Automotive Conformal Coatings Market Report

Published Date: 02 February 2026 | Report Code: automotive-conformal-coatings

Automotive Conformal Coatings Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Automotive Conformal Coatings market, exploring its growth potential and trends from 2023 to 2033. It offers insights into market size, segmentation, regional dynamics, product performance, and key industry players.

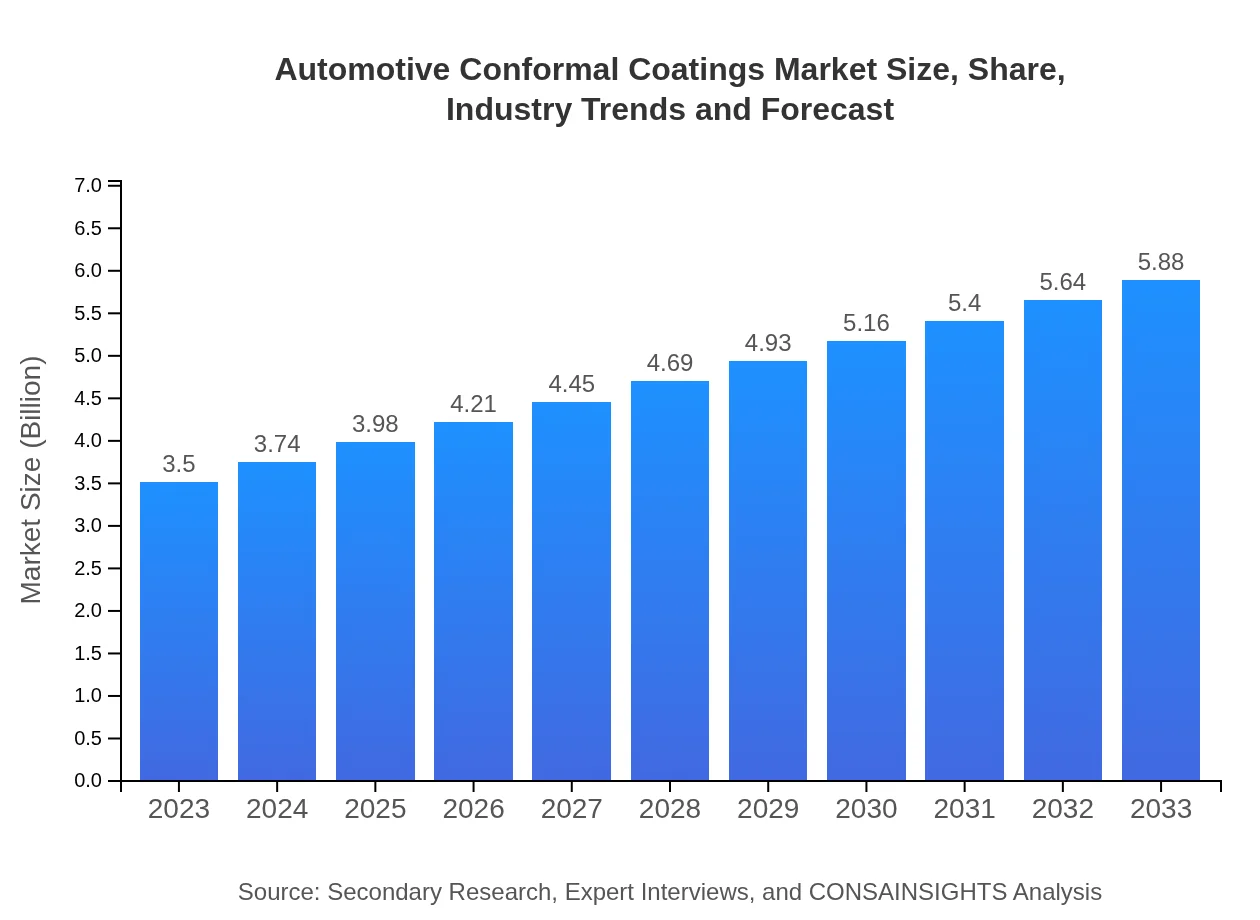

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $5.88 Billion |

| Top Companies | Henkel AG & Co., Dow Inc., AECOM, 3M Company, DuPont de Nemours, Inc. |

| Last Modified Date | 02 February 2026 |

Automotive Conformal Coatings Market Overview

Customize Automotive Conformal Coatings Market Report market research report

- ✔ Get in-depth analysis of Automotive Conformal Coatings market size, growth, and forecasts.

