Bakelite Market Report

Published Date: 02 February 2026 | Report Code: bakelite

Bakelite Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report provides an in-depth analysis of the Bakelite market, highlighting growth trends, market segmentation, and forecasts for the period 2023-2033. Insights on key market players and regional dynamics are also included.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

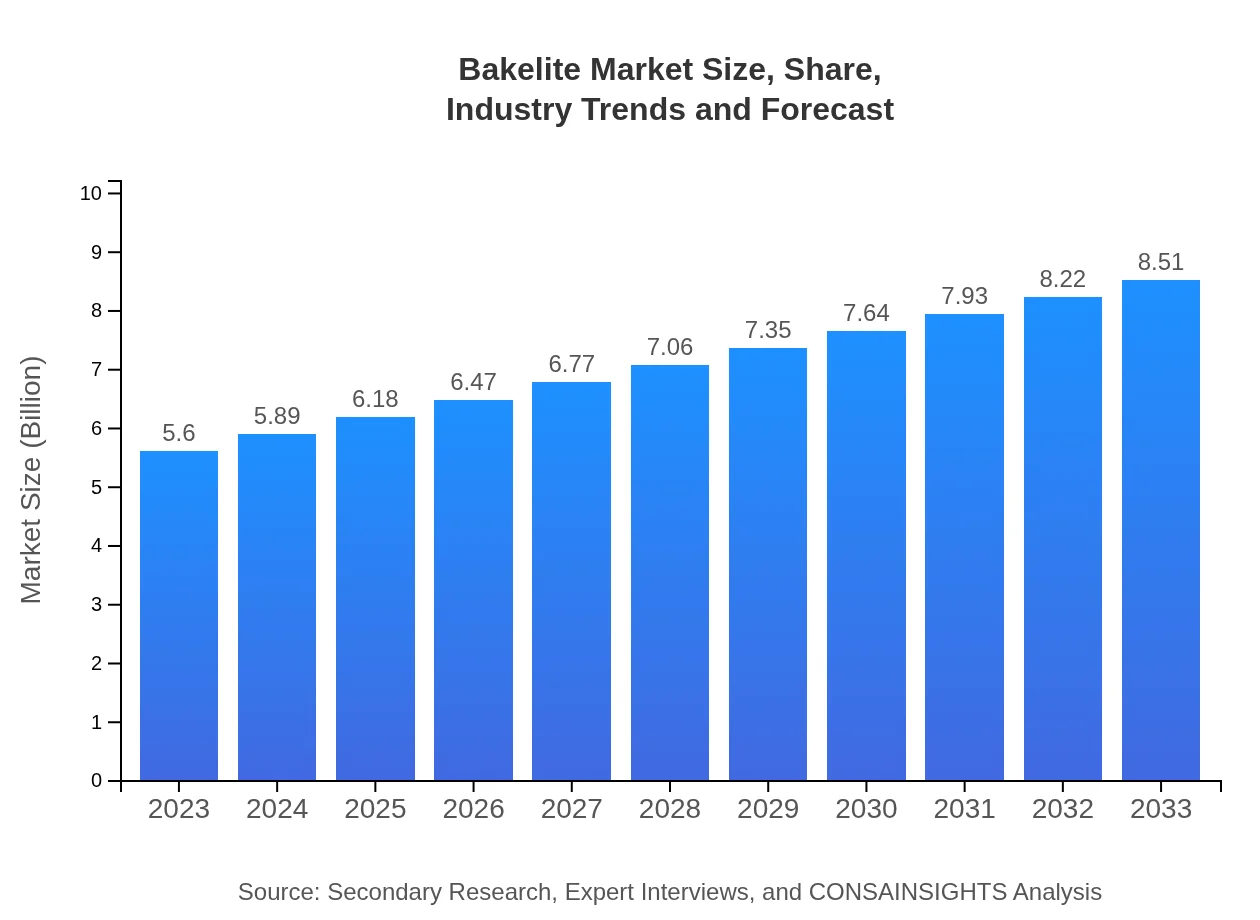

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.2% |

| 2033 Market Size | $8.51 Billion |

| Top Companies | BASF, Hexion, Kraton Corporation, Ineos Group |

| Last Modified Date | 02 February 2026 |

Bakelite Market Overview

Customize Bakelite Market Report market research report

- ✔ Get in-depth analysis of Bakelite market size, growth, and forecasts.

