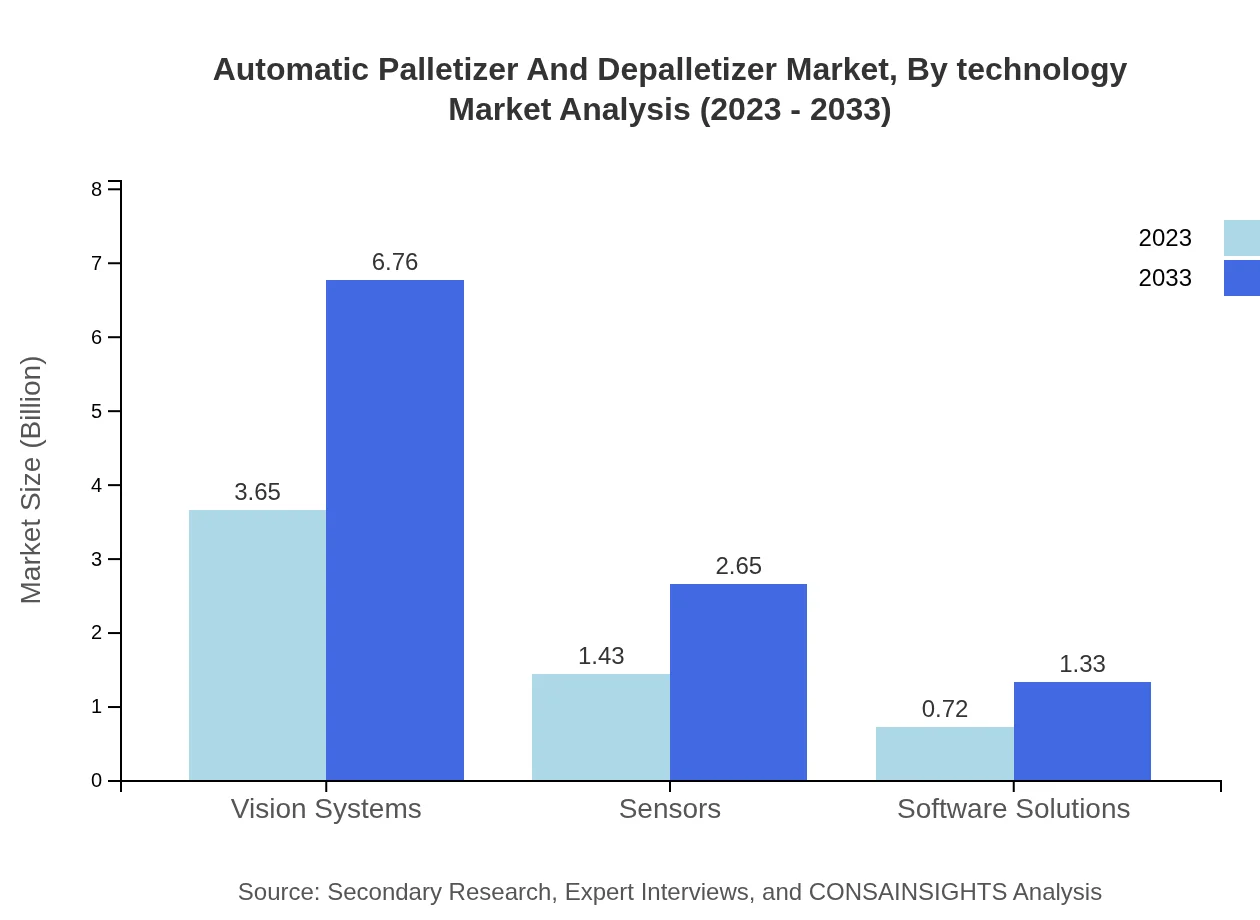

Automatic Palletizer And Depalletizer Market Analysis By Technology

Market demand for advanced technology involving vision systems is projected to increase significantly, growing from $3.65 billion (62.91% share) to $6.76 billion in 2033. Sensors will grow from $1.43 billion (24.69% share) to $2.65 billion, while software solutions will see an increase from $0.72 billion (12.4% share) to $1.33 billion.

Automatic Palletizer And Depalletizer Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automatic Palletizer And Depalletizer Industry

KUKA AG:

KUKA is a leading global supplier of intelligent automation solutions, specializing in robotic polymer and assembly systems for various industries.FANUC Corporation:

FANUC Corporation is renowned for its CNC systems and robotics, providing effective solutions that enhance efficiency and productivity in manufacturing.ABB Ltd.:

ABB is a pioneering technology leader working in areas such as electrification, robotics, and industrial automation, helping factories achieve superior production efficiency.Mitsubishi Electric:

Mitsubishi Electric designs and manufactures advanced factory automation solutions and servo motors that drive efficiency in production lines.We're grateful to work with incredible clients.

FAQs

What is the market size of automatic palletizer and depalletizer?

The global market size for automatic palletizers and depalletizers is projected to reach $5.8 billion by 2033, with a CAGR of 6.2% from 2023 to 2033.

What are the key market players or companies in this industry?

Key players in the automatic palletizer and depalletizer market include KUKA AG, FANUC Corporation, and ABB Ltd., among others, who dominate by offering diverse automated solutions to enhance efficiency in various sectors.

What are the primary factors driving the growth in the industry?

Growth drivers for the automatic palletizer and depalletizer market include increasing demand for efficiency in manufacturing, heightened labor costs, and the growing need for automation across industries like food and beverage and pharmaceuticals.

Which region is the fastest Growing in the market?

The Asia Pacific region is anticipated to be the fastest-growing market for automatic palletizers and depalletizers, with growth projections indicating a rise from $1.11 billion in 2023 to $2.07 billion by 2033.

Does ConsaInsights provide customized market report data for the industry?

Yes, ConsaInsights offers customized market report data tailored to the unique needs of clients in the automatic palletizer and depalletizer industry, ensuring precise insights and analytics relevant to specific business objectives.

What deliverables can I expect from this market research project?

Deliverables from the research project include a comprehensive analysis report, regional market breakdowns, competitive landscape assessments, and actionable insights tailored to strategic decision-making in the automatic palletizer and depalletizer market.

What are the market trends of automatic palletizer and depalletizer?

Current market trends include a significant shift towards robotic palletizers, which comprise a major market share, and an increasing adoption of fully automated systems to enhance operational efficiency across various sectors.