- ✔ Understand Automotive Conformal Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automotive Conformal Coatings

What is the Market Size & CAGR of Automotive Conformal Coatings market in 2023 and 2033?

Automotive Conformal Coatings Industry Analysis

Automotive Conformal Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automotive Conformal Coatings Market Analysis Report by Region

Europe Automotive Conformal Coatings Market Report:

The European market for Automotive Conformal Coatings is expected to increase from USD 1.01 billion in 2023 to USD 1.70 billion by 2033. Factors such as a strong vehicle manufacturing base, growing demand for electric vehicles, and regulatory mandates for efficient vehicle performance contribute to market expansion.Asia Pacific Automotive Conformal Coatings Market Report:

The Asia Pacific region is projected to witness substantial growth, with the market size expected to increase from USD 0.66 billion in 2023 to USD 1.11 billion by 2033. This growth is driven by rising automotive production in countries like China and Japan, increasing demand for advanced coatings, and the growing electronics sector.North America Automotive Conformal Coatings Market Report:

North America holds a significant market share, with its market size projected to grow from USD 1.34 billion in 2023 to USD 2.26 billion by 2033. The region's robust automotive industry, emphasis on electric vehicles, and adherence to stringent environmental regulations propel the demand for conformal coatings.South America Automotive Conformal Coatings Market Report:

In South America, the Automotive Conformal Coatings market is poised to grow from USD 0.32 billion in 2023 to USD 0.54 billion by 2033. The region's growth is influenced by expanding automotive manufacturing and rising consumer purchasing power, coupled with increasing focus on vehicle protection and durability.Middle East & Africa Automotive Conformal Coatings Market Report:

The Market in the Middle East and Africa is projected to grow from USD 0.16 billion in 2023 to USD 0.27 billion by 2033. The expansion is driven by an increase in automotive activities and rising investments in manufacturing facilities, alongside a growing focus on vehicle longevity.Tell us your focus area and get a customized research report.