- ✔ Understand Bakelite's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Bakelite

What is the Market Size & CAGR of Bakelite market in 2023?

Bakelite Industry Analysis

Bakelite Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Bakelite Market Analysis Report by Region

Europe Bakelite Market Report:

Europe's Bakelite market is projected to grow from $1.92 billion in 2023 to $2.92 billion by 2033. Sustainability initiatives and the shift towards eco-friendly materials significantly influence market dynamics in this region.Asia Pacific Bakelite Market Report:

The Asia Pacific region is poised for significant growth, with the market projected to expand from $0.93 billion in 2023 to $1.41 billion by 2033. Increasing industrial activities, particularly in China and India, driven by rapid urbanization and a growing automotive sector, are primary growth factors.North America Bakelite Market Report:

North America is estimated to experience robust growth, with the market projected to increase from $1.96 billion in 2023 to $2.97 billion by 2033. High demand from the automotive and aerospace industries, along with technological innovations, are key drivers.South America Bakelite Market Report:

In South America, the Bakelite market is anticipated to grow from $0.31 billion in 2023 to $0.47 billion by 2033. Factors contributing to this growth include infrastructure development and rising demand for household goods and electrical appliances.Middle East & Africa Bakelite Market Report:

The Bakelite market in the Middle East and Africa is expected to grow from $0.48 billion in 2023 to $0.73 billion by 2033. The region is witnessing an increase in construction activities and a demand for consumer products, driven by a growing population and rising consumer spending.Tell us your focus area and get a customized research report.

