Automotive Adhesive Tape Market Report

Published Date: 02 February 2026 | Report Code: automotive-adhesive-tape

Automotive Adhesive Tape Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Automotive Adhesive Tape market, focusing on market size, growth trends, regional dynamics, and competitive landscape. The insights presented herein are based on data and forecasts for the years 2023 to 2033.

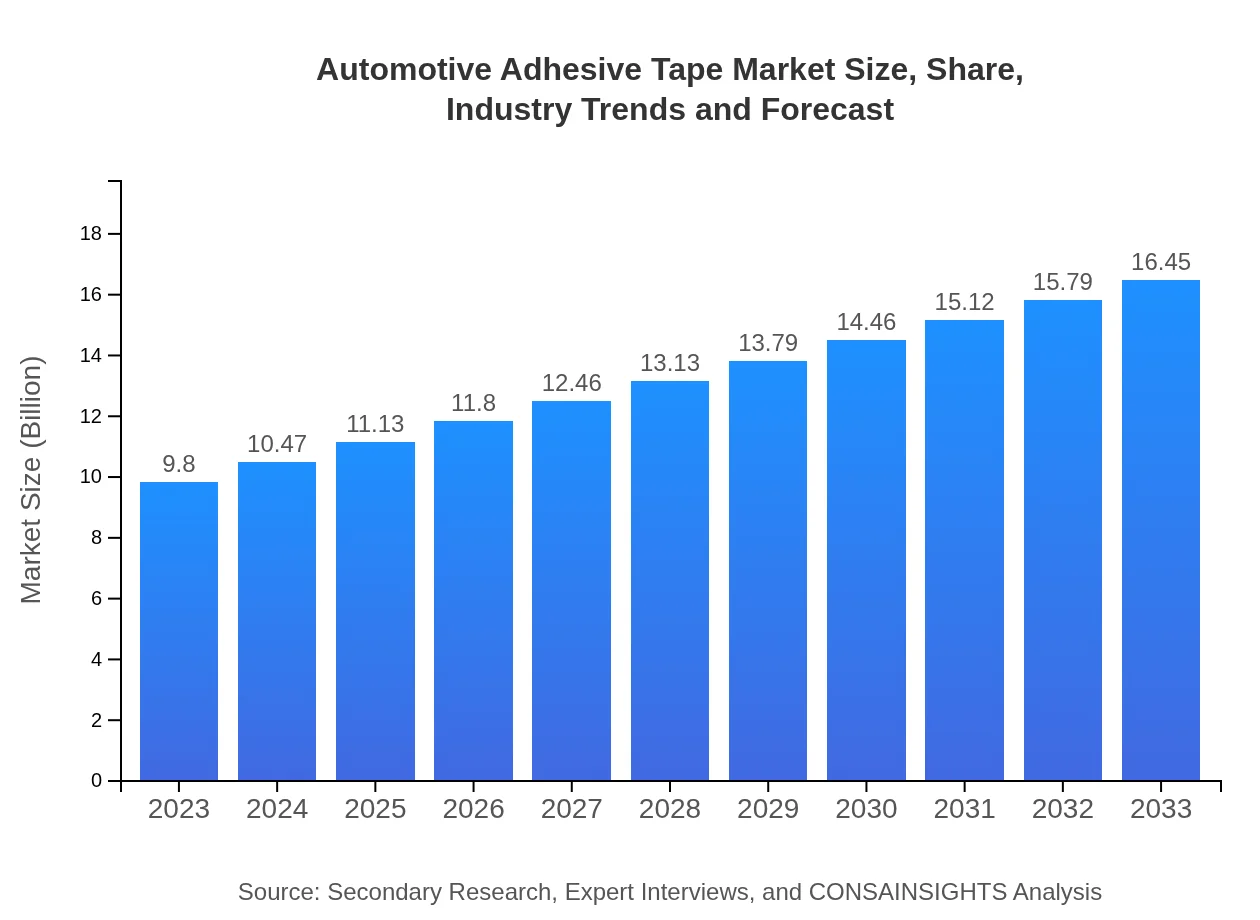

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $9.80 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $16.45 Billion |

| Top Companies | 3M Company, Avery Dennison Corporation, Henkel AG & Co. KGaA, Tesa SE |

| Last Modified Date | 02 February 2026 |

Automotive Adhesive Tape Market Overview

Customize Automotive Adhesive Tape Market Report market research report

- ✔ Get in-depth analysis of Automotive Adhesive Tape market size, growth, and forecasts.

