Automotive Die Casting Lubricants Market Report

Published Date: 02 February 2026 | Report Code: automotive-die-casting-lubricants

Automotive Die Casting Lubricants Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Automotive Die Casting Lubricants market, including market size, growth trends, segmentation, and forecasts from 2023 to 2033. Insights into regional performance, industry dynamics, and competitive landscape are detailed for informed decision-making.

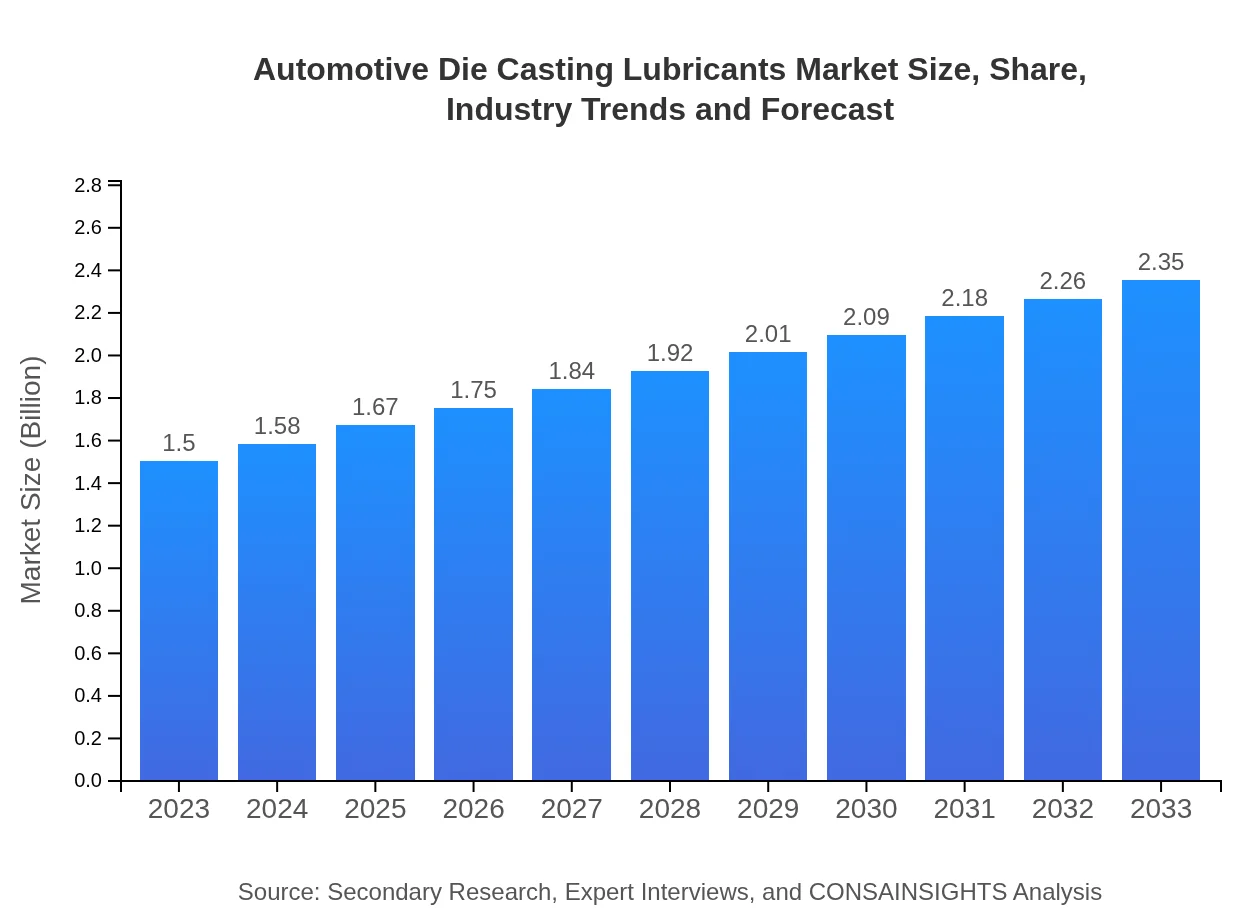

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $2.35 Billion |

| Top Companies | Fuchs Petrolub SE, Castrol Ltd., Chevron Corporation, ExxonMobil |

| Last Modified Date | 02 February 2026 |

Automotive Die Casting Lubricants Market Overview

Customize Automotive Die Casting Lubricants Market Report market research report

- ✔ Get in-depth analysis of Automotive Die Casting Lubricants market size, growth, and forecasts.