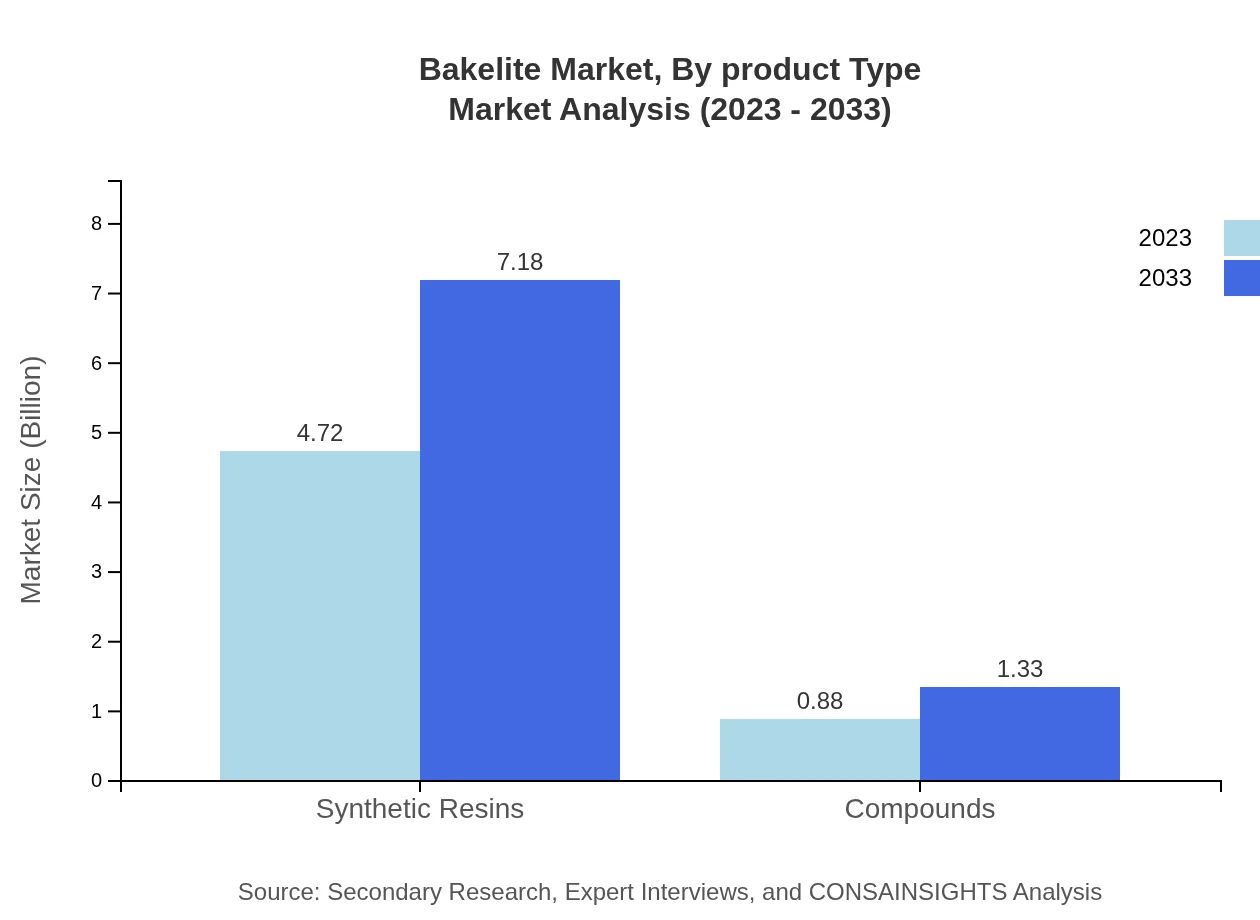

Bakelite Market Analysis By Product Type

The Bakelite market is heavily driven by Synthetic Resins, which comprise approximately 84.33% of the market share in 2023, with a projected growth from $4.72 billion to $7.18 billion by 2033. Compounds follow, holding around 15.67% of the market share, expected to grow from $0.88 billion to $1.33 billion. This indicates a robust demand for both product types.