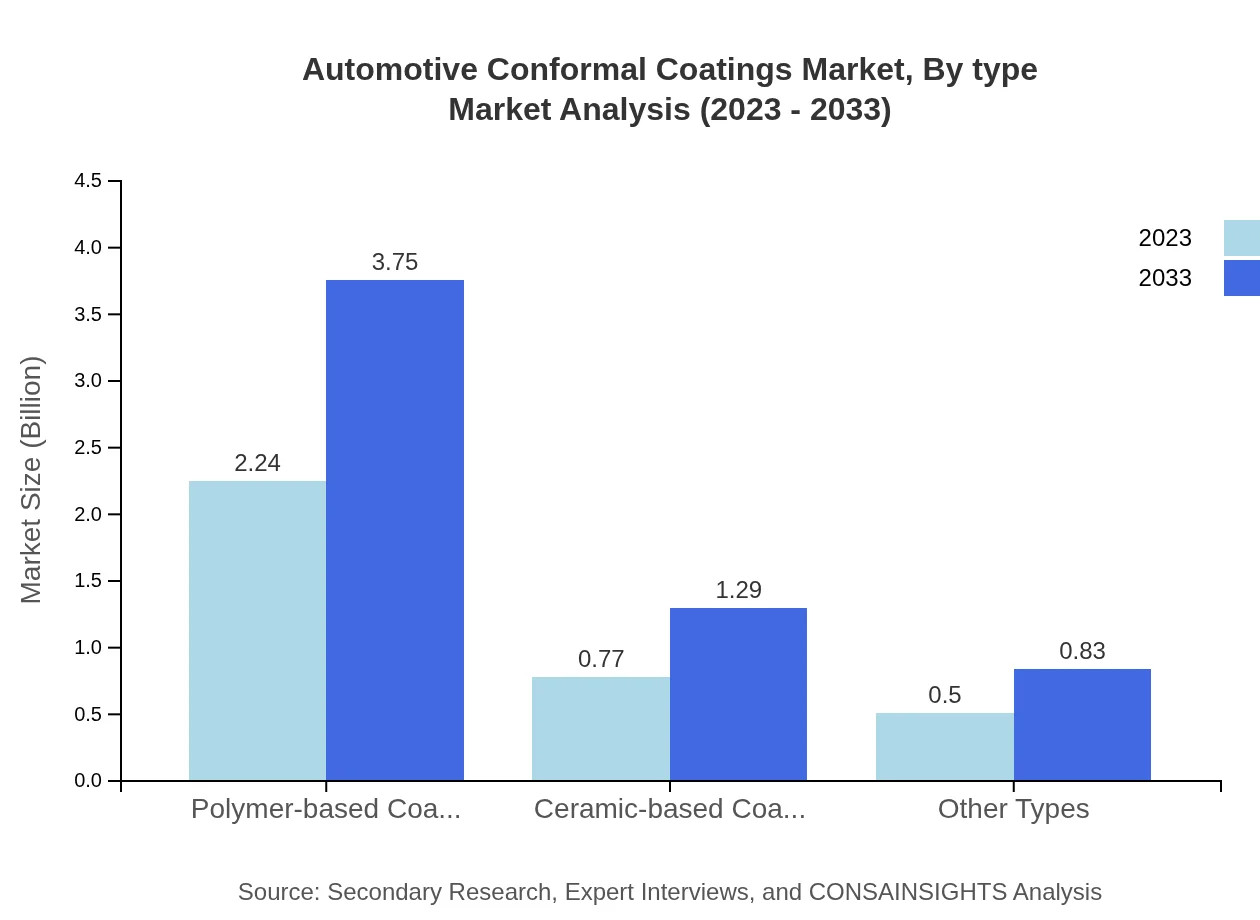

Automotive Conformal Coatings Market Analysis By Type

The Automotive Conformal Coatings market is predominantly driven by polymer-based coatings, which constituted a market size of USD 2.24 billion in 2023 and are anticipated to grow to USD 3.75 billion by 2033, maintaining a market share of 63.86%. Ceramic-based coatings, anticipated to rise from USD 0.77 billion to USD 1.29 billion while holding 21.99% market share, are gaining popularity due to their high thermal performance. Other types account for a growing segment, increasing from USD 0.50 billion to USD 0.83 billion and holding a 14.15% share.