- ✔ Understand Automotive Die Casting Lubricants's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automotive Die Casting Lubricants

What is the Market Size & CAGR of Automotive Die Casting Lubricants market in 2023 and 2033?

Automotive Die Casting Lubricants Industry Analysis

Automotive Die Casting Lubricants Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automotive Die Casting Lubricants Market Analysis Report by Region

Europe Automotive Die Casting Lubricants Market Report:

Europe accounted for a market size of $0.37 billion in 2023, which is expected to expand to $0.58 billion by 2033. Stringent environmental regulations and the increasing push toward sustainability in auto manufacturing are influencing lubricant development in this region.Asia Pacific Automotive Die Casting Lubricants Market Report:

The Asia Pacific region held a market share of approximately $0.29 billion in 2023, expected to reach $0.46 billion by 2033, driven by rapid industrialization and a growing automotive sector. Countries like China and India are significant contributors to this growth due to their burgeoning automotive manufacturing capabilities.North America Automotive Die Casting Lubricants Market Report:

The North American market was approximately $0.58 billion in 2023 and is projected to reach $0.92 billion by 2033. The presence of leading automakers and the high adoption of advanced die-casting technologies are key drivers in this region.South America Automotive Die Casting Lubricants Market Report:

In South America, the market was valued at around $0.07 billion in 2023 and is forecasted to grow to about $0.11 billion by 2033. The expansion of the automotive sector, particularly in Brazil, is bolstering the demand for die casting lubricants.Middle East & Africa Automotive Die Casting Lubricants Market Report:

The Middle East and Africa market, valued at around $0.19 billion in 2023, is anticipated to grow to $0.29 billion by 2033. Growth is driven by automotive manufacturing efforts in nations like South Africa, enhancing the demand for high-performance lubricants.Tell us your focus area and get a customized research report.