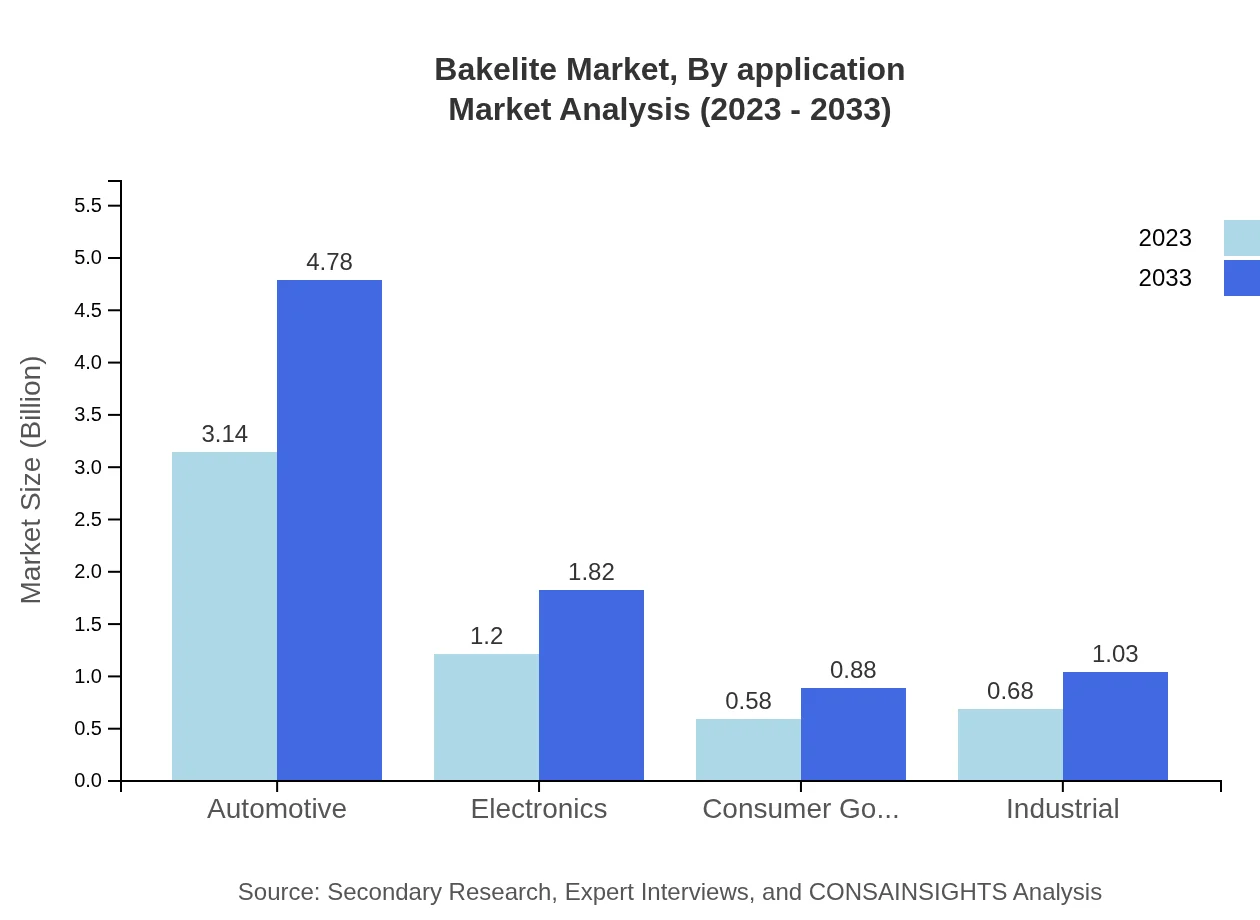

Bakelite Market Analysis By Application

In 2023, the Automotive application leads with a size of $3.14 billion and a market share of 56.15%. By 2033, its market size is projected to reach $4.78 billion. Electronics and Consumer Goods are also significant, with respective sizes of $1.20 billion and $0.58 billion in 2023, showcasing the diverse applications across industries.