- ✔ Understand Automotive Adhesive Tape's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automotive Adhesive Tape

What is the Market Size & CAGR of Automotive Adhesive Tape market in 2023?

Automotive Adhesive Tape Industry Analysis

Automotive Adhesive Tape Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automotive Adhesive Tape Market Analysis Report by Region

Europe Automotive Adhesive Tape Market Report:

The European market is projected to grow significantly from USD 3.27 billion in 2023 to USD 5.48 billion by 2033, supported by stringent environmental regulations and the push for sustainability in automotive production. The presence of leading automotive manufacturers enhances regional demand for high-quality adhesive tapes.Asia Pacific Automotive Adhesive Tape Market Report:

In the Asia Pacific region, the automotive adhesive tape market is anticipated to grow from USD 1.66 billion in 2023 to USD 2.78 billion by 2033. This growth is driven by increasing automotive production in countries like China and India, along with a rising demand for lightweight vehicles. The availability of cost-effective raw materials and a large consumer base contributes to market expansion.North America Automotive Adhesive Tape Market Report:

North America is expected to witness growth from USD 3.46 billion in 2023 to USD 5.80 billion by 2033, driven by advancements in automotive technologies and a shift towards electric vehicles. The established automotive industry and high consumer spending on vehicle enhancements further fuel market growth.South America Automotive Adhesive Tape Market Report:

The South American market for automotive adhesive tape is projected to rise from USD 0.30 billion in 2023 to USD 0.51 billion in 2033. Factors such as growth in the automotive sector and the demand for improved vehicle performance boost market prospects. However, economic fluctuations in the region may pose challenges in sustaining growth.Middle East & Africa Automotive Adhesive Tape Market Report:

In the Middle East and Africa, the market for automotive adhesive tape is set to increase from USD 1.12 billion in 2023 to USD 1.87 billion by 2033. The expansion of the automotive industry, coupled with increased investments in infrastructure and vehicle production, drives market growth in this region.Tell us your focus area and get a customized research report.