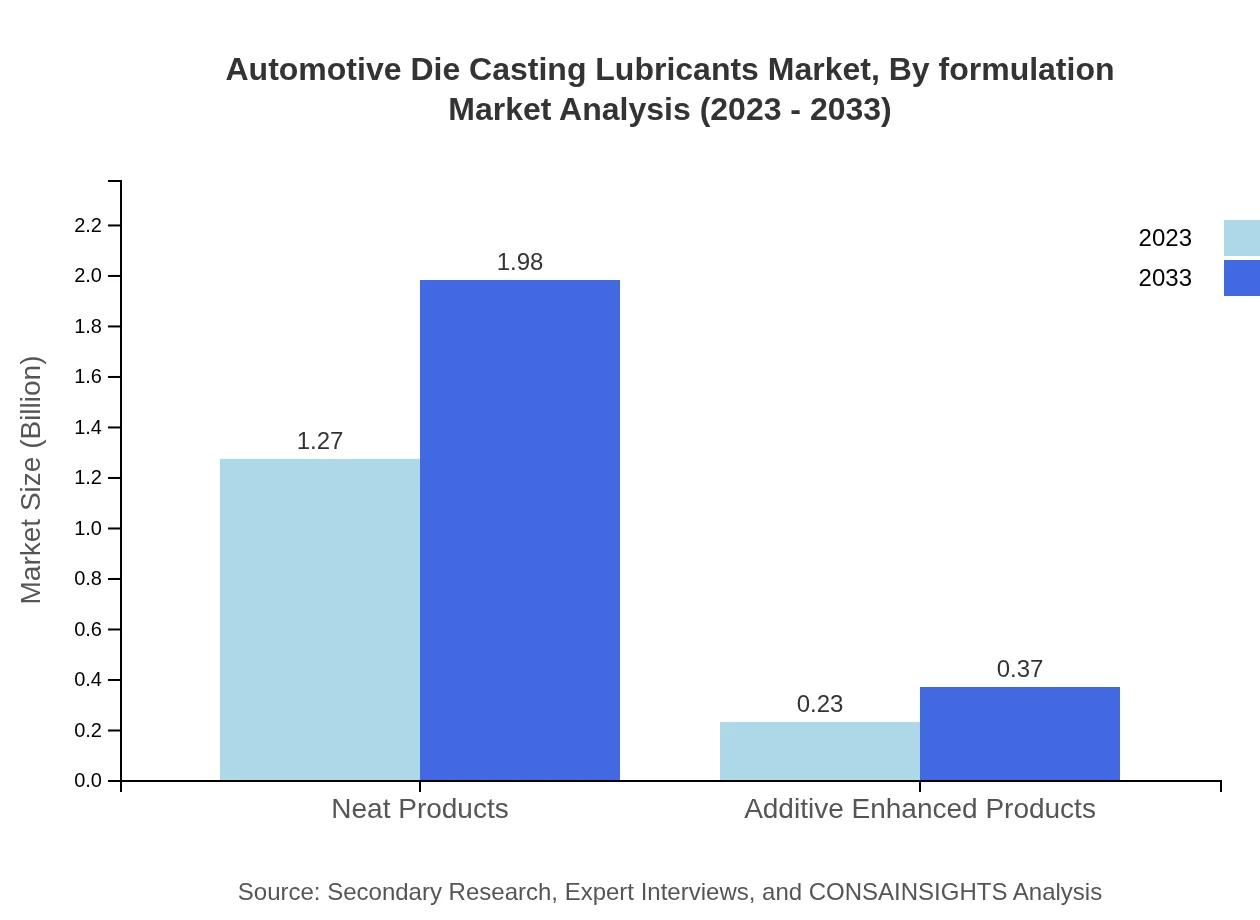

Automotive Die Casting Lubricants Market Analysis By Product Type

The market is primarily segmented into Neat Products and Additive Enhanced Products. In 2023, neat products accounted for $1.27 billion, showing their predominant usage due to their high performance in die casting applications. By 2033, this segment is expected to grow to $1.98 billion. Additive Enhanced Products, while smaller at $0.23 billion in 2023, also show a favorable growth trend, projected to reach $0.37 billion by 2033.