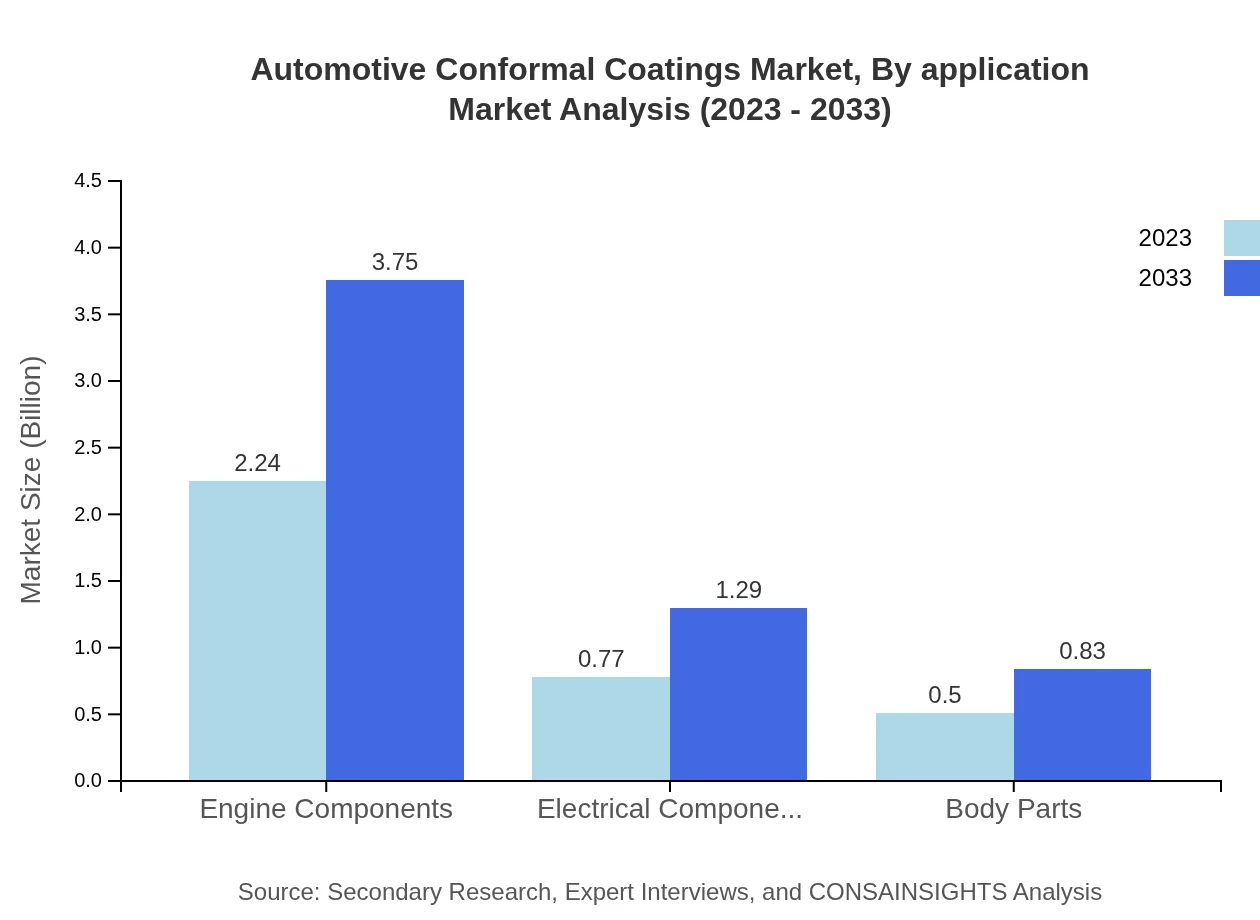

Automotive Conformal Coatings Market Analysis By Application

Engine Components are the leading application segment, representing a market size of USD 2.24 billion in 2023, estimated to rise to USD 3.75 billion by 2033, capturing 63.86% of the market share. Electrical components follow closely, expected to grow from USD 0.77 billion to USD 1.29 billion with a 21.99% share. Body parts segment is also significant, increasing from USD 0.50 billion to USD 0.83 billion and holding a 14.15% share.