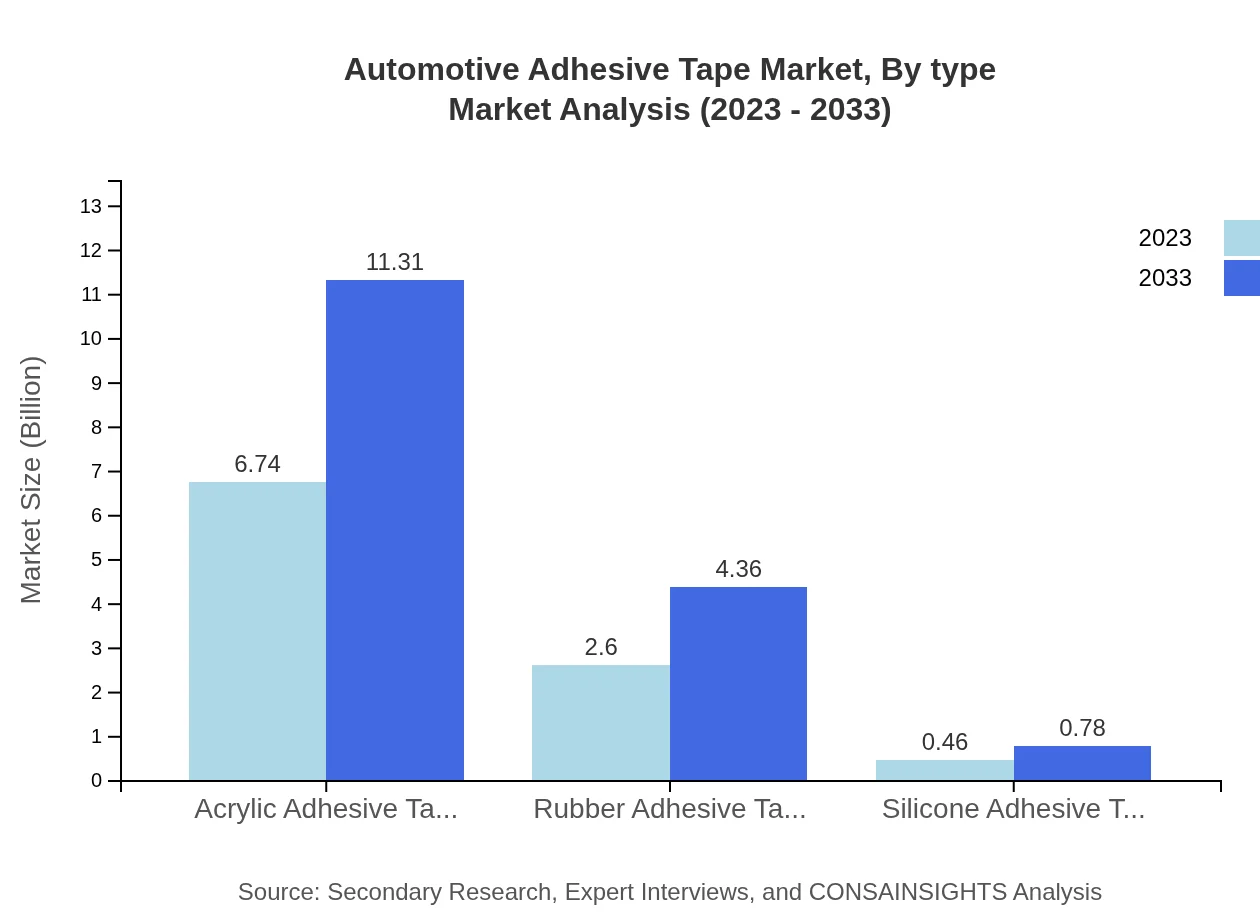

Automotive Adhesive Tape Market Analysis By Type

Acrylic adhesive tapes dominate the market, valued at USD 6.74 billion in 2023 and expected to reach USD 11.31 billion by 2033. They offer excellent adhesion and are resistant to temperature variations. Rubber adhesive tapes follow with a market size of USD 2.60 billion in 2023, projected to grow to USD 4.36 billion by 2033, known for their flexibility and strong bonding properties. Silicone adhesive tapes, while smallest, are also growing, expected to increase from USD 0.46 billion in 2023 to USD 0.78 billion by 2033, appreciated for their heat resistance and versatility.