Automotive Die Casting Lubricants Market Analysis By Application

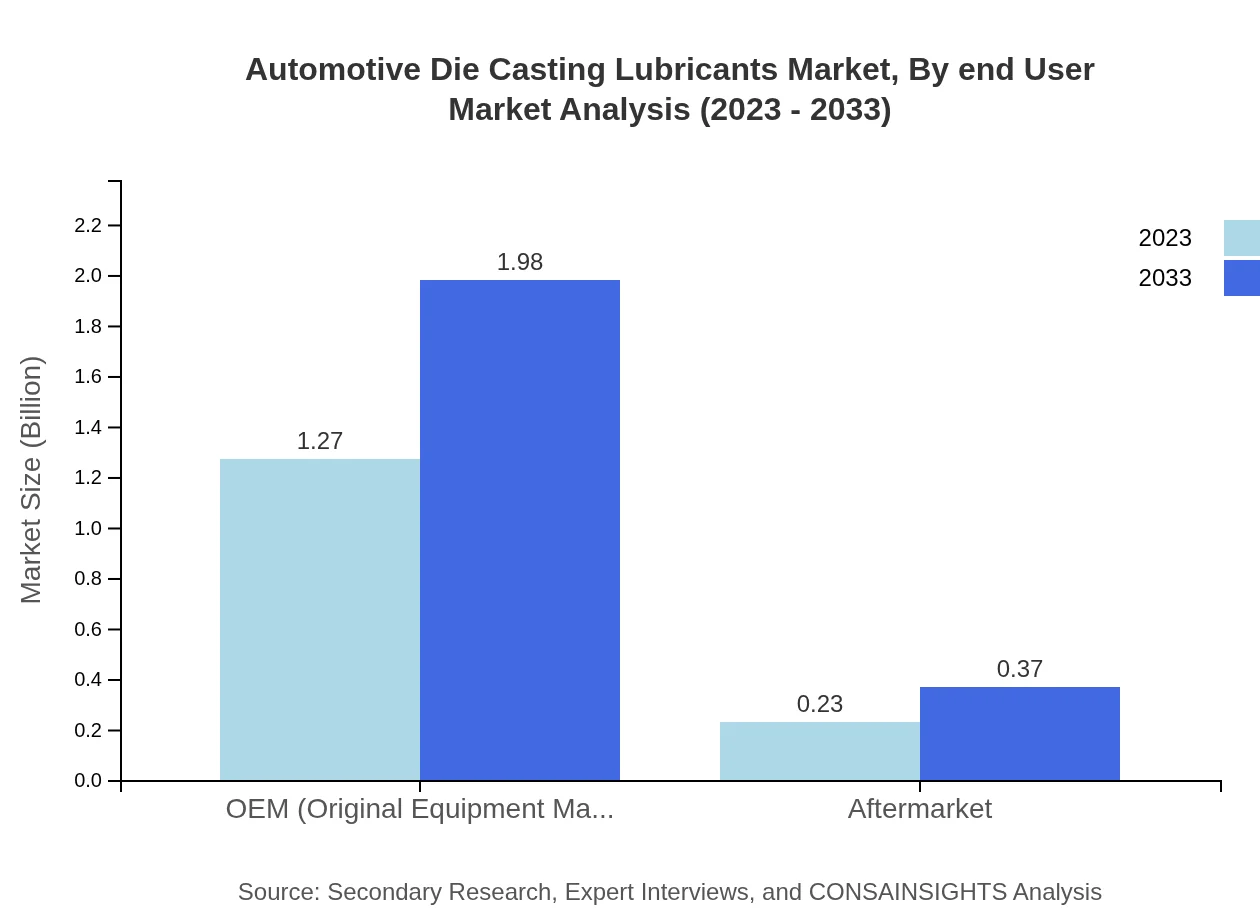

Applications can be categorized into categories like OEMs and Aftermarket. The OEM segment was significant at $1.27 billion in 2023 and is expected to rise to $1.98 billion by 2033. The aftermarket segment, while smaller, is anticipated to grow from $0.23 billion in 2023 to $0.37 billion by 2033, reflecting ongoing vehicle maintenance needs.