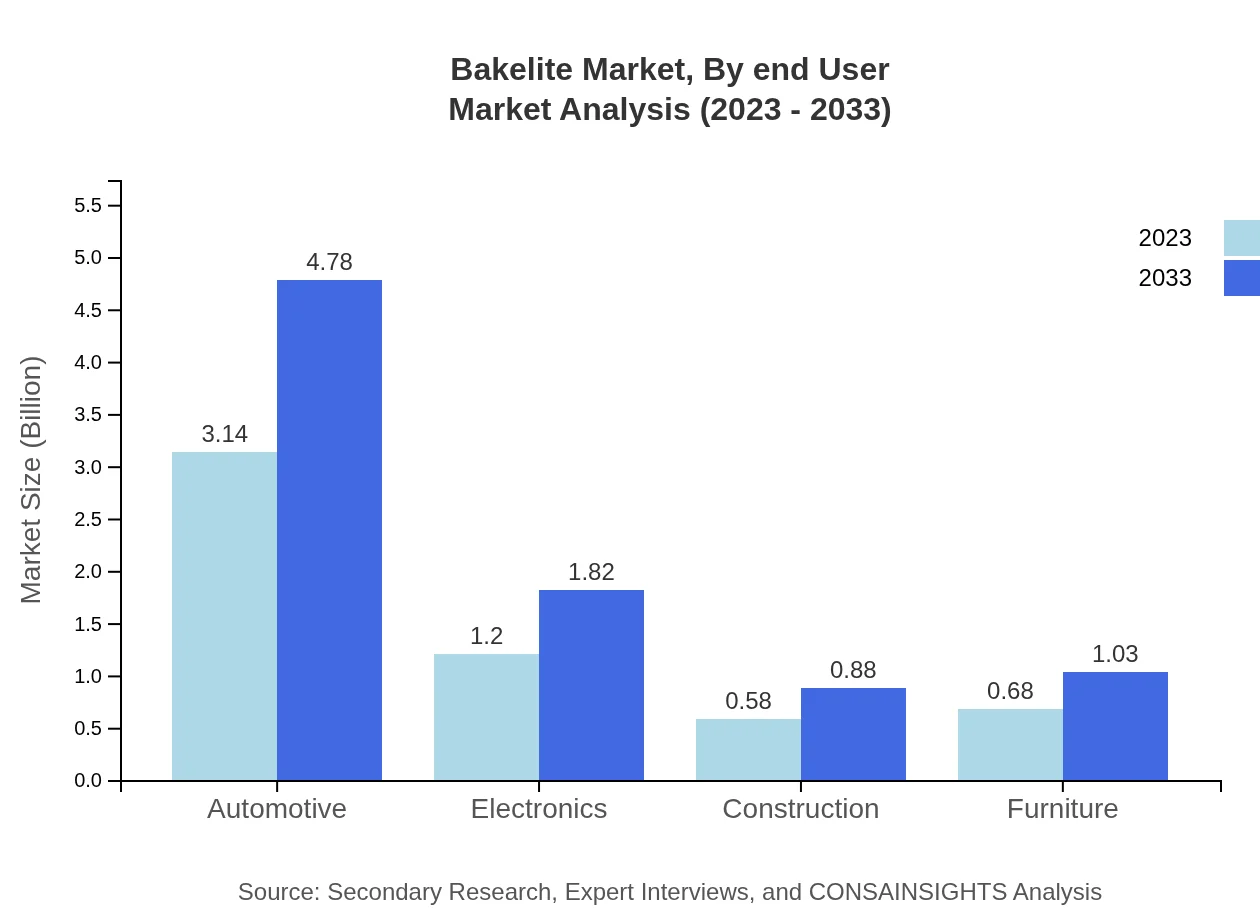

Bakelite Market Analysis By End User

The automotive sector is the largest end-user, absorbing a significant portion of Bakelite production. In 2023, the sector size is pegged at $3.14 billion, destined to increase to $4.78 billion by 2033. Other noteworthy end-users include industrial and consumer markets, demonstrating Bakelite's industrial versatility.