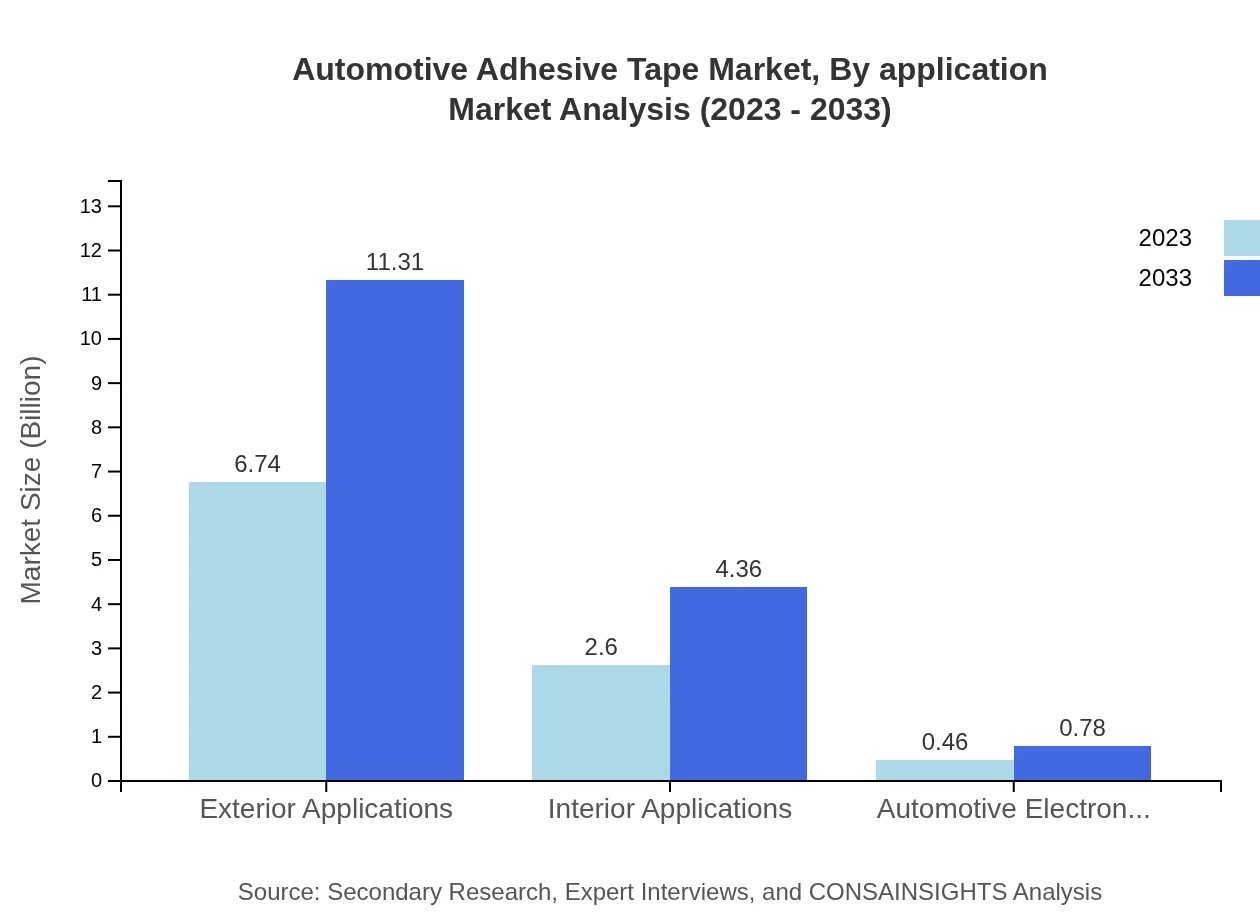

Automotive Adhesive Tape Market Analysis By Application

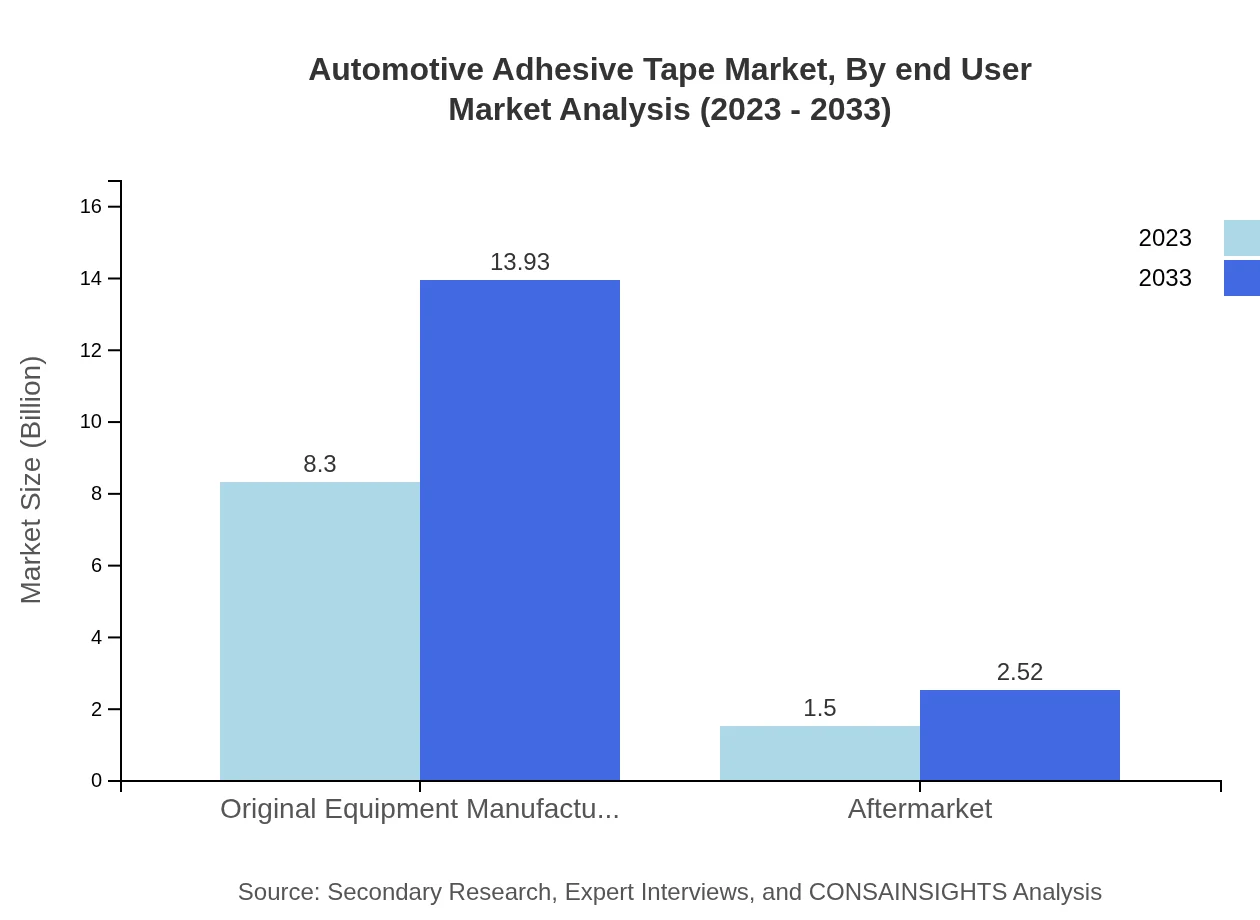

The OEM segment is the leading application for automotive adhesive tapes, accounting for USD 8.30 billion in 2023 and forecasted to reach USD 13.93 billion by 2033, driven by the growing automotive manufacturing sector. The aftermarket segment is also significant, with a projected growth from USD 1.50 billion in 2023 to USD 2.52 billion by 2033, fueled by increasing vehicle maintenance and repair activities.