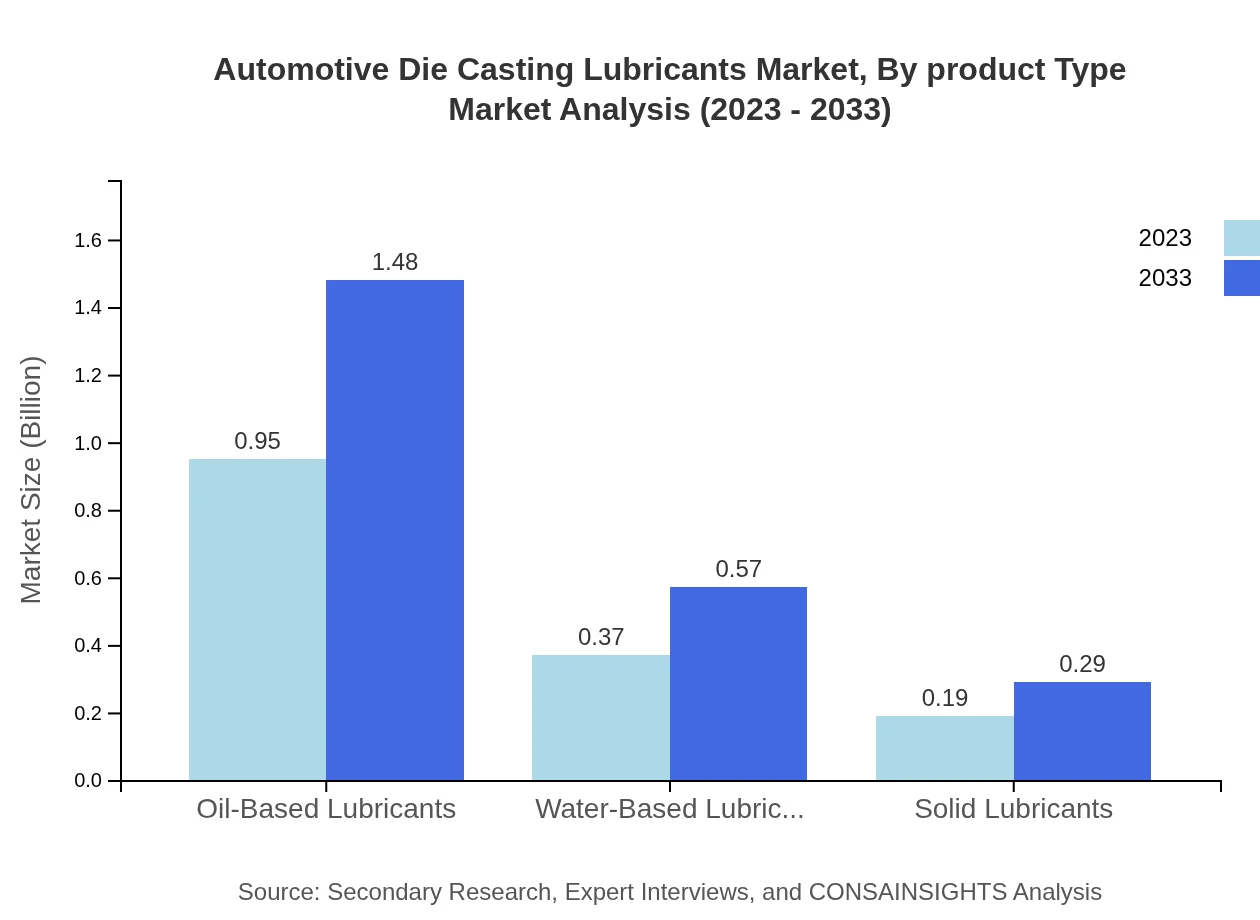

Automotive Die Casting Lubricants Market Analysis By Formulation

The formulations include Oil-Based and Water-Based lubricants. Oil-based lubricants dominate with a market size of $0.95 billion in 2023, projected to reach $1.48 billion by 2033. Water-based lubricants, holding $0.37 billion in 2023, also present growth, anticipated to reach $0.57 billion by 2033.