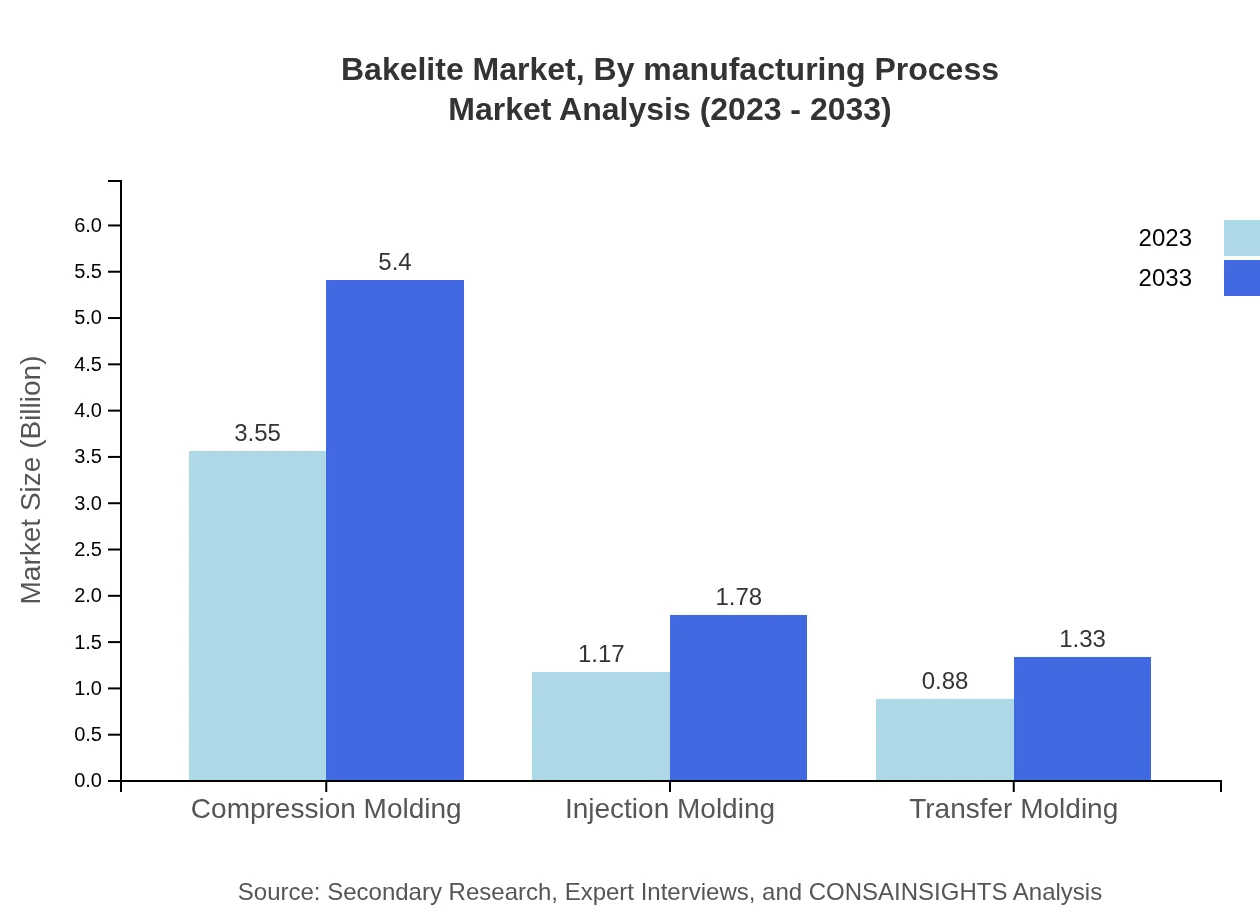

Bakelite Market Analysis By Manufacturing Process

Compression molding commands a significant share of the Bakelite manufacturing processes, with an expected market size of $3.55 billion in 2023, growing to $5.40 billion by 2033. Injection molding and transfer molding also contribute notably, reflecting a well-rounded manufacturing framework that caters to diverse applications.

Bakelite Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Bakelite Industry

BASF:

A leading chemical company that provides innovative plastics and is heavily involved in the production of Bakelite, focusing on sustainability.Hexion:

A global leader in thermoset resins and Bakelite products, Hexion invests heavily in R&D to enhance product offerings.Kraton Corporation:

Known for its high-performance polymers, Kraton actively engages in developing Bakelite formulations with improved material properties.Ineos Group:

This multinational chemicals company focuses on deriving innovative solutions, including Bakelite applications in various industries.We're grateful to work with incredible clients.

FAQs

What is the market size of Bakelite?

The Bakelite market was valued at $5.6 billion in 2023, with a projected CAGR of 4.2% through 2033, indicating a steady growth trajectory in demand across various sectors.

What are the key market players or companies in the Bakelite industry?

Key players in the Bakelite market include global manufacturers and suppliers operating in automotive, electronics, and construction sectors. Their collaboration and innovations significantly shape market dynamics.

What are the primary factors driving the growth in the Bakelite industry?

Driving growth in the Bakelite industry include increasing applications in automotive and electronics, the rise of eco-friendly materials, and technological advancements in production processes.

Which region is the fastest Growing in the Bakelite market?

The Asia Pacific region is the fastest-growing market for Bakelite, with projections showing an increase from $0.93 billion in 2023 to $1.41 billion by 2033.

Does ConsaInsights provide customized market report data for the Bakelite industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs, facilitating informed decision-making within the Bakelite industry.

What deliverables can I expect from this Bakelite market research project?

Expect detailed market analysis, regional insights, segment data, growth forecasts, and competitive landscape evaluations as key deliverables from the Bakelite market research project.

What are the market trends of Bakelite?

Current trends in the Bakelite market include increased demand for sustainable products, innovations in manufacturing techniques, and growth in the automotive and electronics sectors.