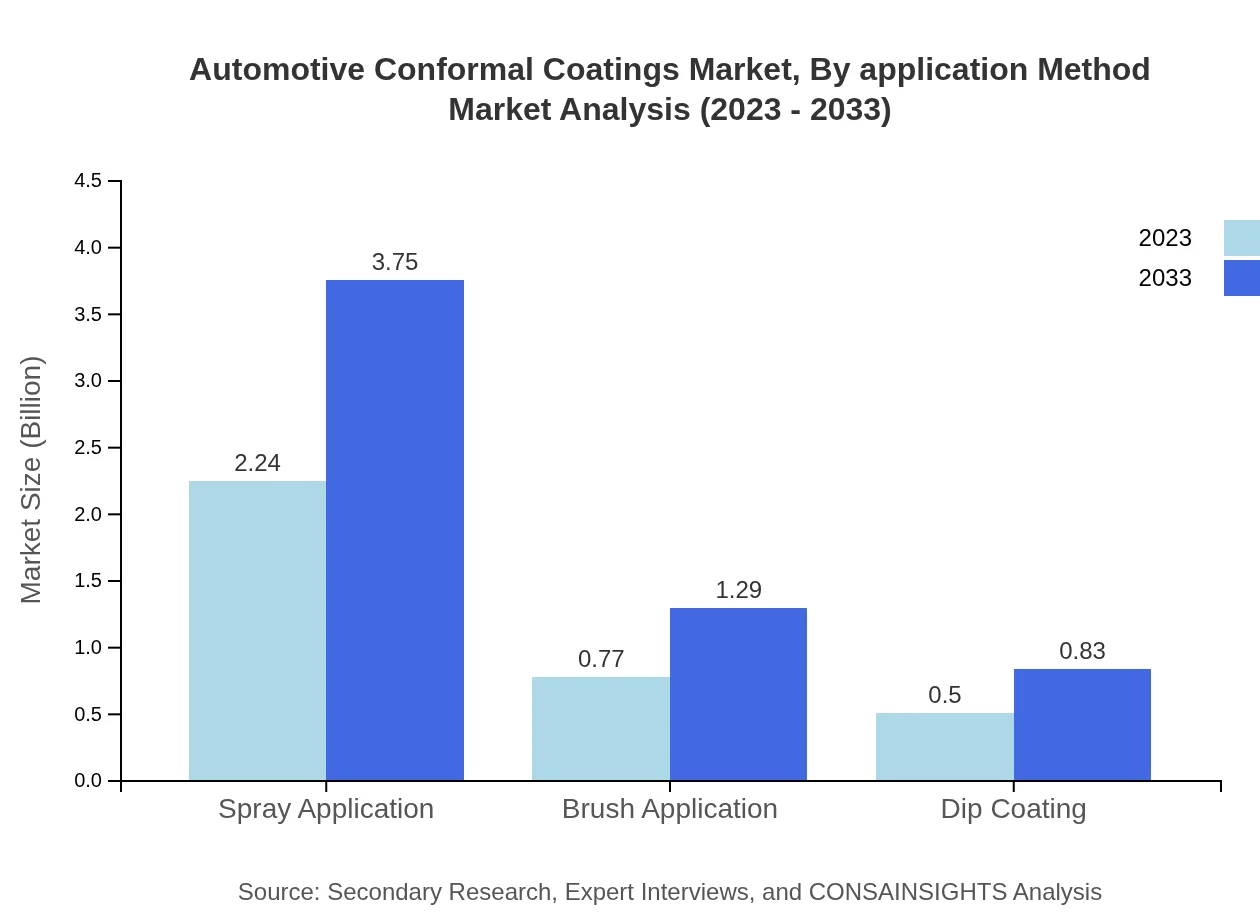

Automotive Conformal Coatings Market Analysis By Application Method

Spray application dominates the market, growing from USD 2.24 billion in 2023 to USD 3.75 billion by 2033, holding a share of 63.86%. Brush application accounts for USD 0.77 billion to USD 1.29 billion over the same period, capturing 21.99% market. Dip coating contributes to the overall market by increasing from USD 0.50 billion to USD 0.83 billion, with a 14.15% market share.