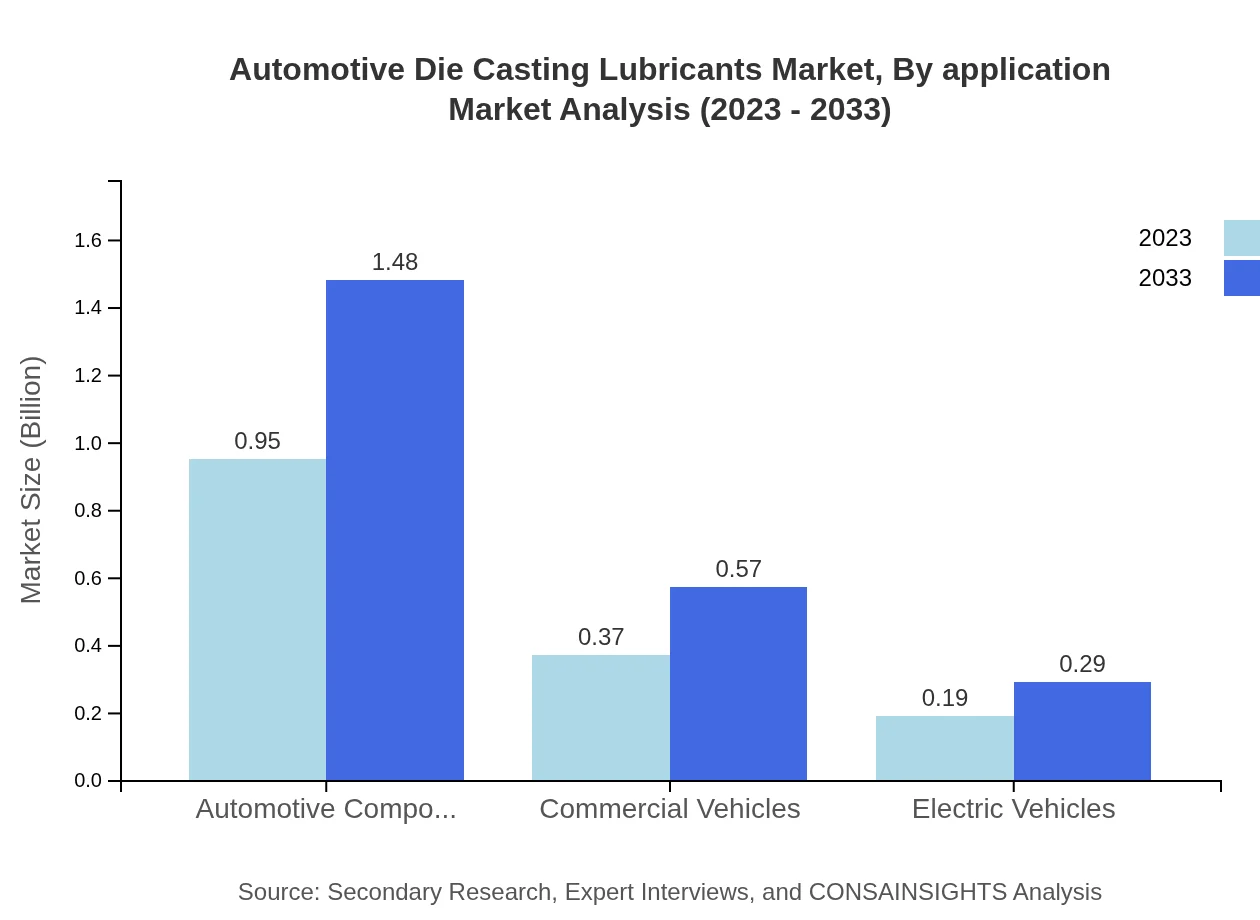

Automotive Die Casting Lubricants Market Analysis By End User

End-users primarily consist of Commercial Vehicles and Electric Vehicles segments. The Commercial Vehicles segment was valued at $0.37 billion in 2023, set to grow to $0.57 billion by 2033. The Electric Vehicles segment starts smaller at $0.19 billion but demonstrates a healthy growth forecast to $0.29 billion by 2033, reflecting the industry's shift towards electrification.