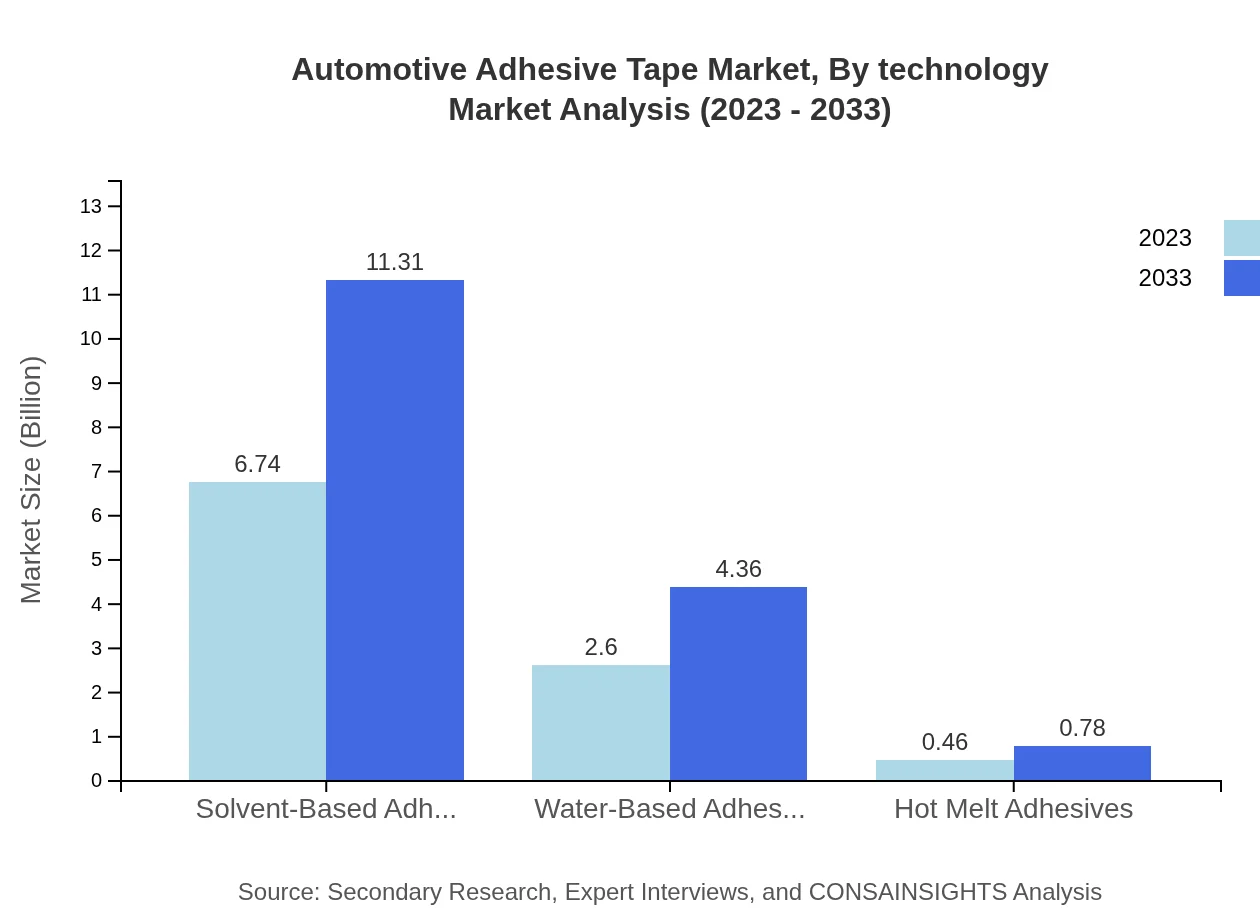

Automotive Adhesive Tape Market Analysis By Technology

Solvent-based adhesives are prominent, valued at USD 6.74 billion in 2023 and expected to grow to USD 11.31 billion by 2033, offering excellent adhesion and durability. Water-based adhesives, accounting for USD 2.60 billion in 2023, are projected to reach USD 4.36 billion by 2033, recognized for their eco-friendliness. Hot melt adhesives, though the smallest segment, are anticipated to see growth from USD 0.46 billion in 2023 to USD 0.78 billion by 2033, due to their quick bonding capabilities and ease of application.

Automotive Adhesive Tape Market Analysis By End User

The OEM end-user segment leads the market, with a size of USD 8.30 billion in 2023 and expected to grow to USD 13.93 billion by 2033, reflecting the robust demand from automotive manufacturers. The aftermarket segment, valued at USD 1.50 billion in 2023, is expected to reach USD 2.52 billion by 2033 as vehicle owners increasingly seek adhesive solutions for repairs and enhancements.

Automotive Adhesive Tape Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automotive Adhesive Tape Industry

3M Company:

3M is a global leader in adhesive tapes, providing innovative solutions for automotive applications. Their extensive product range includes adhesive tapes that enhance vehicle assembly and performance.Avery Dennison Corporation:

Avery Dennison specializes in adhesives and tapes, focusing on sustainable solutions. Their automotive adhesive tapes are designed to meet high-performance standards and support vehicle efficiency.Henkel AG & Co. KGaA:

Henkel is renowned for its adhesive technologies, including high-quality automotive adhesive tapes. Their products are widely used in OEM and aftermarket applications.Tesa SE:

Tesa is a leading manufacturer of adhesive tapes, offering a diverse portfolio tailored for the automotive industry. They provide innovative solutions to enhance productivity and vehicle quality.We're grateful to work with incredible clients.

FAQs

What is the market size of automotive Adhesive Tape?

The global automotive adhesive tape market is projected to reach approximately $9.8 billion by 2033, growing at a CAGR of 5.2%. This growth highlights the increasing demand for adhesive solutions in automotive applications.

What are the key market players or companies in this automotive Adhesive Tape industry?

Key players in the automotive adhesive tape market include manufacturers such as 3M, tesa SE, Nitto Denko Corporation, Avery Dennison, and Henkel AG. These companies are recognized for their innovation and extensive product offerings tailored for automotive applications.

What are the primary factors driving the growth in the automotive Adhesive Tape industry?

The growth of the automotive adhesive tape industry is primarily driven by increasing vehicle production and demand for lightweight materials. Additionally, advancements in adhesive technology and the growing trend towards electric and hybrid vehicles are significant growth factors.

Which region is the fastest Growing in the automotive Adhesive Tape?

The Asia Pacific region is the fastest-growing market for automotive adhesive tapes, expected to grow from $1.66 billion in 2023 to $2.78 billion by 2033. This growth is fueled by rising automotive production and demand in countries like China and India.

Does ConsaInsights provide customized market report data for the automotive Adhesive Tape industry?

Yes, ConsaInsights offers customized market report data for the automotive adhesive tape industry. Clients can request tailored analysis to fit specific needs, ensuring comprehensive insights to guide their strategic decisions.

What deliverables can I expect from this automotive Adhesive Tape market research project?

Deliverables from the automotive adhesive tape market research project include detailed market reports, trend analysis, competitive landscape evaluations, forecasts, and insights on consumer behavior and pricing strategies tailored to your objectives.

What are the market trends of automotive Adhesive Tape?

Current market trends in automotive adhesive tape include a shift towards eco-friendly materials, increased use of digital printing technology, and growth in the aftermarket segment. Innovations in adhesive formulations are also on the rise, catering to various automotive applications.