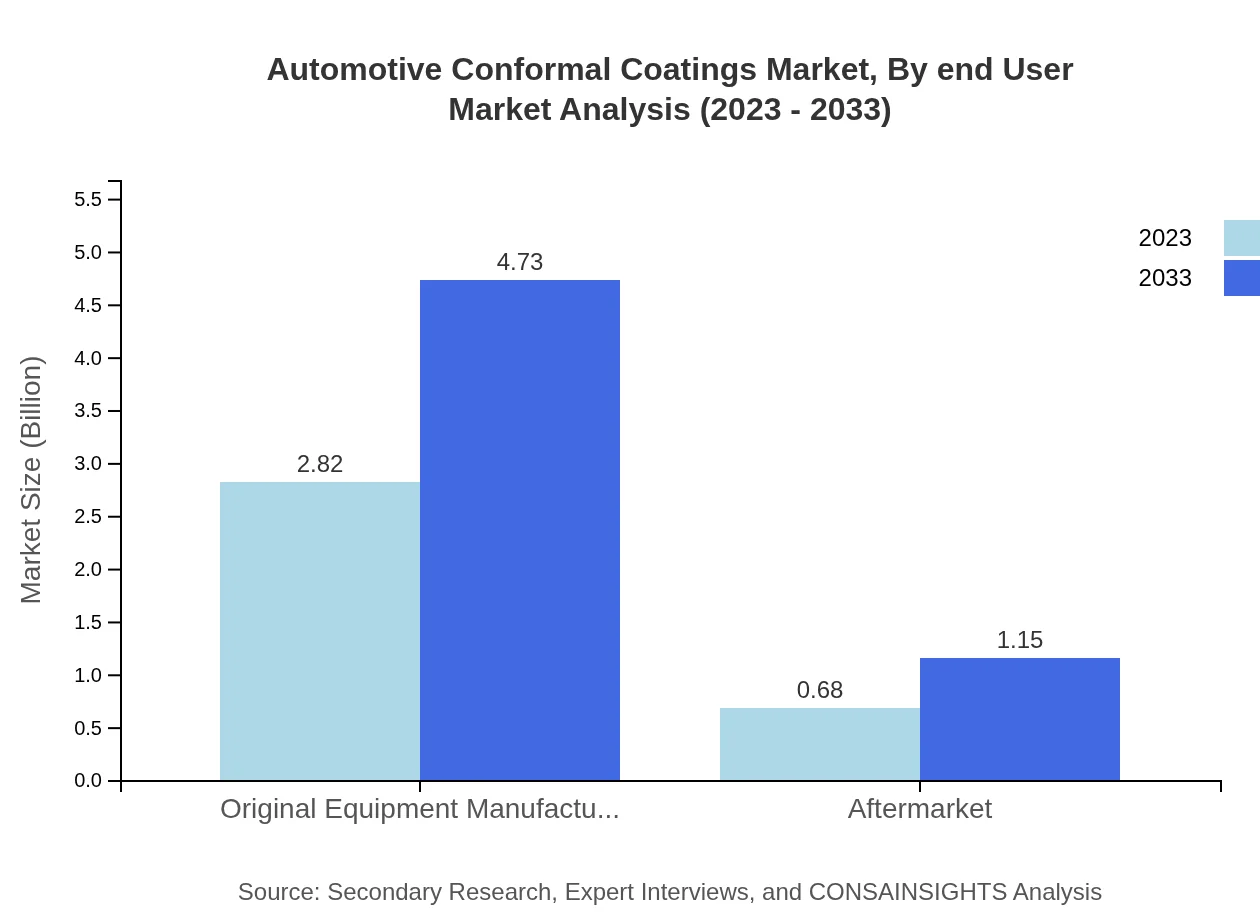

Automotive Conformal Coatings Market Analysis By End User

Original Equipment Manufacturers (OEMs) lead the end-user segment with a market size of USD 2.82 billion in 2023, projected to reach USD 4.73 billion by 2033, representing 80.45% market share. The Aftermarket segment is projected to increase from USD 0.68 billion to USD 1.15 billion during the forecast period, holding a share of 19.55%. This trend underscores the vital role of OEMs in driving conformal coating technologies.

Automotive Conformal Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automotive Conformal Coatings Industry

Henkel AG & Co.:

Henkel is a market leader specializing in adhesives, sealants, and surface treatments, offering advanced conformal coatings to protect sensitive electronic components in automobiles.Dow Inc.:

Dow provides innovative coating solutions, including conformal coatings, to improve automotive durability and functionality, emphasizing sustainability and high performance.AECOM:

AECOM is known for its engineering and construction solutions, focusing on advanced materials and innovative coatings for automotive applications, enhancing vehicle performance.3M Company:

3M develops high-performance conformal coatings that provide exceptional protection for electronic parts in vehicles, leading to enhanced reliability and longevity.DuPont de Nemours, Inc.:

DuPont is a key player in the coatings industry, producing advanced conformal coatings that deliver unique thermal and chemical resistance for automotive applications.We're grateful to work with incredible clients.

FAQs

What is the market size of automotive Conformal Coatings?

The automotive conformal coatings market is valued at approximately $3.5 billion in 2023, and it is projected to grow with a CAGR of 5.2% over the next decade, driving growth in adoption across the automotive industry.

What are the key market players or companies in the automotive Conformal Coatings industry?

Key market players in the automotive conformal coatings industry include companies like PPG Industries, Sherwin-Williams, Henkel AG, and Dow Chemical Company, which are recognized for their innovative coating solutions and significant market share.

What are the primary factors driving the growth in the automotive Conformal Coatings industry?

The growth in the automotive conformal coatings industry is primarily driven by the increasing demand for lightweight materials, technological advancements in coating solutions, and the rising need for enhanced vehicle durability and longevity.

Which region is the fastest Growing in the automotive Conformal Coatings?

The fastest-growing region in the automotive conformal coatings market is North America, with the market projected to grow from $1.34 billion in 2023 to $2.26 billion by 2033, showcasing a strong CAGR.

Does ConsaInsights provide customized market report data for the automotive Conformal Coatings industry?

Yes, ConsaInsights offers customized market report data tailored to the unique requirements of clients in the automotive conformal coatings industry, enabling businesses to make informed decisions.

What deliverables can I expect from this automotive Conformal Coatings market research project?

From the automotive conformal coatings market research project, you can expect comprehensive market reports, actionable insights, detailed regional analysis, and segmented data covering various applications and technologies.

What are the market trends of automotive Conformal Coatings?

Current market trends in automotive conformal coatings include increased adoption of polymer-based coatings, innovation in application techniques, and a focus on sustainable and environmentally-friendly coating products.