Automotive Die Casting Lubricants Market Analysis By Distribution Channel

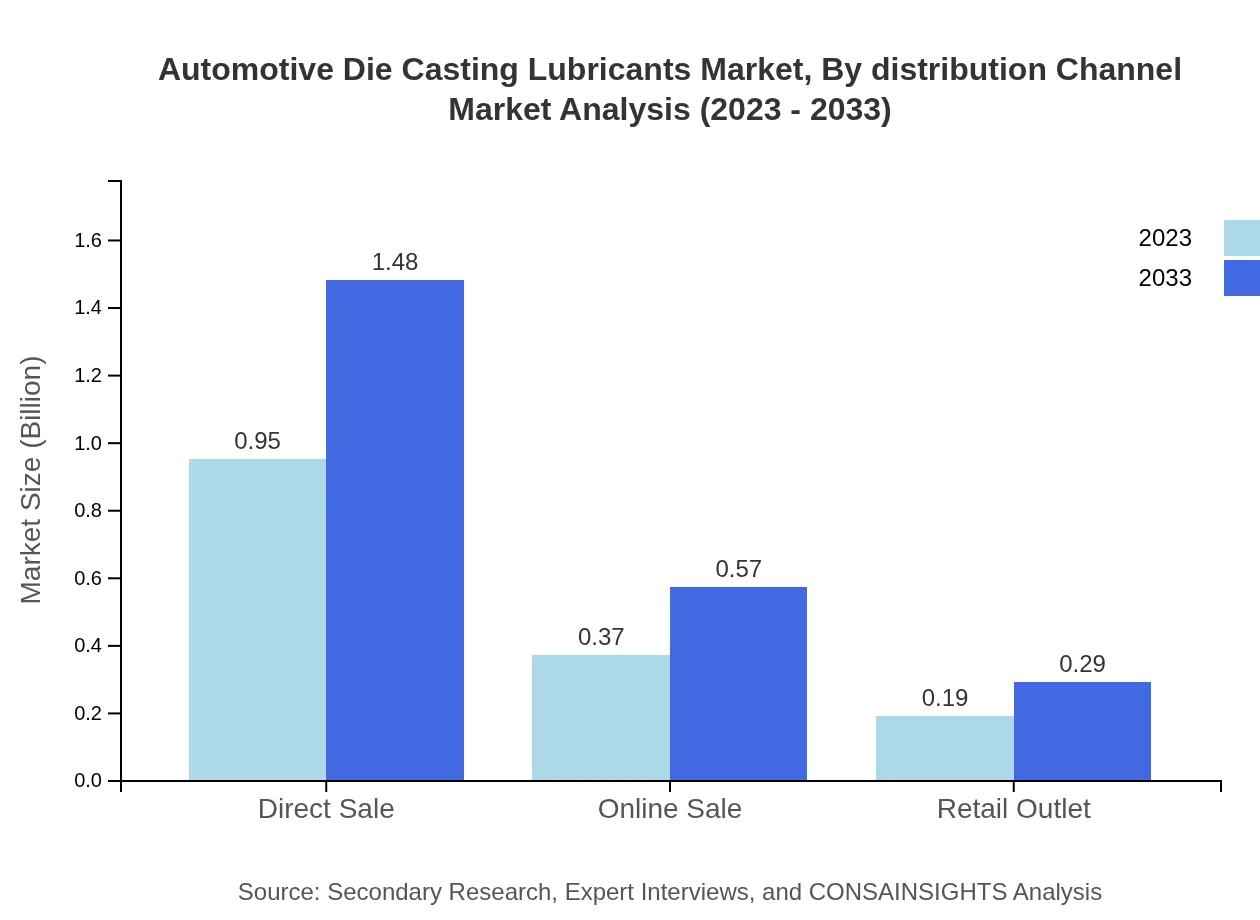

Distribution channels for these lubricants include Direct Sale, Online Sale, and Retail Outlets. Direct sales dominate with a market size of $0.95 billion in 2023, expected to reach $1.48 billion by 2033. Online sales, also growing from $0.37 billion to $0.57 billion, point towards increasing digitalization in distribution.

Automotive Die Casting Lubricants Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automotive Die Casting Lubricants Industry

Fuchs Petrolub SE:

A leading manufacturer known for innovative lubricant solutions, Fuchs offers a range of high-performance die casting lubricants designed to enhance process efficiency.Castrol Ltd.:

A premier brand in automotive lubricants, Castrol provides specialized products that cater to die casting applications, ensuring optimal performance and sustainability.Chevron Corporation:

Chevron's extensive portfolio includes premium lubricants tailored for automotive applications, including die casting, focused on innovation and high-quality standards.ExxonMobil:

With state-of-the-art lubricant formulations, ExxonMobil helps automotive manufacturers meet their production efficiency and sustainability goals.We're grateful to work with incredible clients.

FAQs

What is the market size of automotive die casting lubricants?

The global automotive die casting lubricants market is valued at approximately $1.5 billion in 2023, with a projected CAGR of 4.5% from 2023 to 2033.

What are the key market players or companies in the automotive die casting lubricants industry?

Key players in the automotive die casting lubricants market include major lubricant manufacturers that specialize in both OEM and aftermarket solutions, alongside niche companies focusing solely on die casting applications.

What are the primary factors driving the growth in the automotive die casting lubricants industry?

The automotive die casting lubricants market is primarily driven by the increasing demand for lightweight vehicles, the expansion of electric vehicle production, and advancements in material technology that improve efficiency and reduce emissions.

Which region is the fastest Growing in the automotive die casting lubricants?

The Asia Pacific region is the fastest-growing market for automotive die casting lubricants, expected to increase from $0.29 billion in 2023 to $0.46 billion by 2033 due to rising automotive production and demand.

Does ConsaInsights provide customized market report data for the automotive die casting lubricants industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the automotive die casting lubricants industry, ensuring relevant and actionable insights for different stakeholders.

What deliverables can I expect from this automotive die casting lubricants market research project?

Deliverables include comprehensive market analysis reports, detailed competitor insights, trend analysis, growth forecasts up to 2033, and segmented data across various regions and market sectors.

What are the market trends of automotive die casting lubricants?

Current trends in the automotive die casting lubricants market include the shift towards sustainable lubricants, the growth of the electric vehicle segment, and a focus on optimizing lubricant compositions for enhanced performance.